Method for manufacturing high-toughness traditional Chinese medicine residue / plastic composite material

A technology of traditional Chinese medicine dregs and composite materials, which is applied in the field of preparation of traditional Chinese medicine dregs/plastic composite materials. Easy, easy orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

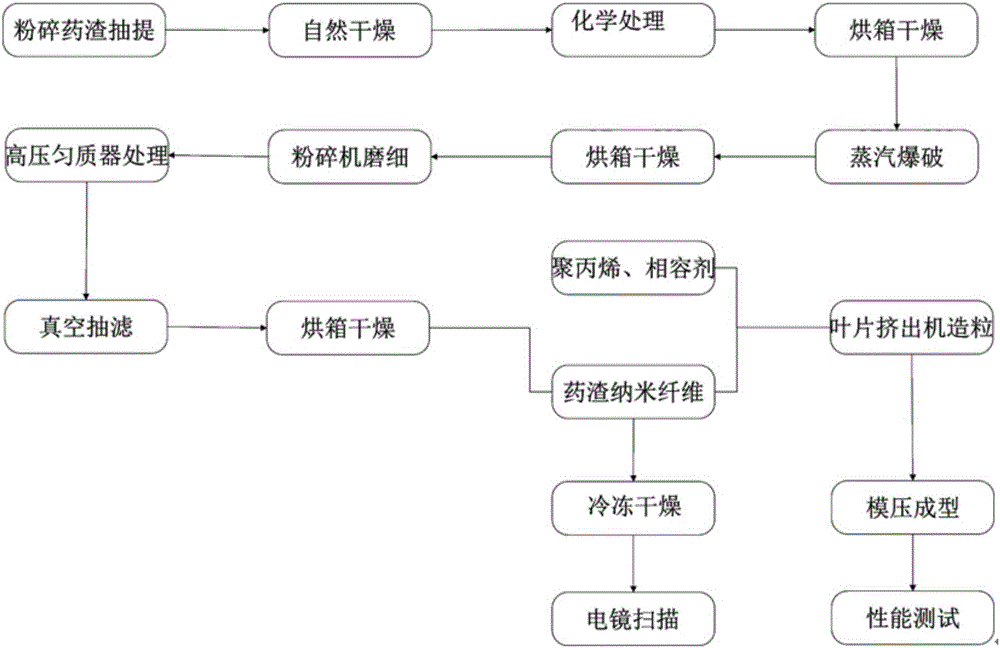

Method used

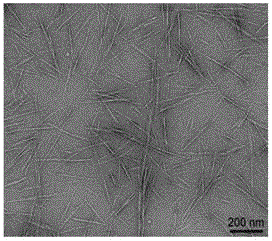

Image

Examples

Embodiment 1

[0024] Embodiment 1: In this embodiment, the medicinal dregs of the sesame root are taken as an example to prepare a high-toughness nanocellulose / plastic composite material of traditional Chinese medicine dregs, and proceed as follows:

[0025] (1) Pulverize a certain amount of sesame root medicinal residues, use ethanol:toluene according to the volume ratio of 1:2 to form a mixed solution, after mixing with a material-liquid ratio of 1:20 (mass ratio), in a Soxhlet extractor Extraction treatment was carried out at 120°C for 48 hours.

[0026] (2) The product obtained in step 1 was subjected to vacuum filtration, and the filter residue was naturally dried in a fume hood for 24 hours.

[0027] (3) Disperse the filter residue treated in step 2 in an aqueous potassium hydroxide solution with a concentration of 3 wt%, with a solid-to-liquid ratio of 1:50 (mass ratio); stir and react for 2 hours in a water bath at 90°C. After the reaction is finished, vacuum suction filtration is ...

Embodiment 2

[0042] Embodiment 2: In this embodiment, taking the Chinese medicine dregs of Dioscorea florida as an example, the high-toughness Chinese medicine dregs nanocellulose / plastic composite material is prepared, and the steps are as follows:

[0043] (1) Grinding the traditional Chinese medicine dregs of Dioscorea floridae with ethanol: toluene mixture solution with a volume ratio of 1:2, and a solid-liquid ratio of 1:20 (mass ratio) for 48 hours of extraction treatment at 120°C.

[0044] (2) The product obtained in step 1 was taken out, and the traditional Chinese medicine residue of Dioscorea florida was taken out, placed in a petri dish, and dried naturally in a fume hood for 24 hours.

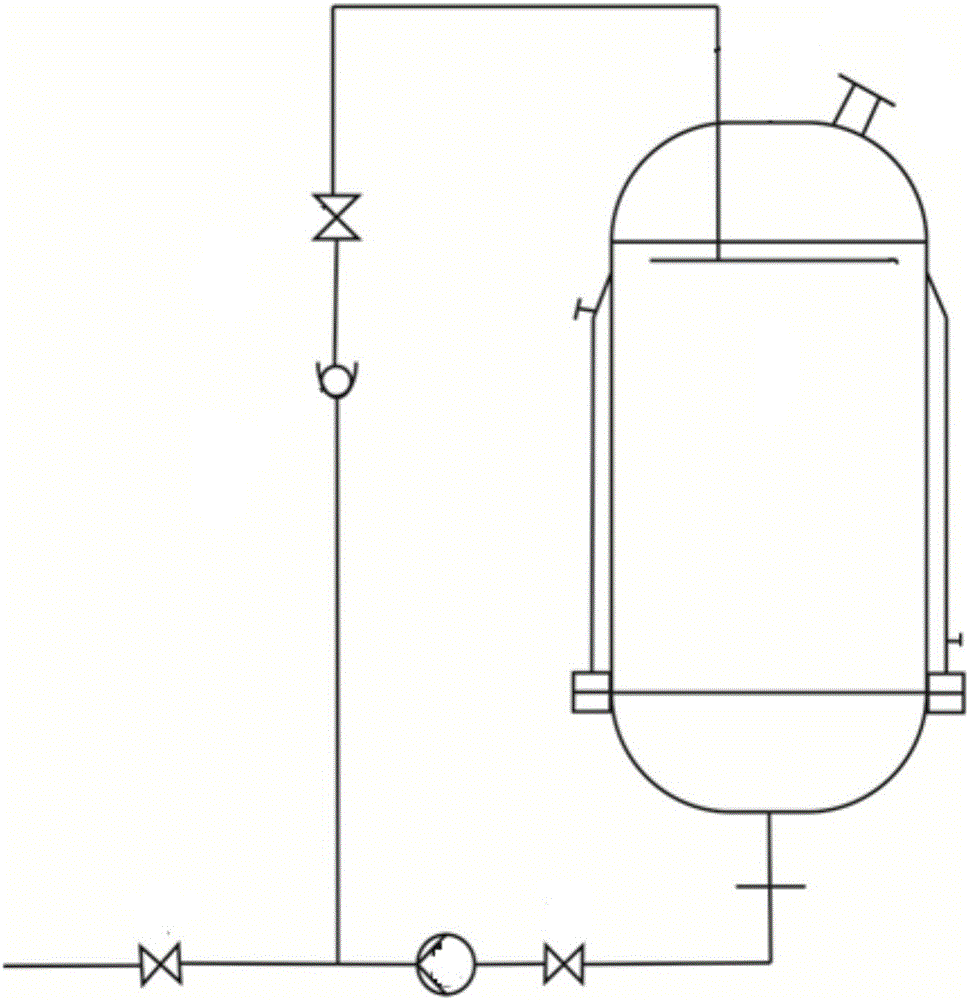

[0045] (3) Put the dregs extracted by ethanol and toluene into a continuous steam explosion machine for 6 minutes at 200° C. and 1.5 MPa for steam explosion.

[0046] (4) Disperse the filter residue treated in step 3 in an aqueous potassium hydroxide solution with a concentration of 3 wt%, with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com