Negative-pressure casting sealed tank for aluminum impeller

A technology of negative pressure casting and sealing tank, which is applied in the field of gypsum-type sealing protection tanks for negative pressure casting of supercharger impellers, which can solve the problems of reducing the yield of castings, not being able to ensure that the blades are well formed, and not easy to form, so as to reduce cracks Destruction, simple structure, and the effect of reducing the proportion of cracked shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

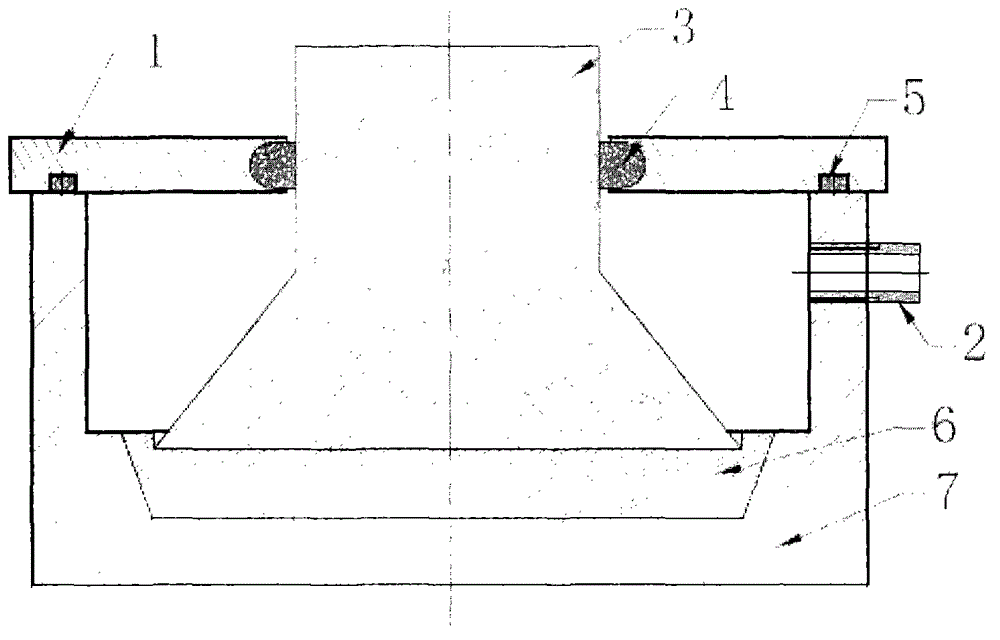

[0010] See figure 1 , an aluminum impeller negative pressure casting sealed tank body of the present invention, comprising a housing 7, the upper end of the housing 7 is provided with an upper cover 1, the center of the upper cover 1 is provided with a round hole 8, and the bottom surface of the upper cover 1 is connected with the A sealing groove 9 is arranged on the ring corresponding to the upper end surface of the casing, and a sealing ring 5 is arranged in the sealing groove 9, and a groove 10 is arranged at the bottom of the casing 7, and a live cold iron 6 is arranged in the groove 10, and the casing The live cold iron 6 in 1 is provided with a gypsum shell 3, the upper part of the gypsum shell 3 passes through the round hole 8 at the center of the upper cover 1, and the edge of the round hole 8 at the center of the upper cover and the gypsum shell 3 A sealing ring 4 is installed, and an air exhaust port 11 is provided on the side wall of the housing 7, and a pipe joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com