Photographing and positioning system for aluminum alloy wheel rims

A positioning system and aluminum alloy technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as low work efficiency, high labor intensity, clamping errors, etc., to improve processing efficiency, reduce difficulty and labor intensity, Realize the effect of unmanned processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

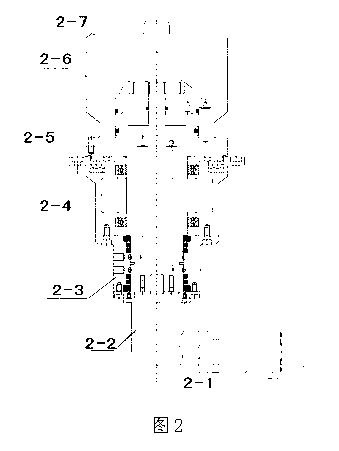

[0011] Depend on figure 1 As known, the aluminum alloy rim camera positioning system is composed of an overall darkroom frame 1, a rotating clamping device 2, a camera frame and a camera 3, an illumination device 4 and a control system, and the lower part of the overall darkroom frame 1 is provided with a rotating clamping The device 2 has a camera frame and a camera 3 on the top, and an illumination device 4 on the side. The rotating clamping device 2 is composed of a servo motor 2-1, a servo reducer 2-2, and an air path rotary joint 2-3. , a rotating spindle 2-4, a power cylinder 2-5, a power chuck 2-6 and a claw 2-7, the camera frame and the camera 3 are manually adjusted to the height of the position of the rotating clamping device 2 by adjusting the screw, The rotary clamping device 2 is driven by the servo motor 2-1 through the servo reducer 2-2 to rotate the power cylinder 2-5, which drives the rotating shaft 2-4 of the rotary clamping device 2 to rotate the hub, the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com