Site moving type laser augmented material repair equipment based on vehicle transport

A laser additive and mobile technology, applied in the direction of freight vehicles, transport objects, article transport vehicles, etc., can solve the problems of difficult repair equipment, low efficiency, inconvenient on-site operation, etc., to improve operating efficiency and improve The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

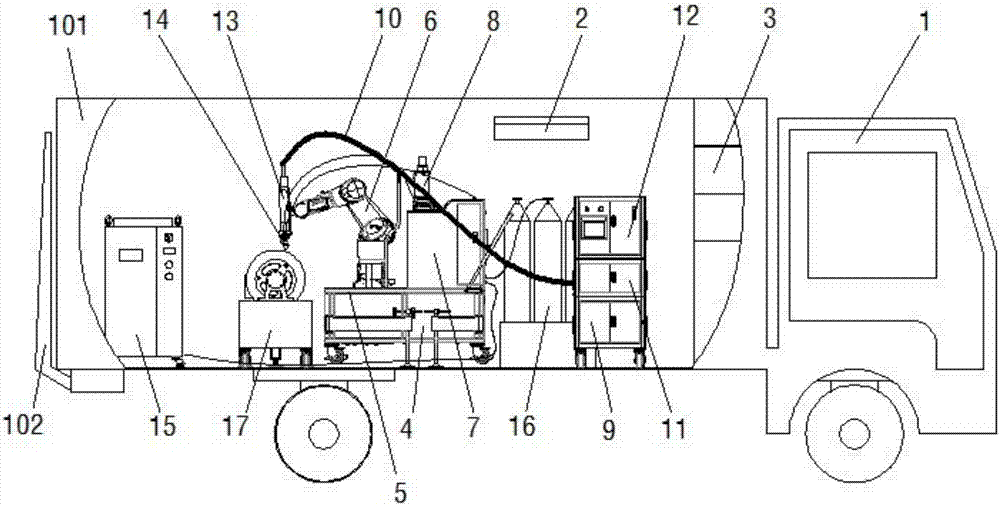

[0036] figure 1 It shows a preferred embodiment of the on-site mobile laser additive repair equipment based on vehicle transportation in this application, which is the same as the traditional laser additive repair equipment in that it also includes multiple equipment units.

[0037] The key improvement of this embodiment is that the equipment also includes a transport vehicle 1 with a compartment 101 , and each of the above-mentioned equipment units can be detachably installed in the aforementioned compartment 101 . specifically:

[0038] A detachable mobile trolley 4 is fixedly arranged in the compartment 101, and the mobile trolley 4 is configured with casters and support legs, which can be pushed to walk, and when in place, the support legs are lowered for positioning. The front side of mobile trolley 4 is equipped with three-stage hydraulic lifting platform 5, and the lifting of lifting platform is formed as 1 meter. An industrial robot 6 is installed on the lifting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com