Method for preparing novel phenolic resin base composite material

A technology of phenolic resin and composite materials, which is applied in the field of building materials, can solve the problems of limited application and promotion, poor hardness and mechanical strength and impact resistance of composite materials, and achieve the effect of improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

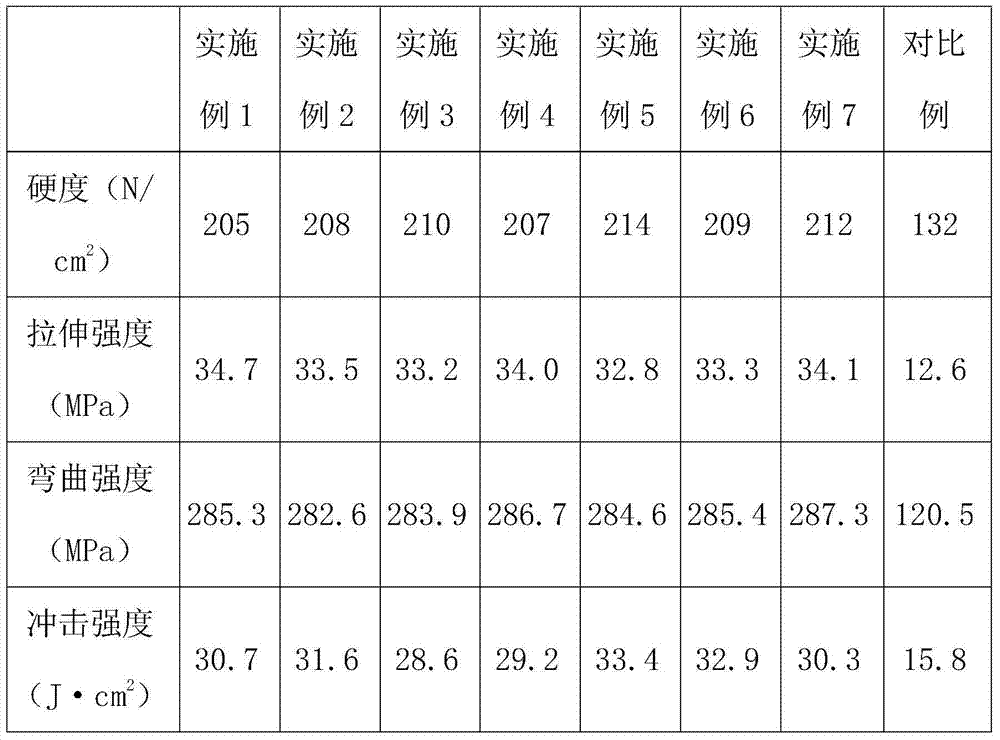

Examples

Embodiment 1

[0026] A preparation method of phenolic resin-based composite material, the steps are as follows:

[0027] (1) Wash the shells with deionized water, remove the surface cuticle, and dry them. After cooling naturally to room temperature, the dried shells are obtained. The dried shells are soaked in a 5% sodium hydroxide solution by mass fraction. After 2 days, Take it out, wash it with deionized water, dry it in a vacuum oven at 80°C for 2 hours, put it into a grinder and grind it for 4 hours to get shell powder;

[0028] (2) dissolving the silane coupling agent in acetone to obtain a silane coupling agent solution, adding the shell powder obtained in step (1) into the silane coupling agent solution and stirring for 10 minutes, then moving into an ultrasonic container for ultrasonic treatment for 40 minutes to obtain the improved Sexual shell powder, wherein, the weight ratio of shell powder, silane coupling agent, acetone is 15:1:100;

Embodiment 2

[0032] A preparation method of phenolic resin-based composite material, the steps are as follows:

[0033] (1) Wash the shells with deionized water, remove the surface cuticle, and dry them. After cooling naturally to room temperature, the dried shells are obtained. The dried shells are soaked in a 5% sodium hydroxide solution by mass fraction. After 2 days, Take it out, wash it with deionized water, dry it in a vacuum oven at 80°C for 2 hours, put it into a grinder and grind it for 4 hours to get shell powder;

[0034] (2) dissolving the silane coupling agent in acetone to obtain a silane coupling agent solution, adding the shell powder obtained in step (1) into the silane coupling agent solution and stirring for 10 minutes, then moving into an ultrasonic container for ultrasonic treatment for 40 minutes to obtain the improved Sexual shell powder, wherein, the weight ratio of shell powder, silane coupling agent, acetone is 15:1:100;

Embodiment 3

[0038] A preparation method of phenolic resin-based composite material, the steps are as follows:

[0039] (1) Wash the shells with deionized water, remove the surface cuticle, and dry them. After cooling naturally to room temperature, the dried shells are obtained. The dried shells are soaked in a 5% sodium hydroxide solution by mass fraction. After 2 days, Take it out, wash it with deionized water, dry it in a vacuum oven at 80°C for 2 hours, put it into a grinder and grind it for 4 hours to get shell powder;

[0040] (2) dissolving the silane coupling agent in acetone to obtain a silane coupling agent solution, adding the shell powder obtained in step (1) into the silane coupling agent solution and stirring for 10 minutes, then moving into an ultrasonic container for ultrasonic treatment for 40 minutes to obtain the improved Sexual shell powder, wherein, the weight ratio of shell powder, silane coupling agent, acetone is 15:1:100;

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com