Full-automatic pipe cutting machine for production line

A fully automatic, pipe cutting machine technology, applied in the direction of pipe shearing device, shearing device, shearing and forming blank device, etc., can solve the problems of difficulty in satisfying automatic production, large deviation of pipe length, time-consuming and labor-intensive pipe, etc., to achieve The length is consistent, the length dimension accuracy is guaranteed, and the incision is smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

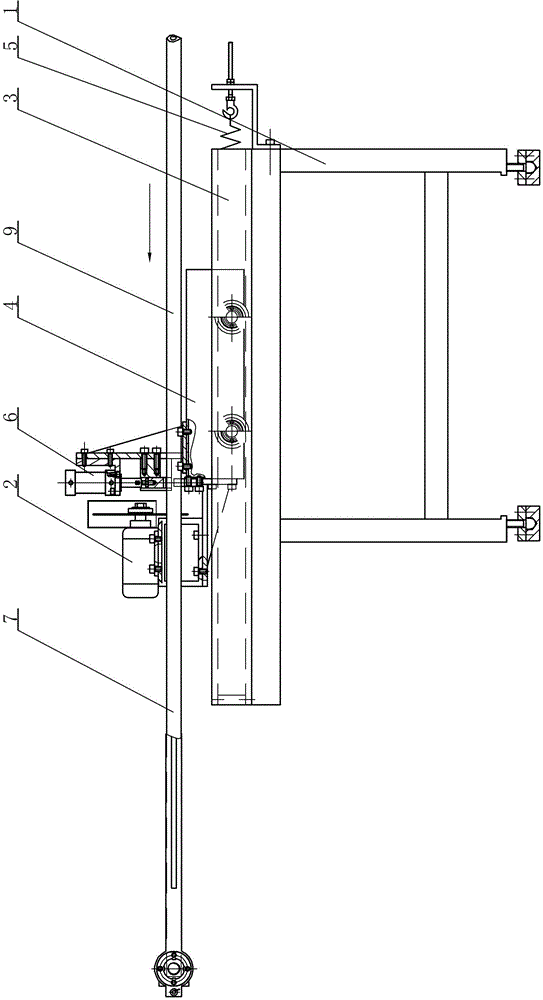

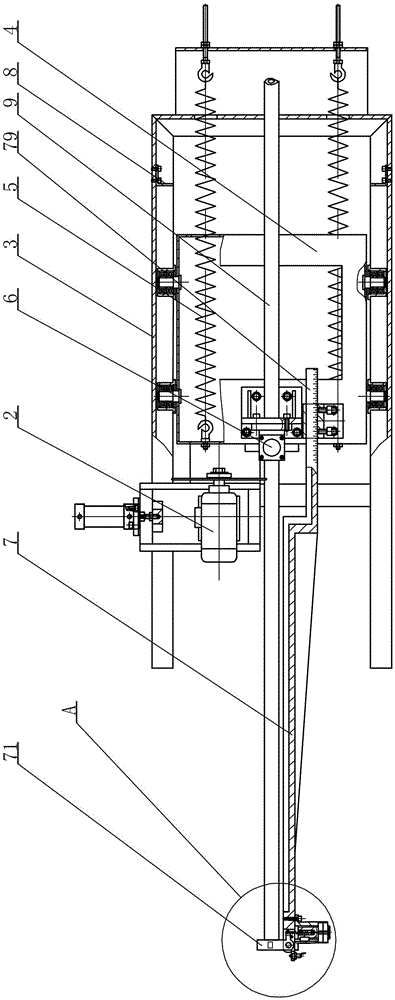

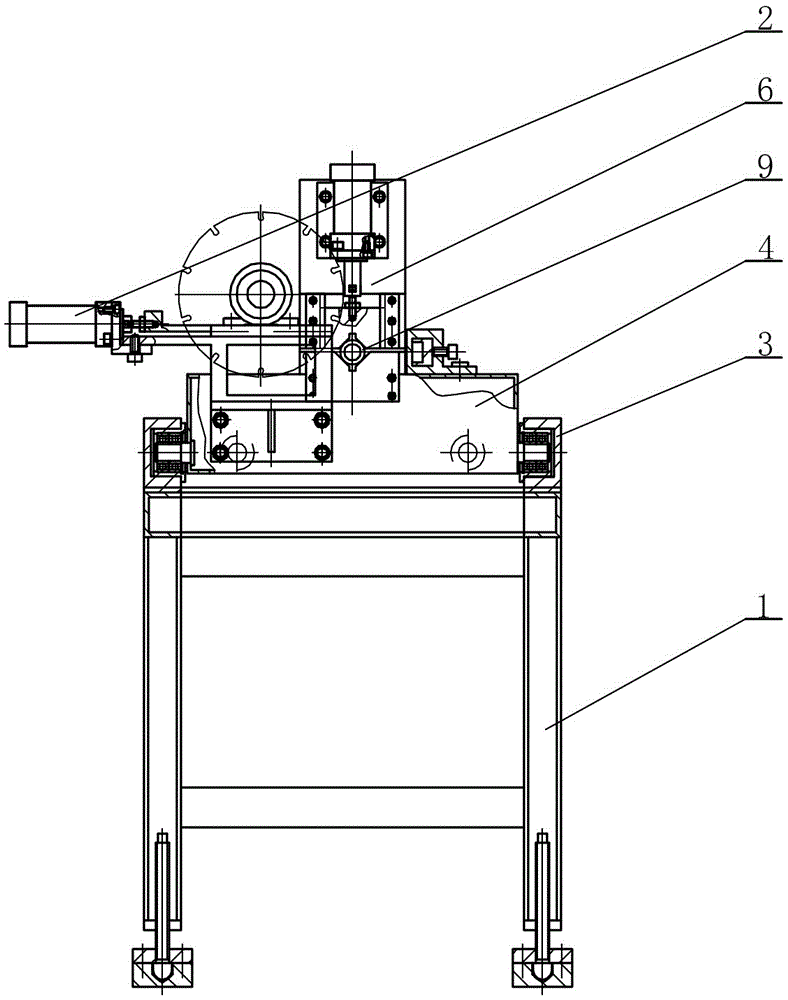

[0021] Depend on Figure 1 to Figure 6 As shown, the automatic pipe cutting machine of the production line includes a bracket 1 and a cutting device 2. The bracket 1 is provided with a guide rail 3 and a walking trolley 4 that reciprocates linearly along the guide rail. One end of the extension spring 5 is connected, and one end of the extension spring 5 is provided with a tension adjustment lever, so that the tension of the extension spring 5 is moderate and reliable, and the return speed of the walking trolley 4 can be steplessly adjusted. Described walking trolley 4 is fixed with clamping device 6 and length-setting mechanism 7, and clamping device 6 comprises fixed lower clamp 61 and movable upper clamp 62, and pipe material passes between lower clamp 61 and upper clamp 62, The clamping device 6 can clamp and loosen the pipe material. The length-determining mechanism 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com