A kind of nylon 6/thermally expanded graphite conductive composite material and preparation method thereof

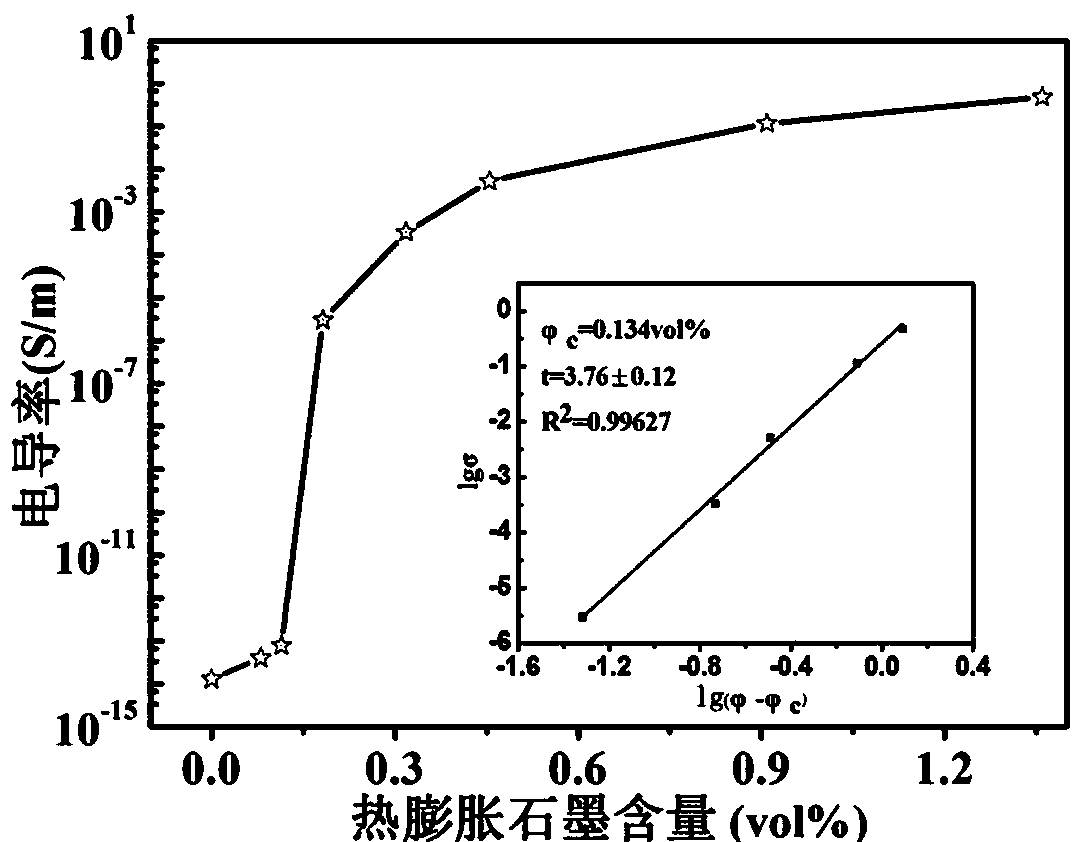

A technology of conductive composite materials and thermally expanded graphite, applied in the field of polymer composite materials, can solve problems such as limiting the application of CPCs, and achieve the effects of easy to master, good electrical conductivity, and low percolation value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

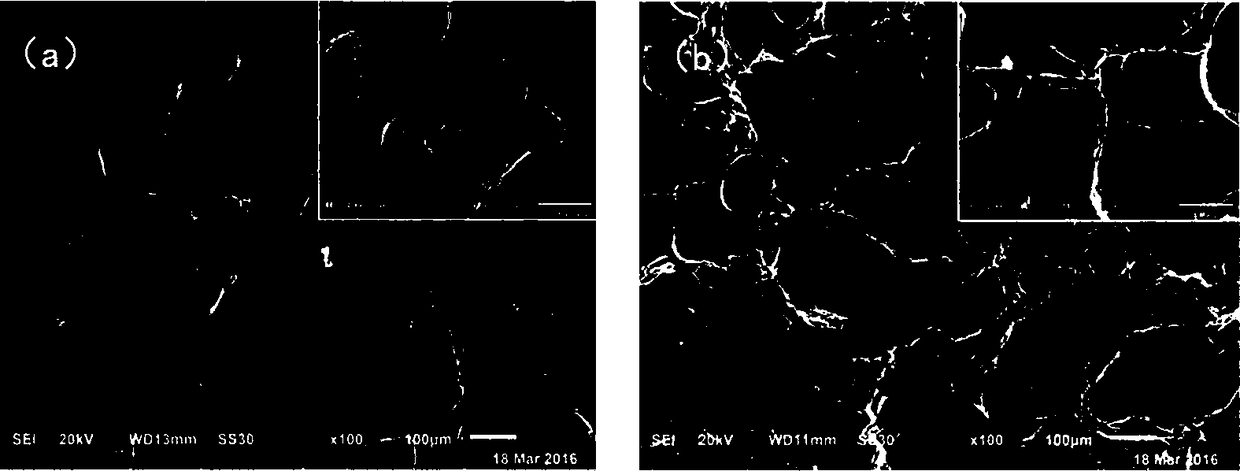

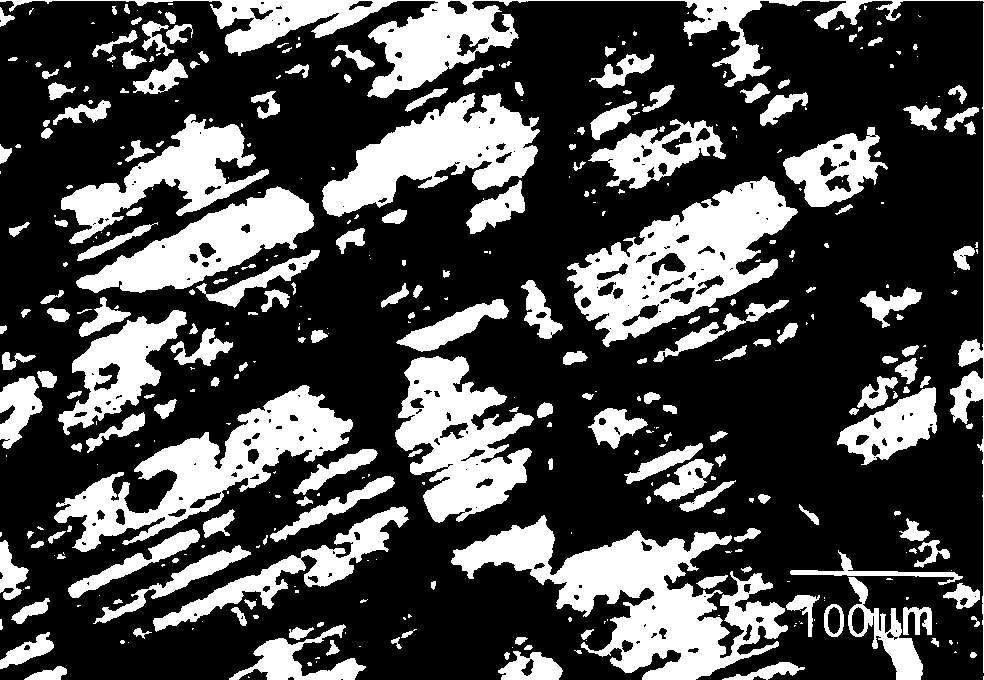

[0020] Embodiment one: the preparation method of the PA6 / EG conductive composite material with isolation structure comprises the following steps:

[0021] (1) Preparation of PA6 / EG conductive composite particles: Mix the dried EG and PA6 particles at a volume ratio of 0.182:99.818 through high-speed mechanical mixing, and realize the uniform coating of EG on the surface of PA6 under the action of mechanical force to obtain PA6 / EG Conductive composite particles, mixing time 5min.

[0022] (2) Compression molding: pre-press the PA6 / EG conductive composite particles prepared in step (1) at 100°C and 10MPa for 2h; then preheat at 225°C for 15min; then hot-press at 3MPa for 5min; Finally, it was cold-pressed to room temperature to obtain a conductive composite material.

Embodiment 2

[0023] Embodiment two: the preparation method of the PA6 / EG conductive composite material with isolation structure comprises the following steps:

[0024] (1) Preparation of PA6 / EG conductive composite particles: Mix the dried EG and PA6 particles at a volume ratio of 0.318:99.682 through high-speed mechanical mixing, and realize the uniform coating of EG on the surface of PA6 under the action of mechanical force to obtain PA6 / EG Conductive composite particles, mixing time 5min.

[0025] (2) Compression molding: pre-press the PA6 / EG conductive composite particles prepared in step (1) at 100°C and 10MPa for 2h; then preheat at 225°C for 15min; then hot-press at 3MPa for 5min; Finally, it was cold-pressed to room temperature to obtain a conductive composite material.

Embodiment 3

[0026] Embodiment three: the preparation method of the PA6 / EG conductive composite material with isolation structure comprises the following steps:

[0027] (1) Preparation of PA6 / EG conductive composite particles: Mix the dried EG and PA6 particles at a volume ratio of 0.455:99.545 by high-speed mechanical mixing, and realize the uniform coating of EG on the surface of PA6 under the action of mechanical force to obtain PA6 / EG Conductive composite particles, mixing time 5min.

[0028] (2) Compression molding: pre-press the PA6 / EG conductive composite particles prepared in step (1) at 100°C and 10MPa for 2h; then preheat at 225°C for 15min; then hot-press at 3MPa for 5min; Finally, it was cold-pressed to room temperature to obtain a conductive composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com