Car instrument panel IP tube welding and machining all-in-one machine

A technology for automobile instrument panel and welding machine, applied in the field of machinery, can solve the problems of low welding precision, low welding efficiency, inability to realize automatic mass production, etc., and achieve the effects of improving production efficiency, improving welding, and ingenious structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

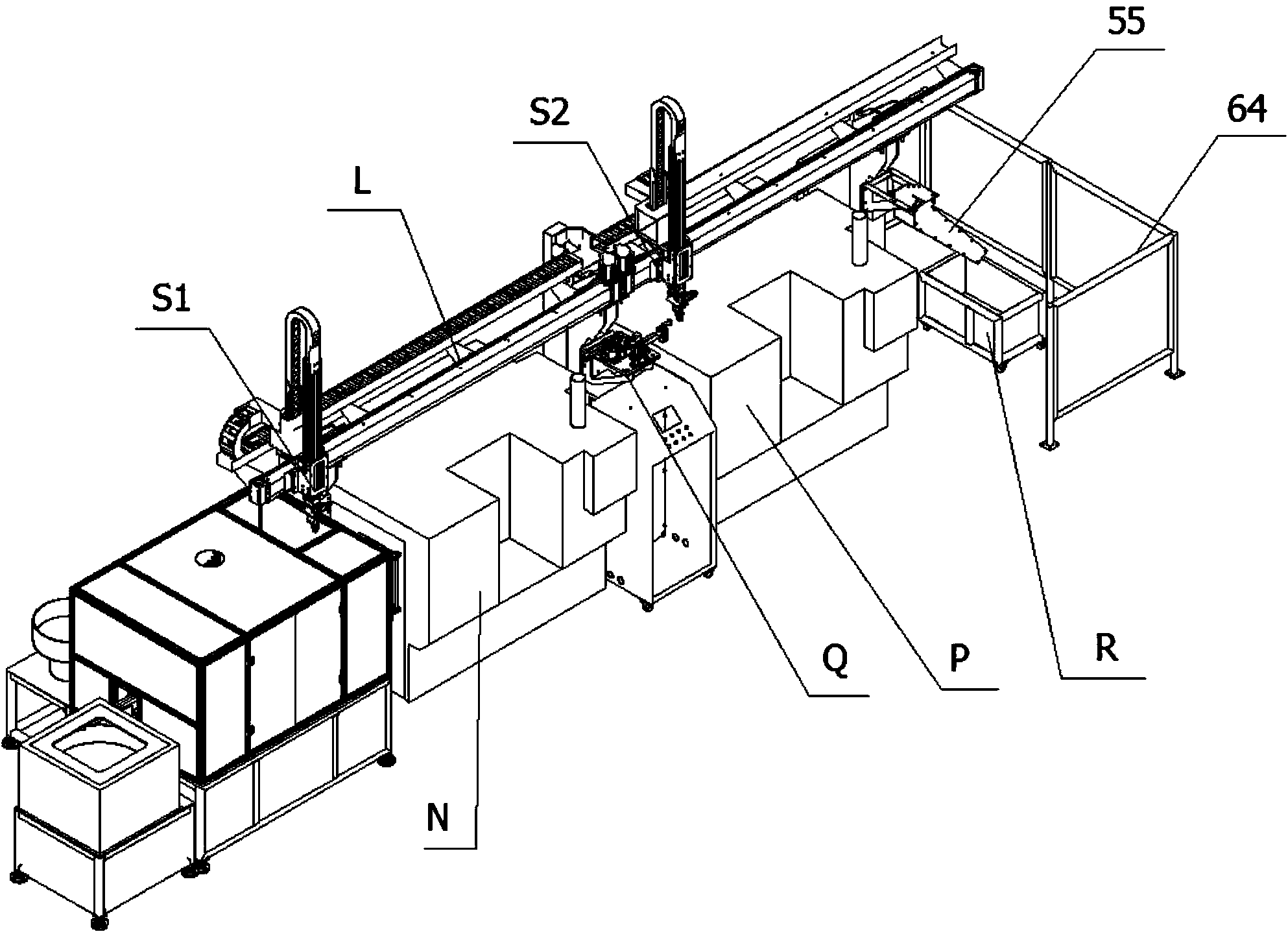

[0053] see figure 1 , a kind of welding machine plus all-in-one machine for automobile instrument panel IP pipe, comprising a welding station and a machine adding station, the right end of the welding station is connected with the left end of the machine adding station.

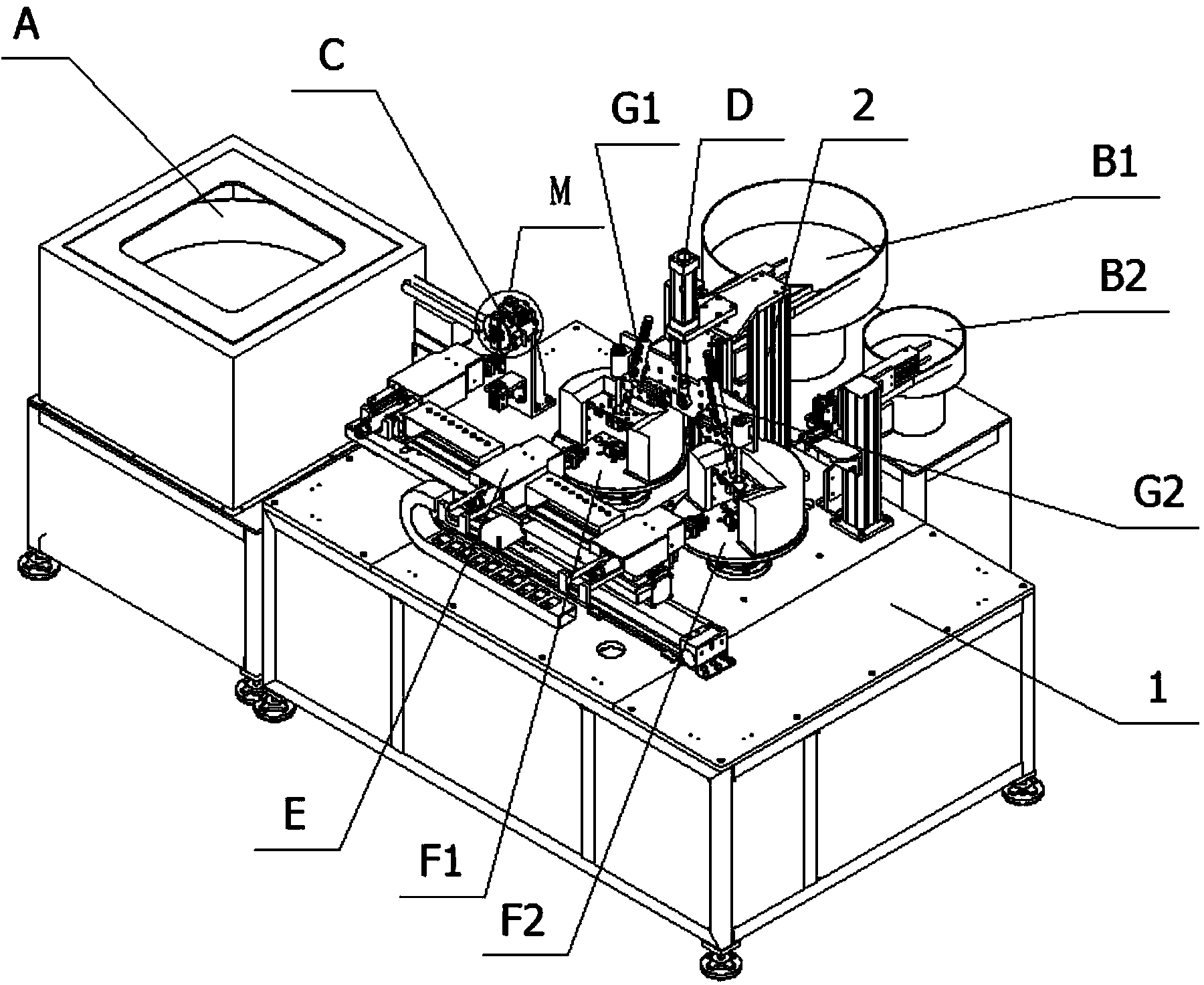

[0054] see Figure 2 to Figure 6 , the welding station is composed of workbench 1, casing vibrating feeder A installed on workbench 1, first washer vibrating feeder B1, second washer vibrating feeder B2, flipping feeding mechanism C, and welding torch support The component D, the workpiece clamping manipulator mechanism E, the first workpiece welding rotating assembly F1 and the second workpiece welding rotating assembly F2 are composed.

[0055] see figure 1 and Figure 16 , the machining station includes a truss robot L, a first lathe N, a second machine tool P, an indexing device Q, and a receiving device R.

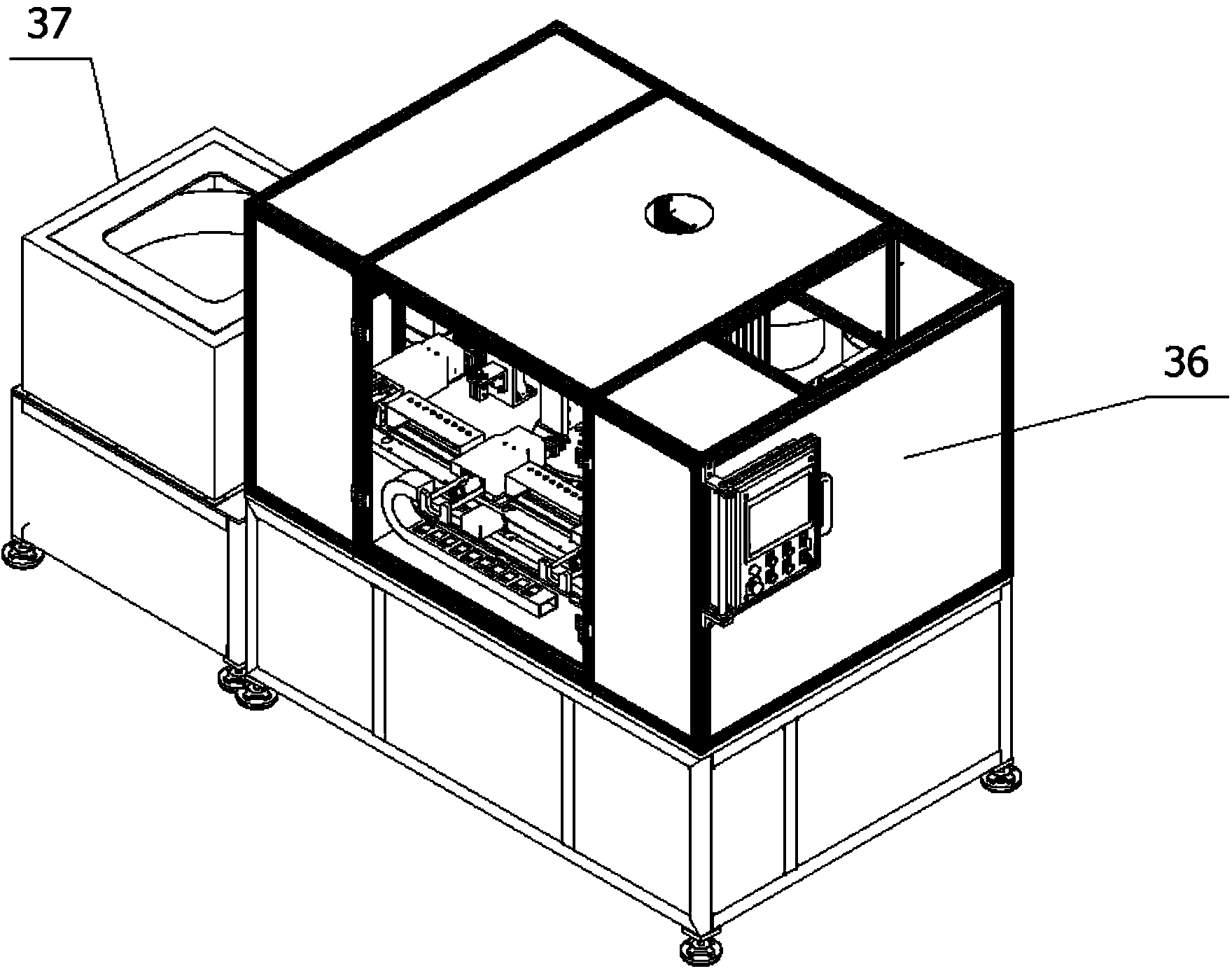

[0056] Figure 2 to Figure 6 The structure of the welding station is shown. The casing vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com