Prefabricated reinforced concrete hollow pier socket and spigot joint connecting structure and manufacturing method

A reinforced concrete and node connection technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of large thickness of the bearing platform, unclear force performance, weak connection, etc., and achieve easy quality, high construction accuracy requirements, grouting large space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

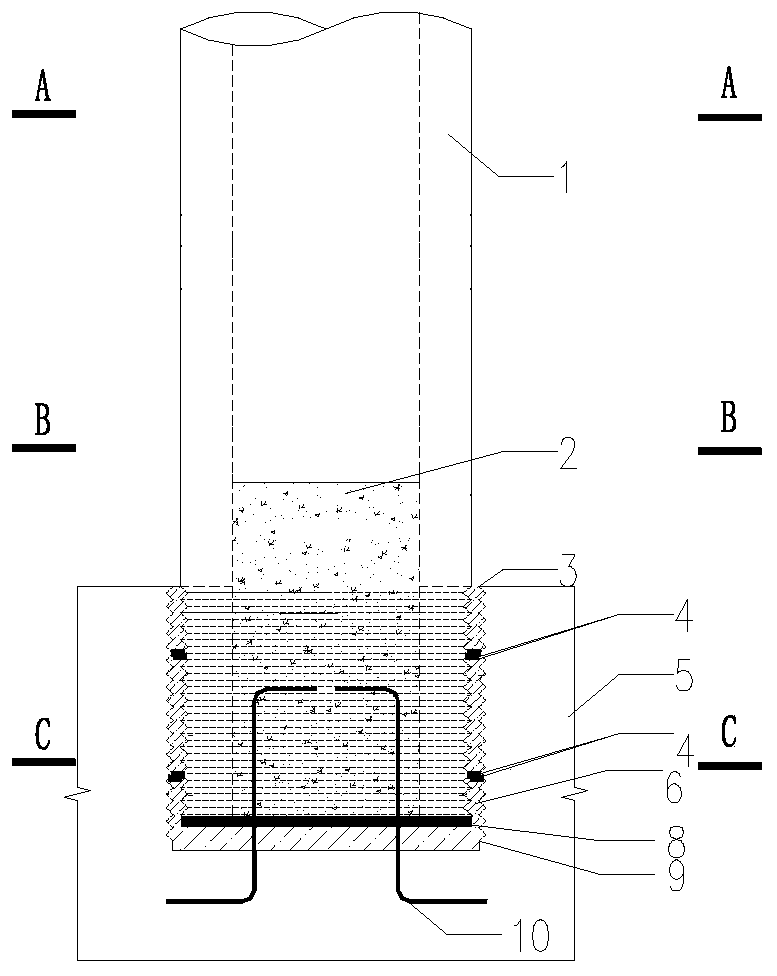

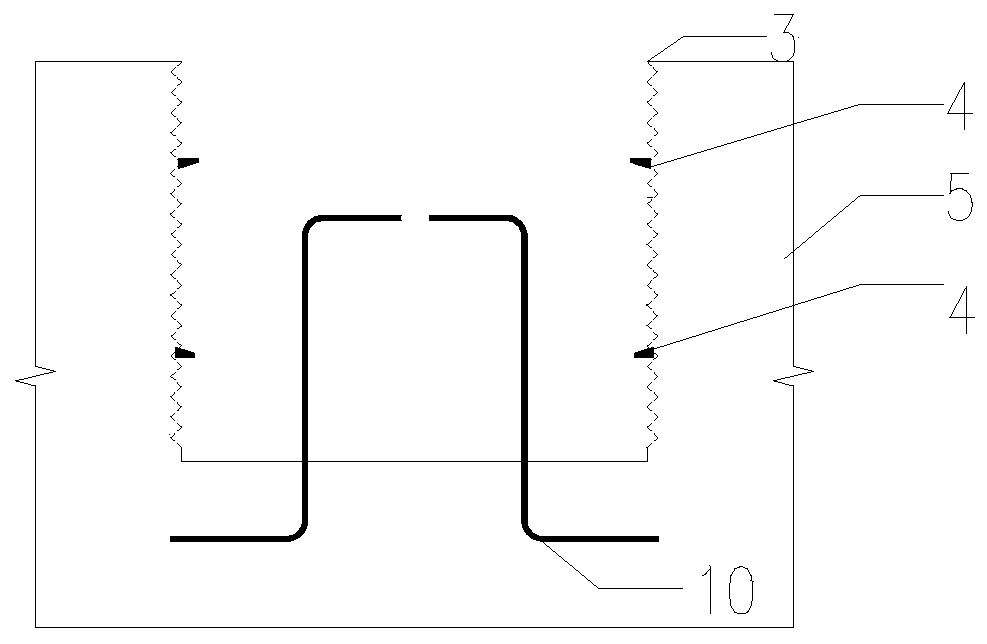

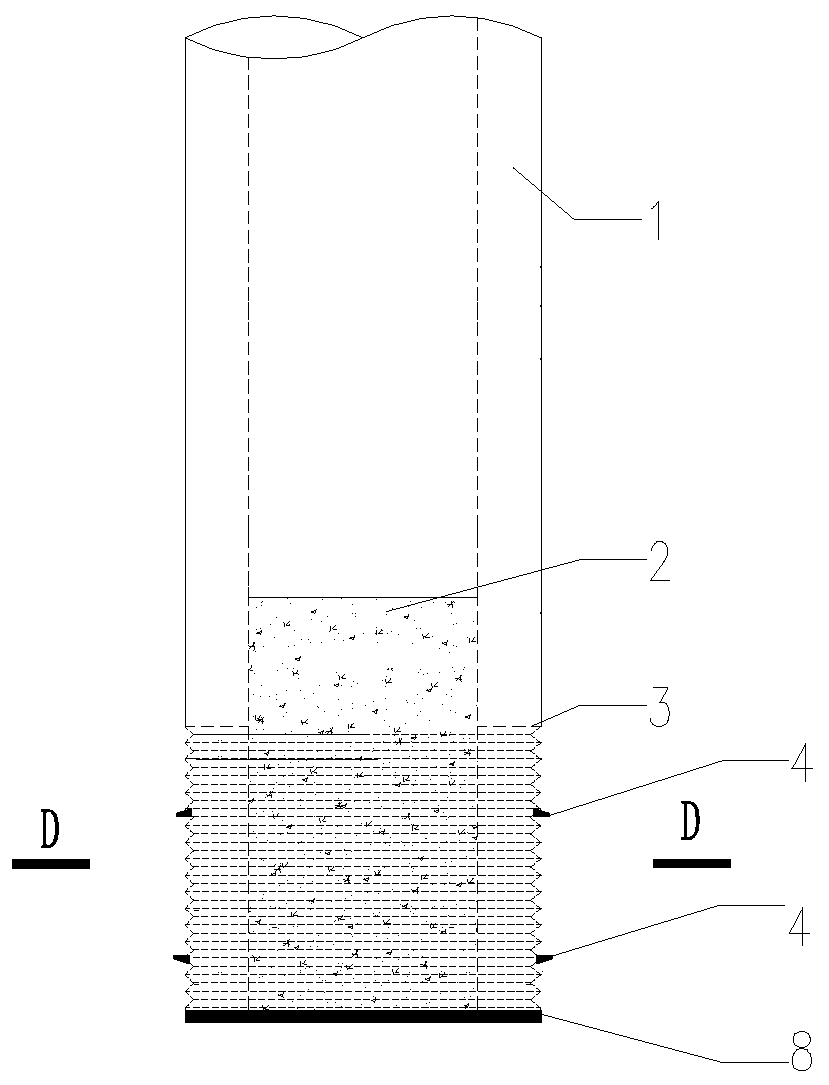

[0029] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

[0030] A prefabricated reinforced concrete hollow bridge pier socket connection joint structure, including: the solid part of the hollow bridge pier 1, cast-in-place core concrete 2, spiral corrugations at the interface between pier columns and caps 3, steel wedges between pier columns and caps 4, and cast-in-place The solid part of the cap 5, the filling joint UHPC 6, the steel plate hole at the bottom of the bridge pier 7, the steel plate at the bottom of the bridge pier 8, the sitting grout UHPC 9 and the anchoring steel bar 10 protruding from the cap. The structure consists of two components; component one is a prefabricated cap, and component two is a prefabricated hollow pier column; component one and component two are connected through a socket, and the gap between them is filled with UHPC; the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com