Semidry method hot gunning repair device and method of rotary kiln lining refractory material

A repair method and rotary kiln technology, which is applied to lining repair, lighting and heating equipment, furnaces, etc., can solve the problems of production line shutdown, repair time-consuming, and affecting the production of the next process, so as to avoid production stoppage, repair time is short, increase The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the drawings.

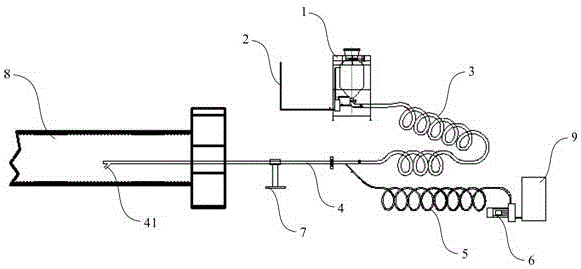

[0021] reference figure 1 As shown, one embodiment of the present invention is a semi-dry thermal gunning repair device for a rotary kiln lining refractory material. The repair device needs to include a gunning machine 1, and the aforementioned gunning machine 1 is connected with a compressed air pipe 2 The high-pressure air source (not shown in the figure) is connected. In addition, the spray gun 1 needs to be connected to the spray gun 4 through the first high-pressure pipe 3, and the spray gun 4 needs to be connected to the water tank 9 through the second high-pressure pipe 5 ; As shown in the figure, a self-priming pump 6 needs to be installed between the aforementioned water tank 9 and the second high-pressure pipe 5; in the aforementioned device structure, the gunning material can be transferred from the gunning machine 1 by high-pressure air from the first The high-pressure pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com