Strong-basicity carbon nano tube-graphene composite ion exchange resin material and preparation method thereof

An ion exchange resin and graphene composite technology, applied in ion exchange, anion exchange, organic anion exchanger, etc., can solve the problems of uneven dispersion, uneven dispersion of graphene and carbon nanotubes, and easy to agglomerate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

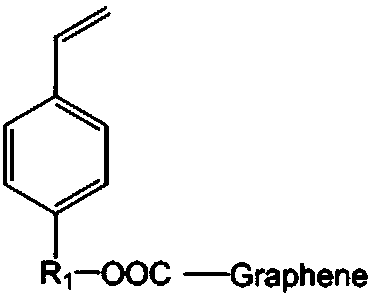

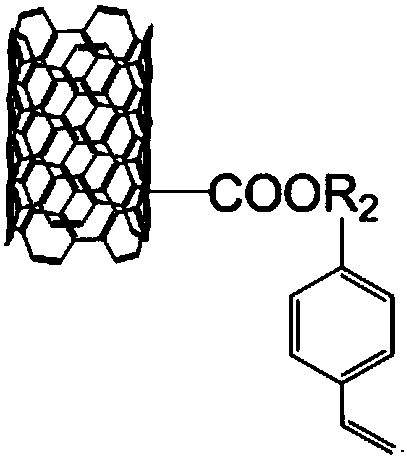

[0073] Take 1g of carbon nanotubes, add 200ml of acid solution (the volume ratio of concentrated sulfuric acid to concentrated nitric acid is 3:1) and reflux for oxidation for 20min. After the oxidation is completed, the reaction solution is filtered, washed with water for 5 times, and vacuum-dried at 60° C. to obtain oxidized carbon nanotubes. Graphene oxide was prepared by the Hummers method.

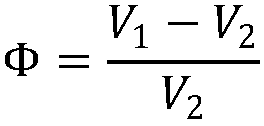

[0074] Mix carbon oxide nanotubes and graphene oxide powder at a mass ratio of 1:3, disperse them into 100ml of a dispersion with a concentration of 1mg / ml by ultrasonic or stirring, add an alkali solution with a concentration of 1mmol / L, and adjust the pH to 9 to prepare To the mixed carboxylate solution of oxidized carbon nanotubes and graphene oxide, 0.2 g of tetraoctyl ammonium bromide and 1.0 g of p-chloromethyl styrene were added, and the mixture was stirred and reacted in an oil bath at 98° C. for 3 h. After the reaction is complete, cool to room temperature, add 100ml of chlo...

Embodiment 2

[0079] Take 1g of carbon nanotubes, add 200ml of acid solution (the volume ratio of concentrated sulfuric acid to concentrated nitric acid is 3:1) and reflux for oxidation for 20min. After the oxidation is completed, the reaction solution is filtered, washed with water for 5 times, and vacuum-dried at 60° C. to obtain oxidized carbon nanotubes. Graphene oxide was prepared by the Hummers method.

[0080] Mix carbon oxide nanotubes and graphene oxide powder at a mass ratio of 1:3, disperse them into 100ml of a dispersion with a concentration of 1mg / ml by ultrasonic or stirring, add an alkali solution with a concentration of 1mmol / L, and adjust the pH to 9 to prepare To the mixed carboxylate solution of oxidized carbon nanotubes and graphene oxide, 0.2 g of tetraoctyl ammonium bromide and 1.0 g of p-chloromethyl styrene were added, and the mixture was stirred and reacted in an oil bath at 98° C. for 3 h. After the reaction is complete, cool to room temperature, add 100ml of carb...

Embodiment 3

[0085] Take 1g of carbon nanotubes, add 200ml of acid solution (the volume ratio of concentrated sulfuric acid to concentrated nitric acid is 3:1) and reflux for oxidation for 20min. After the oxidation is completed, the reaction solution is filtered, washed with water for 5 times, and vacuum-dried at 60° C. to obtain oxidized carbon nanotubes. Graphene oxide was prepared by the Hummers method.

[0086] Mix carbon oxide nanotubes and graphene oxide powder at a mass ratio of 1:3, disperse them into 100ml of a dispersion with a concentration of 1mg / ml by ultrasonic or stirring, add an alkali solution with a concentration of 1mmol / L, and adjust the pH to 9 to prepare To the mixed carboxylate solution of oxidized carbon nanotubes and graphene oxide, 0.2 g of tetraoctyl ammonium bromide and 1.0 g of p-chloromethyl styrene were added, and the mixture was stirred and reacted in an oil bath at 98° C. for 3 h. After the reaction is complete, cool to room temperature, add 100ml of chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com