Nanometer material repairing agent capable of repairing engine cylinder block

A technology of nanomaterials and repairing agents, applied in the direction of additives, petroleum industry, lubricating compositions, etc., can solve the problems of nanomaterial production process or dispersion process, hinder the three-way catalytic converter exhaust gas purification, anti-wear and anti-friction effects Can not meet the use requirements and other problems, to achieve the effect of improving anti-oxidation stability, reducing friction coefficient, and improving heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

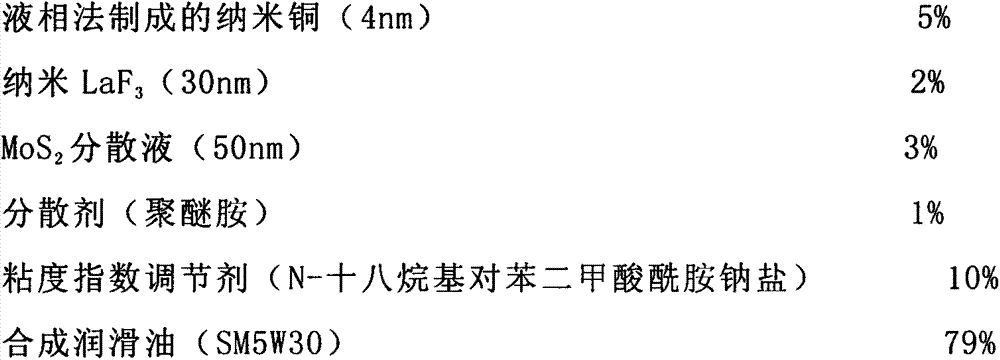

[0025] A nanomaterial repairing agent capable of repairing an engine block, the mass percentage of which is composed of:

[0026]

[0027] The above materials were dispersed with a high-speed disperser for 3 hours, and then oscillated with a 46KHz ultrasonic wave for 1 hour.

[0028] How to use: Just mix 400ml of repairing agent into 4L of new engine oil, no need to change the engine oil within 5000 kilometers.

Embodiment 2

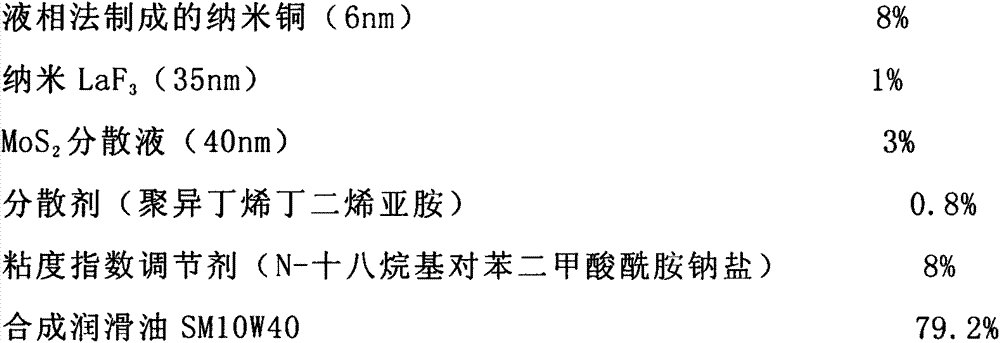

[0030] A nanomaterial repairing agent capable of repairing an engine block, the mass percentage of which is composed of:

[0031]

[0032] The above materials were dispersed with a high-speed disperser for 3 hours, and then oscillated with a 46KHz ultrasonic wave for 2 hours.

[0033] How to use: Just mix 400ml of repairing agent into 4L of new engine oil, no need to change the engine oil within 5000 kilometers.

Embodiment 3

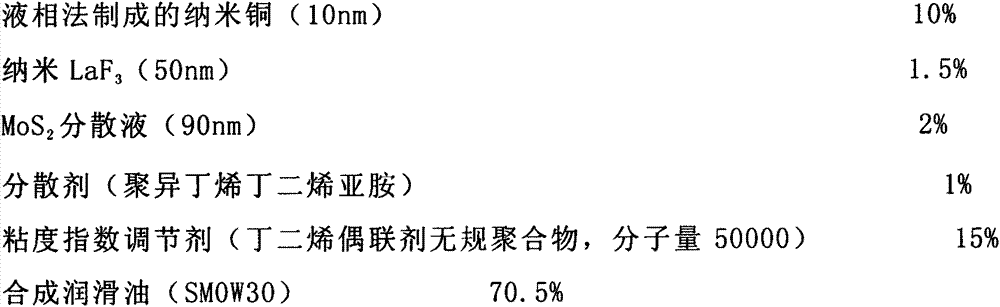

[0035] A nanomaterial repairing agent capable of repairing an engine block, the mass percentage of which is composed of:

[0036]

[0037] The above materials were dispersed with a high-speed disperser for 4 hours, and then oscillated with a 46KHz ultrasonic wave for 2 hours.

[0038] How to use: Just mix 400ml of repairing agent into 4L of new engine oil, no need to change the engine oil within 5000 kilometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com