Material for nylon elastomer coupler knuckle pin of rail wagon and preparation method of material

A railway freight car and nylon technology is applied to the material and preparation field of the nylon elastomer coupler yoke pin for railway freight cars, which can solve the problems of large amount of wear, bad working conditions, cracked hook ear hole bushing and the like, and achieves improved toughness. , high tensile modulus, reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

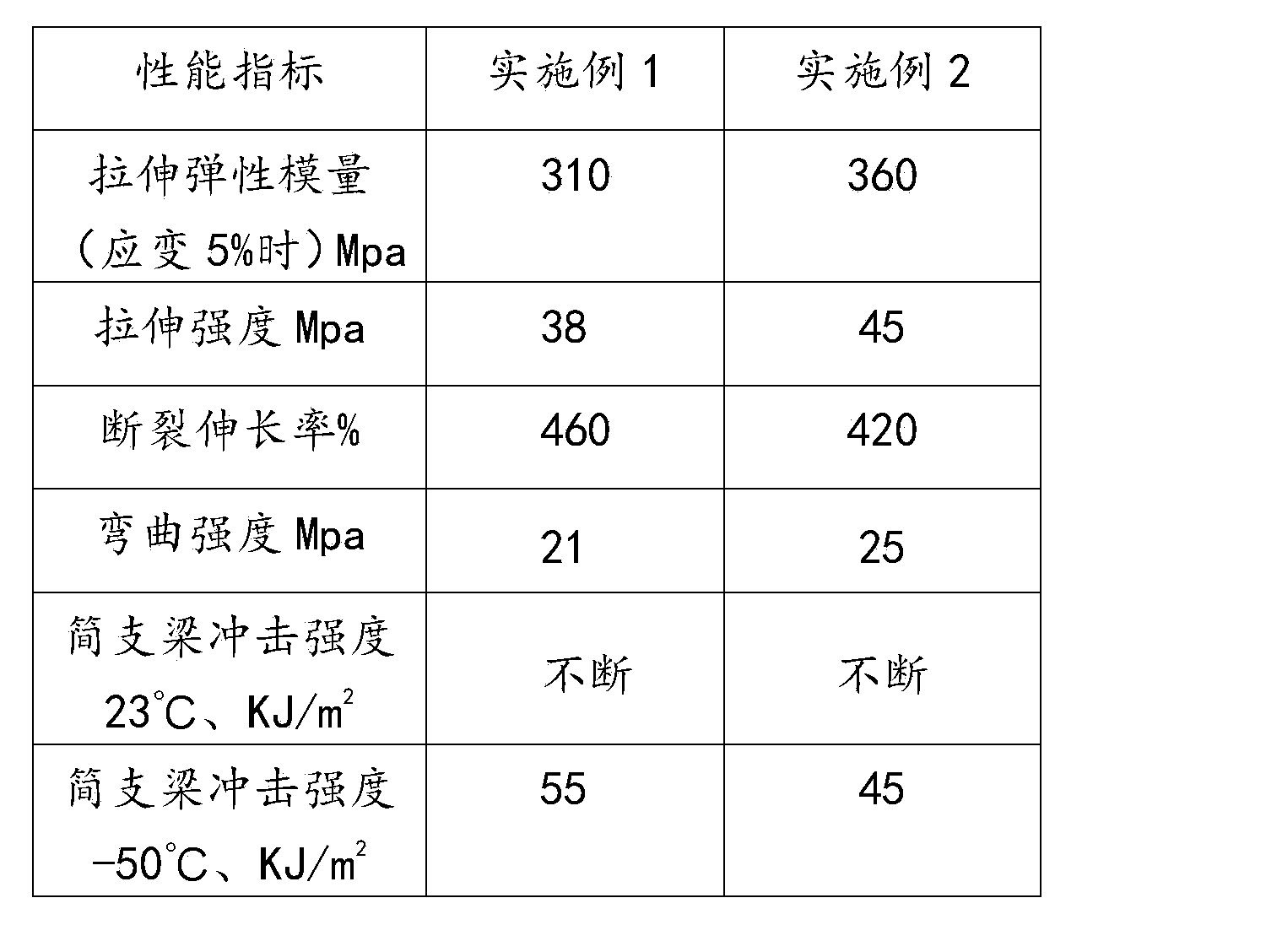

Embodiment 1

[0012] The material for the nylon elastomer coupler knuckle pin of the railway freight car of this embodiment has the following components and weight percentages: nylon 1212, 70%; maleic anhydride grafted ethylene-propylene-diene copolymer (MAH-g-EPDM), 12 %; maleic anhydride grafted polyethylene (MAH-g-HDPE), 10%; nucleating agent P22, 3%; silicone, 3%; antioxidant H10, 1%; paraffin, 0.5%; white oil ( C16~C31 mixture of normal isoparaffins, type P60), 0.5%.

[0013] The preparation method of the nylon elastomer coupler knuckle pin of railway freight cars using the above materials comprises the following steps: (1) weighing nylon 1212, maleic anhydride grafted EPDM copolymer, maleic anhydride grafted poly Ethylene, silicone, paraffin, nucleating agent P22, antioxidant H10, and special white oil are put into a high-speed mixer and stirred for 5-10 minutes;

[0014] (2) Discharge after stirring, and then extrude and granulate through a twin-screw extruder at a processing temper...

Embodiment 2

[0017] The material for the nylon elastomer coupler knuckle pin of railway freight cars in this embodiment has the following components and weight percentages: nylon 1212, 75%; maleic anhydride grafted ethylene-propylene-diene copolymer (MAH-g-EPDM), 10 %; maleic anhydride grafted polyethylene (MAH-g-HDPE), 8%; nucleating agent P22, 2.5%; silicone, 2.5%; antioxidant H10, 1%; paraffin, 0.5%; white oil ( C16~C31 mixture of normal isoparaffins, type P60), 0.5%.

[0018] The preparation method of the nylon elastomer coupler knuckle pin of railway freight cars using the above materials comprises the following steps: (1) weighing nylon 1212, maleic anhydride grafted EPDM copolymer, maleic anhydride grafted poly Ethylene, silicone, paraffin, nucleating agent P22, antioxidant H10, and special white oil are put into a high-speed mixer and stirred for 5-10 minutes;

[0019] (2) Discharge after stirring, and then extrude and granulate through a twin-screw extruder at a processing temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com