Purline-free rapid assembly type high-sound-reduction-index composite sound absorption and insulation modular structure

A modular and assembled technology, applied in the direction of sound insulation, insulation layer, building components, etc., to prevent the penetration of water, improve stability, and improve the effect of sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

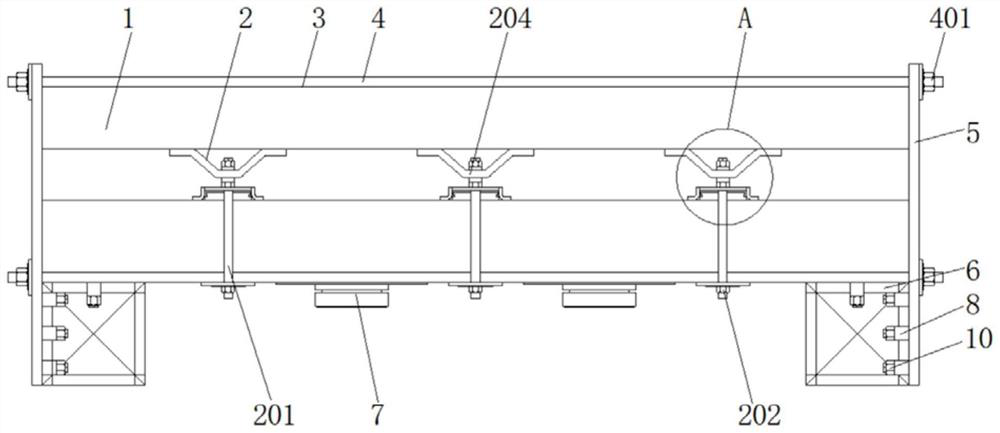

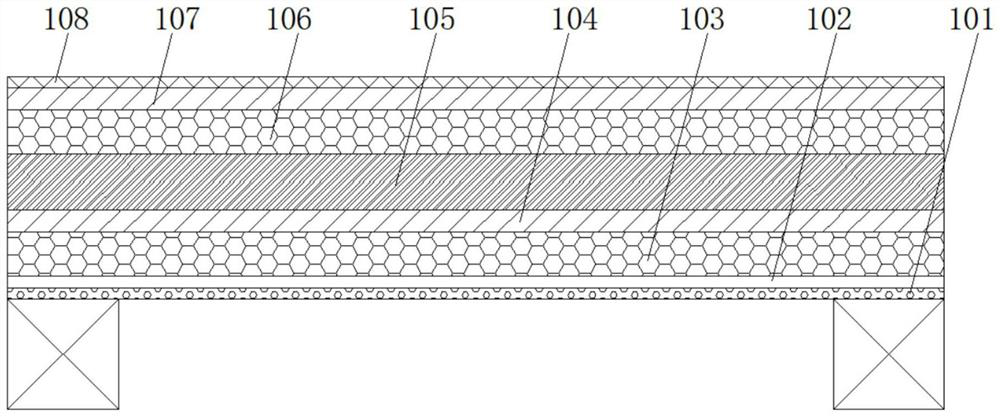

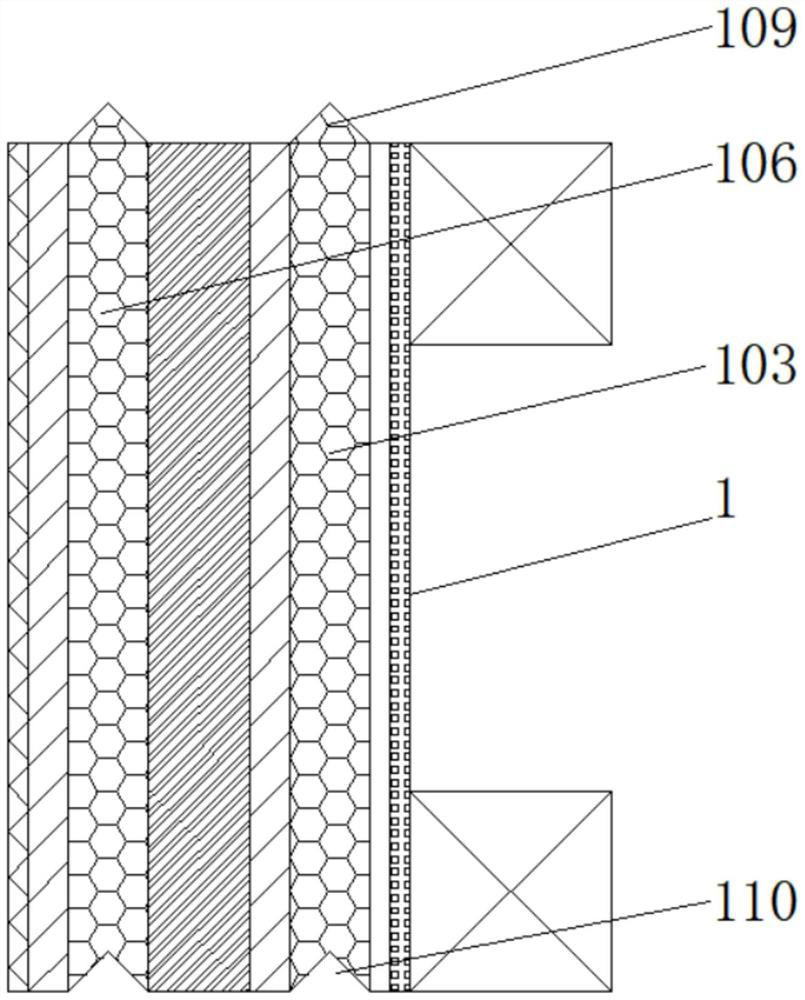

[0030] as attached figure 2 and image 3 As shown, the present invention provides a technical solution: a purlin-free quick-assembled high sound insulation composite sound absorption and sound insulation modular structure, comprising a modular structure body 1 and a limit support mechanism arranged on the modular structure body 1 2. Two special connectors 6 for steel structure frames, and several damping sound-absorbing shock absorbers 7, which are fixed on the modular structure 1 by bolts, and can be used In order to absorb part of the sound energy and vibration energy received by the modular structure 1, the special connector 6 for the steel structure frame is made of one or several metal materials among aluminum profiles, carbon steel, hot-dip galvanized steel and stainless steel, which can The special connector 6 for the steel structure frame is fixed on the modular structure body 1, and can assist the splicing of two modular structure bodies 1. The modular structure bod...

Embodiment 2

[0032] The scheme in the first embodiment will be further introduced below in conjunction with the specific working mode, see the following description for details:

[0033] like figure 1 As shown, as a preferred embodiment, on the basis of the above-mentioned method, the modular structure 1 is further provided with a number of fixed pressure rods 4, and side strips 5 located at both ends of the fixed pressure rods 4, modularized The structural body 1 is also provided with a slot 3 that is adapted to the fixed pressure rod 4. The fixed pressure rod 4 penetrates through the interior of the slot 3, and the two ends respectively pass through the side strip 5 to threadedly engage the locking nut. 401, the fixed pressure rod 4 can be pressed into the interior of the slot 3, the two ends of the fixed pressure rod 4 can be respectively passed through the two side strips 5, and the locking nut 401 can be threadedly sleeved on the fixed pressure rod 4 The two side strips 5 can be connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com