Polypropylene pipeline

A polypropylene and polypropylene layer technology, applied in the pipeline field, can solve problems such as high production costs, resource consumption, and difficulty in ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

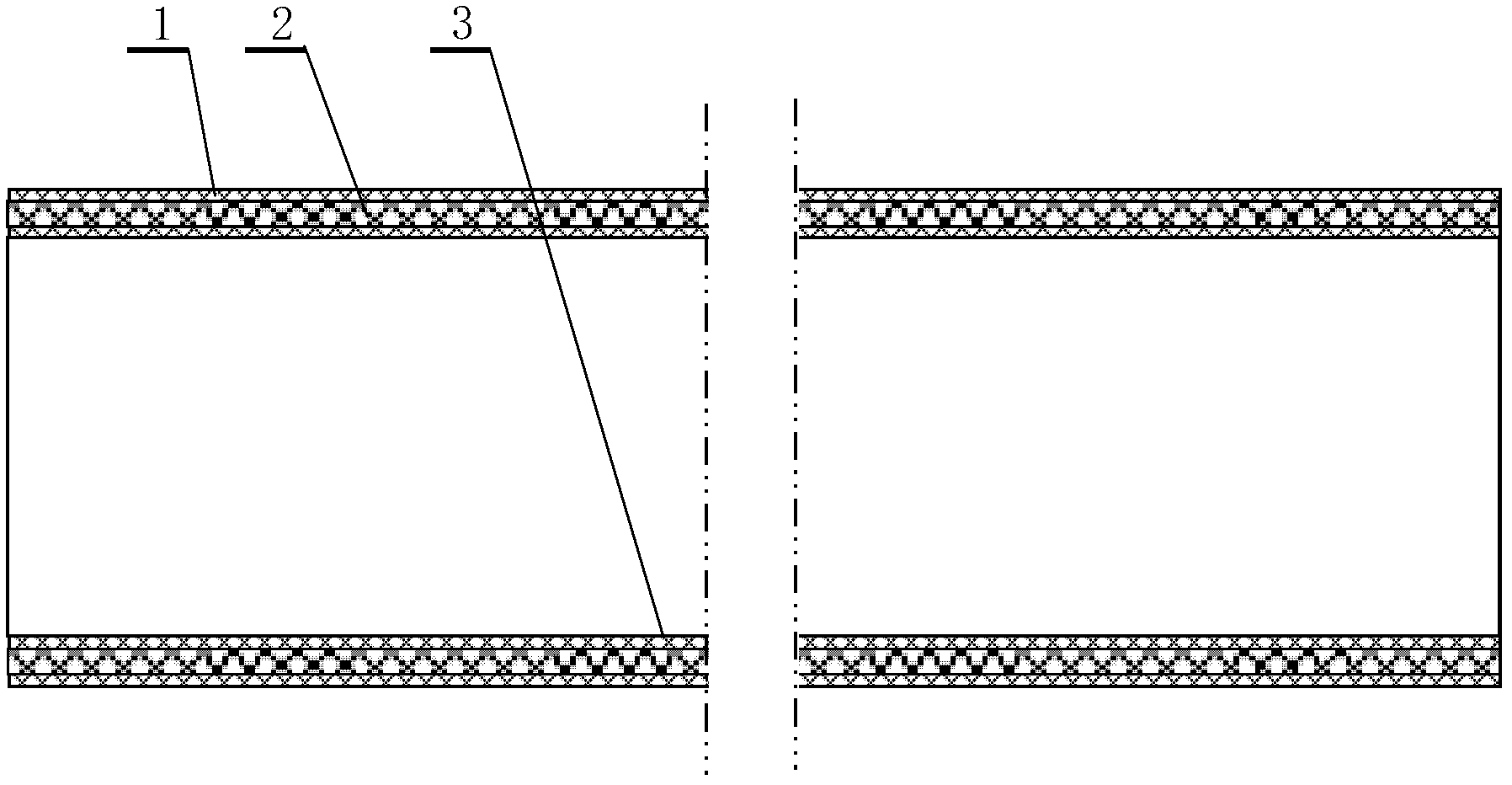

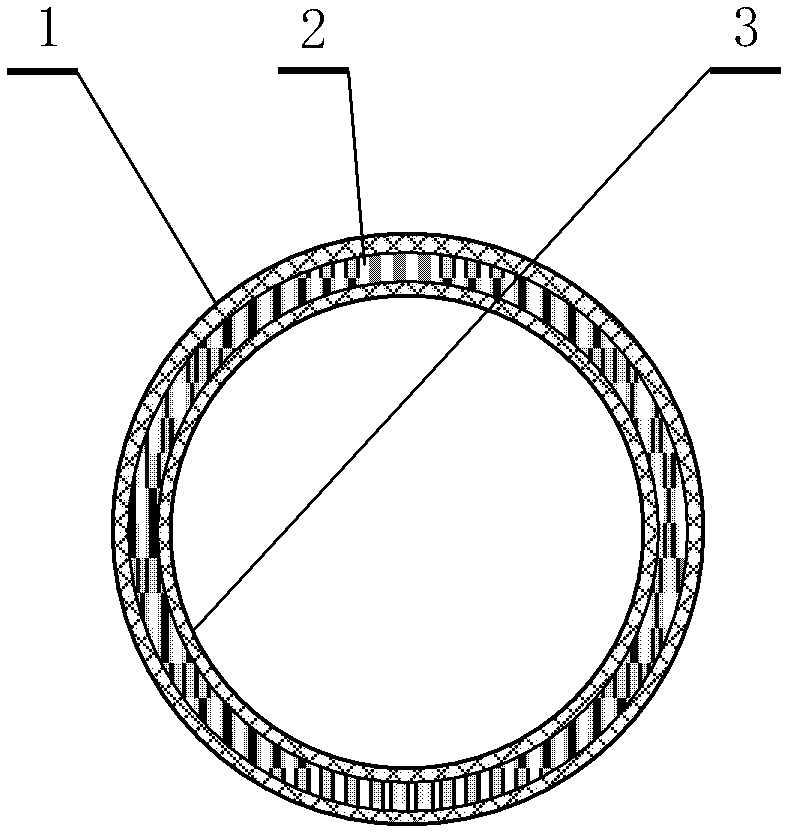

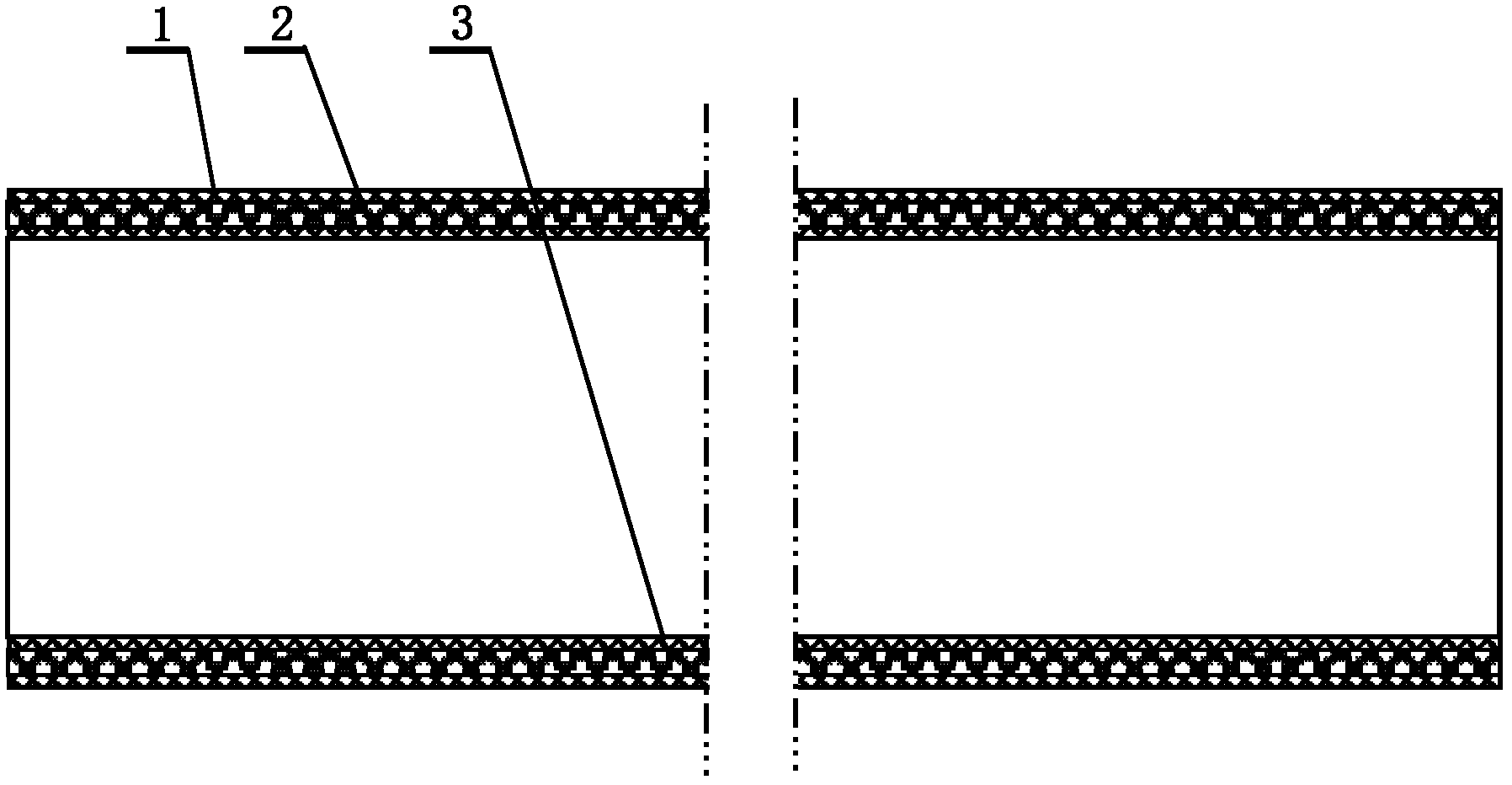

[0009] Describe in detail below in conjunction with accompanying drawing and embodiment:

[0010] Be a kind of circular duct of the present invention among the figure, also can make the duct of other shapes obviously. Including the pipe, the main points are: the pipe wall has three layers, and the inner and outer layers 1 and 3 are antistatic polypropylene layers, that is, the polypropylene material is mixed with conductive carbon fibers with a weight ratio of 1 to 5% and a weight ratio of 2 to 8. % conductive carbon black polypropylene layer; the middle layer 2 is a glass fiber reinforced polypropylene layer, that is, the polypropylene material is mixed with a weight ratio of 25 to 45% glass fiber and an amine weight ratio of 1 to 5 per thousand Polypropylene layer of beta-nucleating agent.

[0011] In order to reduce costs and improve cost performance, the weight ratio of conductive carbon fiber in the antistatic polypropylene layer is 1-2%, and the weight ratio of conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com