Bottle management device

A bottle unscrambler and bottle technology, which is applied in the field of automation equipment, can solve the problems that the user enterprise cannot bear, it is difficult to ensure the processing quality, and the manual operation efficiency is low, and the effect of reducing labor costs, improving work efficiency and meeting production needs is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

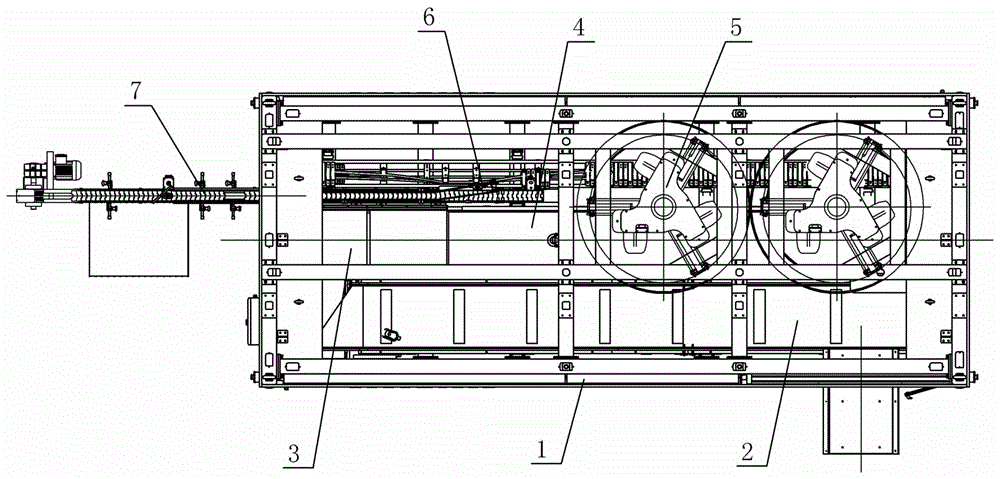

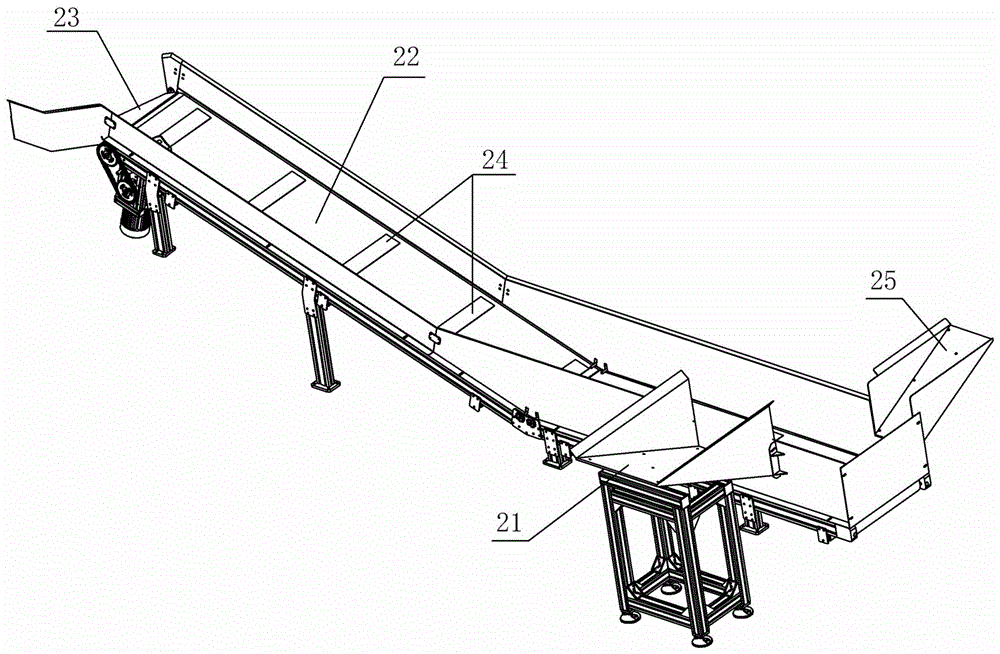

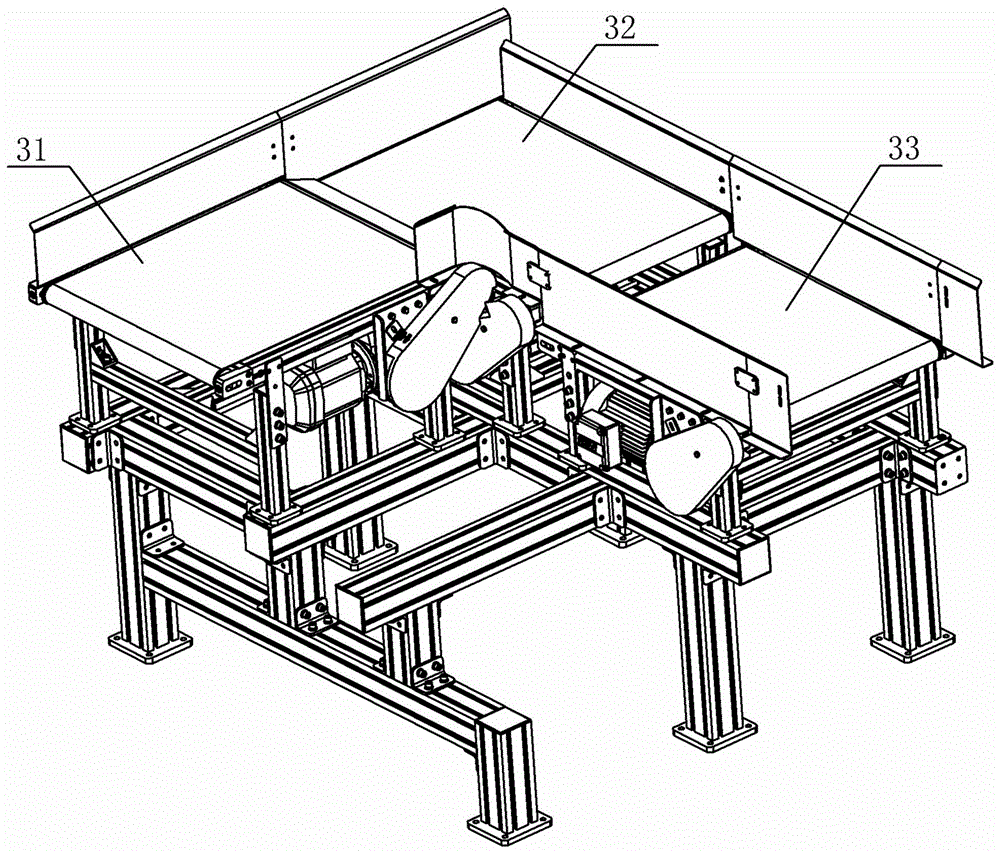

[0015] Such as figure 1 As shown, a bottle unscrambling device includes an equipment frame 1, a feed conveying assembly 2 that will input bottles is housed on the frame, a grasping conveying assembly 4 that sends the bottle to a grasping robot 5, and a feed conveying assembly There is an acceleration conveying assembly 3 to increase the conveying speed between the grasping and conveying assembly, an overturning assembly 6 to turn the bottle in the inverted state into an upright state, and a discharge conveying assembly 7 to send out the bottle after the erection. The fetching robot is arranged between the grabbing and conveying assembly and the overturning assembly, and the grabbing robot takes off the bottle from the grabbing and conveying assembly and places it lying down on the overturning assembly. The bottle unscrambler can automatically arrange the messy bottles and send them to the filling work, which meets the needs of automated production, greatly improves work effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com