Finish turning clamp with detecting function

A finishing car and jig technology, applied in clamping, manufacturing tools, measuring/indicating equipment, etc., can solve the problem of batch scrapping of disc gears, incorrect installation of disc gears, and inability to ensure the completeness of the gear positioning surface and the finishing fixture positioning surface Fitting and other problems to achieve the effect of improving reliability and stability and ensuring air output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

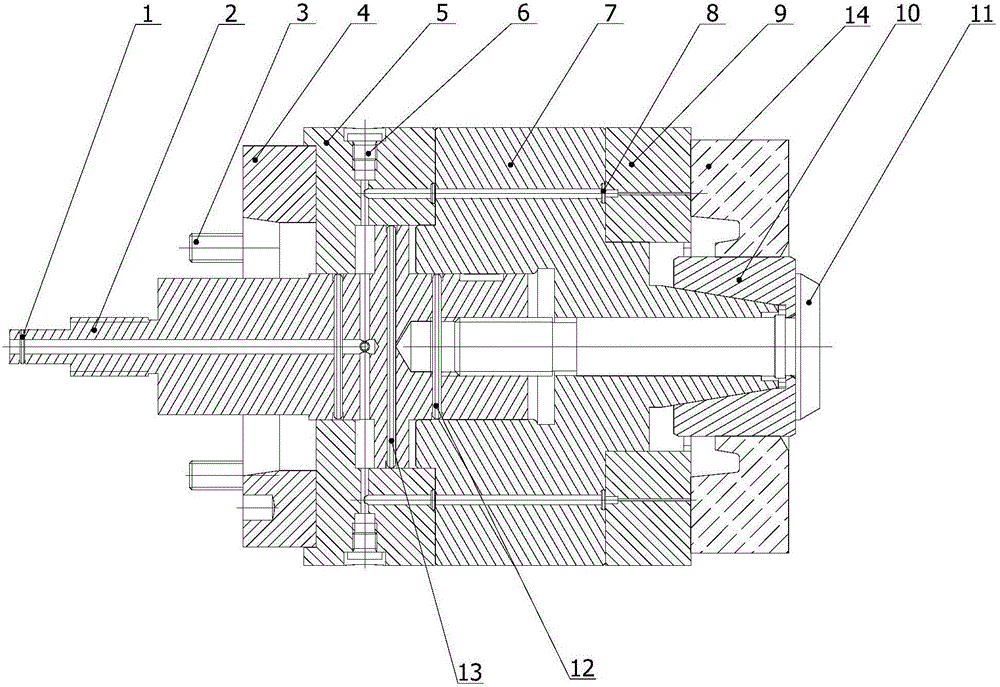

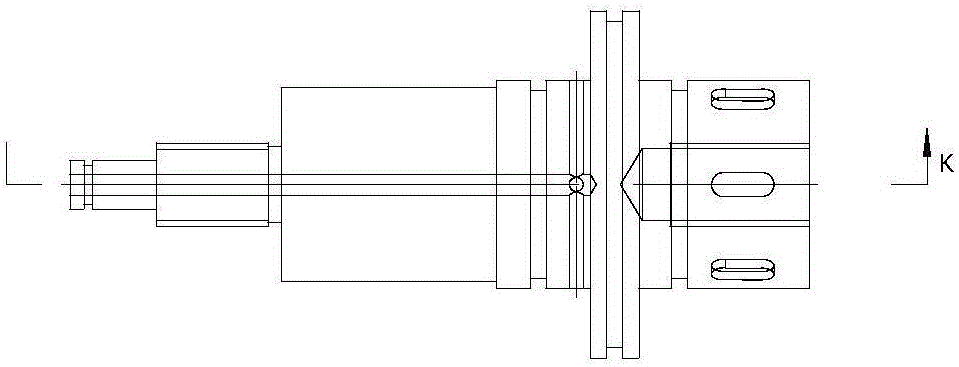

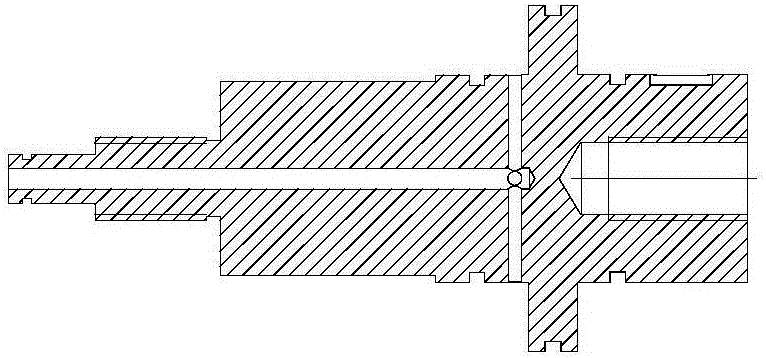

[0028] Such as figure 1 As shown, the present invention designs a finishing fixture with detection function, which can automatically detect whether the positioning surface of the gear and the positioning surface of the finishing fixture are completely attached before processing, and whether it can be processed normally; including the air detection piston rod 2, the transition Flange 4, gas detection sealing cylinder 5, sealing plug 6, body 7, gas detection pad 9, integrated expansion sleeve 10, and integrated tie rod 11.

[0029] The air detection piston rod 2 and the integrated expansion sleeve 10 are respectively arranged at both ends of the body 7, and the integrated tie rod 11 passes through the body 7 to connect with the air detection piston rod 2 and the integrated expansion sleeve 10; the air detection sealing cylinder 5 is set on the air detection piston The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com