Patents

Literature

40results about How to "Reduce cracking damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

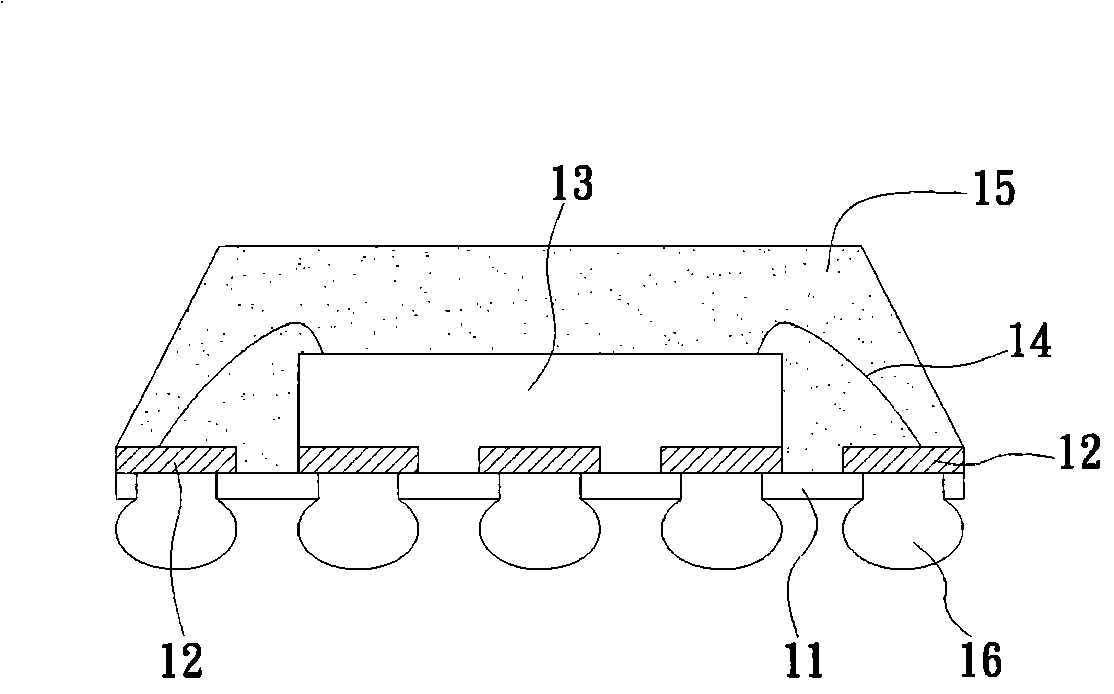

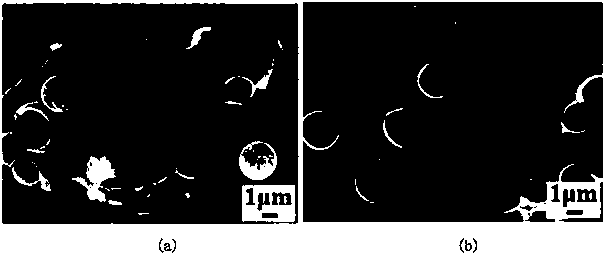

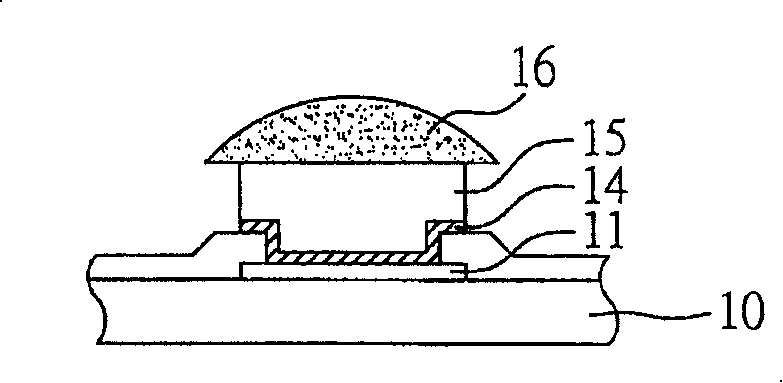

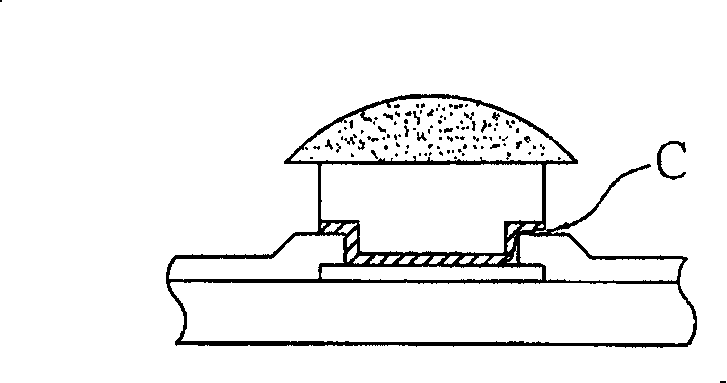

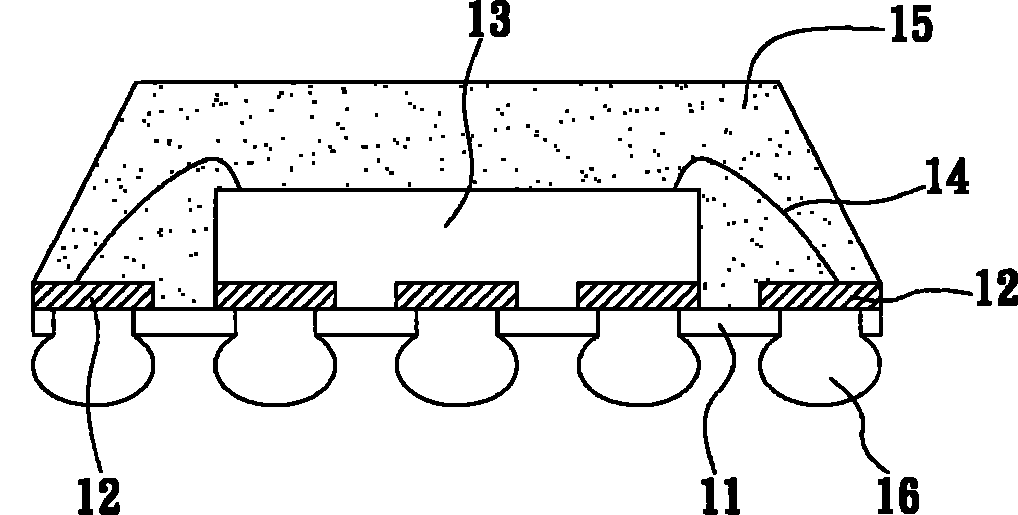

Semiconductor package and manufacturing method thereof

InactiveCN101335217AReduce cracking damageSolve instabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor chip

The invention discloses a semi-conductor packaging unit and a manufacturing method hereof, which provides a carrier plate, wherein, a plurality of metal blocks and a metallic layer for coating the metal blocks are formed on the carrier plate so as to electrically connect at least one semi-conductor to the metallic layer, and then a packaging colloid coating the semi-conductor chip is also formed on the metallic carrier plate, then, the carrier plate and the metal blocks are removed to form a plurality of grooves on the surface of the packaging colloid correspondingly. At the bottom surface and the side of the grooves are covered with a metallic layer so as to lead the conductive elements to be effectively positioned in the grooves and fully conjugated with the metallic layer.

Owner:SILICONWARE PRECISION IND CO LTD

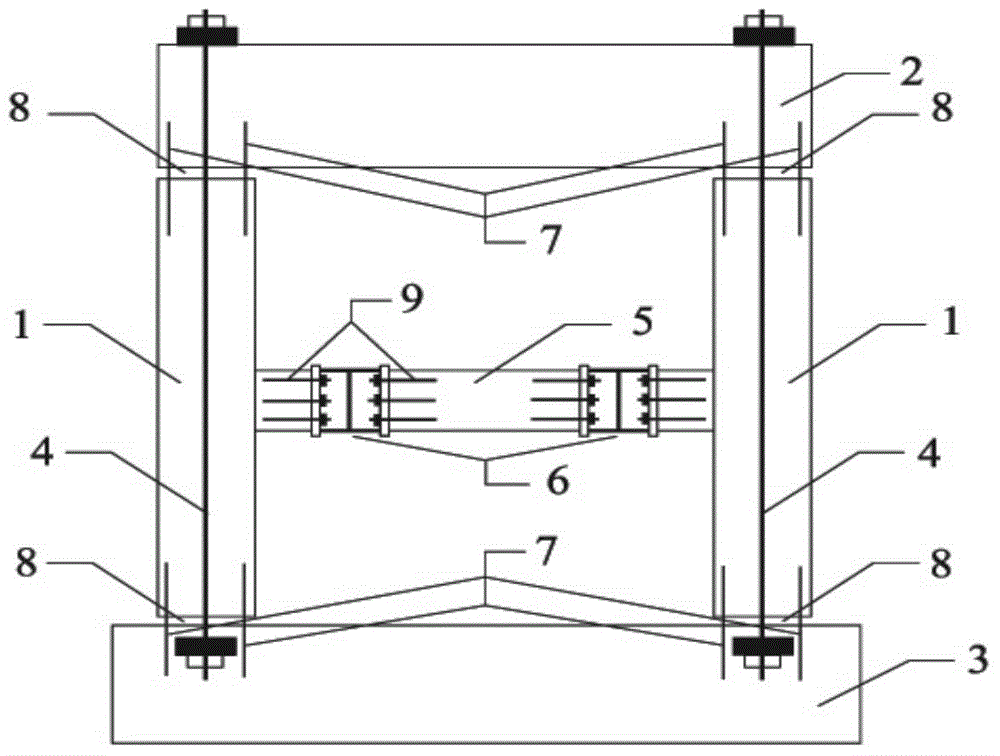

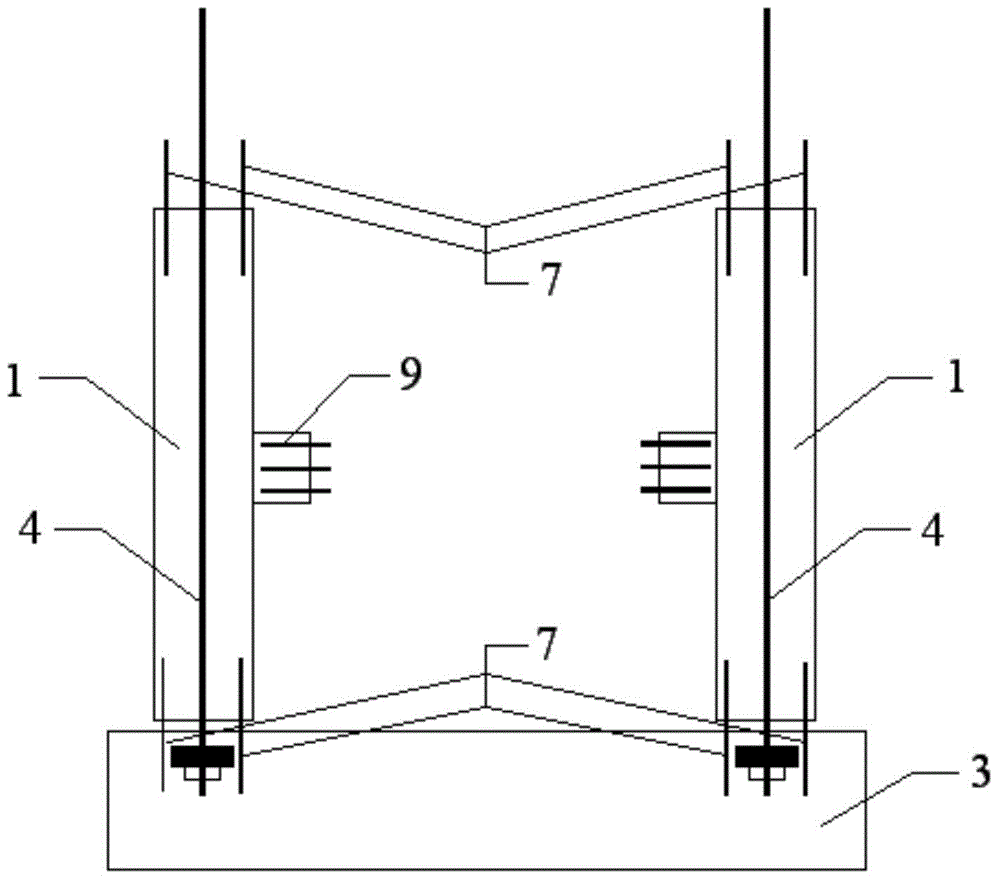

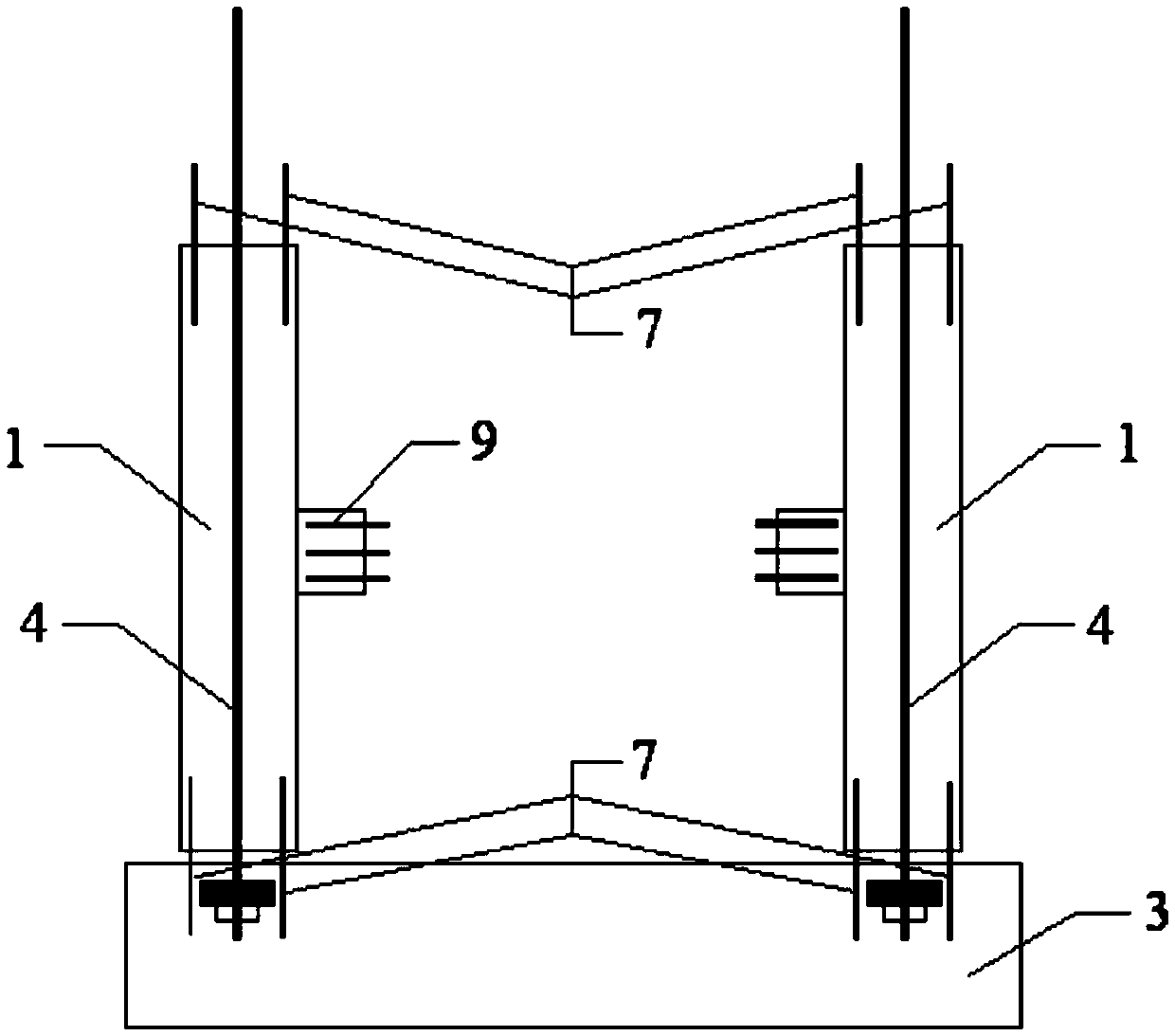

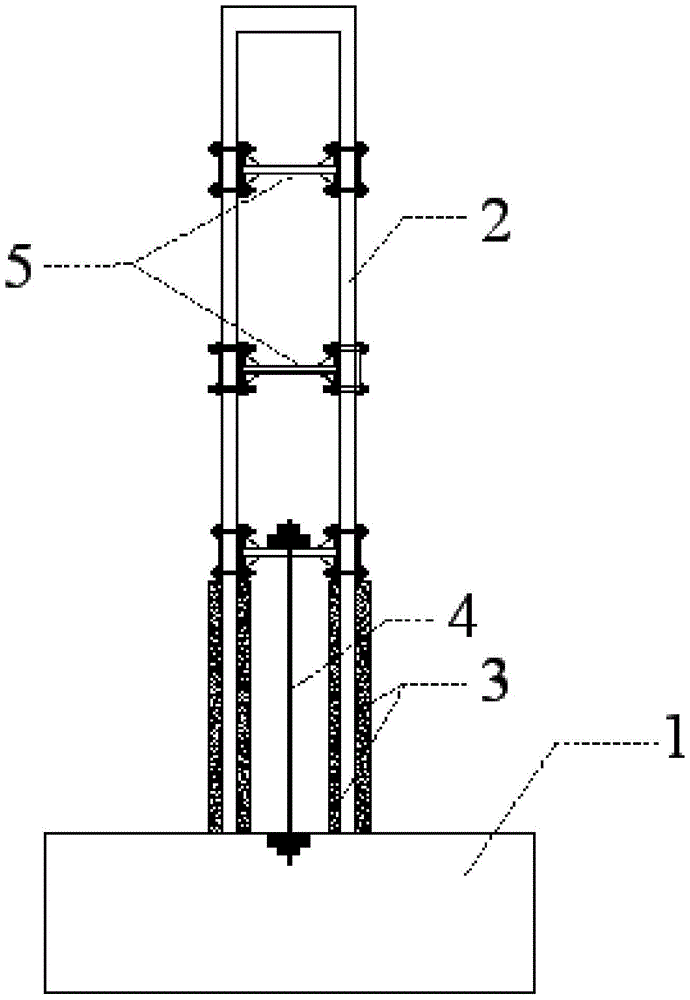

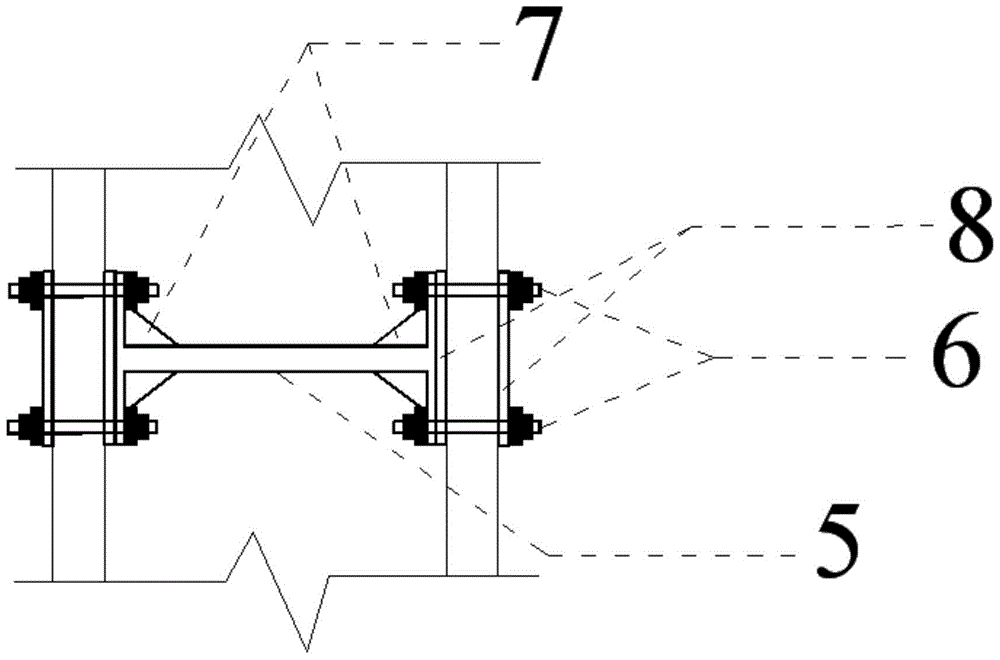

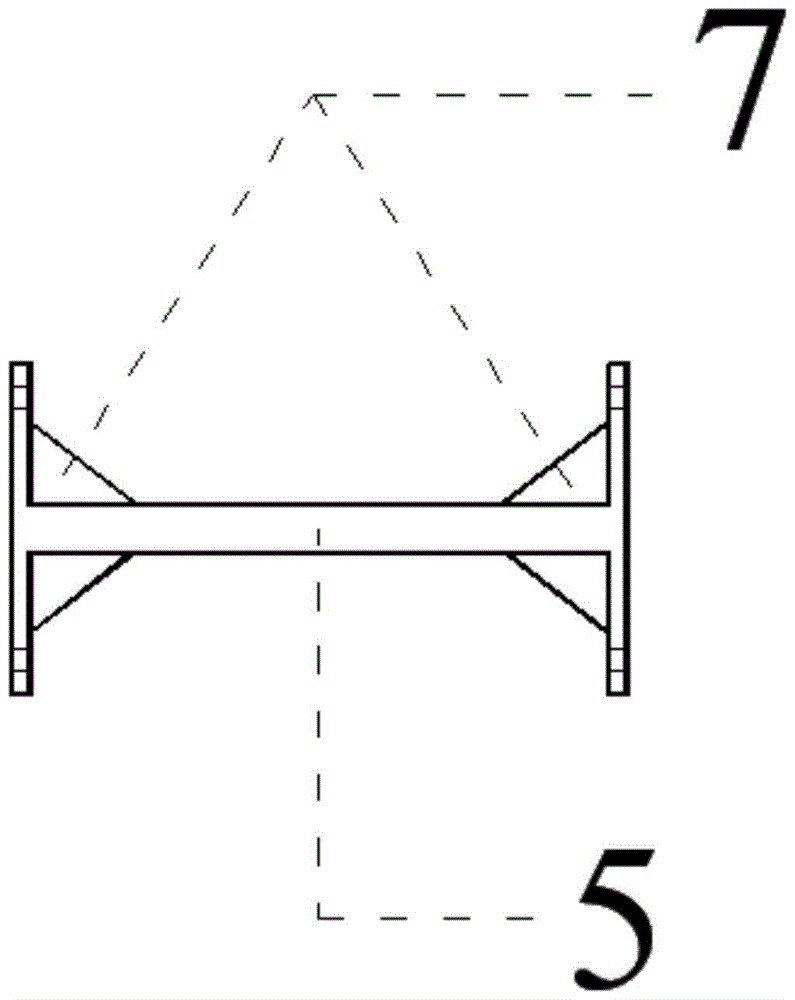

Swing self-reset bridge bent frame with ductility replaceable collar beam and installation method thereof

InactiveCN104452566ARealize the concept of "separation of functions"Restoring the anti-seismic ability of the bent frameBridge structural detailsBridge erection/assemblyPre stressShear force

The invention discloses a swing self-reset bridge bent frame with a ductility replaceable collar beam. The swing self-reset bridge bent frame with the ductility replaceable collar beam comprises a bridge foundation, a prefabricated cover beam and two prefabricated piers, wherein the prefabricated piers are arranged on the bridge foundation and used for supporting the left side and the right side of the prefabricated cover beam. The swing self-reset bridge bent frame with the ductility replaceable collar beam further comprises the replaceable collar beam transversely arranged between the two prefabricated piers. Unbonded prestress tendons are longitudinally arranged in the prefabricated piers. The two ends of each unbonded prestress tendon extend out of the upper end and the lower end of the corresponding prefabricated pier and are fixedly connected with the prefabricated cover beam and the bridge foundation respectively. The junction between each prefabricated pier and the prefabricated cover beam is provided with a shear key for connection, and is also provided with an energy dissipation longitudinal bar fixedly connected with the prefabricated pier and the prefabricated cover beam respectively. By the adoption of the technical scheme, the prefabricated parts are assembled rapidly, the overall structure is stable by means of the junctions, the replaceable collar beam and the unbonded prestress tendons, and the swing self-reset bridge bent frame has the swing and self-reset structural characteristic.

Owner:DALIAN MARITIME UNIVERSITY

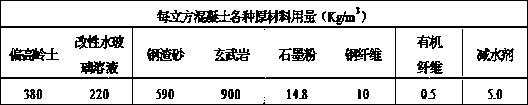

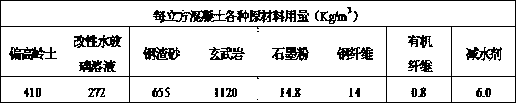

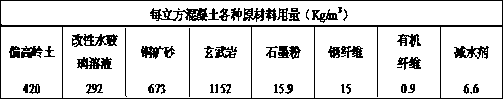

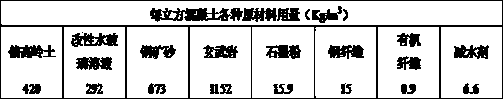

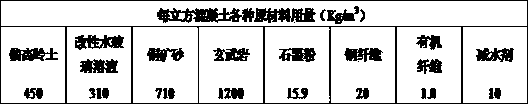

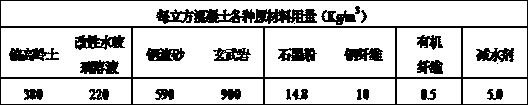

Novel heat accumulation concrete for solar thermal power station and preparation method for novel heat accumulation concrete

The invention belongs to the field of building materials, and in particular relates to a functional concrete material and a preparation method thereof. The invention relates to novel heat accumulation concrete for a solar thermal power station. 1 square meter of heat accumulation concrete is characterized by being prepared from the following raw materials by weight: 380 to 450 kilograms / meter<3> of metakaolin, 220 to 310 kilograms / meter<3> of modified sodium silicate solution, 5 to 10 kilograms / meter<3> of water reducing agent, 900 to 1,200 kilograms / meter<3> of basalt, 590 to 710 kilograms / meter<3> of fine aggregates, 10 to 20 kilograms / meter<3> of steel fibers, 0.5 to 1 kilogram / meter<3> of organic fibers and 10 to 20 kilograms / meter<3> of graphite powder, wherein a liquid-solid ratio of the modified sodium silicate solution to the metakaolin is (0.60-0.70):1; and the fine aggregates comprise ordinary sand, copper ores and steel slag sand. The high-temperature heat accumulation material prepared by the method has the characteristics of low cost, stable performance, high coefficients of heat conductivity, high durability and the like, and is easy to prepare on site.

Owner:WUHAN UNIV OF TECH

Novel earthquake damage control system for thin-wall hollow pier

InactiveCN104674649AReduce residual displacementReduce widthBridge structural detailsBridge erection/assemblyPre stressTorsional strength

The invention discloses a novel earthquake damage control system for a thin-wall hollow pier. The novel earthquake damage control system comprises a pier base, a thin-wall hollow pier, high-tenacity fiber-enhanced cement-based composite material expanded sections, an unbonded prestressed tendon and steel energy consumption elements, wherein the thin-wall hollow pier is arranged on the upper end surface of the pier base, so that the torsional strength and the energy-dissipating capacity of the thin-wall pier are improved. The high-tenacity fiber-enhanced cement-based composite material expanded sections are arranged on the inner side and the outer side of the lower part of thin-wall hollow pier; a series of steel energy consumption elements are arranged in the thin-wall hollow pier along the pier height; the lower part of the unbonded prestressed tendon is anchored on the pier base; and the upper part of the unbonded prestressed tendon is anchored at the center of the first steel energy consumption element from bottom to top. By virtue of the unbonded prestressed tendon, the self-resetting capacity of the pier after the earthquake is provided; and the crack width of the pier after the earthquake is reduced. By virtue of the high-tenacity fiber-enhanced cement-based composite material expanded sections, the axis-compression ratio of the bottom section of the thin-wall hollow pier is reduced; the shear-bearing capacity and the anti-bending capacity of the thin-wall hollow pier are increased; and the steel energy consumption elements can be arranged as rapid exchange components, so that the repairability after the earthquake is increased.

Owner:DALIAN MARITIME UNIVERSITY

Reinforcing and repairing structure for purlin and beam node of historic building

InactiveCN105863295AIncrease the bearing areaImprove bending abilityBuilding repairsPurlinStructural engineering

The invention provides a reinforcing and repairing structure for a purlin and a beam node of a historic building. The two ends of the purlin are erected above a beam head; pillow-shaped timbers are arranged on the left and right sides of the beam head; the pillow-shaped timbers are arranged between the purlin and a purlin frame; the bottom surfaces of the pillow-shaped timbers are ejected above the purlin frame; the heights of the pillow-shaped timbers are greater than the height of the beam head; the widths of the pillow-shaped timbers are greater than the diameter of the purlin; and on the basis of not changing raw materials and a construction process, the purlin and the beam node of the historic building are reinforced.

Owner:LUOYANG INST OF SCI & TECH

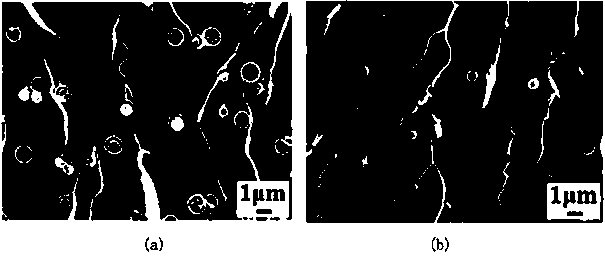

Self-repairing cyanate ester resin system and preparation method thereof

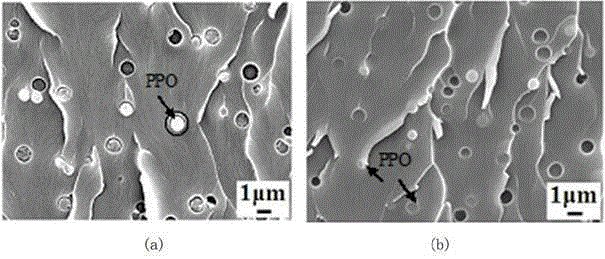

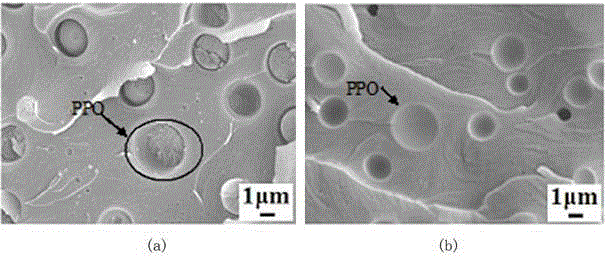

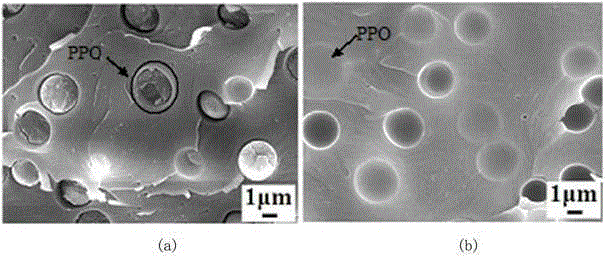

The invention relates to a self-repairing cyanate ester resin system and a preparation method of the self-repairing cyanate ester resin system. The preparation method comprises the steps of adding vinyl terminated poly-p-phenylene oxide (PPO) resin with low molecular weight into a cyanate ester (CE) resin system, and using 4,4 phi-diamino diphenyl sulfone (DDS) as a catalyst to treat the CE / PPO resin system through low-temperature process to obtain the self-repairing cyanate ester resin system with high performance. According to the technical scheme, the vinyl terminated PPO is utilized for maintaining thermoplasticity of the CE during forming; after the cured CE resin system is damaged, the PPO ingredients can be melted and flow to fill a crack to realize material repairing through a heating system, therefore, the vinyl terminated PPO has positive effects on prolonging the service life of the material and improving the safety of the material; the resin system can be used for preparing high-performance composite materials, electronic devices and the like for aerospace construction.

Owner:丹阳市俊琪塑业有限公司

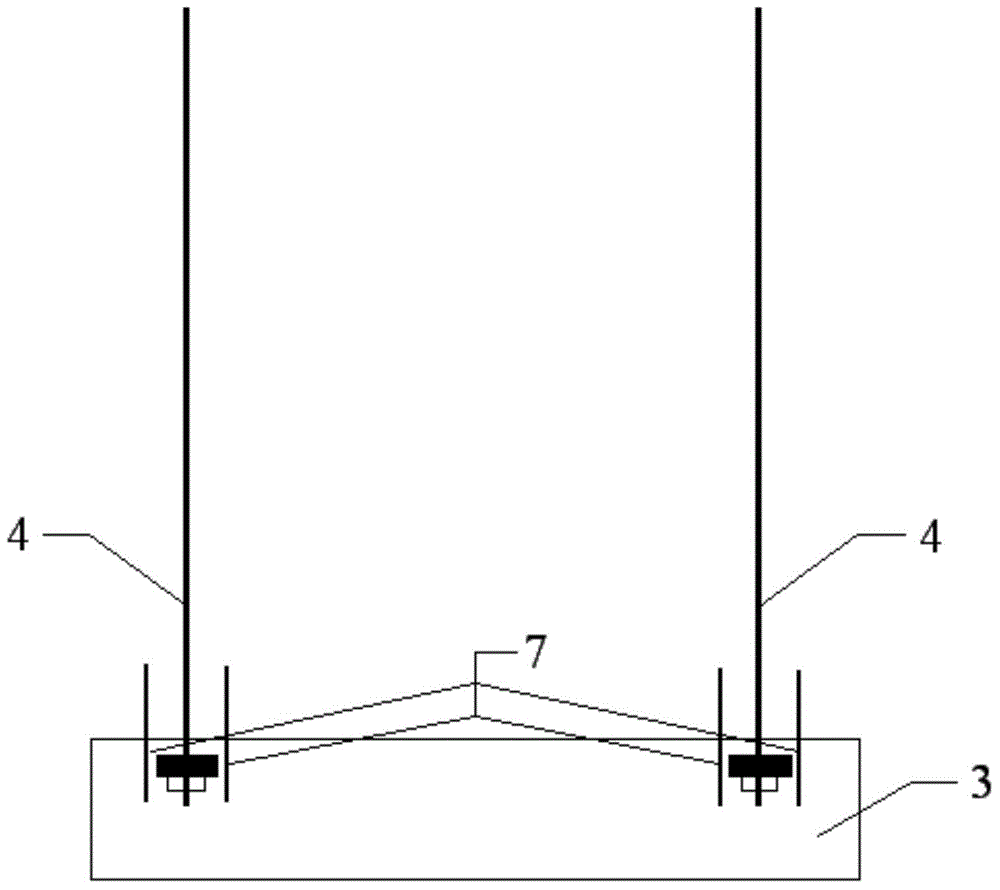

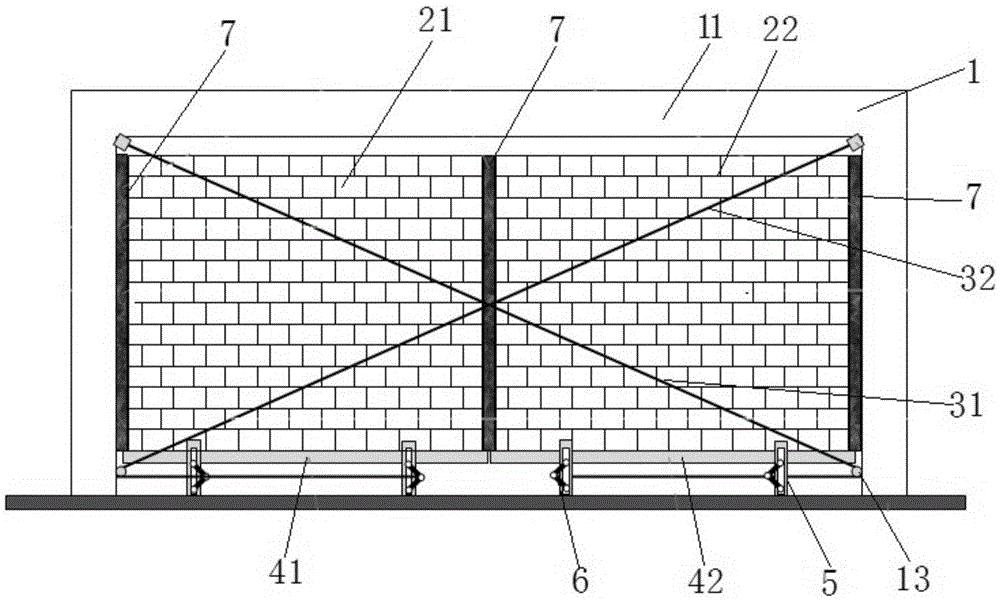

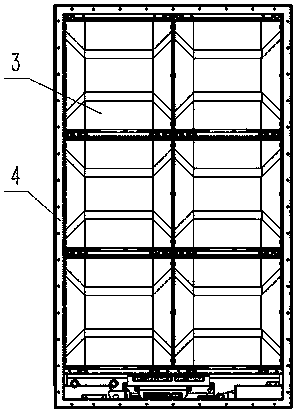

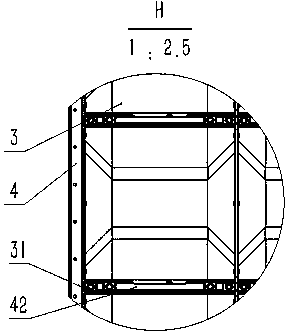

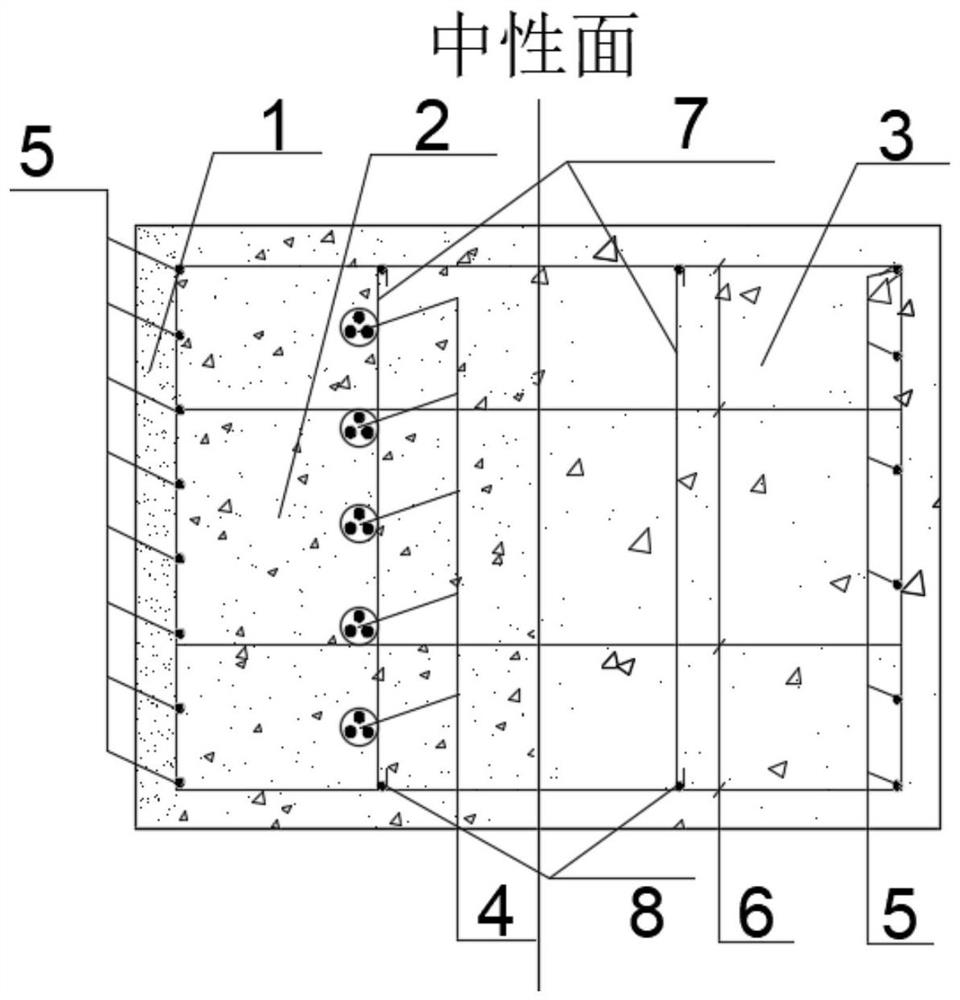

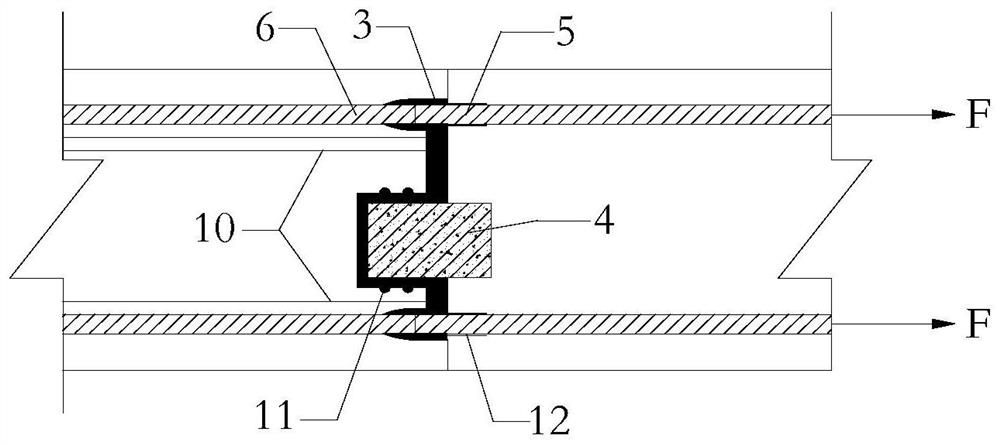

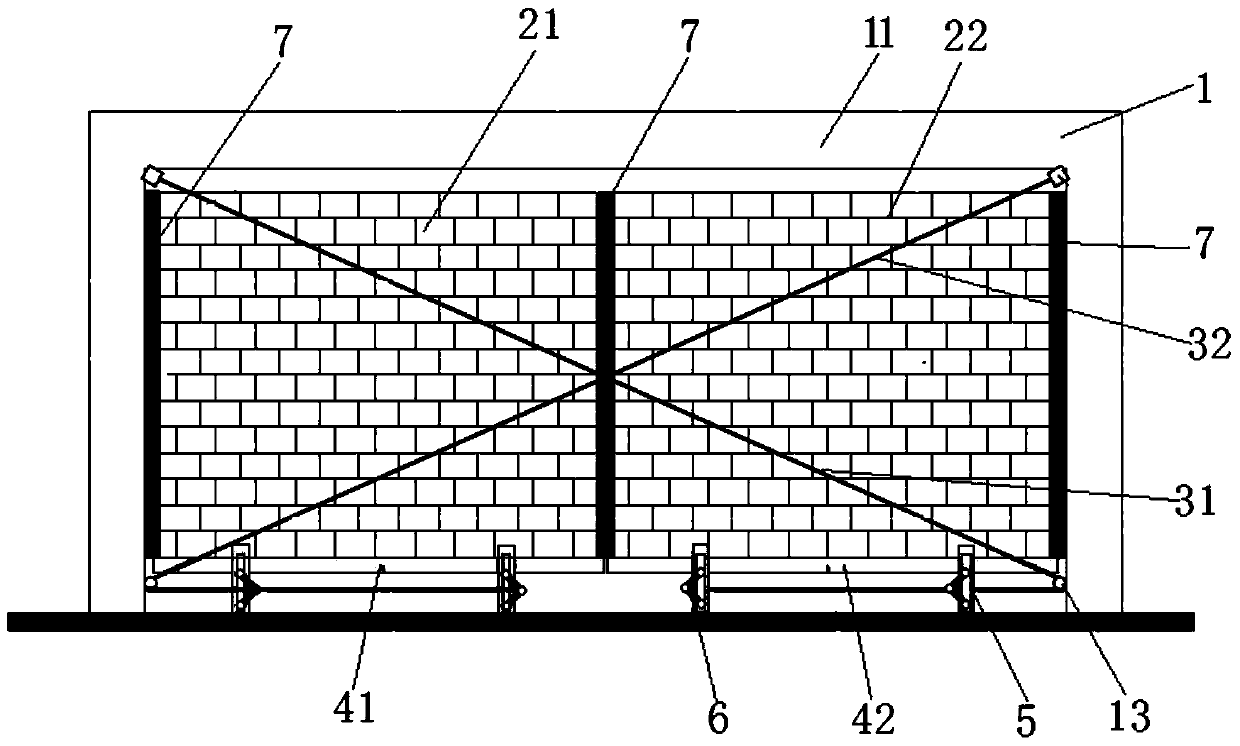

Gravity type damping filling wall

ActiveCN105649236AReduce earthquake damageReduces risk of cracking breakage and out-of-plane tippingWallsShock proofingEngineeringPre stress

The invention relates to the technical field of fixed buildings, in particular to a gravity type damping filling wall which comprises a frame structure, two brickworks arranged in the frame structure side by side, and prestress ribs located on the two sides of the two brickworks and crossed at the diagonal position of the frame structure. A steel groove support is arranged below each brickwork. The two ends of each steel groove support are connected with the ground through opposite supporting legs respectively. Slide grooves are formed in the supporting legs. V-shaped supports are arranged between every two opposite supporting legs. The two ends of each V-shaped support are arranged in the slide grooves of the corresponding supporting legs on the two sides. Slide wheels are arranged at the bottom ends of frame columns of the frame structure. The top ends of the prestress ribs are fixed to the upper portion of the frame structure. The bottom ends of the prestress ribs are wound around the slide wheels and fixed to the middles of the V-shaped supports on the corresponding sides. By stretching or releasing the prestress ribs, the field angles of the V-shaped supports are changed. The two brickworks in the frame structure deform in the lateral direction of the frame structure so as to vertically and oppositely move, and therefore energy consumption happens to a damping medium in the filling wall, and the risks of cracking breakage and plane outward collapse of the filling wall are reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Optical accelerant concrete wood-filament board and production method thereof

InactiveCN101037318AService life is not affectedReduce cracking damageSolid waste managementAir quality improvementPolymer scienceAir cleaning

A manufacturing method for a photo catalysis cement excelsior board, including following steps: mixing the sliced bamboo and wooden thread with cement and water uniformly, pressing into a bamboo and wooden thread plate, coating a SiO2 sol-to-gel by soaking or sparying, soaking in a TiO2 photo catalysis nano sol-to-gel or coating by the bamboo and wooden thread plate with a SiO2 protective film after drying and filmforming, and drying. The plate is widely applied in the decoration of the buildings such as teaching building, room, auditoria, odeum, broadcasting studio and has advantages of lightweight, high strength, sound isolation, heat isolation, sterilization, mildewproo, deodorization, air cleaning, anti-pollution, contacting to the air with a large surface and not being destroyed easily.

Owner:ZHEJIANG FORESTRY UNIVERSITY

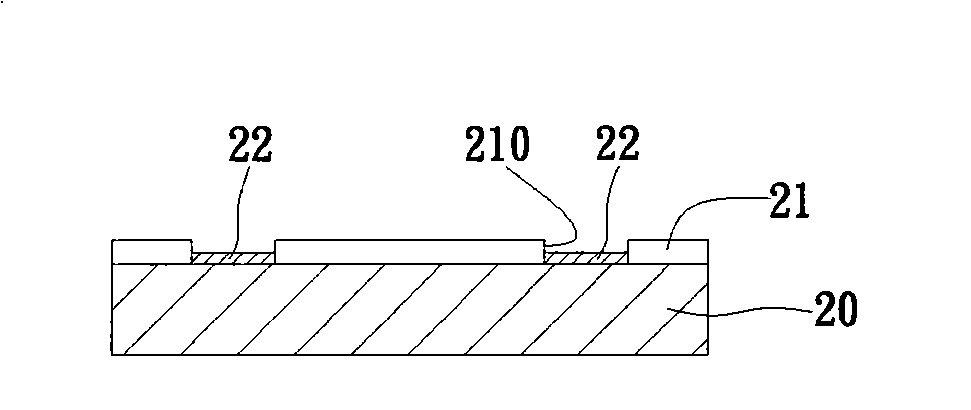

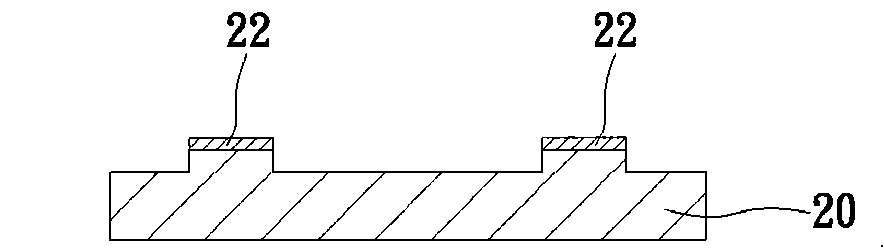

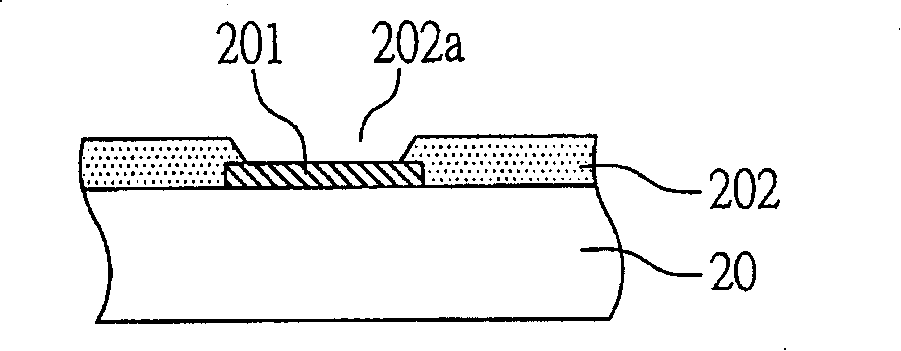

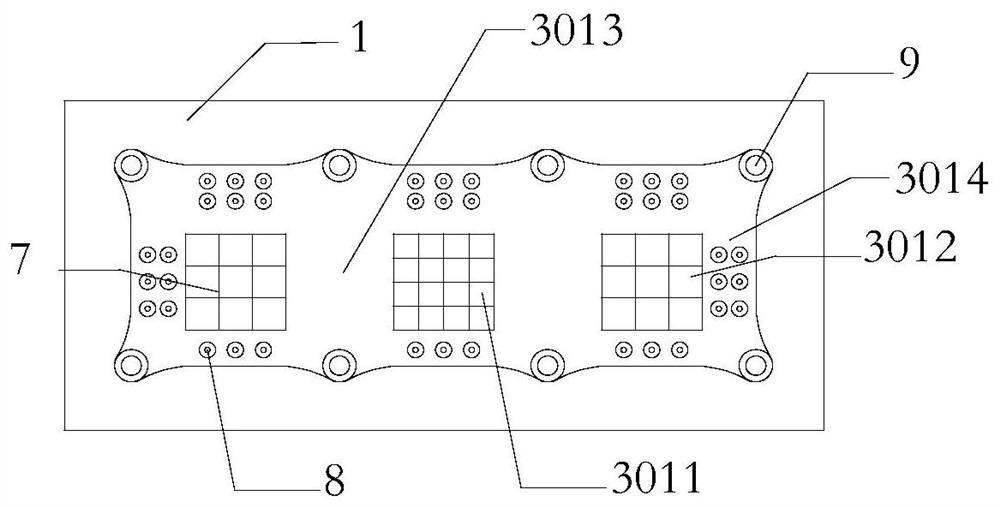

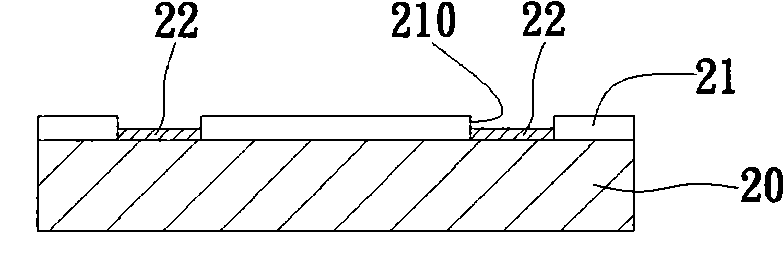

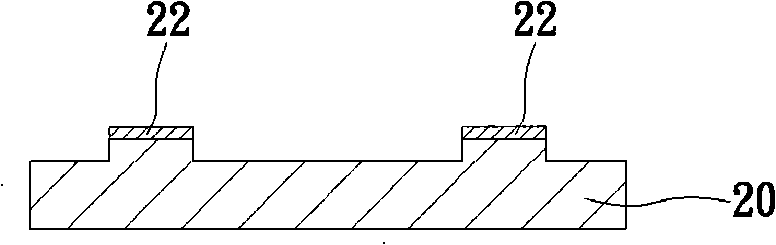

Semiconductor device has conductive projection and its manufacturing method

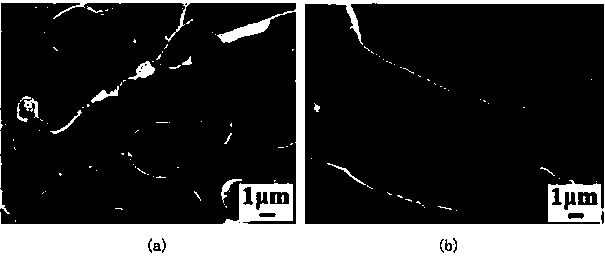

InactiveCN101221913AReduce cracking damageReduce problems such as delaminationSemiconductor/solid-state device detailsSolid-state devicesUnder bump metallurgySemiconductor

The invention discloses a semiconductor device with a conductive lug and a method for preparing the same, wherein the method mainly is that: a first metal layer electrically connected with the welding pad is formed on a semiconductor base material with a welding pad and a protective layer and is covered with and partially exposed from a second covering layer; and a second metal layer which is in electric connection with the first metal layer form the exposed part is formed on the second covering layer, and is covered with and is exposed partially from an opening of a third covering layer, and a conductive bump having a metal column and a soldering tin material is formed on the second metal layer in the opening accordingly, thereby providing a buffer effect by means of the covering layers and the metal layers and avoiding the problem of layer separation because the prior under bump metallurgy of a welding block formed on the welding pad directly withstands the stress transmitted by the metal column.

Owner:SILICONWARE PRECISION IND CO LTD

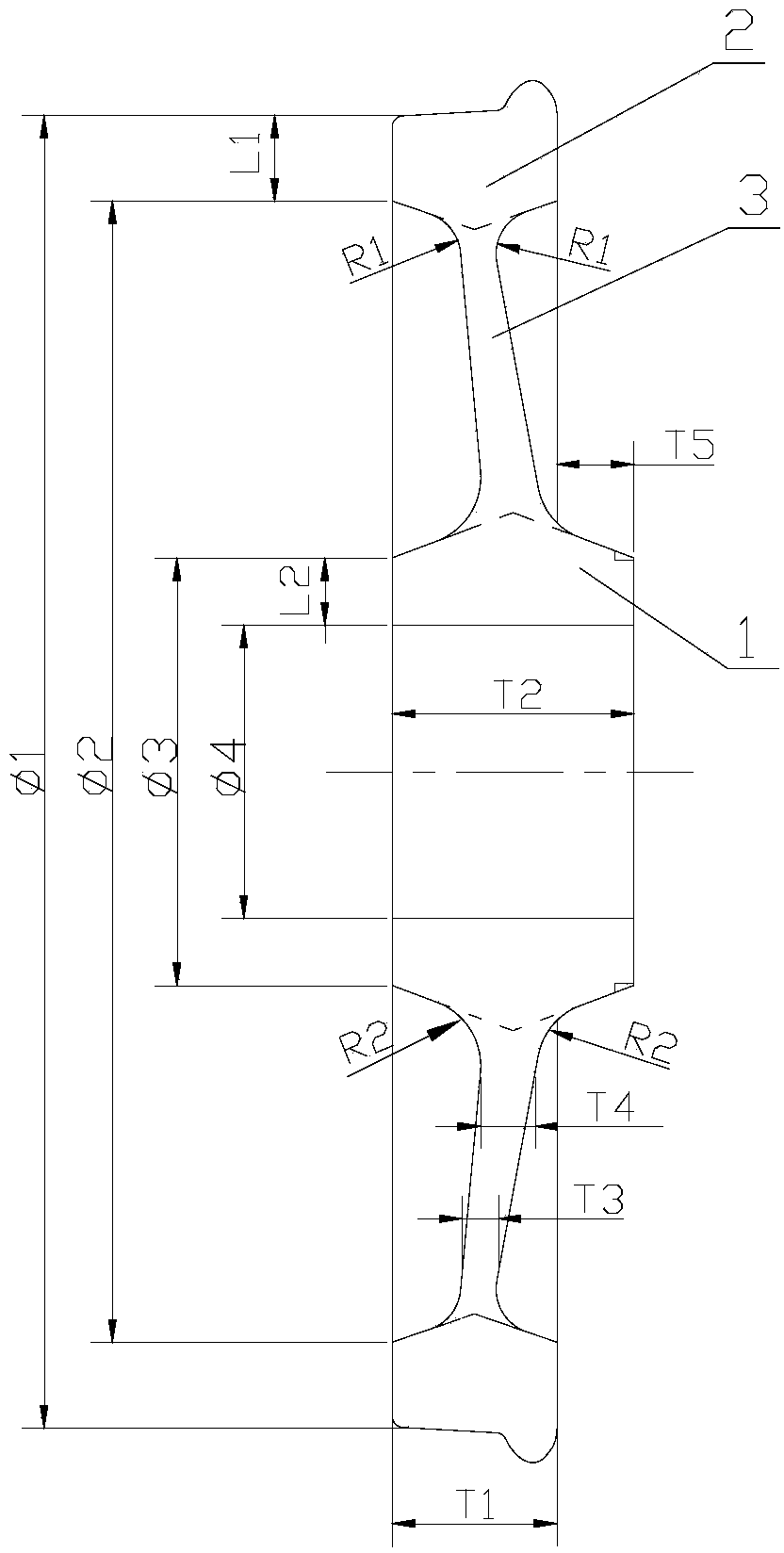

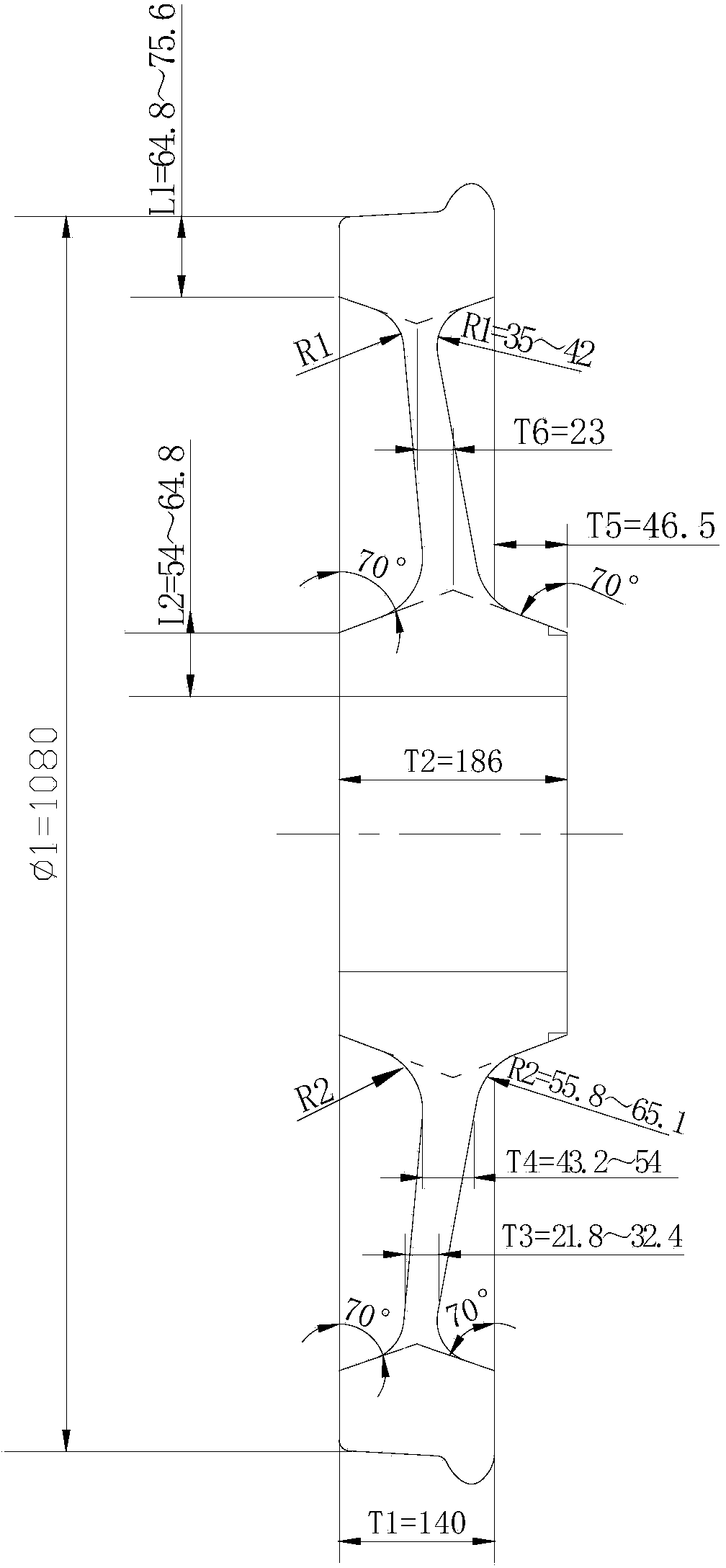

Train wheel and train

InactiveCN103507560AUniform force distributionReduce crack damageRail-engaging wheelsRailway vehiclesMechanical engineeringStress distribution

The invention provides a train wheel and a train. The train wheel comprises a hub and a rim, wherein the hub is connected with the rim through wheel disks, the thickness of the rim is 6%-7% of the diameter of a rolling circle of the wheel, and the thickness of the hub is 5%-6% of the diameter of the rolling circle of the wheel; the thickness of each wheel disk close to the rim is 2%-3% of the diameter of the rolling circle of the wheel; the thickness of each wheel disk close to the hub is 4%-5% of the diameter of the rolling circle of the wheel. According to the train wheel and the train, sizes of various parts of the wheel are optimized, stress distribution of the various parts can be even under the circumstance that the wheel is subjected to alternating stress, and the probability of the phenomena of cracking and damage to the wheel due to deformation and uneven stress is reduced.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

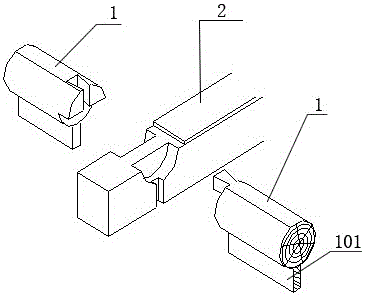

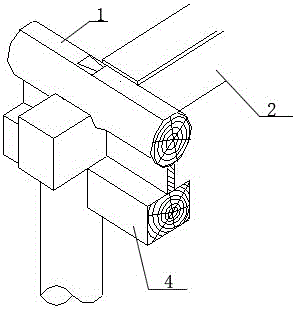

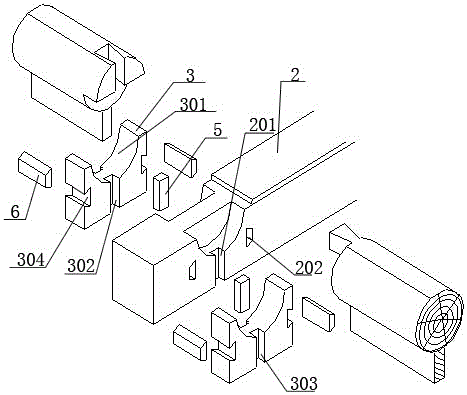

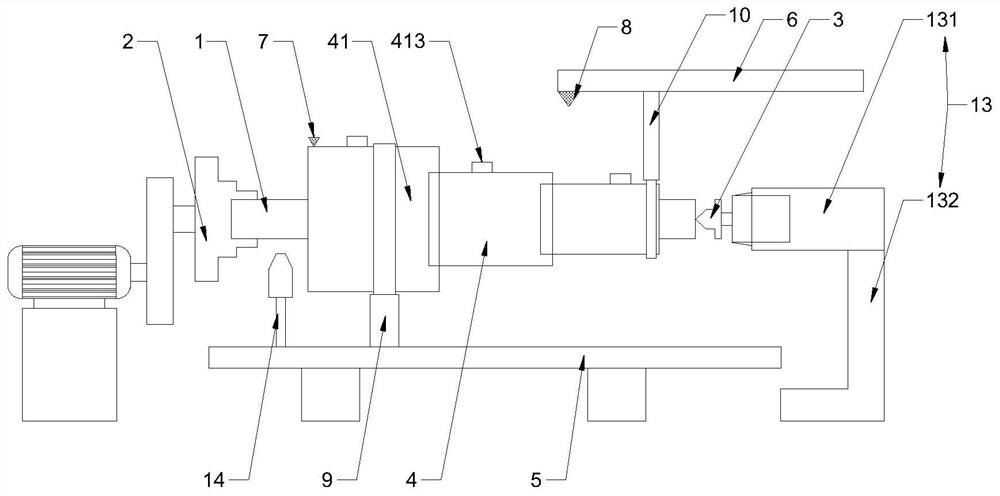

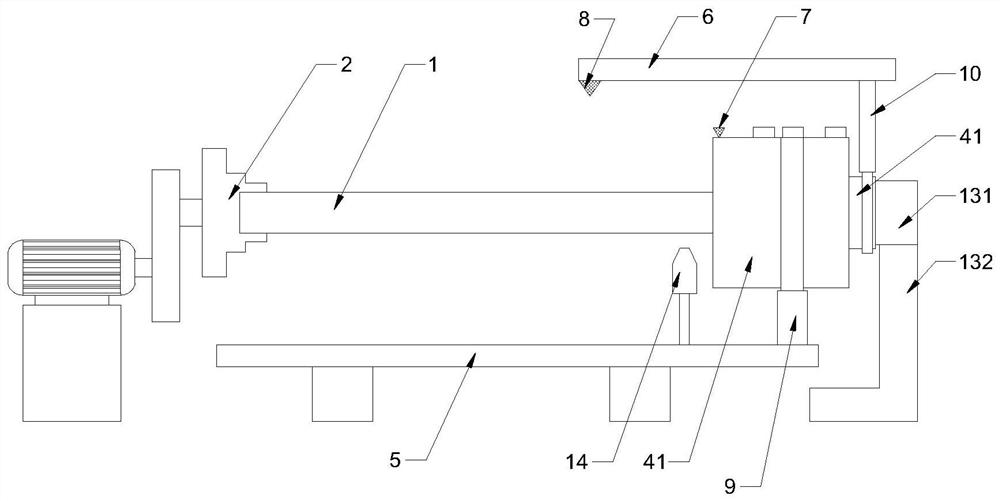

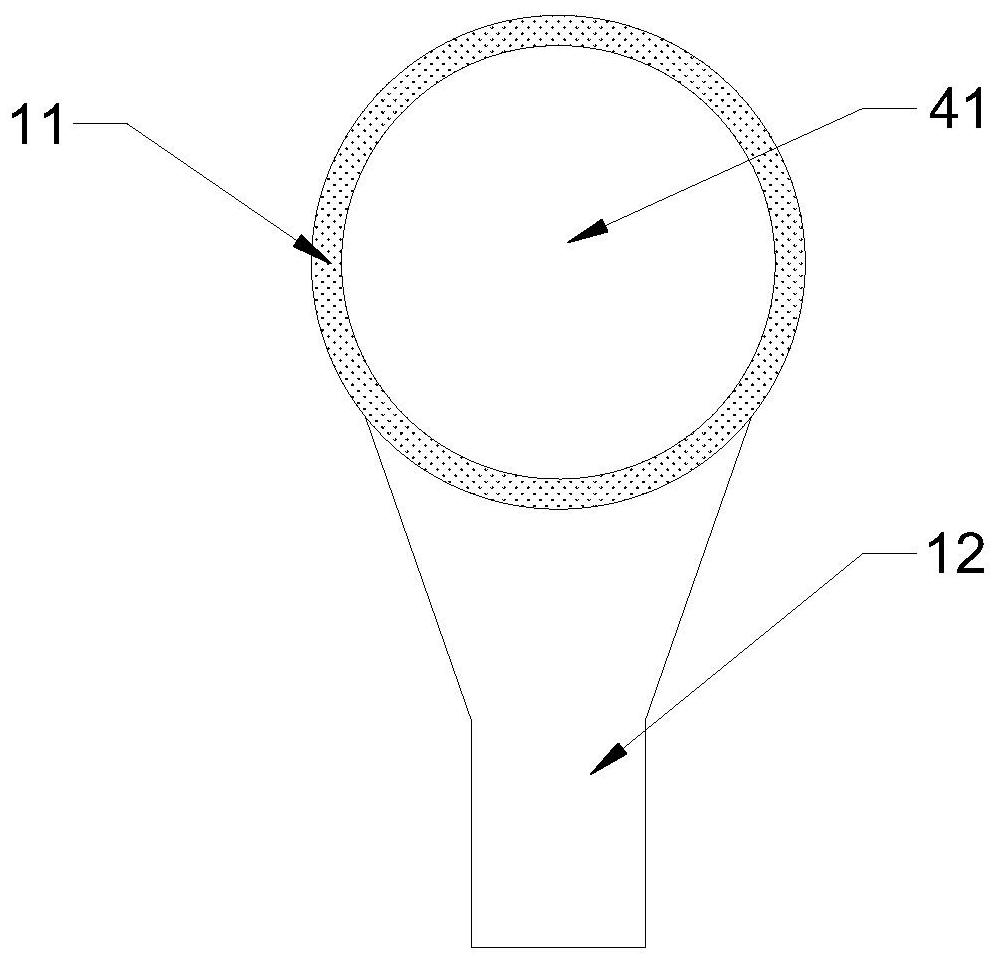

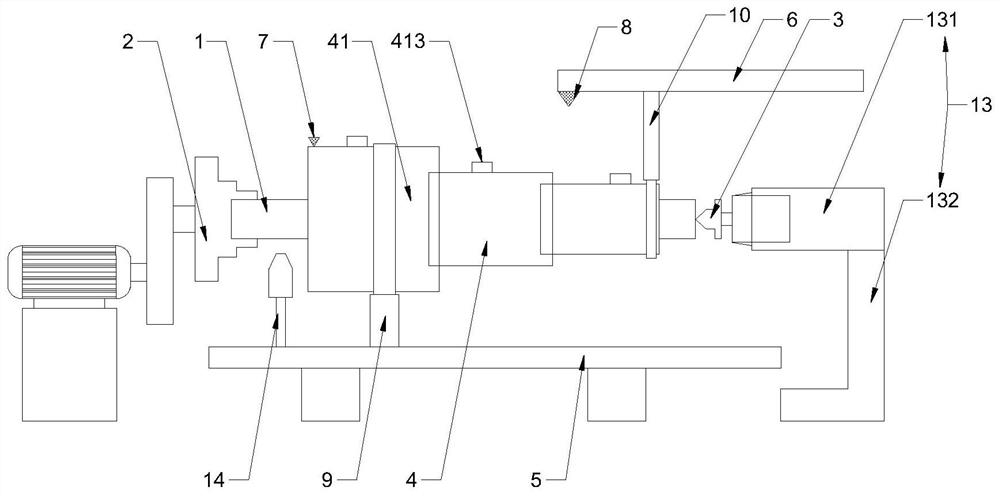

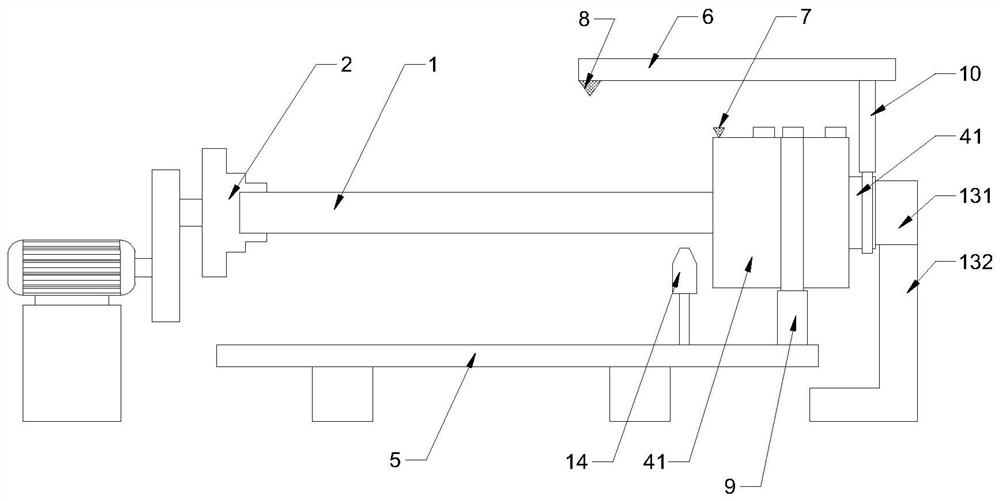

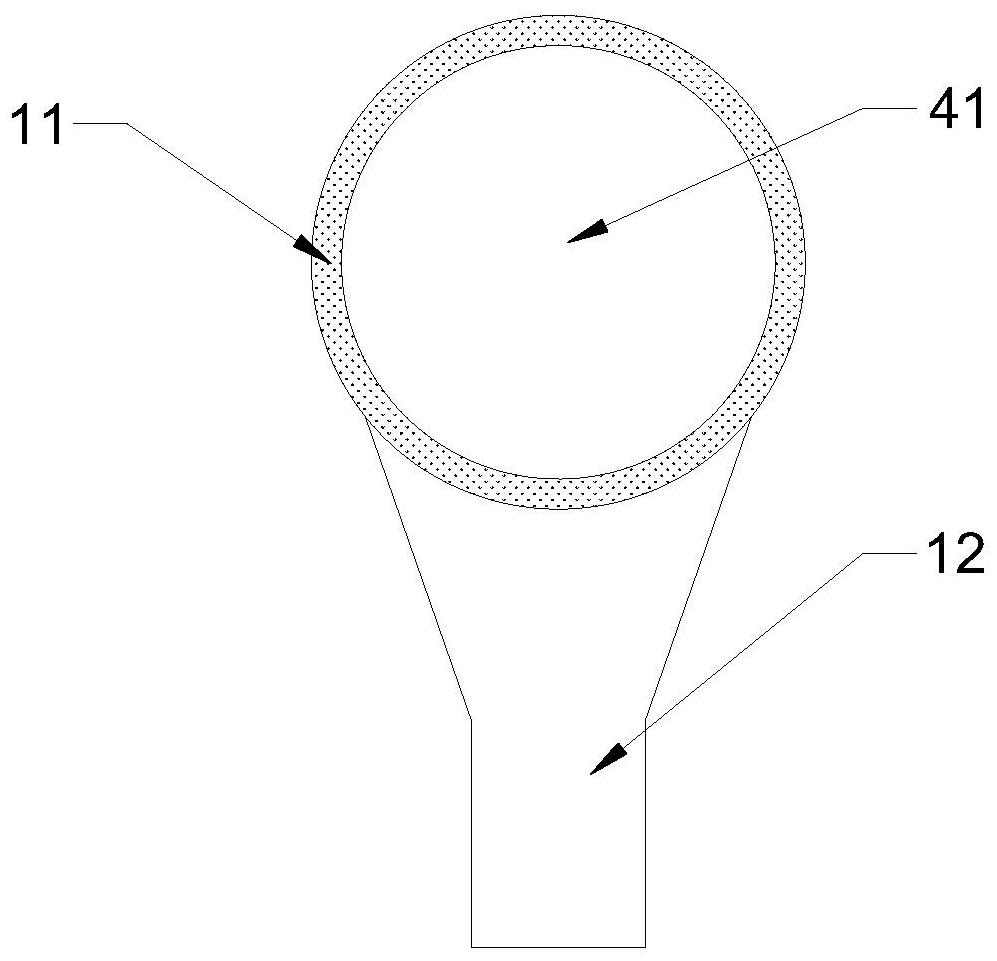

Laser cladding device and laser cladding method for long and thin workpiece

ActiveCN111809179AProtection securityControl residual stressMetallic material coating processesStructural engineeringMechanical engineering

The invention discloses a laser cladding device and a laser cladding method for a long and thin workpiece. The laser cladding device comprises a clamping jaw, an ejector pin, a telescopic preheating sleeve, a laser cladding nozzle, a first guide rail and a second guide rail, wherein the clamping jaw and the ejector pin clamp the two ends of the workpiece; the laser cladding nozzle slides on the first guide rail; the telescopic preheating sleeve comprises a plurality of sections of heating cylinders of which the diameters are sequentially reduced from the clamping jaw to the ejector pin; the heating cylinder with the maximum diameter is connected to the first guide rail through a first bracket in a sliding manner; the heating cylinder with the minimum diameter is connected to the second guide rail through a second bracket in a sliding manner; the telescopic preheating sleeve synchronously moves and contracts along with the movement of the laser cladding nozzle, so that the workpiece isalways kept in a preheating state before laser cladding; after the laser cladding of the workpiece is finished, the telescopic preheating sleeve reversely moves and stretches, so that the workpiece issubjected to heat treatment; the workpiece is clamped and then preheated, so that the safety of a worker in the operation process is protected; and the workpiece is preheated and subjected to heat treatment, so that the residual stress of a cladding layer can be effectively controlled, the crack damage is reduced, and the laser cladding quality is improved.

Owner:江苏智远激光装备科技有限公司

Porous carbon material for filtering and preparation method thereof

The invention discloses a porous carbon material for filtering and a preparation method thereof. The preparation method specifically comprises the following steps that a raw material, an adhesive anda pore-forming agent are prepared, wherein the raw material is one of green petroleum coke and raw asphalt coke, the adhesive is petroleum asphalt, and the pore-forming agent is a mixed powder of butadiene styrene rubber powder and tire rubber powder; the preparation method comprises the following steps: crushing and balling the raw materials into powder, then screening the obtained powder by using a vibrating screen to obtain two-stage raw materials of -60 to +80 meshes and -80 to +120 meshes, and finally proportioning the two-stage raw materials of-60 to + 80 meshes and-80 to + 120 meshes according to a mass ratio of (30-40): (60-70); heating and mixing the prepared raw material and the pore-forming agent, then adding the adhesive which is heated and melted in advance, and mixing for 2 hours at the temperature of 150 DEG C to obtain a mixture; wherein the mass part ratio of the raw material to the adhesive to the pore-forming agent is (60-76): (20-30): (4-10); carrying out compression molding on the mixture to form a blank; and introducing the blank in a roasting furnace for segmented heating roasting to obtain the porous carbon material. The porous carbon material prepared by the method is narrow in pore size distribution and high in strength.

Owner:ZIGONG YUXING CARBON PRODS

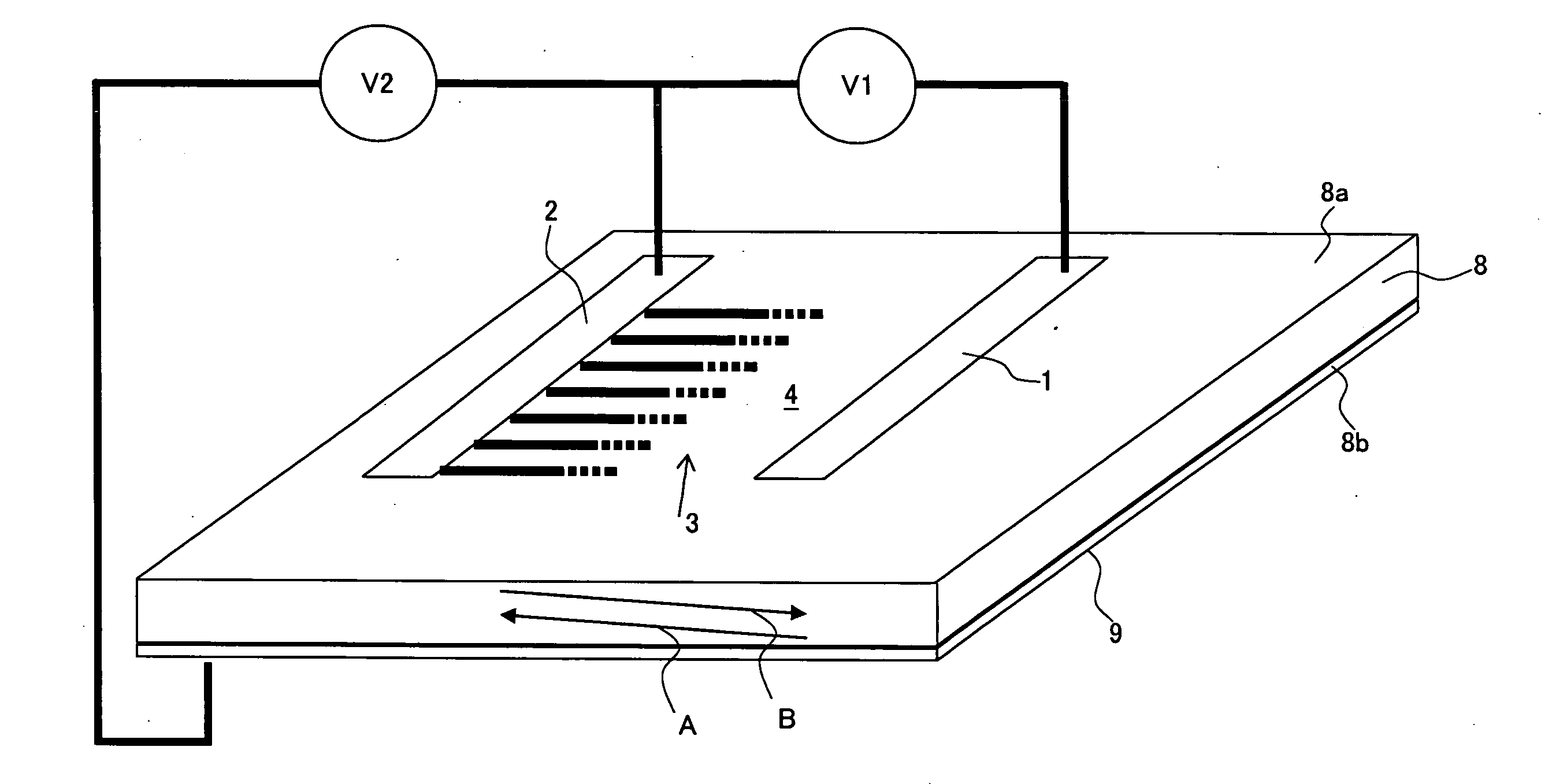

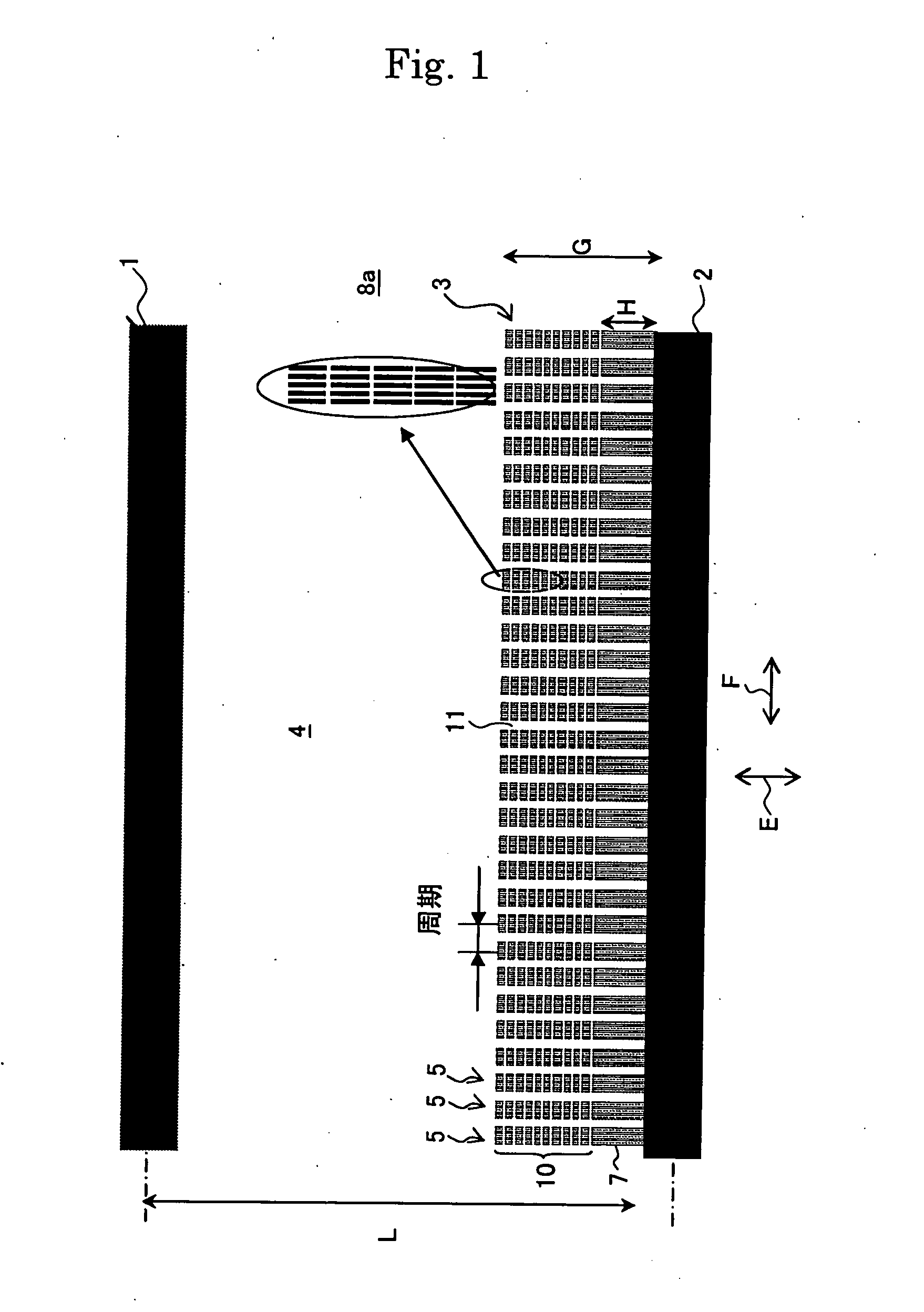

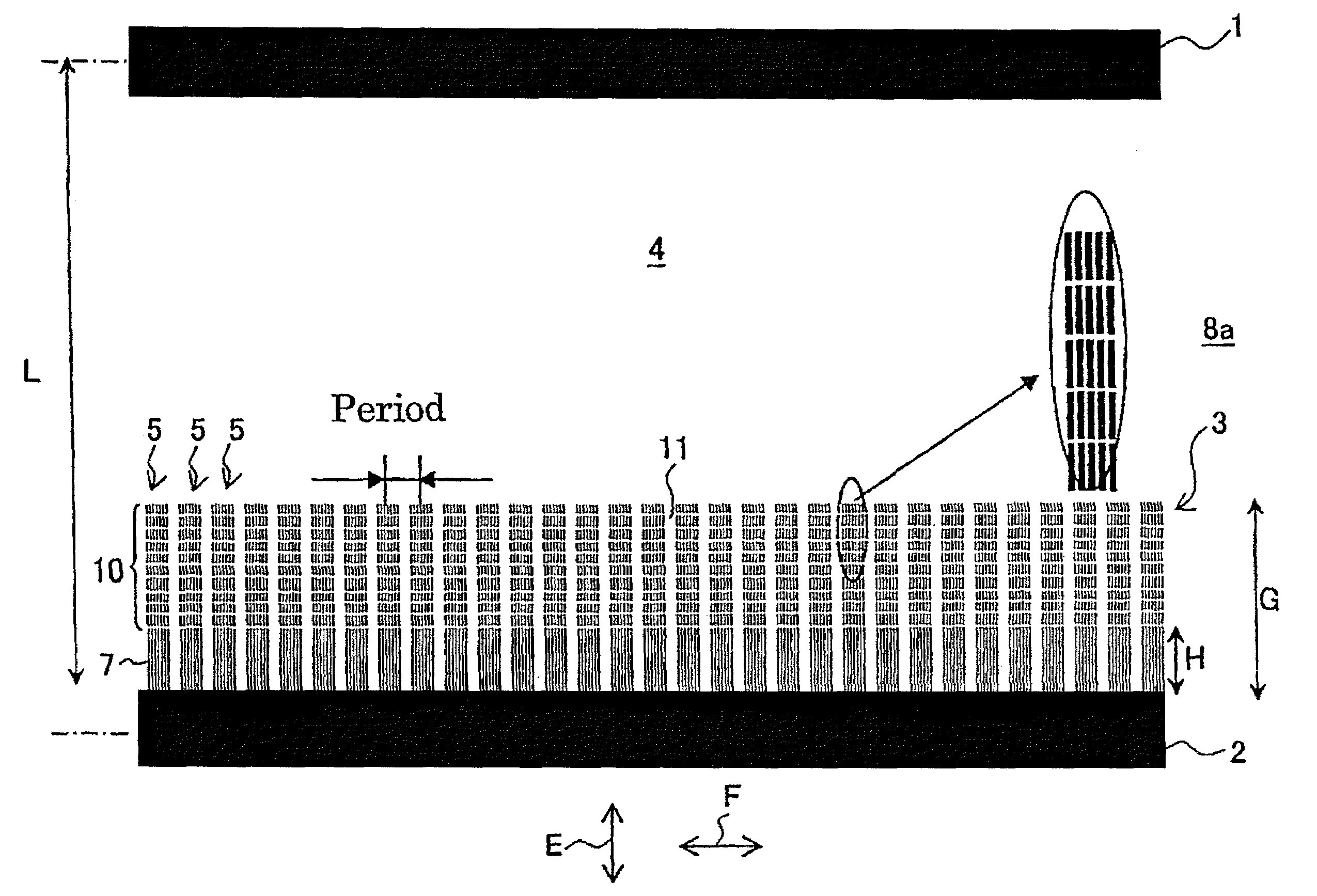

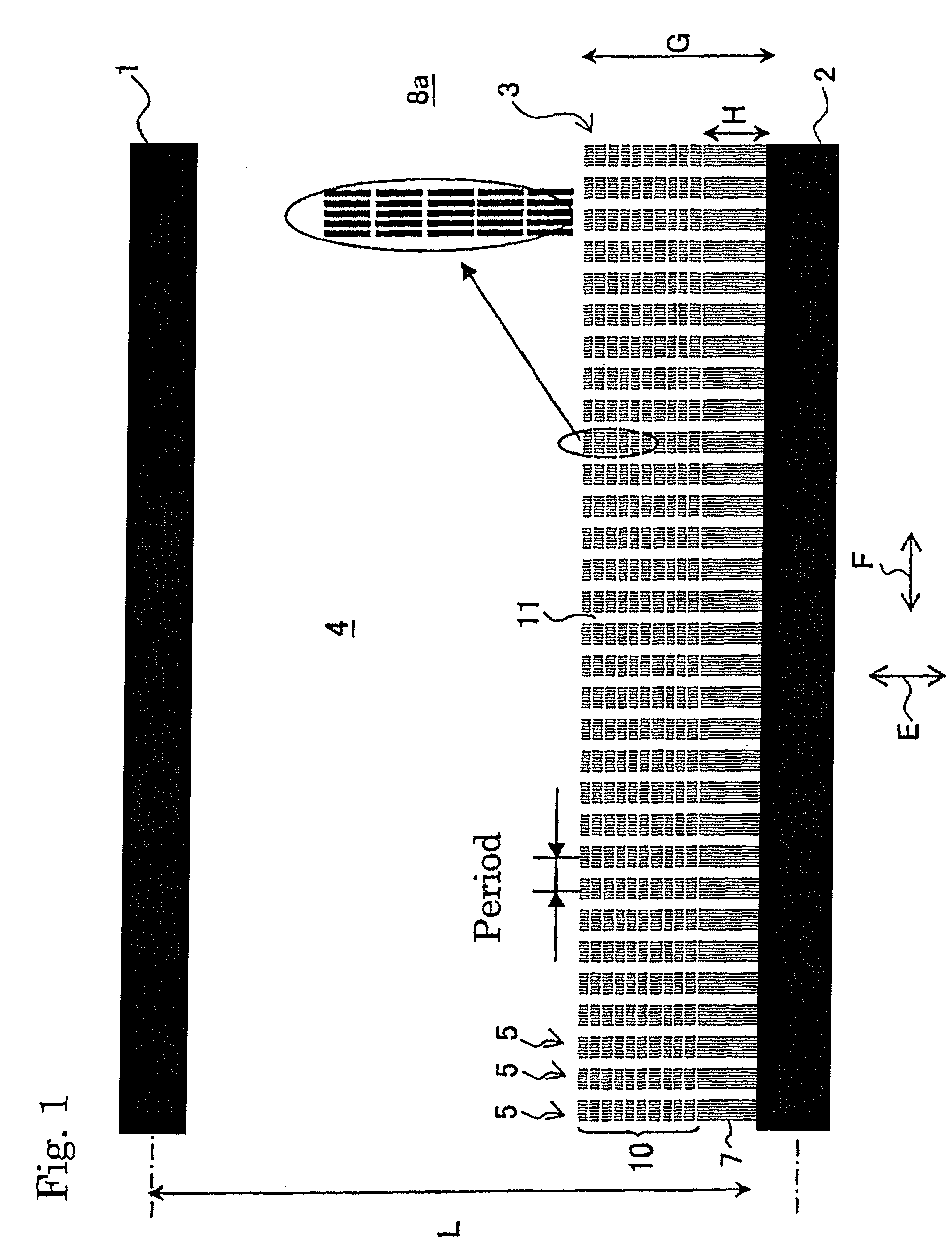

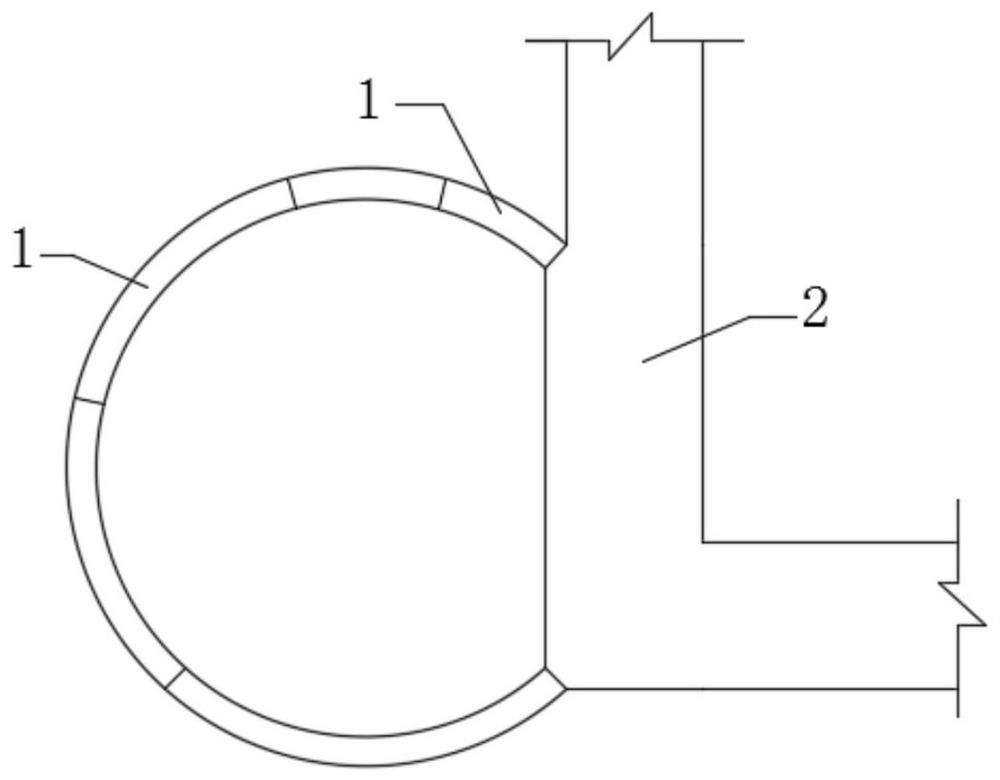

Method for fabricating polarization reversal structure and reversal structure

ActiveUS20070258131A1Avoid damageLower resistanceCoupling light guidesLight demodulationSingle crystalA domain

When a domain inversion part is produced by means of electric field polling process, damage in the vicinity of the forward end of a comb electrode and deviation of width of each domain inversion part are to be reduced. A polarization domain inversion structure has polarization domain inversion parts is produced by electric field poling process using a comb electrode formed on one surface of a substrate of a ferroelectric single crystal and of a single domain, and the comb electrode has a plurality of electrode portions and feeding portion. Each of the electrode portions corresponds with each domain inversion part of the domain inversion structure. The electrode portion has a plurality of low resistance pieces arranged in a direction “F” intersecting the longitudinal direction “E” of the electrode portion and spaced apart with each other.

Owner:NGK INSULATORS LTD +1

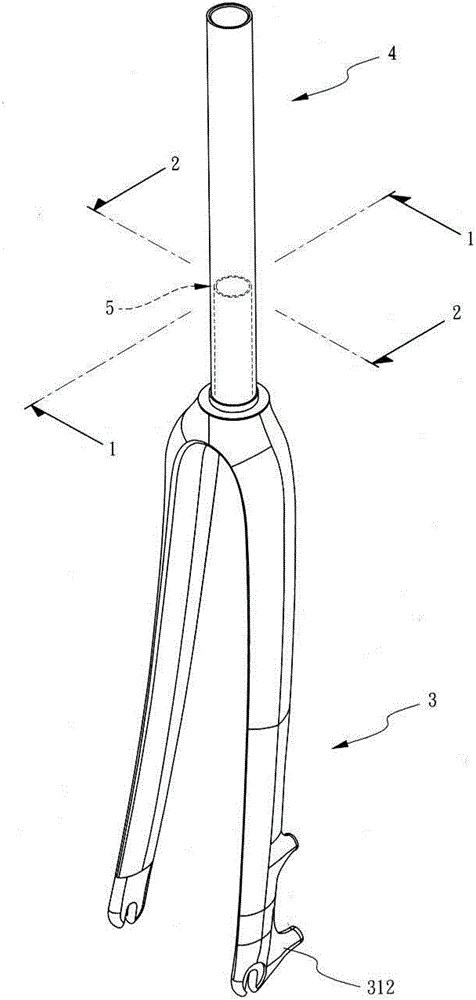

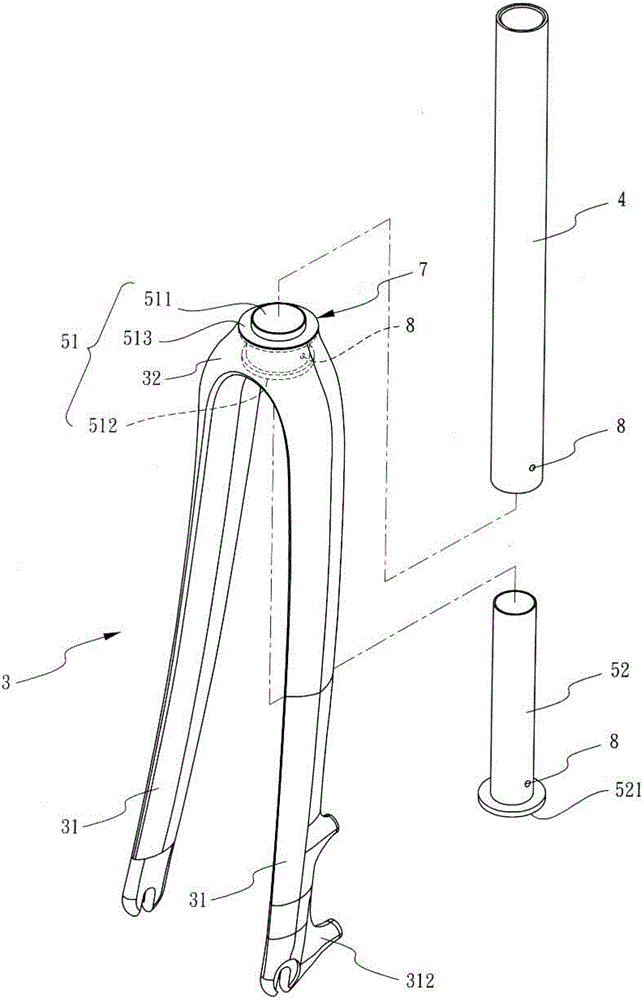

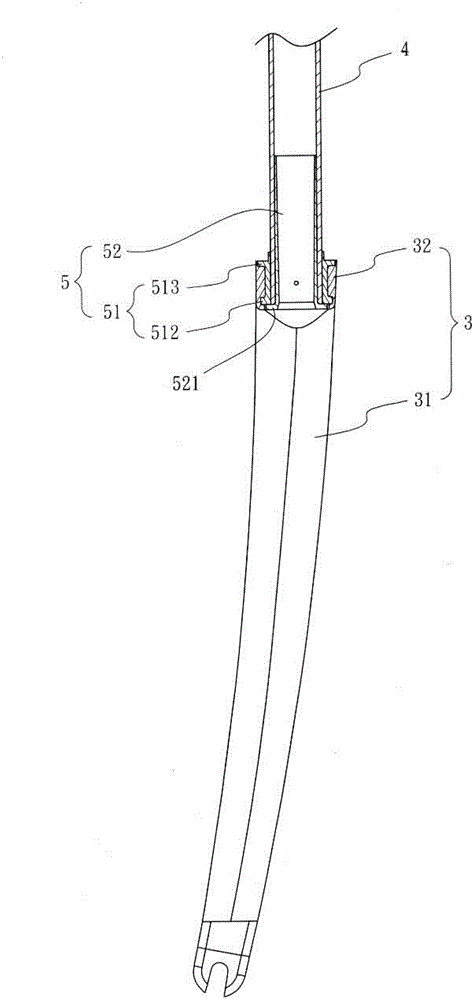

Bicycle fork body device

The invention relates to a bicycle fork body device. The bicycle fork body device comprises a bifurcated rod, a connecting rod and an accessory, wherein the bifurcated rod comprises two hollow supports and a base portion for connecting one ends of the two supports, and a combined hole which runs through the top end of the base portion to the bottom end of the base portion is formed in the base portion; the accessory arranged in the combined hole comprises a pipe casing part and a long pipe fitting, wherein the pipe casing part is arranged in the combined hole in an assembling manner; a set of holes are additionally formed and run through the pipe casing part; the long pipe fitting penetrates through the set of holes; an annual retaining part extends outward on the peripheral side of the long pipe fitting at one end close to the bifurcated rod; an insertion space is formed between an outer wall surface of the long pipe fitting and an inner wall surface of the pipe casing part; the connecting rod is sheathed in the long pipe fitting and enters the insertion space towards the direction of the bifurcated rod. According to the device, the accessory is set, so that the connecting rod can be quickly connected with the bifurcated rod, a fork body can maintain the existing strength, the overall weight can be lightened, and the occurrence of cracks and damages can be reduced.

Owner:李木荣

A kind of self-healing cyanate ester resin system and preparation method thereof

The invention relates to a self-repairing cyanate ester resin system and a preparation method of the self-repairing cyanate ester resin system. The preparation method comprises the steps of adding vinyl terminated poly-p-phenylene oxide (PPO) resin with low molecular weight into a cyanate ester (CE) resin system, and using 4,4 phi-diamino diphenyl sulfone (DDS) as a catalyst to treat the CE / PPO resin system through low-temperature process to obtain the self-repairing cyanate ester resin system with high performance. According to the technical scheme, the vinyl terminated PPO is utilized for maintaining thermoplasticity of the CE during forming; after the cured CE resin system is damaged, the PPO ingredients can be melted and flow to fill a crack to realize material repairing through a heating system, therefore, the vinyl terminated PPO has positive effects on prolonging the service life of the material and improving the safety of the material; the resin system can be used for preparing high-performance composite materials, electronic devices and the like for aerospace construction.

Owner:丹阳罡威新材料科技有限公司

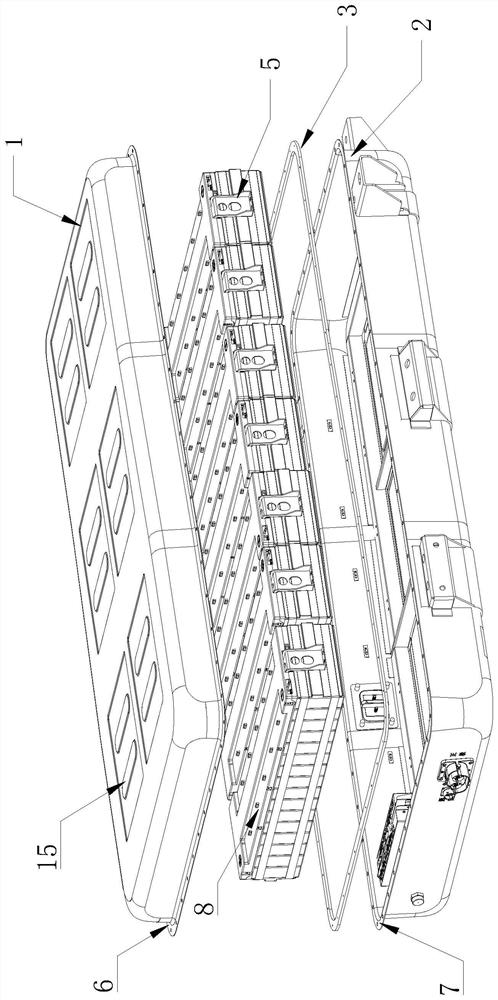

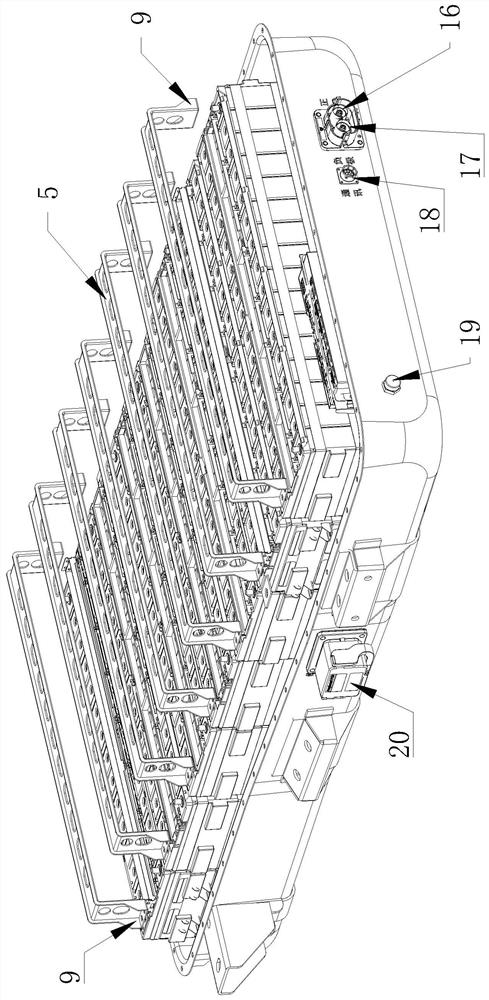

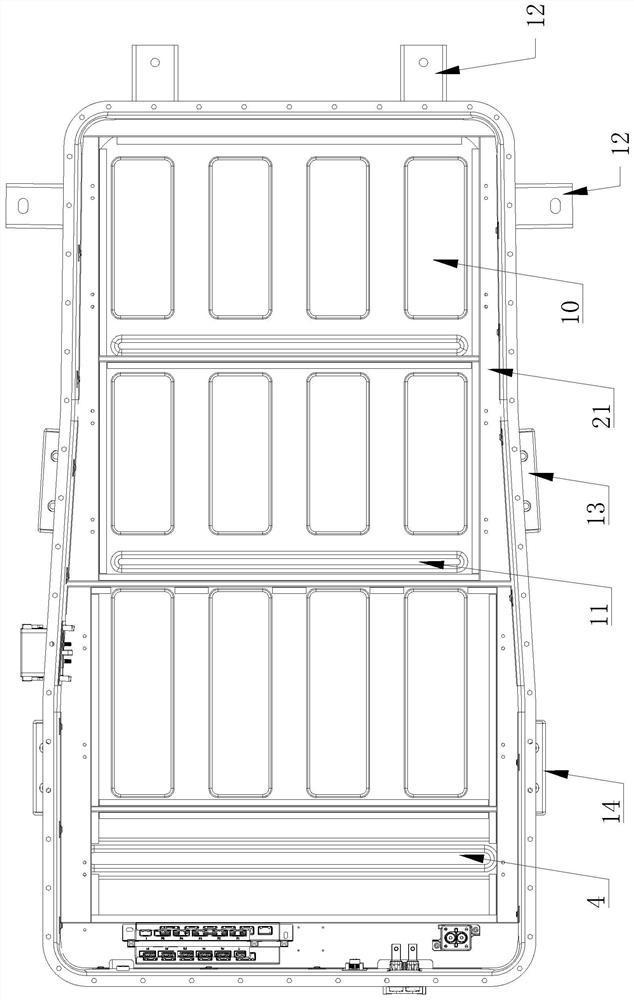

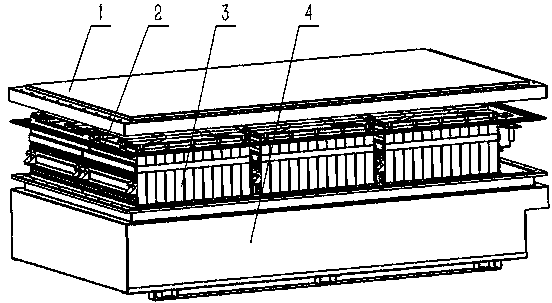

Battery pack box body and battery pack

The invention belongs to the technical field of electric vehicles, and specifically relates to a battery pack box body and a battery pack. A first skirt edge is arranged on the periphery of an upper box cover, a second skirt edge is arranged on the periphery of the top of a lower box body, the upper box cover and the lower box body are combined together in a matched mode in the mode that the firstskirt edge and the second skirt edge are overlapped and fixed together, and a sealing strip is arranged between the first skirt edge and the second skirt edge. The module mounting beam is mounted onthe inner upper side of the lower box body and provided with a fixing part for fixing a battery module, L-shaped fixing lugs are arranged at the two ends of the module pressing strip, and a block-shaped reinforcing rib and a strip-shaped reinforcing rib are formed on the inner bottom face of the lower box body in a punching mode. The pressing strip structure fixing mode is high in strength, good in stability, simple in installation process, light in weight and high in efficiency, and the safety performance of a system is improved. Installation process is simple, weight is light, and efficiencyis high. The battery pack box body adopts an enveloping structure, the height of the side keel is designed at the height of the gravity center horizontal plane of the battery pack cell, the lower boxbody strength is increased, the battery module fixed horizontal plane moment arm is zero, and the tension fracture damage of the moment to the battery pack box body is reduced.

Owner:江西安驰新能源科技有限公司

Battery box body

PendingCN108063202AReduce cracking damageHigh bulk densityBattery isolationCell sealing materialsChinese charactersElectrical battery

The invention relates to a battery box body, which comprises an upper cover, a sealing strip, modules and a lower box body, wherein upper bosses and lower bosses are arranged on the upper surface andthe lower surface of the sealing strip separately; mounting angles are arranged on two opposite side surfaces of each module; the mounting angles on two side surfaces of the module are horizontally arranged in a staggered manner; the horizontal heights of the mounting angles and the gravity center of each module are located in the same horizontal plane; support keels and mounting brackets of a structure shaped like a Chinese character ''ji'' are arranged in the lower box body; each module is hoisted between two adjacent mounting brackets in the lower box body; the mounting angles of two adjacent modules are horizontally arranged on the corresponding mounting brackets in a staggered manner; and the sealing strip is arranged between the upper cover and the lower box body and seals the uppercover and the lower box body through bolts. According to the battery box body, tensile breakage of torque to the box body is reduced, the volume density of the battery box body is improved by adoptingstaggered installation, the airtightness of the battery box body is improved through designing the bosses on the sealing strip; and the structure strength of the battery box body is strengthened through coordination design of the keels and the mounting brackets.

Owner:江西安驰新能源科技有限公司

Swing self-resetting bridge bent with ductile replaceable tie beams and its installation method

InactiveCN104452566BRestoring the anti-seismic ability of the bent frameFree from earthquake damageBridge structural detailsBridge erection/assemblyPre stressShear force

The invention discloses a swing self-reset bridge bent frame with a ductility replaceable collar beam. The swing self-reset bridge bent frame with the ductility replaceable collar beam comprises a bridge foundation, a prefabricated cover beam and two prefabricated piers, wherein the prefabricated piers are arranged on the bridge foundation and used for supporting the left side and the right side of the prefabricated cover beam. The swing self-reset bridge bent frame with the ductility replaceable collar beam further comprises the replaceable collar beam transversely arranged between the two prefabricated piers. Unbonded prestress tendons are longitudinally arranged in the prefabricated piers. The two ends of each unbonded prestress tendon extend out of the upper end and the lower end of the corresponding prefabricated pier and are fixedly connected with the prefabricated cover beam and the bridge foundation respectively. The junction between each prefabricated pier and the prefabricated cover beam is provided with a shear key for connection, and is also provided with an energy dissipation longitudinal bar fixedly connected with the prefabricated pier and the prefabricated cover beam respectively. By the adoption of the technical scheme, the prefabricated parts are assembled rapidly, the overall structure is stable by means of the junctions, the replaceable collar beam and the unbonded prestress tendons, and the swing self-reset bridge bent frame has the swing and self-reset structural characteristic.

Owner:DALIAN MARITIME UNIVERSITY

Novel heat accumulation concrete for solar thermal power station and preparation method for novel heat accumulation concrete

The invention belongs to the field of building materials, and in particular relates to a functional concrete material and a preparation method thereof. The invention relates to novel heat accumulation concrete for a solar thermal power station. 1 square meter of heat accumulation concrete is characterized by being prepared from the following raw materials by weight: 380 to 450 kilograms / meter<3> of metakaolin, 220 to 310 kilograms / meter<3> of modified sodium silicate solution, 5 to 10 kilograms / meter<3> of water reducing agent, 900 to 1,200 kilograms / meter<3> of basalt, 590 to 710 kilograms / meter<3> of fine aggregates, 10 to 20 kilograms / meter<3> of steel fibers, 0.5 to 1 kilogram / meter<3> of organic fibers and 10 to 20 kilograms / meter<3> of graphite powder, wherein a liquid-solid ratio of the modified sodium silicate solution to the metakaolin is (0.60-0.70):1; and the fine aggregates comprise ordinary sand, copper ores and steel slag sand. The high-temperature heat accumulation material prepared by the method has the characteristics of low cost, stable performance, high coefficients of heat conductivity, high durability and the like, and is easy to prepare on site.

Owner:WUHAN UNIV OF TECH

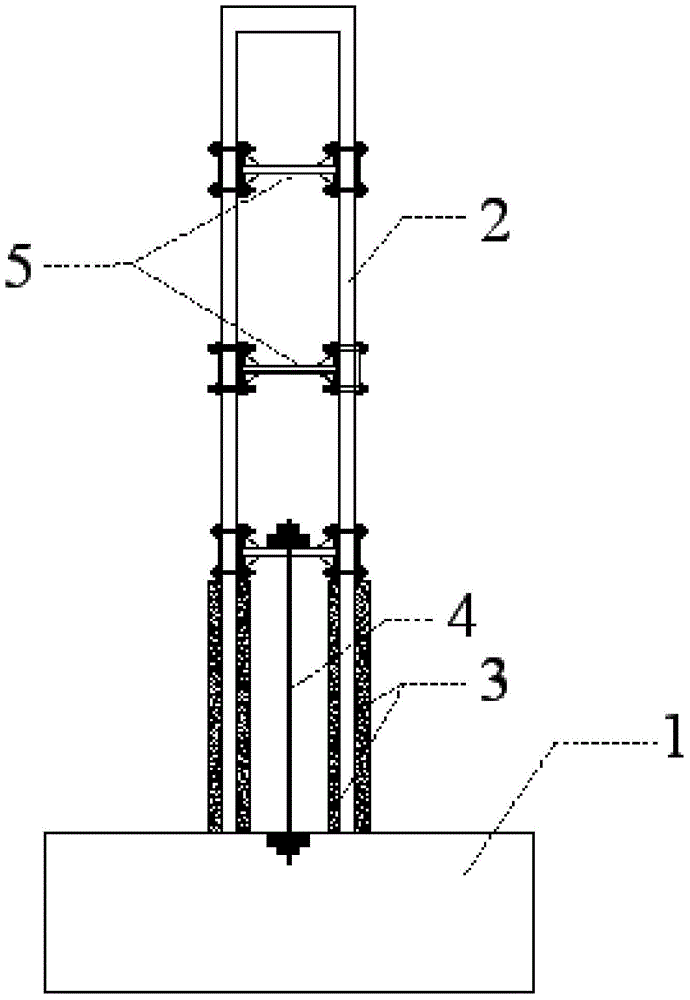

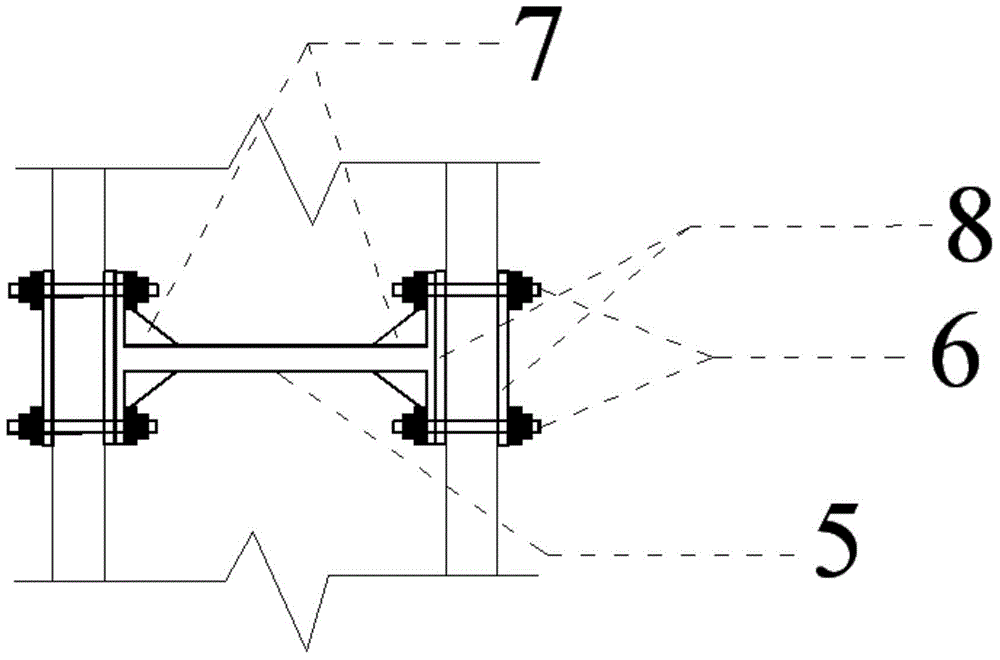

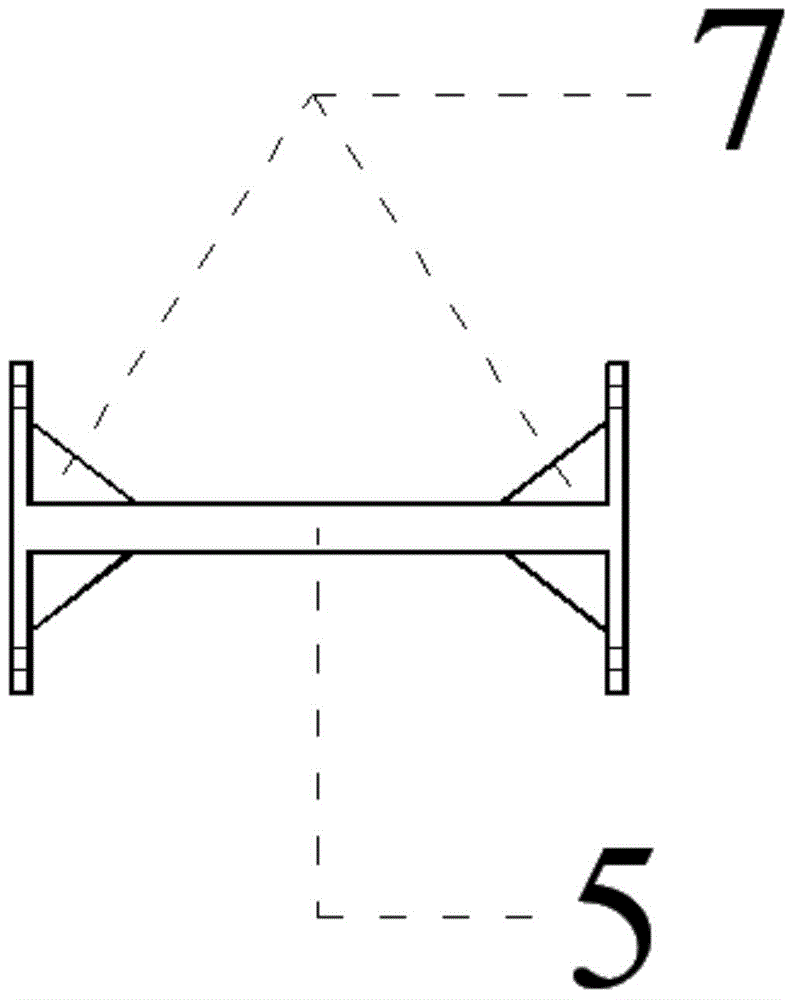

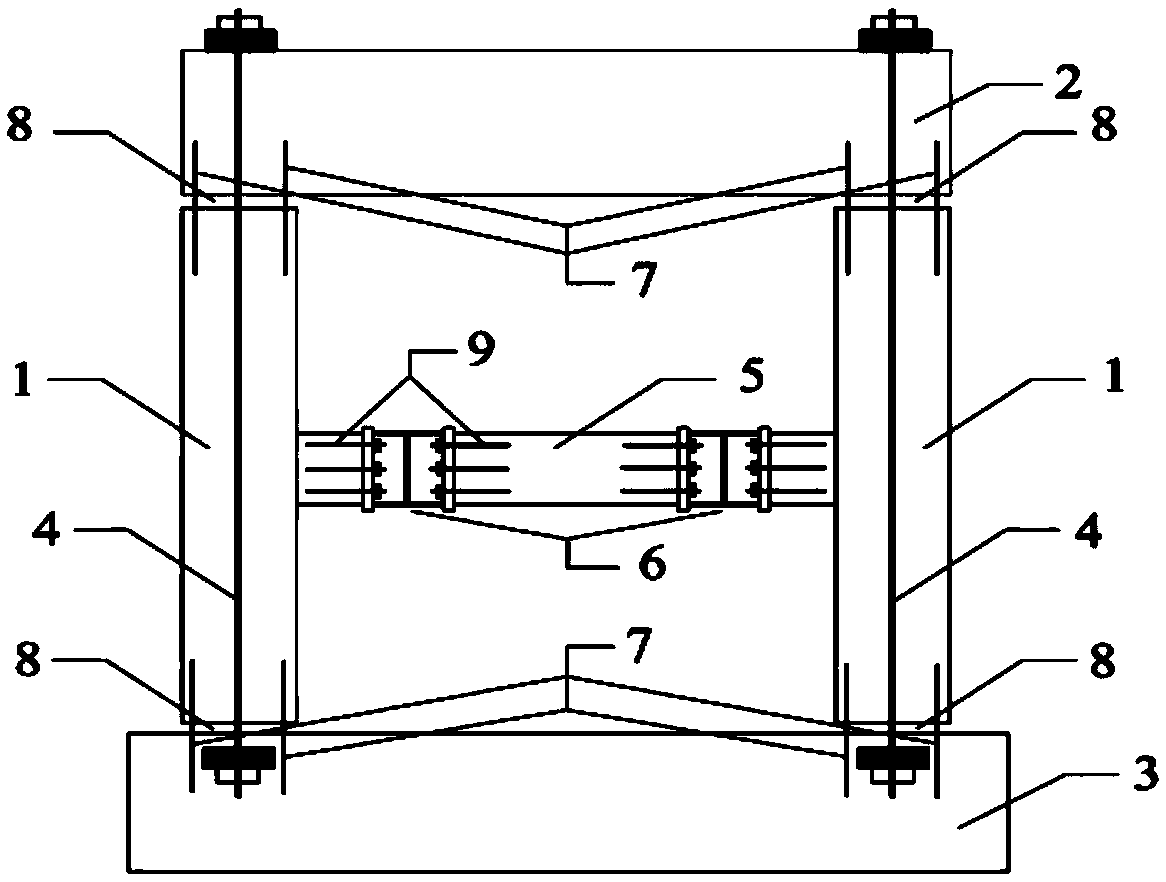

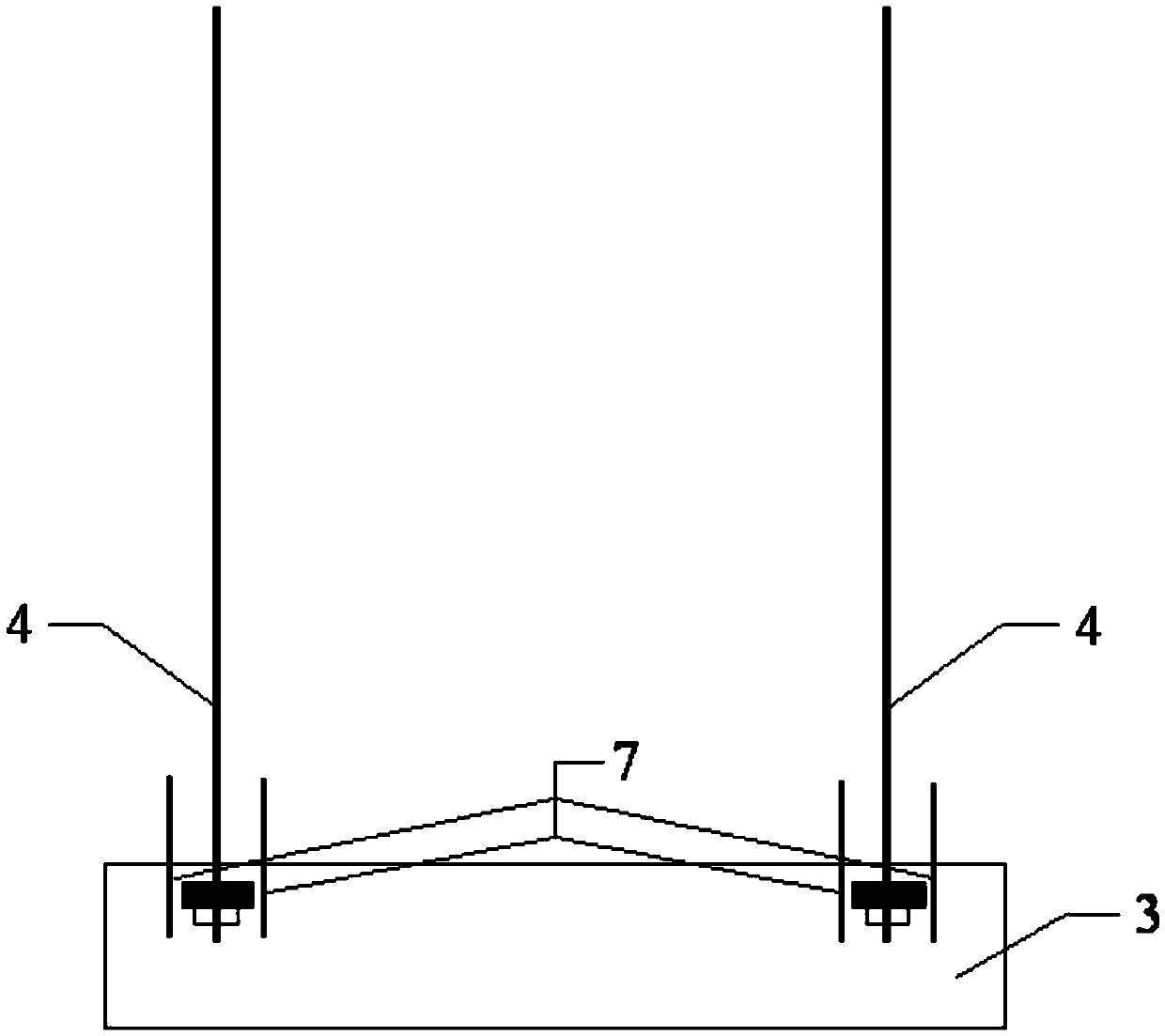

A swinging double-deck bridge bent frame and its installation method

InactiveCN104452567BImprove construction progressImprove traffic capacityBridge erection/assemblyBuckling-restrained braceService condition

The invention discloses a novel swing type double-deck bridge bent frame which comprises a bent frame foundation, a group of bottom prefabricated bridge piers, a bottom prefabricated cover beam, a group of top prefabricated bridge piers, a top prefabricated cover beam, unbonded prestressing tendons, buckling-restrained braces and steel connecting pieces, wherein the bottom prefabricated bridge piers are respectively arranged at the left end and the right end of the bent frame foundation, and the bottom prefabricated cover beam is arranged at the top ends of the bottom prefabricated bridge piers; the top prefabricated bridge piers are respectively arranged at the left end and the right end of the bottom prefabricated cover beam, and the top prefabricated cover beam is arranged at the top ends of the top prefabricated bridge piers; the unbonded prestressing tendons penetrate through the two ends of the bottom prefabricated bridge piers, are respectively connected with the bent frame foundation and the bottom prefabricated cover beam and used for providing self-restoring capacity for the bent frame; the buckling-restrained braces are arranged between the bottom prefabricated cover beam and the bent frame foundation and used for providing main transverse stiffness and energy-dissipating capacity. The design of the double-deck bridge bent frame realizes the idea of functional separation, and the vertical bearing capacity of the bent frame is born by the prefabricated bridge piers and the prefabricated cover beams under a normal service condition. The transverse bridge stiffness and the energy-dissipating capacity of the bent frame are mainly born by the buckling-restrained braces under the action of an earthquake.

Owner:DALIAN MARITIME UNIVERSITY

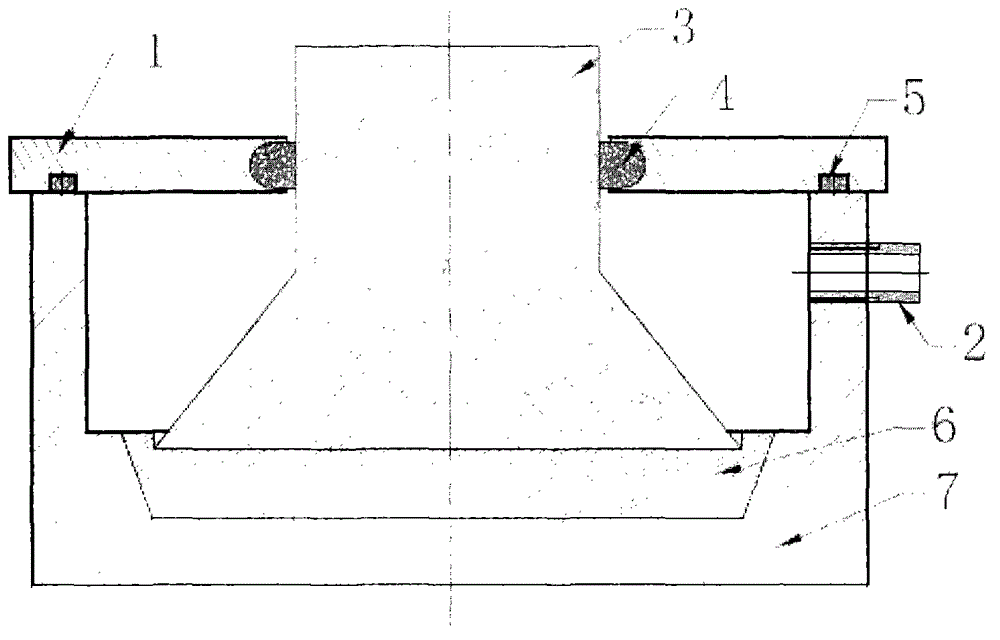

Negative-pressure casting sealed tank for aluminum impeller

The invention discloses a negative-pressure casting sealed tank for an aluminum impeller. The negative-pressure casting sealed tank comprises a shell, wherein an upper cover is arranged at the upper end of the shell; a circular hole is formed in the center of the upper cover; a sealing groove is annularly formed in the bottom surface of the upper cover corresponding to upper end face of the shell; a sealing ring is arranged in the sealing groove; a groove is formed in the bottom in the shell; a piece of active cold iron is arranged in the groove; a gypsum mold shell is arranged on the active cold iron in the shell; the upper part of the gypsum mold shell passes through the circular hole in the center of the upper cover; a sealing ring is arranged between the edge of the circular hole in the center of the upper cover and the gypsum mold shell; a suction opening is formed in the side wall of the shell; a pipe joint for vacuumizing is arranged on the suction opening. The negative-pressure casting sealed tank has the advantages of simple structure, convenience in operation and the like. A double-layer structure consisting of a tank body and the upper cover is adopted, and the upper cover and the tank body are sealed movably, thereby reducing the impact of mold clamping force on a gypsum mold, lowering the cracking proportion of the gypsum mold, adapting to negative-pressure casting of a booster impeller, and reducing crack damages to the gypsum mold during sealing.

Owner:侯伟

Laser cladding device and laser cladding method for slender workpiece

ActiveCN111809179BProtection securityControl residual stressMetallic material coating processesEngineeringMechanical engineering

The invention discloses a laser cladding device and a laser cladding method for a slender workpiece, comprising a gripper, a thimble, a telescopic preheating sleeve, a laser cladding nozzle, a first guide rail and a second guide rail; the gripper and a thimble Both ends of the workpiece are clamped; the laser cladding nozzle slides on the first guide rail; the telescopic preheating sleeve includes a multi-section heating cylinder whose diameter gradually decreases from the jaw to the thimble; the heating cylinder with the largest diameter is slidably connected by the first bracket On the first guide rail, the heating cylinder with the smallest diameter is slidably connected to the second guide rail through the second bracket; the telescopic preheating sleeve moves and shrinks synchronously with the movement of the laser cladding nozzle, so that the workpiece is always kept preheated before laser cladding. Thermal state; after the laser cladding of the workpiece is completed, the telescopic preheating sleeve moves in reverse and stretches to heat the workpiece; clamping first and then preheating protects the safety of workers during operation; workpiece preheating and heat treatment can effectively Control the residual stress of the cladding layer, reduce crack damage, and improve the quality of laser cladding.

Owner:江苏智远激光装备科技有限公司

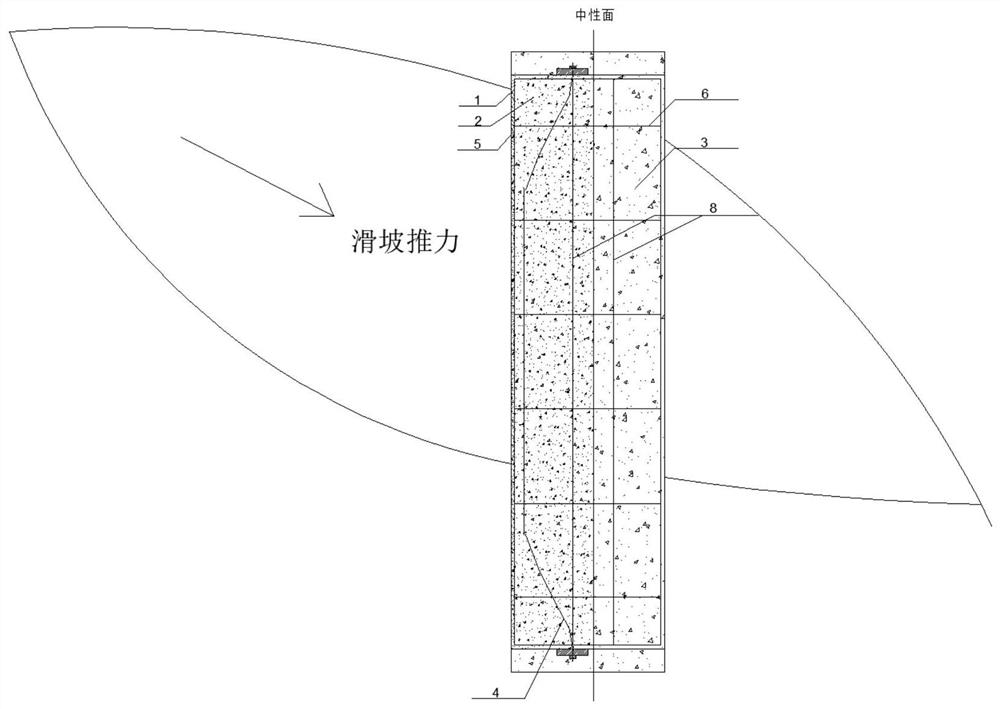

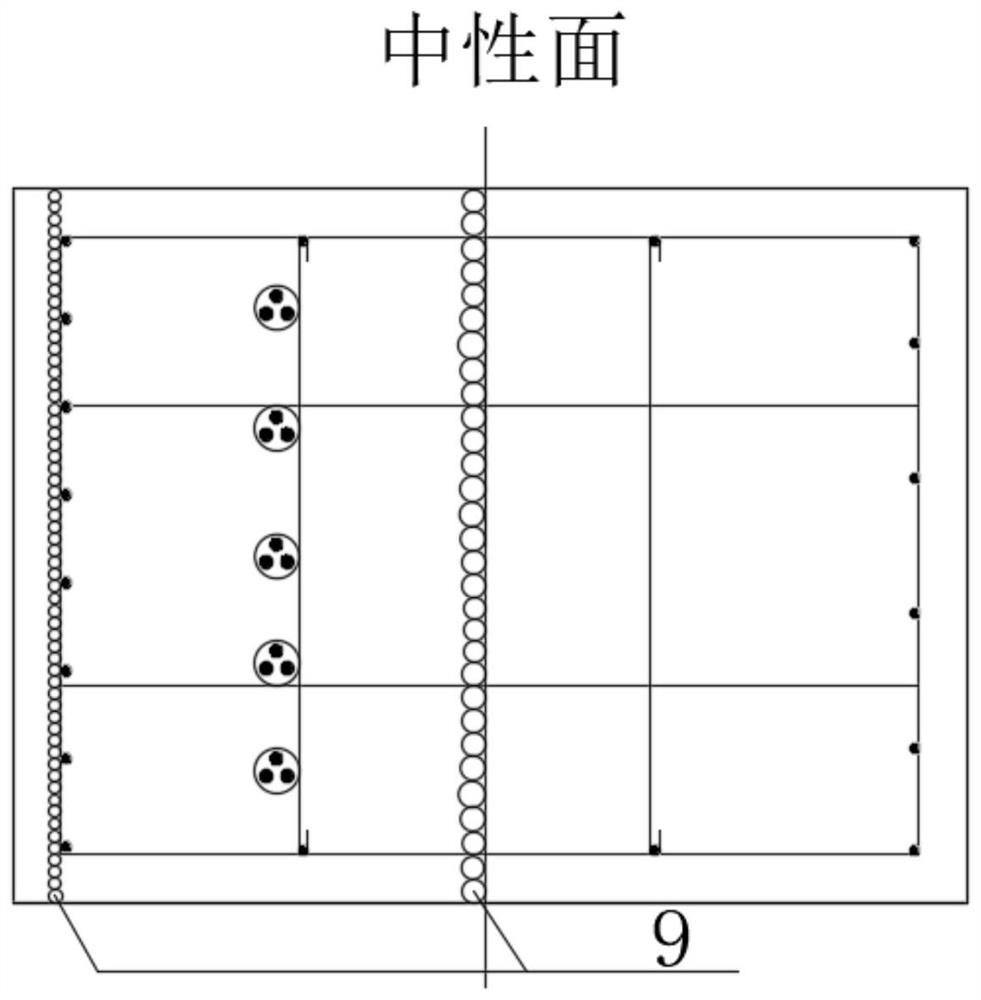

High-toughness functionally graded material slide-resistant pile and construction method

ActiveCN113684842AProtection against rustProtective bonding effectClimate change adaptationExcavationsFunctionally graded materialDuctility

The invention discloses a high-toughness functionally graded material slide-resistant pile. The high-toughness functionally graded material slide-resistant pile comprises a PVA-ECC material protection layer, tensile area small-particle-size coarse aggregate concrete and a compression area large-particle-size coarse aggregate concrete layer. The PVA-ECC material protection layer, the tensile area small-particle-size coarse aggregate concrete layer and the compression area large-particle-size coarse aggregate concrete layer are sequentially arranged from inside to outside in the landslide thrust direction, and different subareas are poured at the same time. Functional division is carried out according to different stress characteristics of the section of the slide-resistant pile, different material designs are carried out according to a gradient structure, and the prepared functionally graded material slide-resistant pile has high toughness, better deformation ductility and bending and shearing bearing capacity. Steel strands and the small-particle-size coarse aggregate concrete in the tension area can keep deformation coordination, meanwhile, the PVA-ECC protection layer with excellent ductile deformation is arranged on the portion bearing the landslide thrust, cracking damage is reduced, and the toughness and the bending resistance of the whole pile body are improved.

Owner:WUHAN UNIV

Method for fabricating polarization reversal structure and reversal structure

ActiveUS7522791B2Reduce cracking damageReduce widthCoupling light guidesLight demodulationSingle crystalA domain

When a domain inversion part is produced by means of electric field polling process, damage in the vicinity of the forward end of a comb electrode and deviation of width of each domain inversion part are to be reduced. A polarization domain inversion structure has polarization domain inversion parts is produced by electric field poling process using a comb electrode formed on one surface of a substrate of a ferroelectric single crystal and of a single domain, and the comb electrode has a plurality of electrode portions and feeding portion. Each of the electrode portions corresponds with each domain inversion part of the domain inversion structure. The electrode portion has a plurality of low resistance pieces arranged in a direction “F” intersecting the longitudinal direction “E” of the electrode portion and spaced apart with each other.

Owner:NGK INSULATORS LTD +1

Method for improving stability of a die-molded composite door panel

ActiveCN102602112BIncrease productionReduce warpageLamination ancillary operationsLaminationMedium density fiberboardPressure reduction

The invention relates to a method for improving the stability of a die-molded composite door panel, which comprises the following four steps of: 1, selecting materials, to be specific, selecting a piece of melamine decorative paper and a middle-density fiberboard as materials for producing the die-molded composite door panel; 2, softening the middle-density fiberboard by spring an ammonia or urea solution; 3, limiting the depth and height of patterned fluctuation as well as a curvature radius of the patterned fluctuation transition of a mold; and 4, selecting a hot press for simultaneously closing multiple layers, setting high temperature and low temperature for press plates of the hot press at intervals one by one in die molding, doing different arrangements on a pavement sequence of raw materials on a high-temperature press plate and a low-temperature press plate, and giving special parameters to a closing speed, pressure, pressure holding time and pressure reduction speed in the pressurizing process so as to solve the stress balance problem of the die-molded composite door panel on different aspects. According to the invention, a set of feasible method is provided to guarantee the flatness of the die-molded composite door panel, reduce the fracture damage and guarantee the product quality.

Owner:ZHEJIANG FORESTRY UNIVERSITY

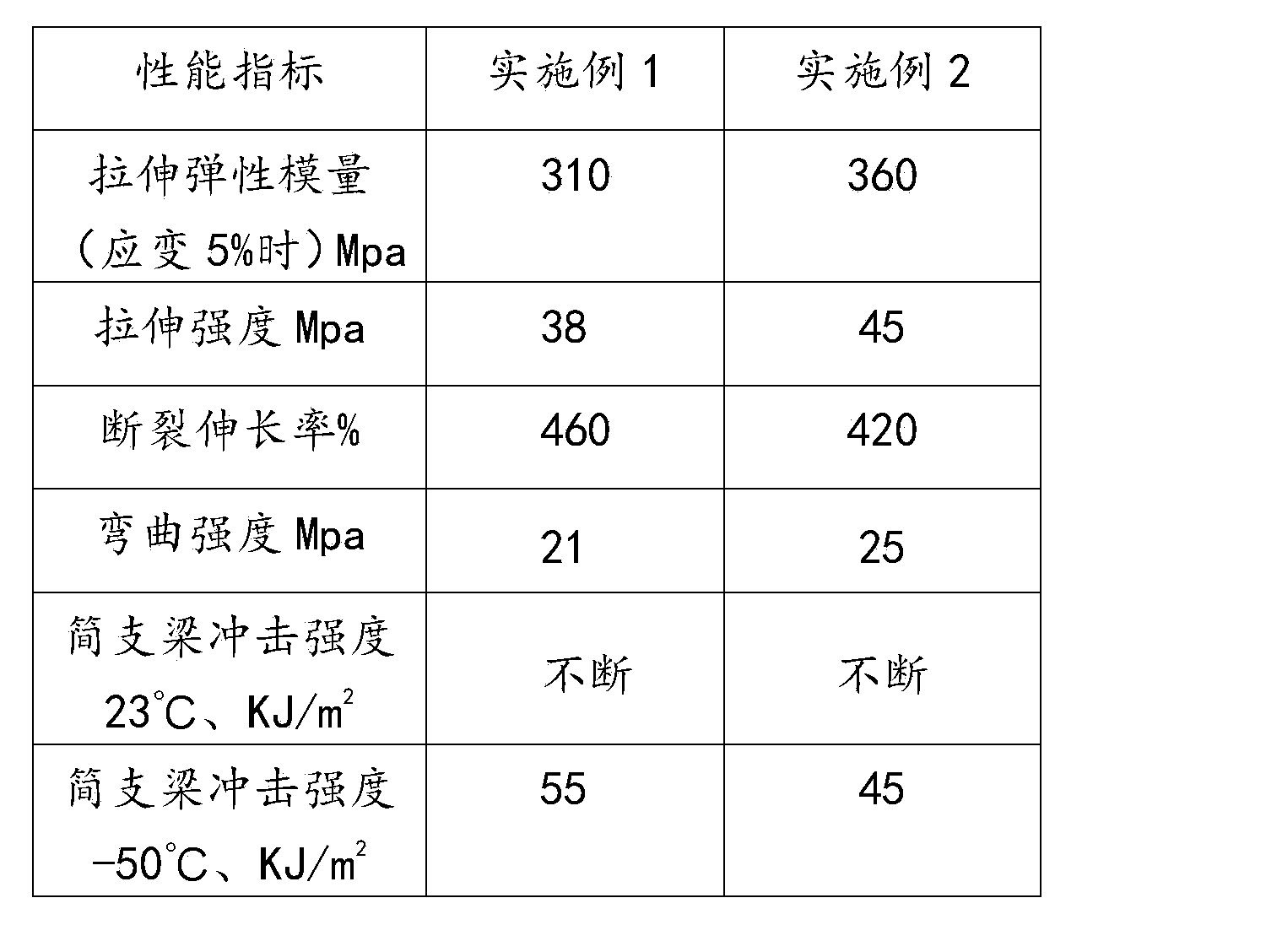

Material for nylon elastomer coupler knuckle pin of rail wagon and preparation method of material

The invention relates to a material for a nylon elastic coupler knuckle pin of a rail wagon, which comprises the following components by weight percentage: 65-80% of nylon 1212, 5-20% of maleic anhydride grafted ethylene-propylene-diene terpolymer, 5-20% of maleic anhydride grafted polyethylene, 0.5-5% of nucleating agent P22, 0.5-5% of silicone, 0.1-1.5% of antioxygen H10, 0.1-2% of paraffin and 0.1-1% of special white oil. The material for the nylon elastic coupler knuckle pin of the rail wagon is a high-polymer elastic material with better elasticity and toughness; for the coupler knuckle pin of the rail wagon, which is made of the material, the contact among a coupler knuckle, the coupler knuckle pin and a coupler lug hole is changed to flexible collision from the original rigid collision, the coupler knuckle pin is further higher in tensile modulus, impact strength and abrasion resistance, and the abrasion and cracking of the coupler knuckle, coupler lug hole bushing and other components are reduced.

Owner:JIANGSU TIEKE NEW MATERIAL CO LTD

Earthquake damage control system for thin-walled hollow bridge piers

InactiveCN104674649BNo harmIncreased durabilityBridge structural detailsBridge erection/assemblyControl systemPre stress

The invention discloses a novel earthquake damage control system for a thin-wall hollow pier. The novel earthquake damage control system comprises a pier base, a thin-wall hollow pier, high-tenacity fiber-enhanced cement-based composite material expanded sections, an unbonded prestressed tendon and steel energy consumption elements, wherein the thin-wall hollow pier is arranged on the upper end surface of the pier base, so that the torsional strength and the energy-dissipating capacity of the thin-wall pier are improved. The high-tenacity fiber-enhanced cement-based composite material expanded sections are arranged on the inner side and the outer side of the lower part of thin-wall hollow pier; a series of steel energy consumption elements are arranged in the thin-wall hollow pier along the pier height; the lower part of the unbonded prestressed tendon is anchored on the pier base; and the upper part of the unbonded prestressed tendon is anchored at the center of the first steel energy consumption element from bottom to top. By virtue of the unbonded prestressed tendon, the self-resetting capacity of the pier after the earthquake is provided; and the crack width of the pier after the earthquake is reduced. By virtue of the high-tenacity fiber-enhanced cement-based composite material expanded sections, the axis-compression ratio of the bottom section of the thin-wall hollow pier is reduced; the shear-bearing capacity and the anti-bending capacity of the thin-wall hollow pier are increased; and the steel energy consumption elements can be arranged as rapid exchange components, so that the repairability after the earthquake is increased.

Owner:DALIAN MARITIME UNIVERSITY

Steel bar surface type connecting joint adopting nodular cast iron member

ActiveCN112814286AImprove connection strengthImprove energy consumptionBuilding reinforcementsRebarEarthquake resistant

The invention discloses a steel bar surface type connecting joint adopting a nodular cast iron member. The steel bar surface type connecting joint comprises a shield segment and a subway station wall column, the shield segment and the subway station wall column are connected through the nodular cast iron member, a tooth groove shear-resistant member and a non-bonding section prestressed steel bar, and the nodular cast iron member comprises a belly part, an upper wing and a lower wing. The belly part is connected with the tooth groove shear-resistant member, a longitudinal tensile steel bar is arranged in the shield segment, the non-bonding section prestressed steel bar is arranged in the subway station wall column, and the longitudinal tensile steel bar and the non-bonding section prestressed steel bar are connected through a longitudinal steel bar connecting sleeve. The steel bar surface type connecting joint has high connection strength and energy dissipation performance, is suitable for complex underground engineering construction, can bear large bending moment and shearing force at the same time, and is good in anti-seismic performance; and the duct piece section embedded nodular cast iron member is adopted, so that an embedded member is coordinated with concrete deformation, concentrated stress of longitudinal connecting steel bars is avoided, the integrity of the longitudinal connecting steel bars is enhanced, and a surface type connecting mode of the steel bars is formed.

Owner:JIANGSU UNIV OF SCI & TECH

Gravity Damping Fill Wall

The invention relates to the technical field of fixed buildings, in particular to a gravity type damping filling wall which comprises a frame structure, two brickworks arranged in the frame structure side by side, and prestress ribs located on the two sides of the two brickworks and crossed at the diagonal position of the frame structure. A steel groove support is arranged below each brickwork. The two ends of each steel groove support are connected with the ground through opposite supporting legs respectively. Slide grooves are formed in the supporting legs. V-shaped supports are arranged between every two opposite supporting legs. The two ends of each V-shaped support are arranged in the slide grooves of the corresponding supporting legs on the two sides. Slide wheels are arranged at the bottom ends of frame columns of the frame structure. The top ends of the prestress ribs are fixed to the upper portion of the frame structure. The bottom ends of the prestress ribs are wound around the slide wheels and fixed to the middles of the V-shaped supports on the corresponding sides. By stretching or releasing the prestress ribs, the field angles of the V-shaped supports are changed. The two brickworks in the frame structure deform in the lateral direction of the frame structure so as to vertically and oppositely move, and therefore energy consumption happens to a damping medium in the filling wall, and the risks of cracking breakage and plane outward collapse of the filling wall are reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Semiconductor package and manufacturing method thereof

InactiveCN101335217BReduce cracking damageSolve instabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor chip

The invention discloses a semi-conductor packaging unit and a manufacturing method hereof, which provides a carrier plate, wherein, a plurality of metal blocks and a metallic layer for coating the metal blocks are formed on the carrier plate so as to electrically connect at least one semi-conductor to the metallic layer, and then a packaging colloid coating the semi-conductor chip is also formed on the metallic carrier plate, then, the carrier plate and the metal blocks are removed to form a plurality of grooves on the surface of the packaging colloid correspondingly. At the bottom surface and the side of the grooves are covered with a metallic layer so as to lead the conductive elements to be effectively positioned in the grooves and fully conjugated with the metallic layer.

Owner:SILICONWARE PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com