Swing self-reset bridge bent frame with ductility replaceable collar beam and installation method thereof

An installation method and self-reset technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of unresolved seismic strength and stability of bent frame systems, heavy impact on urban traffic and environment, and speeding up construction progress. Achieve the effect of reducing adverse effects, reducing concrete cracking damage, and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

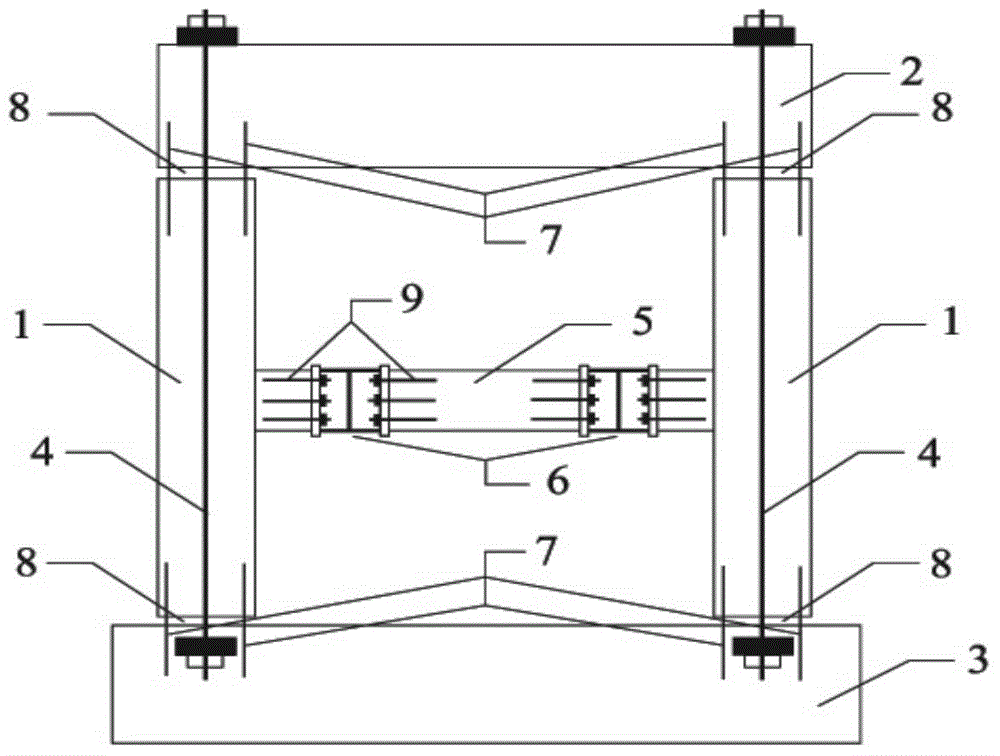

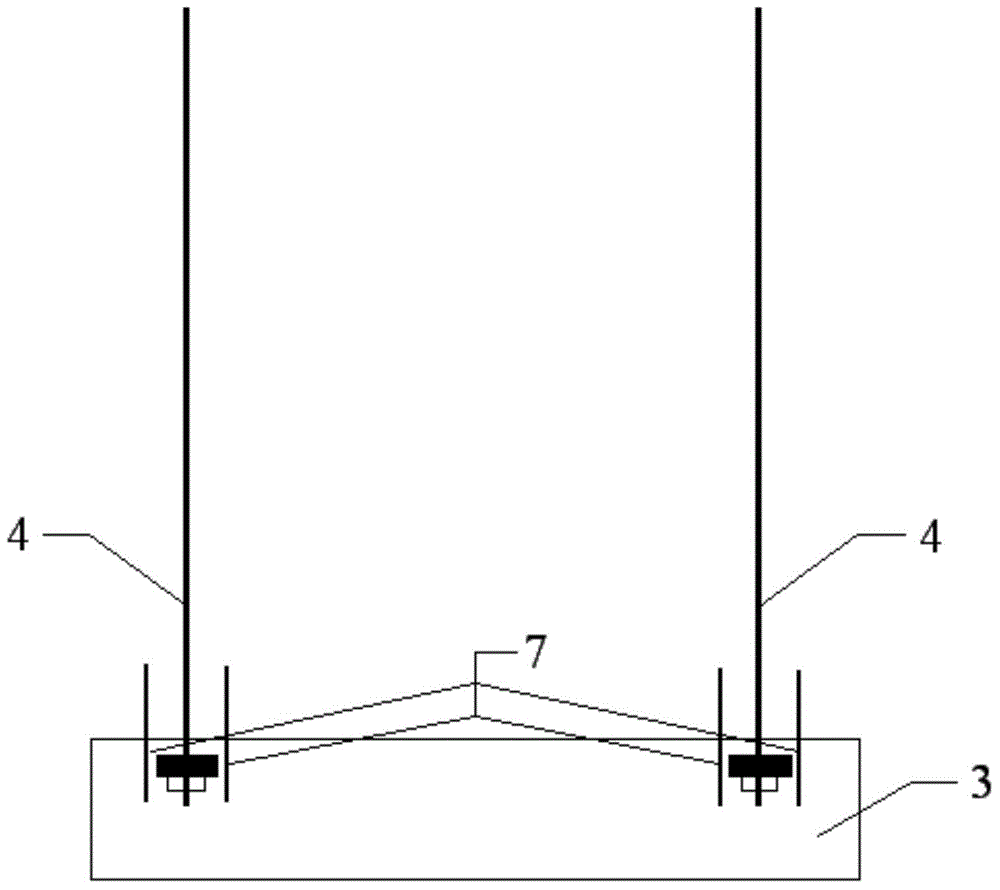

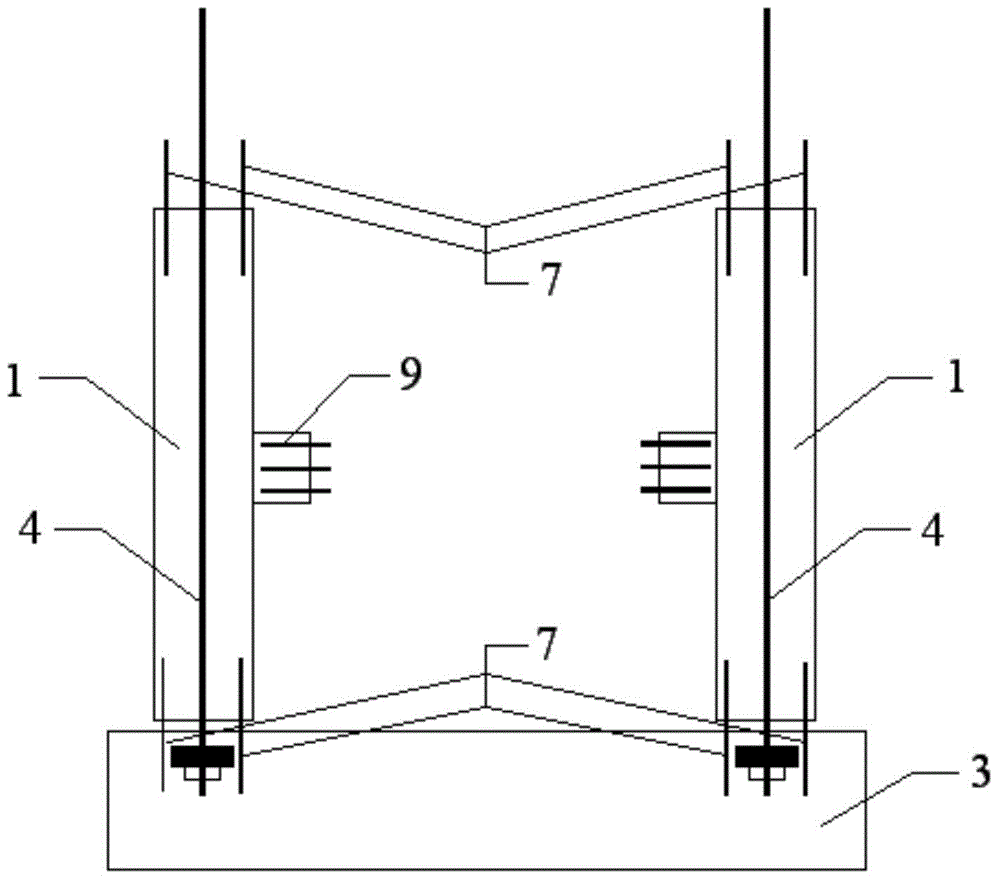

[0033] Such as figure 1 The swinging self-resetting bridge bent with ductile replaceable tie girders shown includes: bridge foundation 3, prefabricated cover girder 2 and two prefabricated piers 1 set on the bridge foundation 3 for supporting the left and right sides of prefabricated cover girder 2 ; Also includes, a replaceable tie beam 5 arranged laterally between two prefabricated bridge piers 1;

[0034] The prefabricated pier 1 is longitudinally provided with unbonded prestressed tendons 4, and the two ends of the unbonded prestressed tendons 4 protrude from the upper and lower ends of the prefabricated pier 1, and are respectively fixed to the prefabricated cap beam 2 and the bridge foundation 3;

[0035] The joint position of prefabricated bridge pier 1 and prefabricated cover beam 2 is connected by shear key 8; the joint position of prefabricated bridge pier 1 and prefabricated cover beam 2 is also provided with energy-dissipating longitudinal reinforcements fixed to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com