High-toughness functionally graded material slide-resistant pile and construction method

A functionally graded material and anti-sliding pile technology, applied in excavation, sheet pile wall, foundation structure engineering, etc., can solve problems such as unsatisfactory effect and inability to give full play to steel strands, so as to reduce local cracking damage and isolate mutual penetration. , The effect of preventing brittle failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

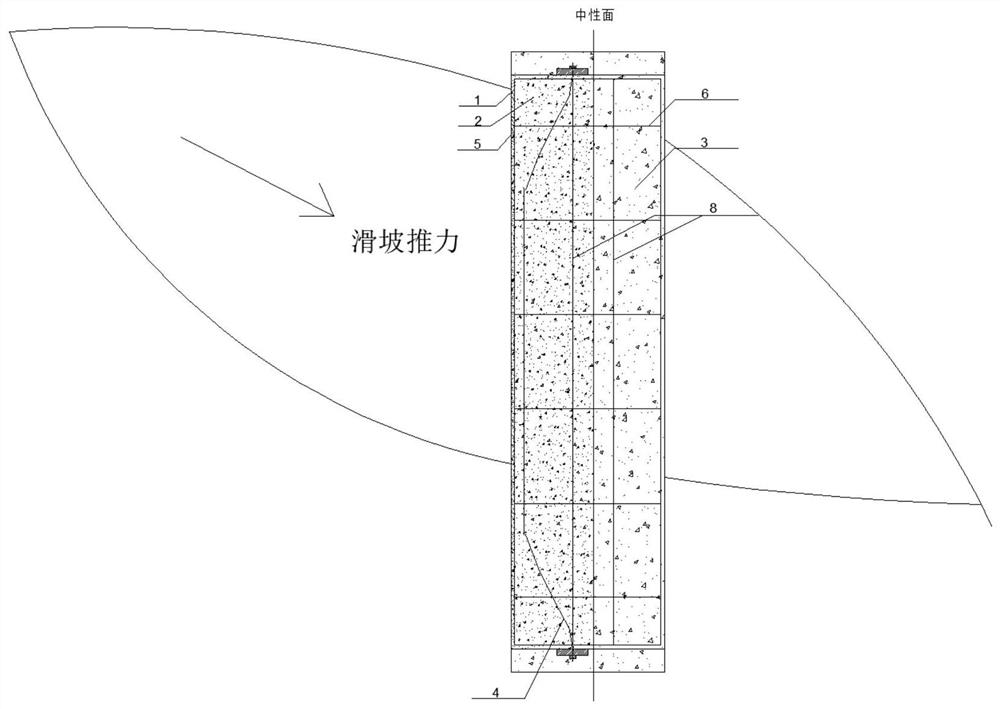

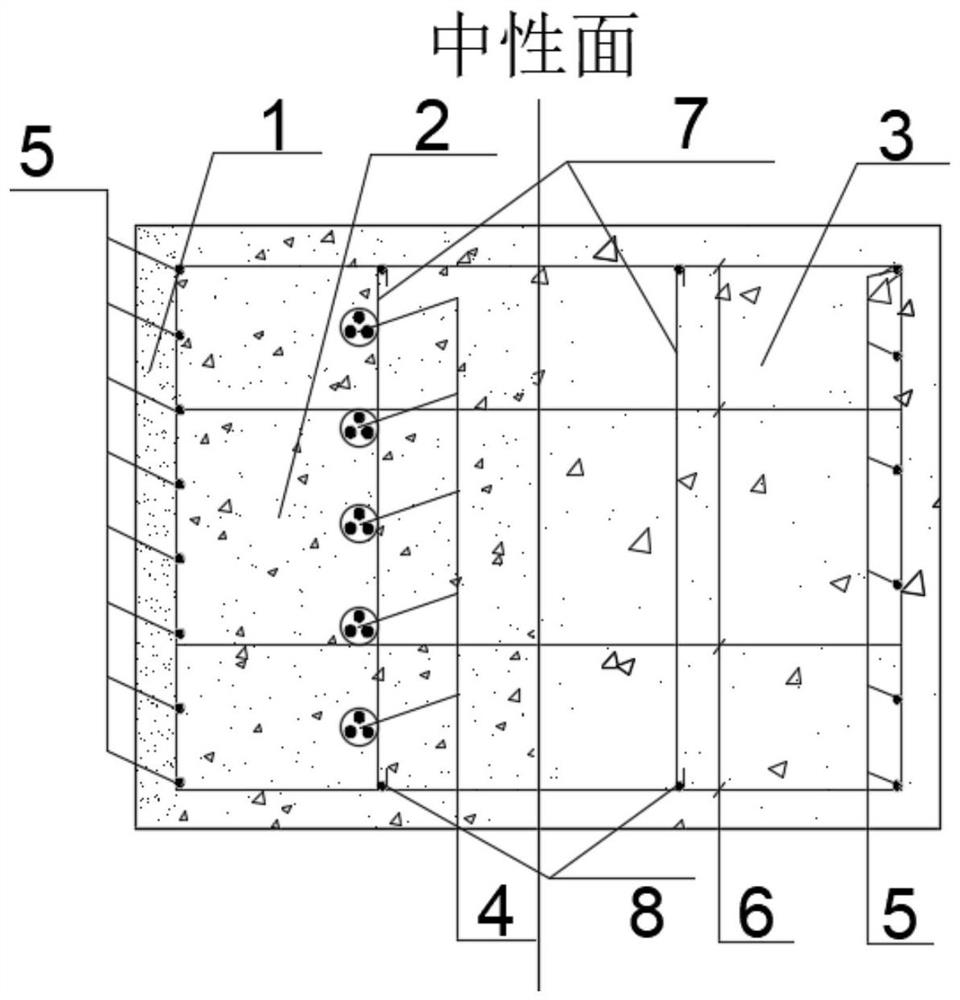

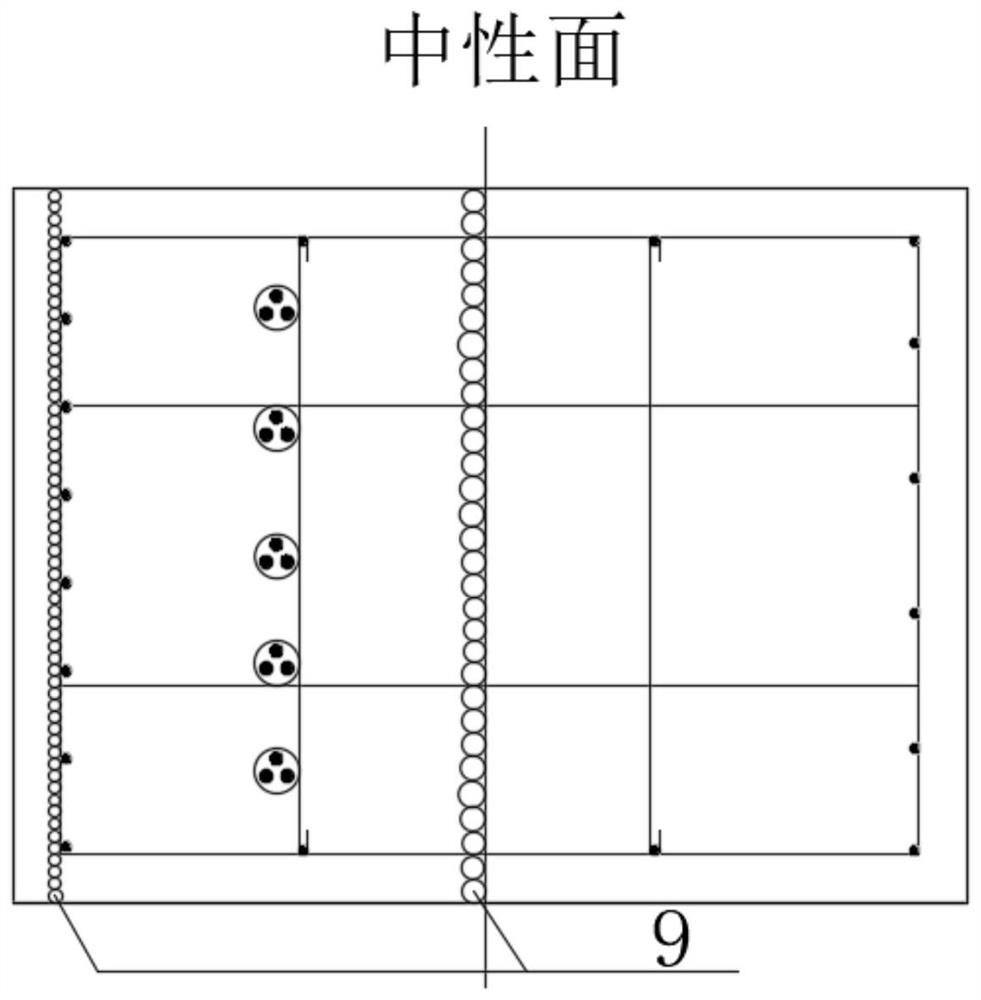

[0027] The following will clearly and completely describe the technical solutions and specific implementation methods of the present invention with reference to the accompanying drawings in the present invention.

[0028] please see Figure 1 ~ Figure 4 , a high-toughness functionally graded material anti-slide pile and construction technology provided by the present invention, comprising a PVA-ECC material protective layer 1, a small particle size coarse aggregate concrete layer 2 in the tension area, and a large particle size coarse aggregate in the compression area Concrete layer 3, steel strand longitudinal reinforcement in tension area 4, steel longitudinal reinforcement 5, stirrup reinforcement 6, tension reinforcement 7, vertical reinforcement reinforcement 8, partition airbag 9.

[0029] The anti-slide pile in this embodiment is considered as a flexural member, and the reinforcement calculation is carried out according to the "Code for Design of Concrete Structures" (G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com