Battery pack box body and battery pack

A technology for battery packs and cabinets, which is applied to battery pack parts, circuits, electrical components, etc., which can solve problems such as heavy cabinet weight, heavy cabinet weight, and conflicting design requirements, and achieve simple installation process and good flatness , the effect of good box consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

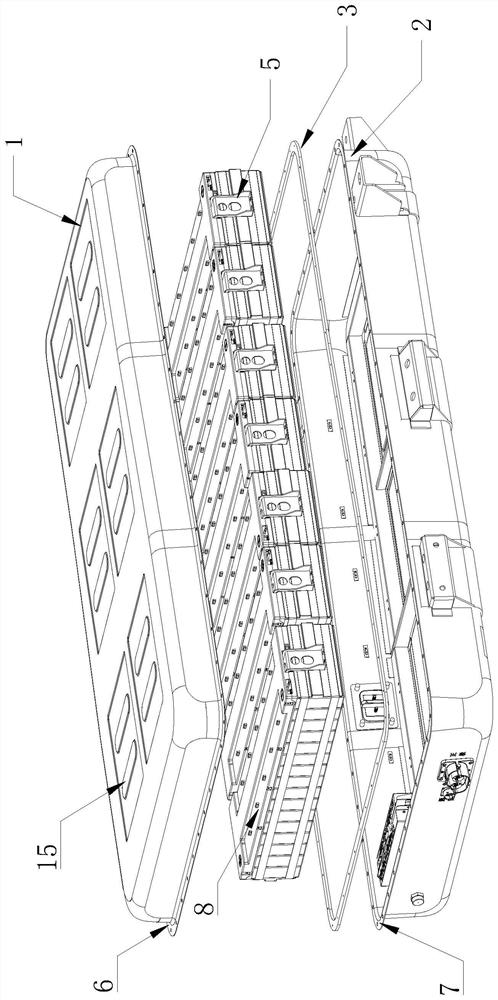

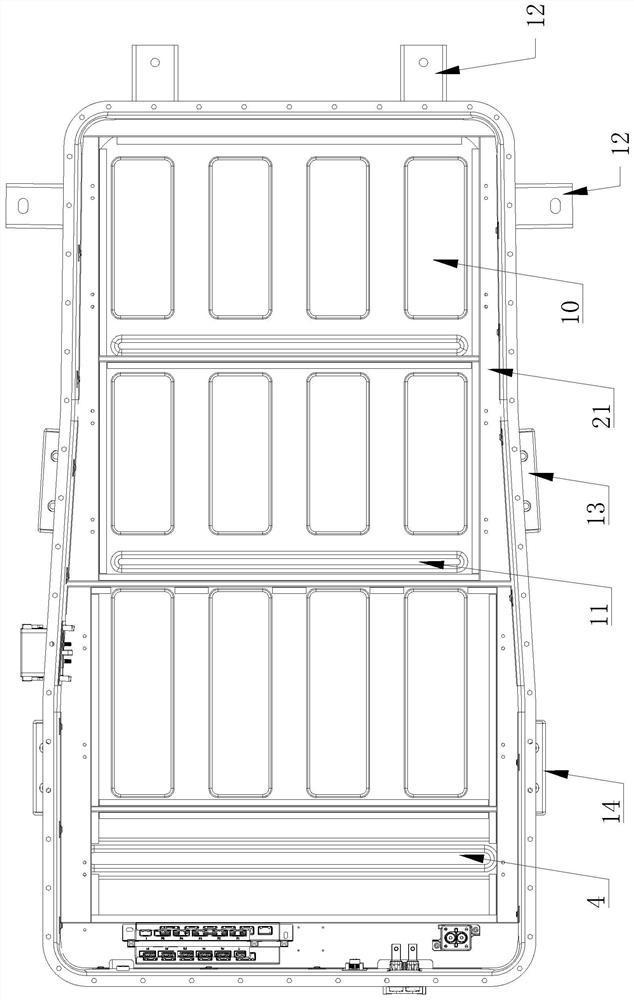

[0029] A battery pack case, such as Figure 1-3 As shown, it includes an upper box cover 1, a lower box body 2, a sealing strip 3, a module installation beam 4, and a module bead 5. The periphery of the upper box cover 1 is provided with a first skirt 6 protruding outward, The periphery of the top of the lower box 2 is provided with a second skirt 7 protruding outwards, and the first skirt 6 and the second skirt 7 are stacked and fixed between the upper box cover 1 and the lower box 2 . Matched and merged together, the sealing strip 3 is tightly arranged between the first skirt 6 and the second skirt 7;

[0030] The first skirt 6 of the upper box cover 1 has a first through hole, the second skirt 7 of the lower box 2 has a second through hole, and the matched first through hole and the second through hole Corresponding to the position, the bolt can pass through the first through hole and the second through hole to install the battery pack box on the vehicle body; wherein, the...

Embodiment 2

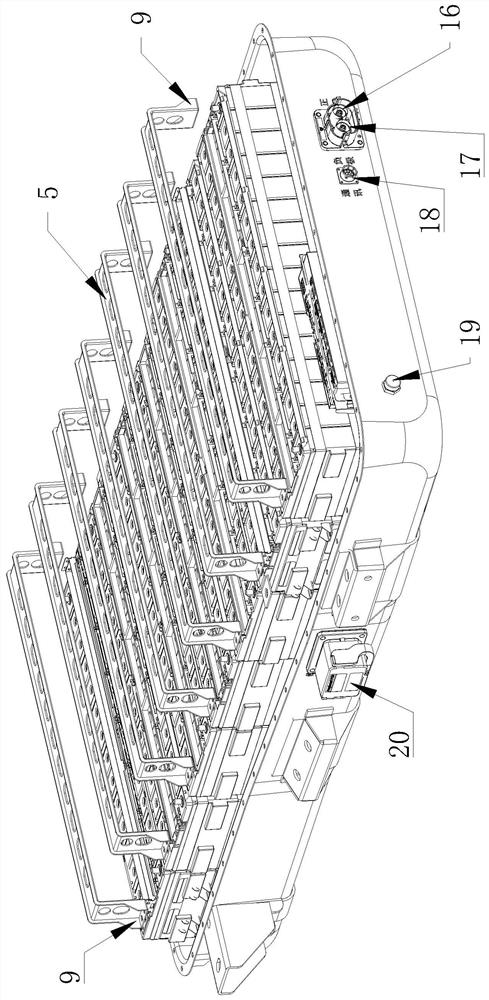

[0043] A battery pack such as figure 1 As shown, it includes a battery module 8 and the battery pack case of Example 1, the battery pack case is placed in the lower case 2, and several of the module press strips 5 are evenly distributed and pressed on the battery pack. On the module 8, the module layer 5 is fixed to the lower box body 2, the high-voltage maintenance switch 20 of the lower box body 2 is connected in series with the modules of the battery module 8, and the main positive wiring harness of the modules of the battery module 8 , the total negative wire harness, and the collection wire harness are connected to the total positive output port 16, the total negative output port 17, and the communication collection port 18 of the lower box 2 in one-to-one correspondence.

[0044] A component positioning and installation module can be arranged in the battery pack box, and a battery management system is installed on the component positioning and installation module.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com