Pipe renovation method and its special renovation material system

A system and pipeline technology, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as undisclosed product design formulas, and achieve cathodic stripping avoidance, good anti-aging performance, and high practical value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] 1. Scheme design

[0103] 1. Relevant parameters of defective pipelines:

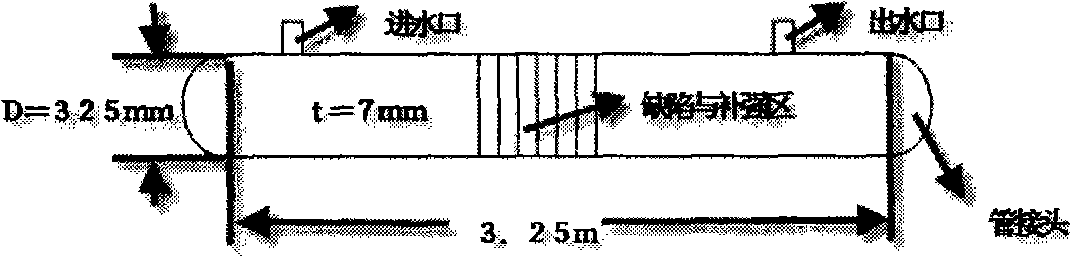

[0105] Pipe length: 3250mm

[0106] Pipe nominal wall thickness: 7.0mm

[0107] The actual wall thickness of the pipe: 6.7mm

[0108] Pipe material material: Q235B steel

[0109] Yield strength of pipe material: 235MPa

[0110] Tensile strength of pipe material: 435~489MPa

[0111] Theoretical burst pressure of flawless pipeline: 18.0~20.2MPa

[0112] Defect depth: 2.8mm, metal loss ratio: 42%

[0113] Defect axial length: 200mm

[0114] Defect circumferential length: 200mm

[0115] 2. Design indicators of carbon fiber composite materials for reinforcement (Table 1):

[0116] Single layer thickness of unidirectional carbon fiber cloth: 0.167mm

[0117] Measured strength of unidirectional carbon fiber cloth: >4000MPa

[0118] Elastic modulus: 235GPa

[0119] Elongation: >1.5%

[0120] Table 1 Performance table of carbon fiber cloth

[0121] pro...

Embodiment 2

[0162] 1. Scheme design

[0163] 1. Relevant parameters of defective pipelines:

[0164] Pipe diameter: 325mm

[0165] Pipe length: 3250mm

[0166] Pipe nominal wall thickness: 7.0mm

[0167] The actual wall thickness of the pipe: 6.7mm

[0168] Pipe material material: Q235B steel

[0169] Yield strength of pipe material: 235MPa

[0170] Tensile strength of pipe material: 435~489MPa

[0171] Theoretical burst pressure of flawless pipeline: 18.0~20.2MPa

[0172] Defect depth: 4.0mm, metal loss ratio: 59.7%

[0173] Defect axial length: 200mm

[0174] Defect circumferential length: 200mm

[0175] 2. Design indicators of carbon fiber composite materials for reinforcement (Table 2):

[0176] Single layer thickness of unidirectional carbon fiber cloth: 0.167mm

[0177] Measured strength of unidirectional carbon fiber cloth: >4000MPa

[0178] Elastic modulus: 235GPa

[0179] Elongation: >1.5%

[0180] Table 2 Performance table of carbon fiber cloth

[0181] p...

Embodiment 3

[0222] 1. Scheme design

[0223] 1. Relevant parameters of defective pipelines:

[0224] Pipe diameter: 325mm

[0225] Pipe length: 3250mm

[0226] Pipe nominal wall thickness: 7.0mm

[0227] The actual wall thickness of the pipe: 6.7mm

[0228] Pipe material material: Q235B steel

[0229] Yield strength of pipe material: 235MPa

[0230] Tensile strength of pipe material: 435~489MPa

[0231] Theoretical burst pressure of flawless pipeline: 18.0~20.2MPa

[0232] Defect depth: 4.7mm, metal loss ratio: 70.1%

[0233] Defect axial length: 200mm

[0234] Defect circumferential length: 200mm

[0235] 2. Design indicators of carbon fiber composite materials for reinforcement (Table 3):

[0236] Single layer thickness of unidirectional carbon fiber sheet: 0.167mm

[0237] Measured strength of unidirectional carbon fiber sheet: >4000MPa

[0238] Young's modulus: 235GPa

[0239] Elongation: >1.5%

[0240] Table 3 Carbon fiber cloth performance table

[0241] prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com