High-reliability thermoelectric device and preparation method

A thermoelectric device and reliability technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device components, etc., can solve problems such as cracks and affect the performance of thermoelectric materials, and achieve the effect of reducing crack damage and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

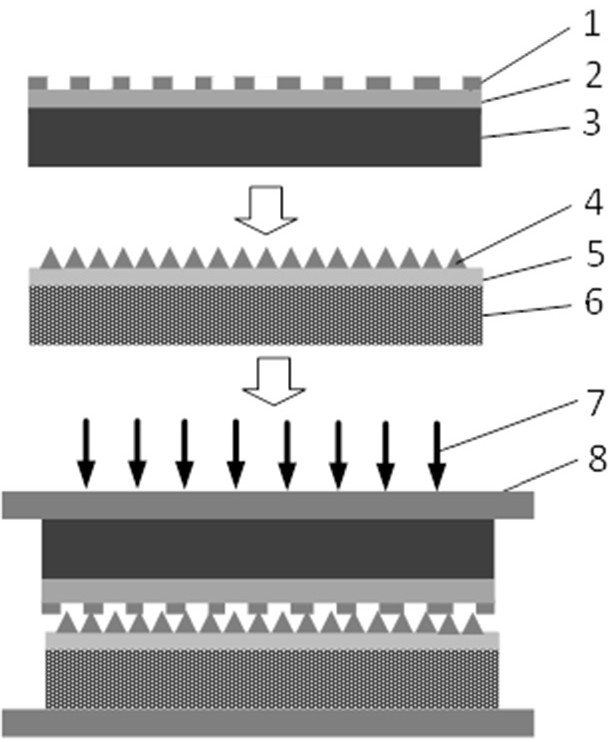

[0026] A method for preparing a high-reliability thermoelectric device comprises the following steps:

[0027] (1) First, slice the thermoelectric material device into a thermoelectric chip 3, clean the bonding surface of the thermoelectric chip 3 by using a standard RCA process, and sputter a nickel metal layer 2 on the package connection surface of the thermoelectric chip 3. The nickel The thickness of the metal layer 2 is 1-2 microns, so as to prevent the copper atoms in the copper metal layer 5 of the copper-clad ceramic substrate 6 from diffusing into the thermoelectric material device.

[0028] (2) Corroding the surface of the sputtered nickel metal layer 2 with a dealloying method to prepare a metal nickel layer 1 with a nanopore structure, the thickness of the metal nickel layer 1 with a nanopore structure is 200-500 nanometers, and its pore diameter is 50 -200 nanometers, with a porosity greater than 60%, use it as a bonding surface for packaging and interconnection, ...

Embodiment 1

[0035] Such as figure 1 As shown, the present invention is a low-temperature bonding method for integrated packaging, including:

[0036] (1) First, the electrothermal material device is cut into several thermoelectric chips 3, the bonding surface of the thermoelectric chips 3 is cleaned by a standard RCA process, and then a nickel metal layer 2 with a thickness of 1 micron is deposited on the substrate by a sputtering process, Finally, on the nickel metal layer 2, a metal nickel layer 1 with a nanopore structure is prepared by a dealloying method.

[0037]The preparation method of the metal nickel layer 1 with a nanopore structure is as follows: firstly, the thermoelectric chip 3 with the nickel metal layer 2 is placed in HCl solution for cleaning, the concentration of the HCl solution is 5%, and the cleaning time is 1 minute, which is used to remove the electric heat. The oxide on the surface of the nickel metal layer 2 of the wafer 3, after that, the thermoelectric chip 3 ...

Embodiment 2

[0043] Such as figure 1 As shown, the present invention is used for the low-temperature bonding method of integrated package, comprises the following steps:

[0044] (1) The electrothermal material device is cut into several thermoelectric chips 3, and the bonding surface of the thermoelectric chips 3 is cleaned by standard RCA process, and then a nickel metal layer 2 is deposited on the substrate by a sputtering process, and the thickness of the nickel metal layer 2 is Two microns, and finally the metal nickel layer 1 with a nanopore structure is prepared by corrosion on the surface of the metal nickel layer 2 by dealloying method.

[0045] The method for preparing the metal nickel layer 1 with a nanopore structure is as follows: the thermoelectric wafer 3 that has been sputtered with the nickel metal layer 2 is placed in a hydrochloric acid solution for cleaning, the concentration of the hydrochloric acid solution is 5%, and the cleaning time is 1 minute for removing The su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Cone base diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com