Vertical aluminum profile processing system with intelligent suspension conveying line

A processing system and conveying line technology, applied in conveyors, mechanical conveyors, manufacturing tools, etc., can solve problems such as overall efficiency to be improved, affecting overall work continuity, and scattered workshop layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

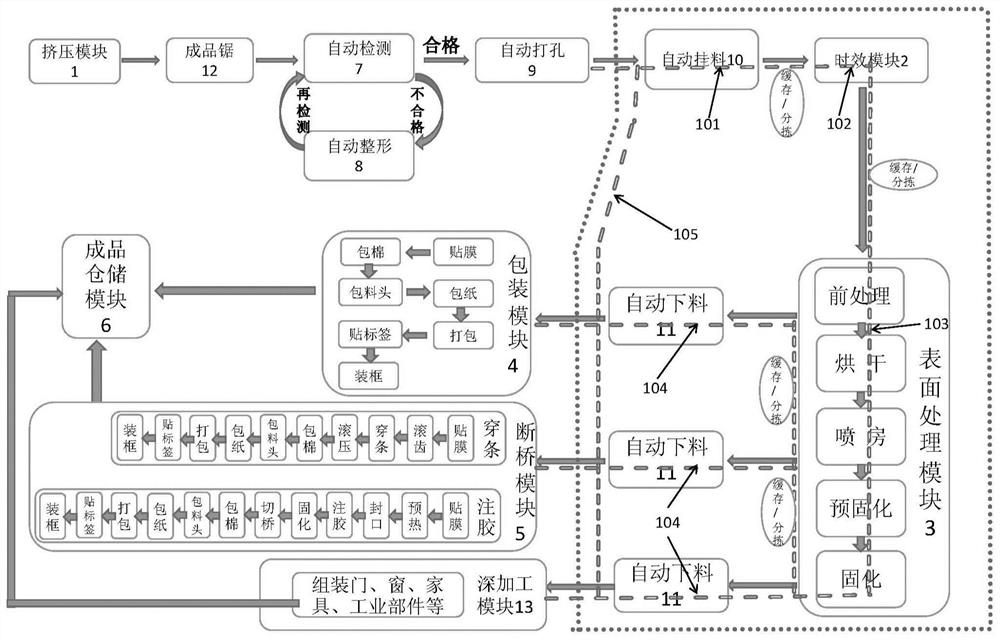

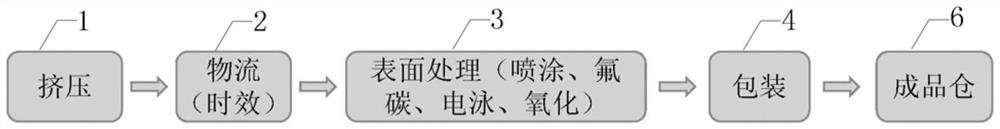

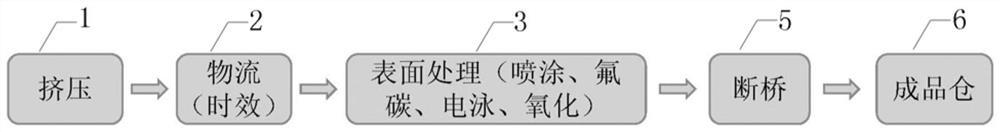

[0048] Such as figure 1 As shown, the process flow diagram of the vertical aluminum profile processing system with intelligent suspension conveyor line in the present invention includes several profile processing modules, and each profile processing module is arranged in a large area or arranged in multiple adjacent areas. It can include: extrusion module 1, aging module 2, surface treatment module 3, packaging module 4, bridge breaking module 5, finished product storage module 6 and deep processing module 13, and also includes automatic or manual detection device 7, automatic or manual shaping device 8. Automatic or manual punching device 9 , automatic or manual material hanging device 10 , automatic or manual unloading device 11 and finished product sawing device 12 . The aluminum ingot is heated by the furnace of the extrusion module 1, extruded by the extrusion machine, cooled, straightened, cut to length by the finished product saw, and then enters the automatic or manual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com