Graphene/HDPE thermistor composite material and preparation method

A high-density polyethylene and composite material technology, applied in graphene/high-density polyethylene PTC thermistor composite material and preparation, polymer-based PTC thermistor composite material field, can solve the problem of low conductive filler content, carbon nanometer Tubes are easily entangled with each other, and PTC strength is low, so as to achieve the effect of high PTC strength, avoiding environmental pollution problems and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of polymer-based PTC thermistor composite material of the present invention, the preparation steps of this composite material are as follows:

[0025] (1) Use a high-speed universal pulverizer to pulverize high-density polyethylene (HDPE) particles, the powder particle size is 100-500 μm, and then weigh a certain amount of pulverized HDPE and graphene according to the ratio (the particle size of graphene powder is 10 ~60μm), and finally mix the two evenly.

[0026] (2) Add the mixture obtained in step (1) into a torque rheometer and melt blend for 5-15 minutes at a temperature of 150-180° C. and a rotational speed of 80-100 r / min.

[0027] (3) Add an appropriate amount of the blend obtained in step (2) into a mold with a thickness of 0.1 to 3mm, preheat on a flat vulcanizing machine at a temperature of 150 to 180°C for 5 to 10 minutes, and hot press for 5 to 15 minutes at a pressure of 10 to 10 minutes. 15MPa, take it out after cooling to room te...

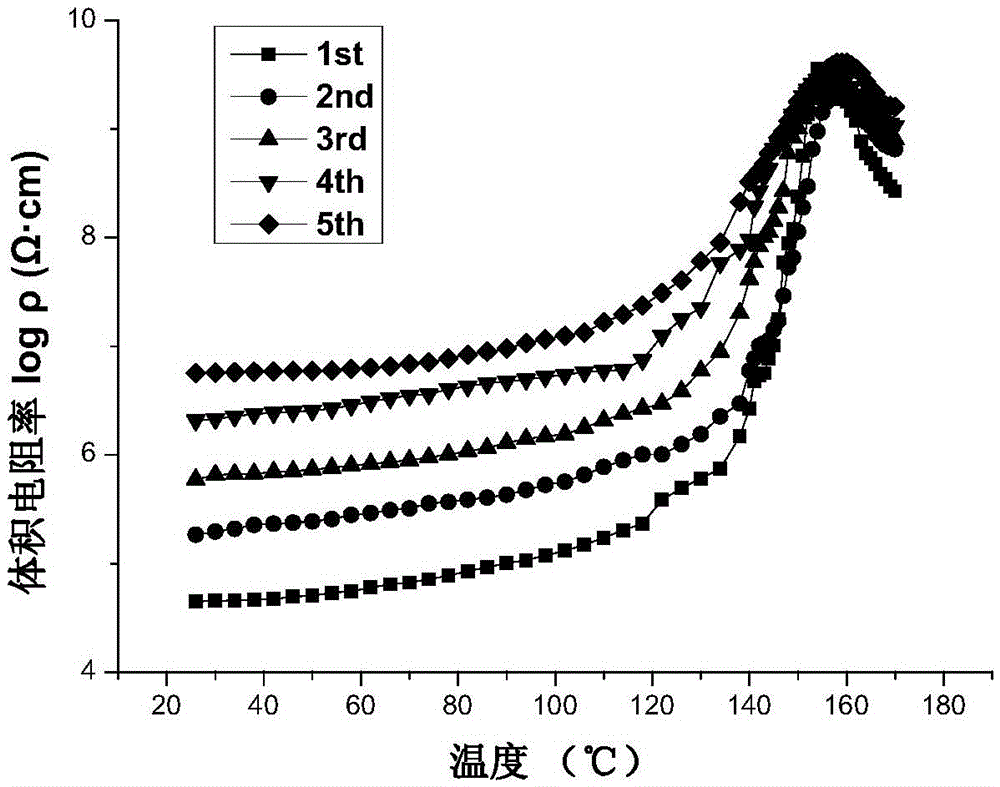

Embodiment 1

[0031] 48g high-density polyethylene powder and 0.48g (1wt%) graphene powder were premixed in a high-speed mixer at 3000rpm for 5 minutes to obtain a uniformly mixed graphene / high-density polyethylene composite powder. Then, the composite powder was blended with a torque rheometer at 160° C. and a rotational speed of 90 r / min for 10 minutes to obtain a blend of graphene and high-density polyethylene. Then the obtained blend was added to a mold with a thickness of 2mm, preheated on a flat vulcanizer at 160°C for 7 minutes, hot pressed for 10 minutes at a pressure of 12MPa, cooled to room temperature and taken out to obtain a composite sheet. After the material was shaped, it was taken out and cooled to room temperature; the prepared plate was put into a vacuum incubator for heat treatment, kept at 130°C for 18 hours, and then cooled to room temperature. However, due to the high resistance of the prepared PTC composite material at room temperature, there is no obvious PTC effect...

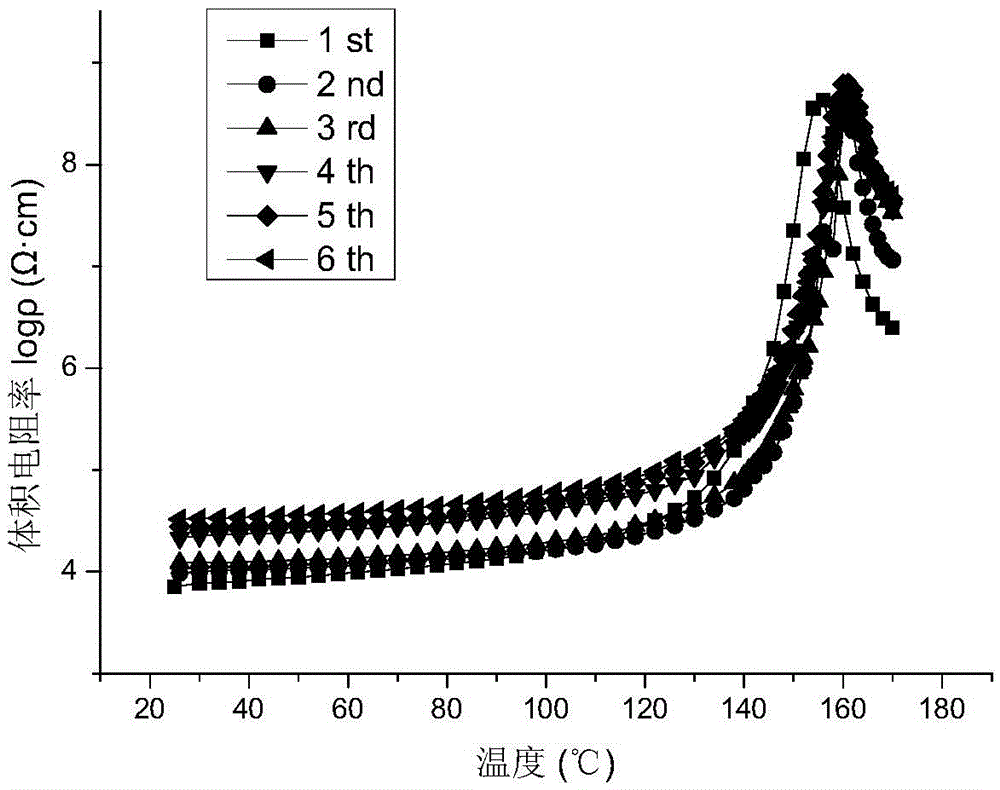

Embodiment 2

[0033] 47.01 g of high-density polyethylene powder and 1.50 g (3 wt%) of graphene powder were premixed in a high-speed mixer at a speed of 4000 rpm for 10 minutes to obtain a uniformly mixed graphene / high-density polyethylene composite powder. All the other preparation methods are the same as in Example 1. The resistance of the obtained PTC material is still large at room temperature, so there is no obvious PTC effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com