Workpiece tray rack

A material tray and rack body technology, which is applied in the field of automatic production auxiliary equipment, can solve the problem that the material tray is easy to slip out, and achieve the effect of improving work efficiency and facilitating handling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

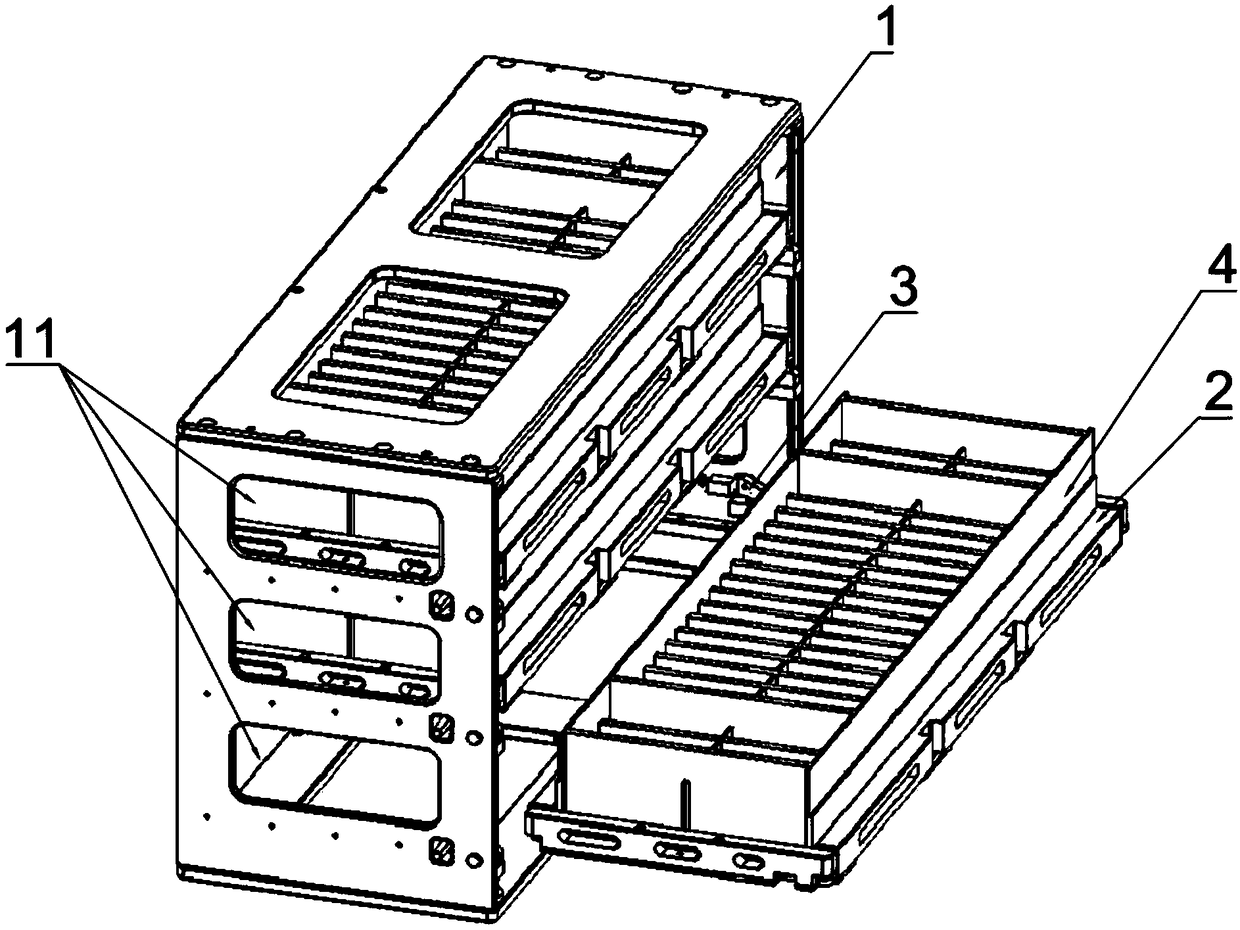

[0045] This embodiment provides a tray rack, the structure of which is as follows: figure 1 As shown, it includes a main frame body 1, a bracket 2, and a tray 3. The main frame body 1 has a storage space that can accommodate several trays 3, and the storage space is divided into several placement layers 11 vertically. Each placement layer 11 is provided with a bracket 2 for carrying the tray 3, and moves out of the placement layer 11 from one side of the main frame body 1 in the horizontal direction; Feed position. Such as figure 1 In the three-layer bracket 2 shown, the lowest layer is in the feeding position, and the upper two layers are in the storage position.

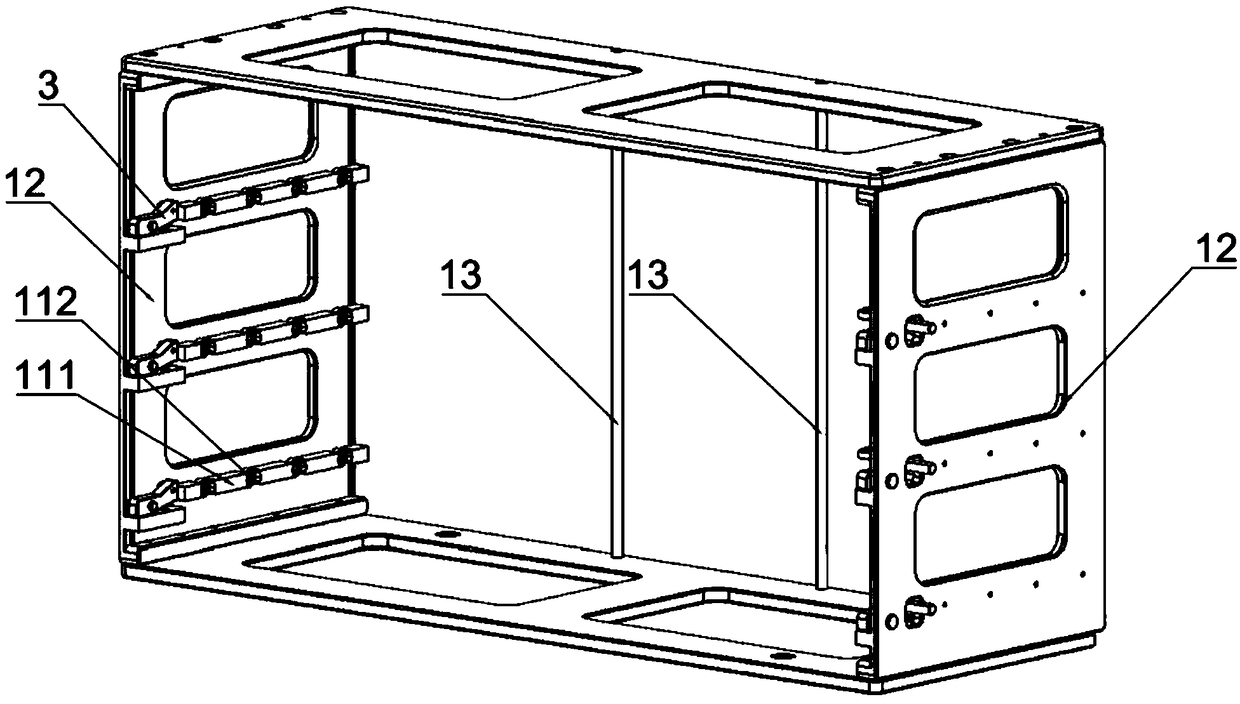

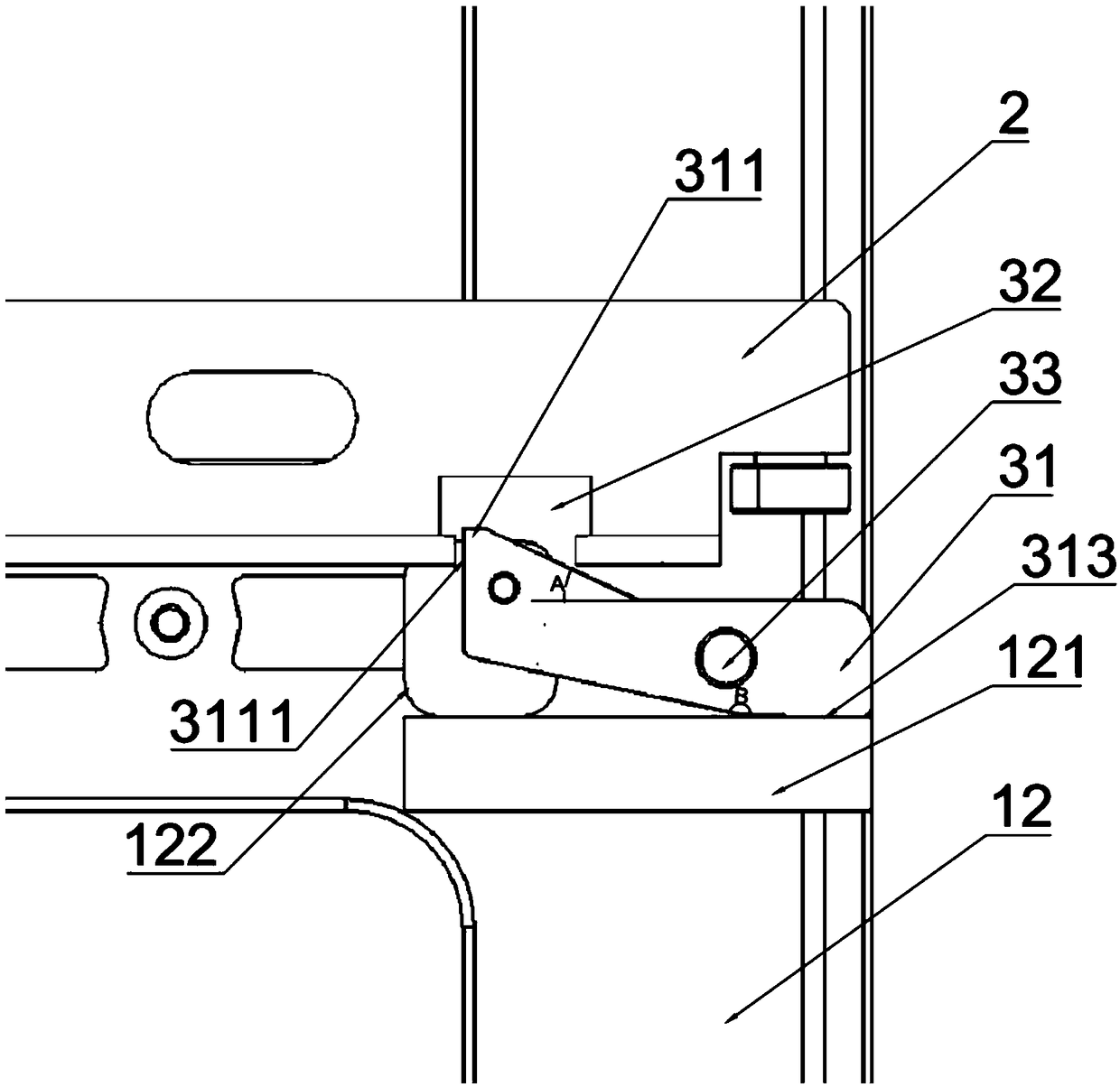

[0046] Such as Figure 2 to Figure 4 As shown, each placement layer 11 in this embodiment is provided with a locking mechanism 3 for restricting the movement of the bracket 2 in the storage position. Including a locking block 31 and a locking hole 32, the locking block 31 is connected to the side wall 12 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com