A welding production line work class assignment system and method based on particle swarm optimization algorithm

A technology of welding production line and particle swarm algorithm, which is applied in the direction of manufacturing computing system, computing, computing model, etc., can solve the problems of robots reducing resource utilization, job backlog, and production link impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

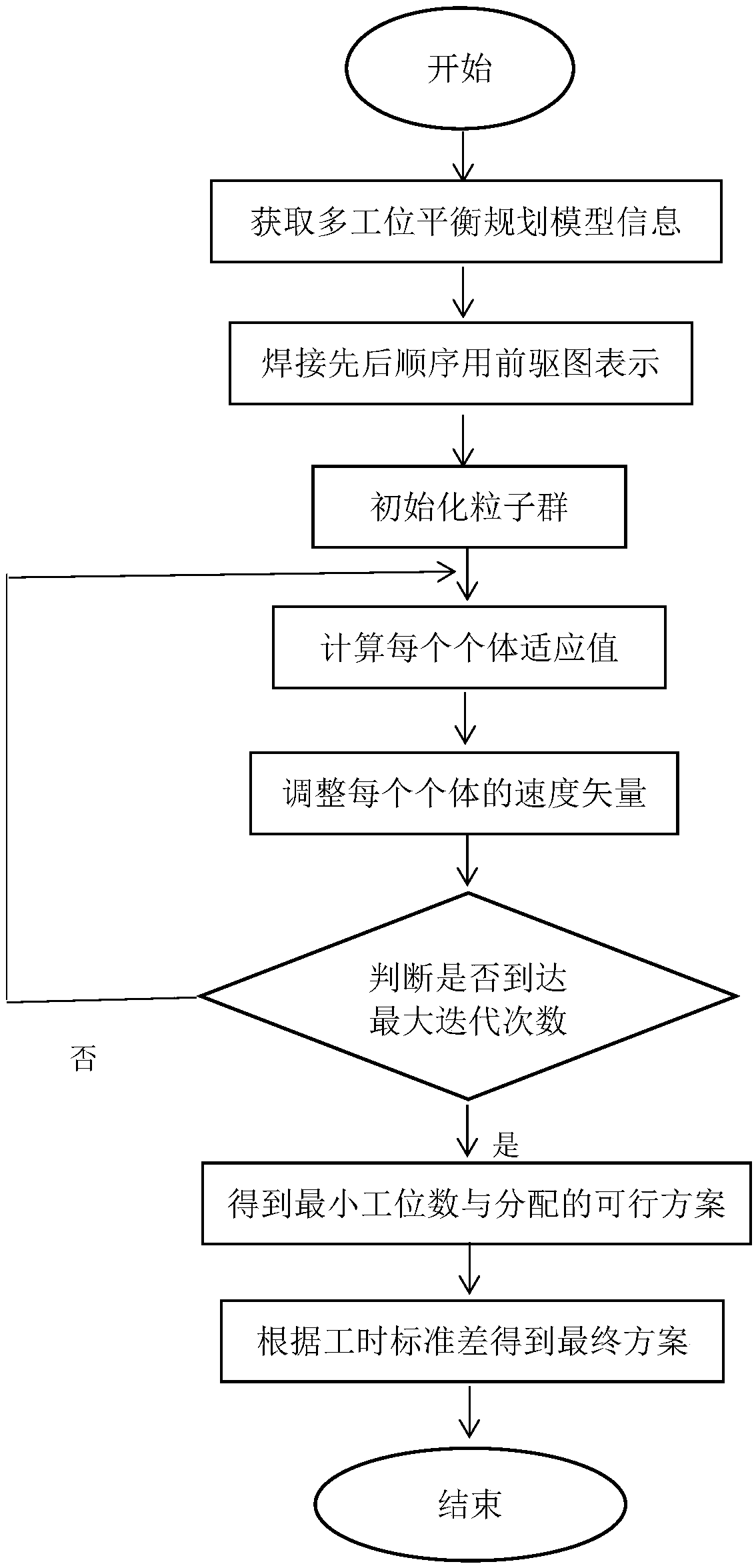

Method used

Image

Examples

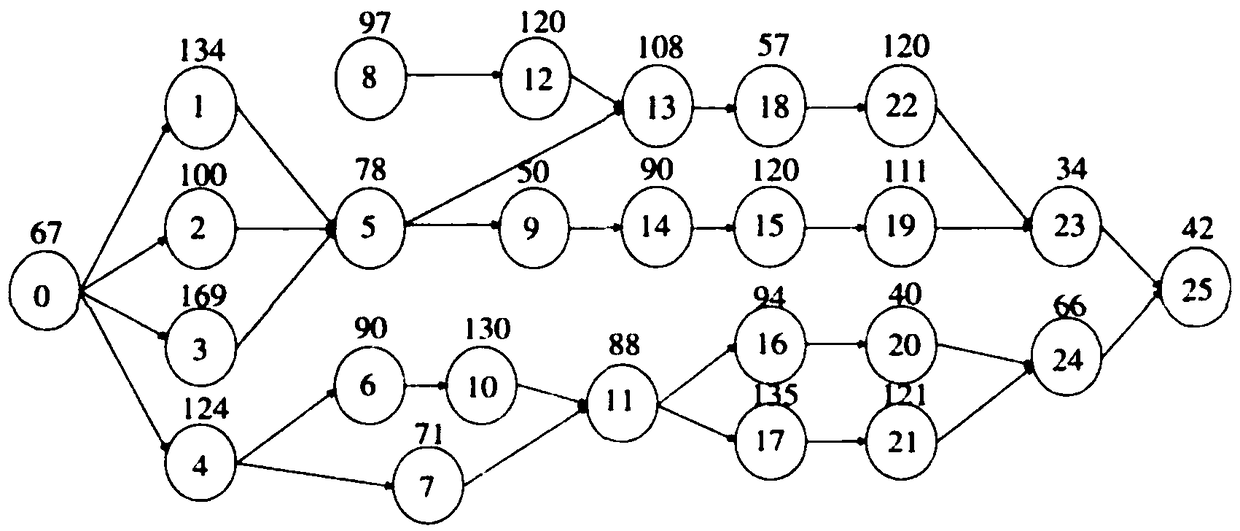

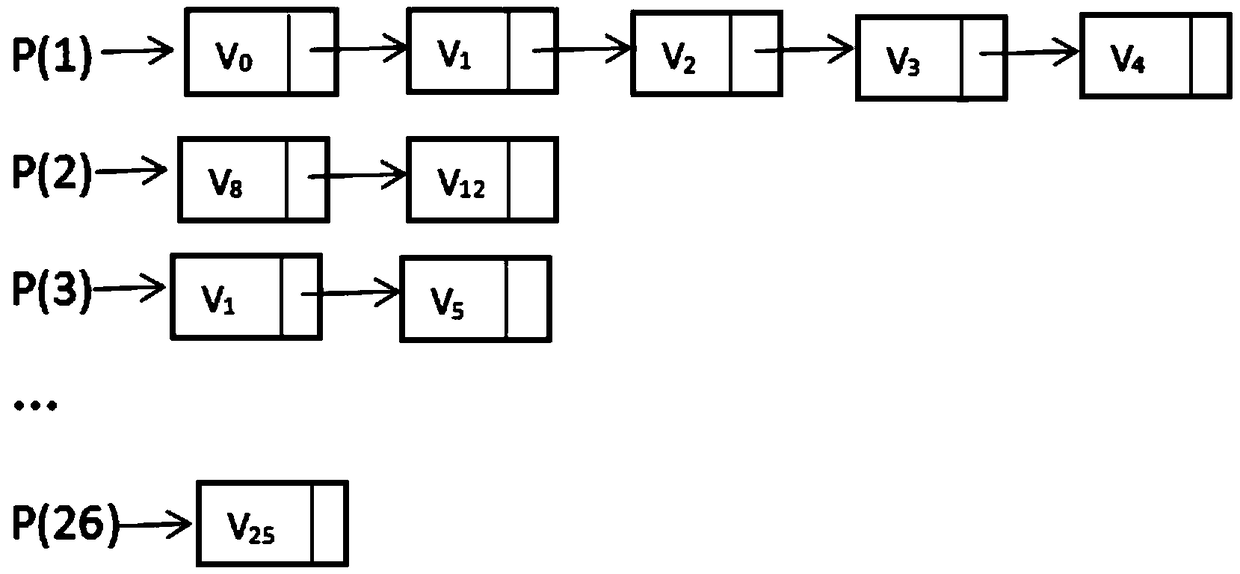

Embodiment Construction

[0016] Step 1: Obtain the information of multi-station balance planning model

[0017] The assembly line balancing problem is a decision-making problem considering the optimization goal, assigning operations / jobs to various stations or workstations. According to the objective function, the station balance planning problem can be divided into four categories:

[0018] (1) Knowing the production beat c, minimize the number of chemical digits (SALBP-1).

[0019] (2) Knowing the number of stations, minimize the production beat c(SALBP-2).

[0020] (3) Both the number of stations and the tact of production are variable, maximizing the line efficiency E=t sum / (c m)(SALBP-3).

[0021] (4) Find a set of feasible equilibrium solutions (SALBP-4).

[0022] The first type of problem (SALBP-1) is studied, which is to minimize the number of workstations under the constraints of fixed production nodes, balance the production time of each workstation, reduce idle waiting time, and improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com