Polymer graft-coated modified calcium sulfate whisker, and preparation method and application thereof

A technology of calcium sulfate whisker and graft modification, applied in the field of material modification, can solve the problems of environmental pollution, low carbon atomic ratio on the surface of modified calcium sulfate whisker, high toxicity, etc. Compatibility and affinity, good effect of stress transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a kind of preparation method of polymer graft coating modified calcium sulfate whisker, it comprises the following steps:

[0039] S1. Dissolve 0.5 g of sodium oleate in 300 mL of deionized water to obtain a sodium oleate aqueous solution, and put the sodium oleate aqueous solution into a four-necked flask equipped with a condensation reflux device, a thermometer, a stirrer, and a nitrogen ventilation device .

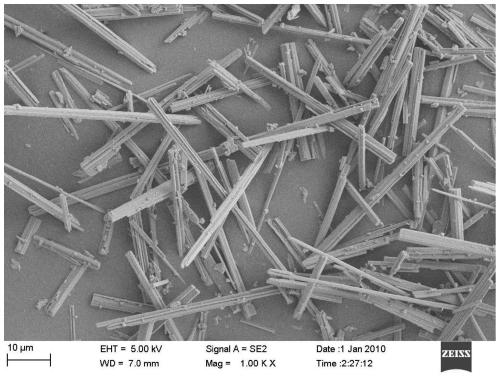

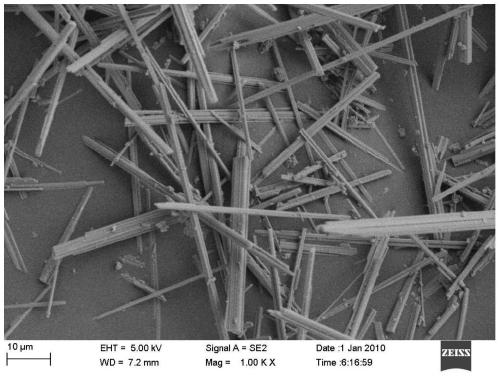

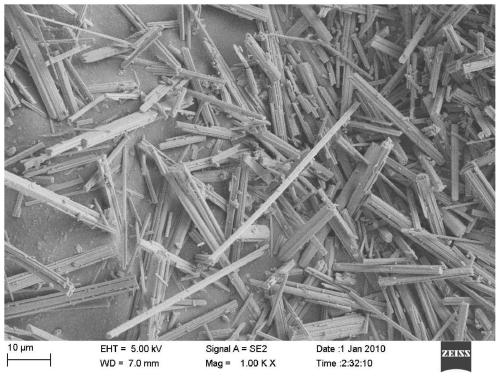

[0040] S2. Introduce nitrogen gas into the above-mentioned sodium oleate aqueous solution while stirring at a speed of 300 rpm; then, after heating the above-mentioned sodium oleate aqueous solution to 50°C, add 10 g of anhydrous calcium sulfate crystals to the above-mentioned sodium oleate aqueous solution It must be stirred and mixed for 20 minutes to obtain a dispersion. Among them, the length of the anhydrous calcium sulfate whiskers is 30-120 μm, and the aspect ratio is 10-80.

[0041] S3. The above-mentioned dispersion liquid is ...

Embodiment 2

[0046] This embodiment provides a kind of preparation method of polymer graft coating modified calcium sulfate whisker, it comprises the following steps:

[0047] S1. Dissolve 0.5 g of sodium oleate in 300 mL of deionized water to obtain a sodium oleate aqueous solution, and put the sodium oleate aqueous solution into a four-necked flask equipped with a condensation reflux device, a thermometer, a stirrer, and a nitrogen ventilation device .

[0048] S2. Introduce nitrogen gas into the above-mentioned sodium oleate aqueous solution while stirring at a speed of 300 rpm; then, after heating the above-mentioned sodium oleate aqueous solution to 50°C, add 10 g of anhydrous calcium sulfate crystals to the above-mentioned sodium oleate aqueous solution It must be stirred and mixed for 20 minutes to obtain a dispersion. Among them, the length of the anhydrous calcium sulfate whiskers is 30-120 μm, and the aspect ratio is 10-80.

[0049] S3. The above-mentioned dispersion liquid is ...

Embodiment 3

[0054] This embodiment provides a kind of preparation method of polymer graft coating modified calcium sulfate whisker, it comprises the following steps:

[0055] S1. Dissolve 0.5 g of sodium oleate in 300 mL of deionized water to obtain a sodium oleate aqueous solution, and put the sodium oleate aqueous solution into a four-necked flask equipped with a condensation reflux device, a thermometer, a stirrer, and a nitrogen ventilation device .

[0056] S2. Introduce nitrogen gas into the above-mentioned sodium oleate aqueous solution while stirring at a speed of 300 rpm; then, after heating the above-mentioned sodium oleate aqueous solution to 50°C, add 10 g of anhydrous calcium sulfate crystals to the above-mentioned sodium oleate aqueous solution It must be stirred and mixed for 20 minutes to obtain a dispersion. Among them, the length of the anhydrous calcium sulfate whiskers is 30-120 μm, and the aspect ratio is 10-80.

[0057] S3. The above-mentioned dispersion liquid is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com