Bicycle fork body device

A bicycle and fork body technology, applied in the field of bicycle fork body devices, can solve the problems of shortened service life, increased cost, heavy weight of the front fork, etc., and achieves the effects of reducing crack damage and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

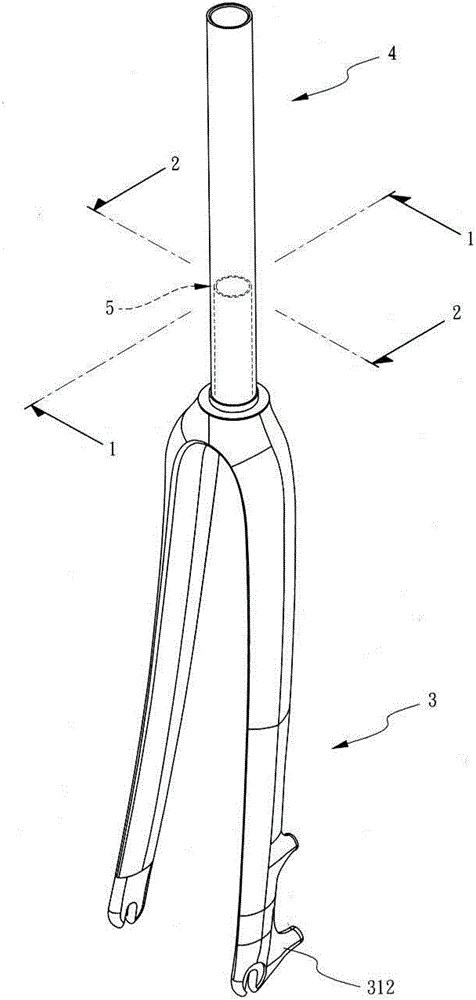

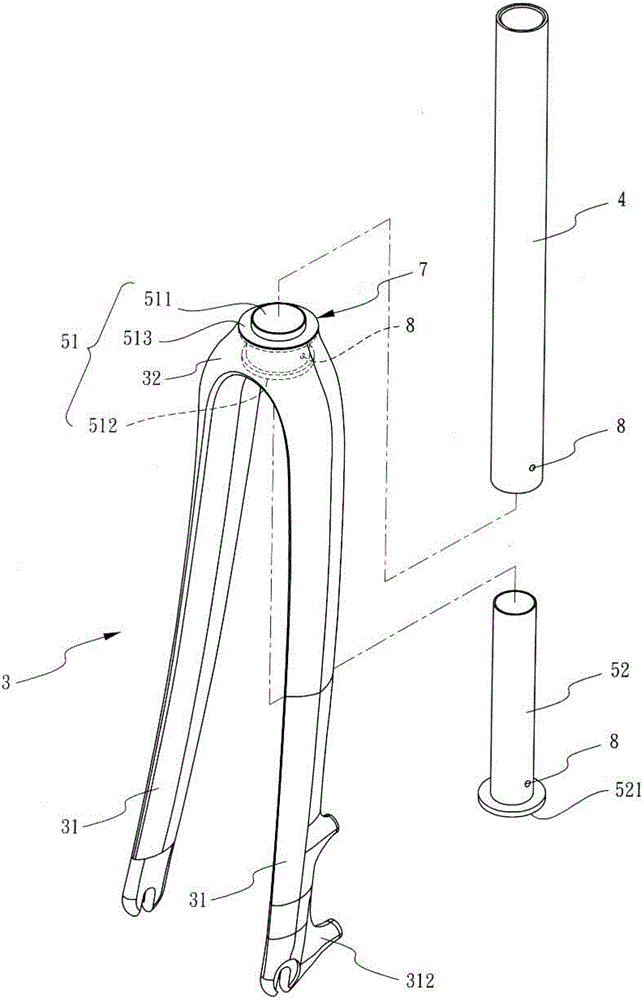

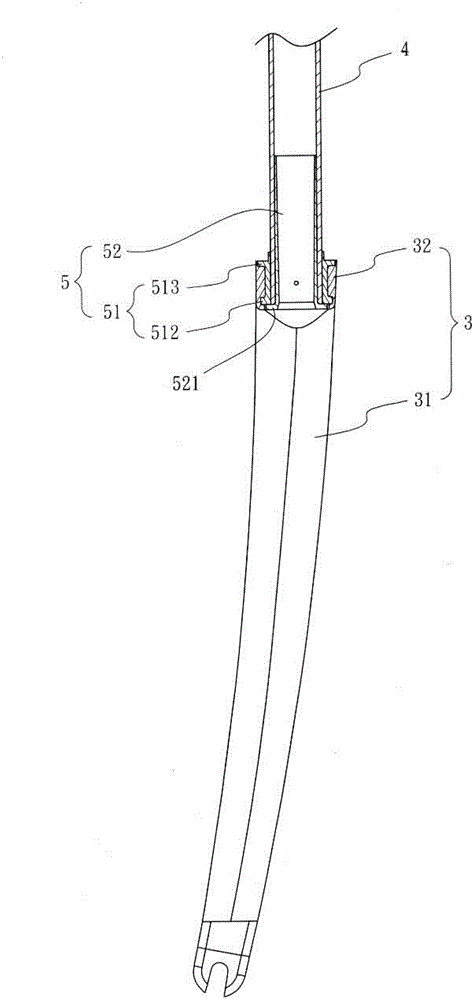

[0033] Different from the prior art, bicycle forks are heavy in structure and insufficient in strength, and it is easy to affect the joint between the Y-shaped rod of the fork and the straight rod due to the lateral force and external force experienced by the riding. Breaking cracks and other shortcomings, the present invention is effective to further reduce the weight of the fork body, and has relative strength, the present invention is about a "bicycle fork body device", and mainly related to its efficacy and characteristics, with the following related The drawings illustrate a simple embodiment.

[0034] See Figure 1 to Figure 6 As shown, a bicycle fork device of the present invention is used to connect a wheel and a bicycle body. It includes a fork rod 3, a connecting rod 4, and an assembly 5 connecting the fork rod 3 and the connecting rod 4, wherein:

[0035] The fork rod 3 includes a hollow bracket 31 arranged at two intervals and a base 32 connected to the ends of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com