Preparation method of high temperature resistant pipeline anticorrosion epoxy powder coating

A technology of anti-corrosion epoxy and powder coatings, which is applied in the direction of powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., and can solve the problems of bending resistance and impact resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

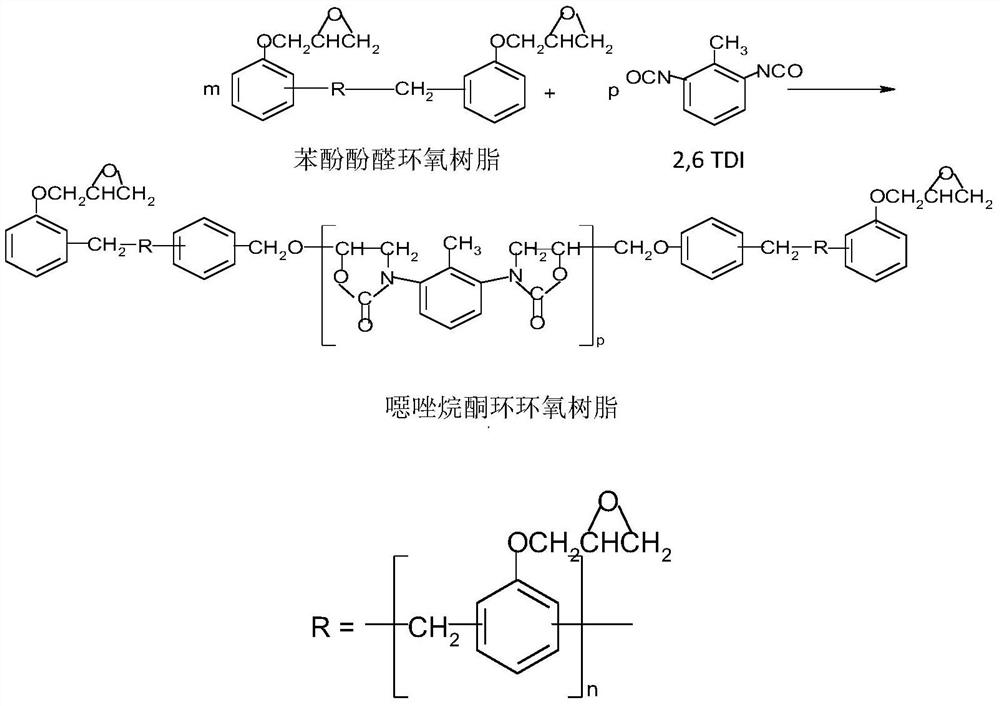

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of high temperature resistant anticorrosion epoxy powder coating of the present invention comprises the following steps:

[0061] First, accurately weigh the required raw materials according to the requirements of the formula, add them to a high-speed mixer with crushing and mix for 5-7 minutes;

[0062] Then, put the mixed raw materials into the twin-screw extrusion equipment, control the temperature at 110-130°C, and cool after extrusion for preliminary crushing;

[0063] Finally, put the extruded and crushed material into a pulverizer to pulverize, and then use a 100-mesh sieve to sieve to obtain the product (the mesh number of the sieve can be adjusted according to the different needs of users).

[0064] 3. The preparation of high temperature resistant and anti-corrosion epoxy powder coating can also be completed according to the usual method:

[0065] The first step is to treat the surface of the substrate so that the surface reaches the Sa2...

Embodiment example 1~3

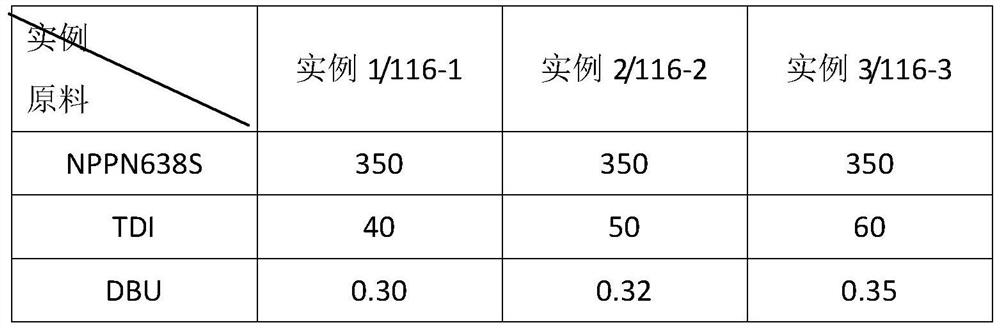

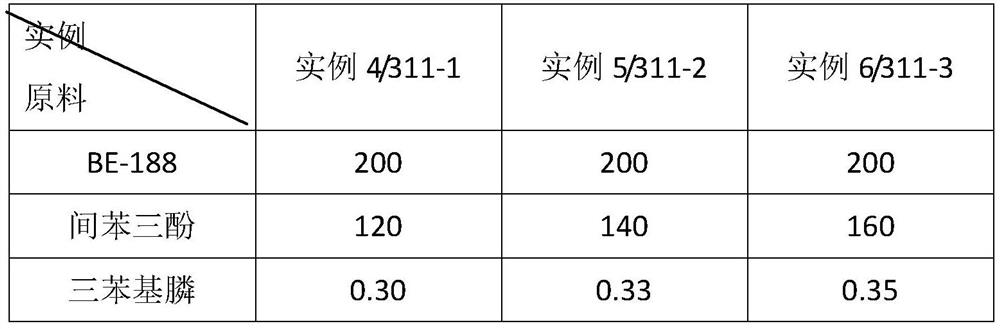

[0075] For preparing the formula and preparation method that contain oxazolidone ring epoxy resin, concrete formula is listed in table 1

Embodiment example 1

[0076] Implementation Case 1 (No. D116-1)

[0077] First, accurately weigh 350 parts of novolac epoxy resin (Nanya Electronic Materials Co., Ltd., NPPN638S), add it into a three-necked reaction bottle, and raise the temperature to 120°C; then add the catalyst 1,8-diazabicycloundedec-7- Add 0.30 parts of ethylene (DBU), and slowly add 40 parts of toluene diisocyanate (TDI) into the reaction kettle in three times while stirring. resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com