Automatic checkout device for quality of plastic gear

An automatic detection device and plastic gear technology, which is applied in the direction of measuring devices, analyzing materials, and optical testing for flaws/defects, can solve problems such as high work intensity, low efficiency, and high missed detection rate, and improve product quality and production efficiency. The effect of high detection accuracy and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

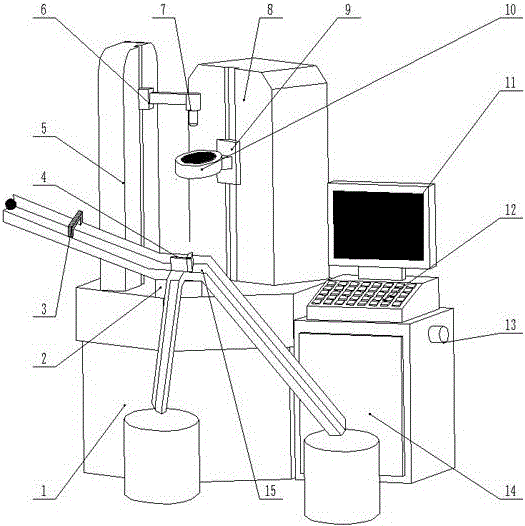

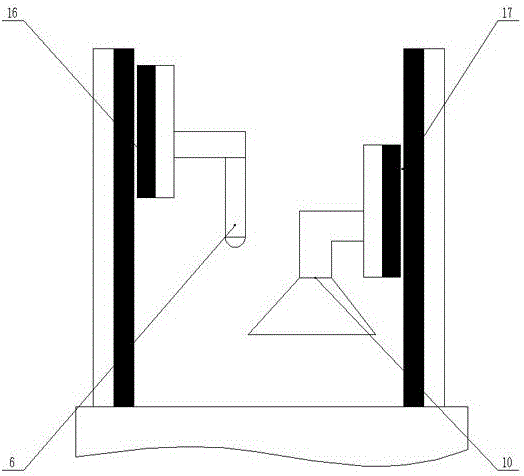

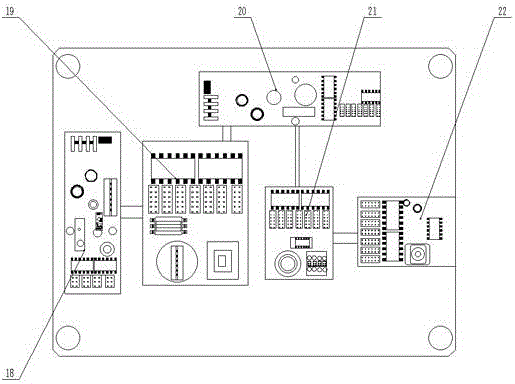

[0023] Such as Figure 1-Figure 9 As shown, an automatic detection device for the quality of plastic gears includes an electromechanical control box 1, a guide groove support base 2, a photoelectric trigger 3, a gear positioning device 4, an image collector 5, a mobile camera bracket 6, a high-definition industrial camera 7, and a gear Guide groove 15, the upper surface of the electromechanical control box 1 is provided with the guide groove support base 2, the upper surface of the guide groove support base 2 is provided with the gear guide groove 15, and the gear guide groove 15 is formed by the entrance chute 23. The defective product guide groove 24 and the qualified product guide groove 25 are composed, the photoelectric trigger 3 is installed in the center of the entrance chute 23, and the outlets of the defective product guide groove 24 and the qualified product guide groove 25 are respectively arranged Defective product recovery box 27 and qualified product packaging bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com