Method for repairing ternary positive electrode material with deteriorated performance and acquired ternary positive electrode material

A technology of positive electrode material and repair method, applied in the direction of positive electrode, active material electrode, electrical components, etc., can solve problems such as electrochemical performance degradation, and achieve the effects of low price, simple process, great application value and social significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

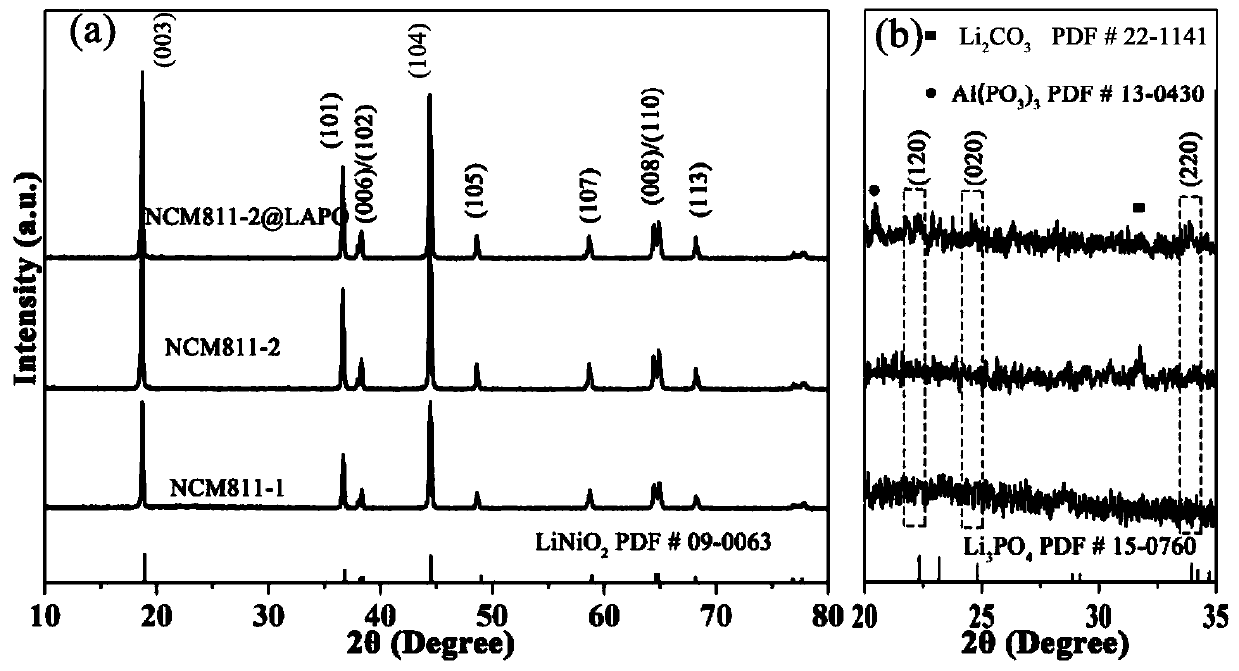

[0055] (1) Using petroleum ether as a solvent, the high-nickel cathode material precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Perform mechanical ball milling with LiOH at a molar ratio of 1:1.05 for 6 h, then evaporate petroleum ether to dryness, place the mixed material in a tube furnace, and sinter at 650 °C for 3 h in an oxygen atmosphere, and then sinter at 800 °C for 10 h. Cool to room temperature, grind and sieve for later use, number NCM811-1.

[0056] (2) Put the nickel-rich ternary material NCM811-1 in an environment with a temperature of about 30°C and an air humidity of about 80% and leave it open for 60 days to obtain NCM811-2, a ternary cathode material with degraded or deteriorated performance. The electrochemical performance before and after is shown in Table 1.

[0057] (3) Add 0.04g of restoration agent aluminum metaphosphate to a solvent containing 20g of absolute ethanol, stir at 400r / min for 10min, add 2g of NCM811-2 material and continue stirring at the same s...

Embodiment 2

[0064] (1) Add 0.04g of repairing agent yttrium metaphosphate to a solvent containing 20g of absolute ethanol, stir at 400r / min for 10min, add 2g of the NCM811-2 material obtained in Example 1 and continue stirring at the same speed for 30min, then, Heat the temperature to 95°C and continue stirring until the ethanol is completely evaporated to obtain product B.

[0065] (2) Place product B in a tube furnace at 2°C min -1 The heating rate was increased to 600 ° C, sintered in an oxygen atmosphere for 6 h, and cooled to room temperature to obtain the positive electrode material NCM811-2@LYPO repaired by yttrium metaphosphate.

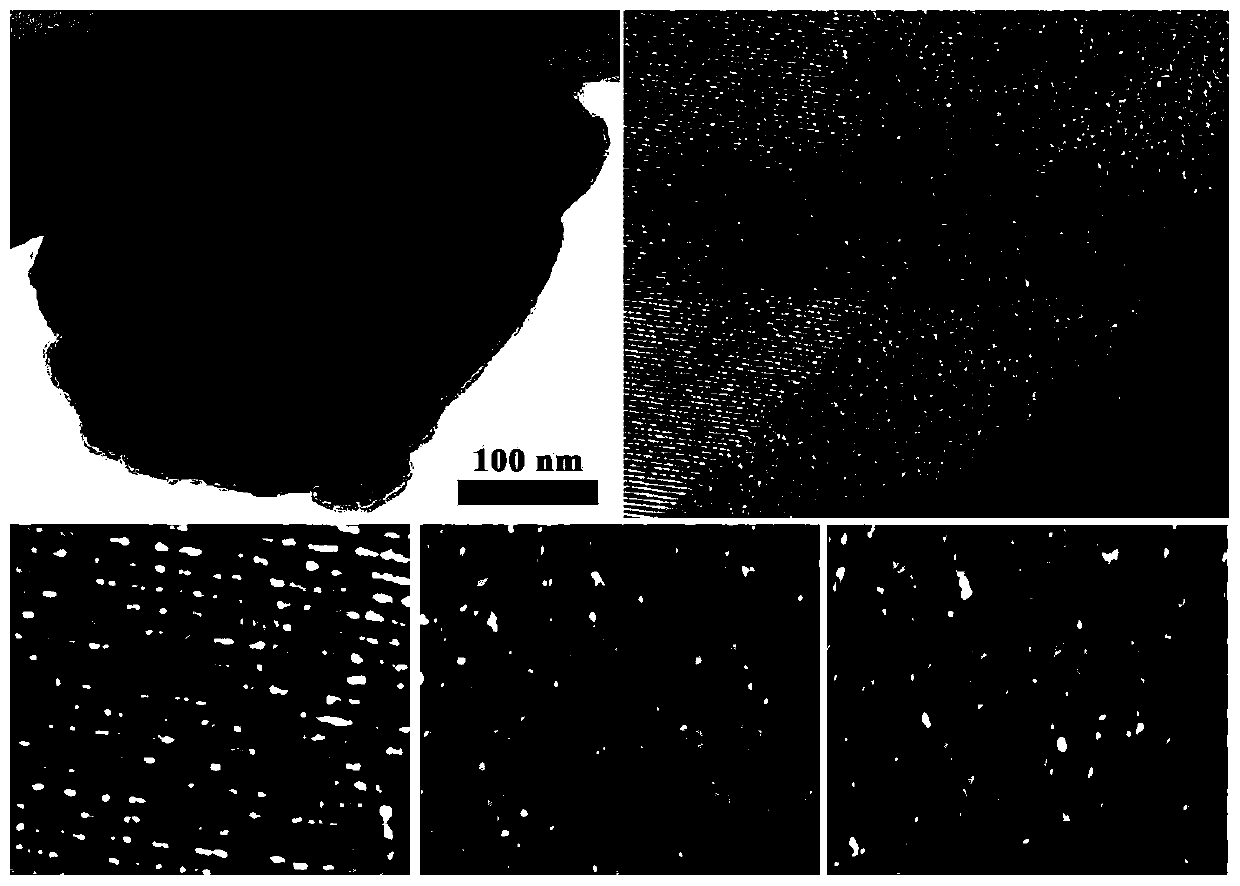

[0066] (3) Test and analyze the NCM811-1, NCM811-2 obtained in Example 1 and NCM811-2@LYPO in Example 2 using a scanning electron microscope (SEM) to obtain its SEM image, as image 3 shown.

[0067] (4) The NCM811-2@LYPO obtained in Example 2 was assembled into a 2016-type button battery and charged and discharged within the voltage range of 3.0-4.3V....

Embodiment 3

[0070] (1) Using petroleum ether as a solvent, the high-nickel cathode material precursor Ni 0.9 co 0.05 mn 0.05 (OH) 2 Perform mechanical ball milling with LiOH at a molar ratio of 1:1.05 for 6 h, then evaporate petroleum ether to dryness, place the mixed material in a tube furnace, and sinter at 650 °C for 3 h in an oxygen atmosphere, and then sinter at 720 °C for 10 h. Cool to room temperature, grind and sieve for later use, code NCM90.

[0071] (2) Put the nickel-rich ternary material NCM90 in an environment with a temperature of about 30°C and an air humidity of about 80% and leave it open for 60 days to obtain NCM90-1, a ternary cathode material with declining or deteriorated performance. The electrochemical properties of the materials are listed in Table 1.

[0072] (3) Add 0.04g of restoration agent aluminum metaphosphate to a solvent containing 20g of absolute ethanol, stir at 400r / min for 10min, add 2g of NCM90-1 material and continue stirring at the same speed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com