Material repair welding method of CB2 casting of ultra-supercritical turbine unit

A technology of ultra-supercritical and steam turbine units, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large differences in mechanical properties between the casting body and the repair welding area, and achieve basically the same performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

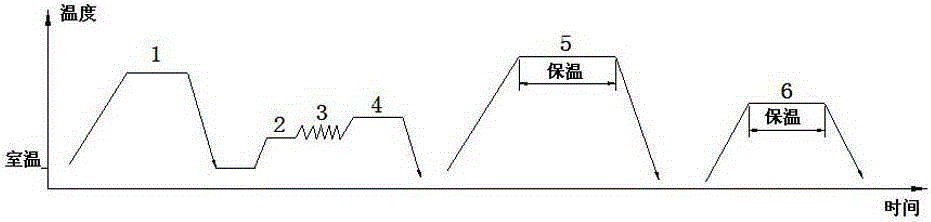

[0023] Such as figure 1 Shown, a kind of ultra-supercritical steam turbine unit CB2 casting material repair welding method comprises the steps:

[0024] 1) After desanding the CB2 casting, perform preheating treatment 1 of high temperature softening and tempering;

[0025] 2) Non-destructive testing for surface defect detection and internal defect detection of castings;

[0026] 3) Eliminate the defective parts according to the flaw detection results, and confirm that the defects are completely eliminated by non-destructive testing;

[0027] 4) Preheat 2 to eliminate the defective parts to meet the temperature requirements of preheat 2;

[0028] 5) Use welding consumables such as THERMANITMTS5Co1 or CHROMETWB2 that match the same material as the base metal for repair welding3;

[0029] 6) After-heating 4 on the repair welding area;

[0030] 7) Non-destructive testing for surface defect detection and internal defect detection for the repaired welding area;

[0031] 8) Heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com