PTC thermistor and substrate applied therein and manufacturing method thereof

A technology of thermistor and manufacturing method, applied in the direction of resistors with positive temperature coefficient, etc., can solve the problems of poor ability to withstand high current multiple shocks, low PTC strength, etc., and achieve the ability to withstand high current multiple shocks Good, low resistance, good for absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also proposes the second preparation method of the thermistor, which includes the following steps:

[0042] Step 1: Preheat the conductive filler and auxiliary filler at 70-180°C for 2-24 hours before use;

[0043] Step 2: Pre-mix a polymer material, auxiliary filler, and antioxidant to make a masterbatch, mix it with another polymer material at room temperature, and mix it with conductive filler, coupling agent, crosslinking agent, and sensitizer The cross-linking agent is mixed at a temperature of 30-60 °C above the melting point of the polymer material, and then extruded or hot-pressed by a single-screw extruder;

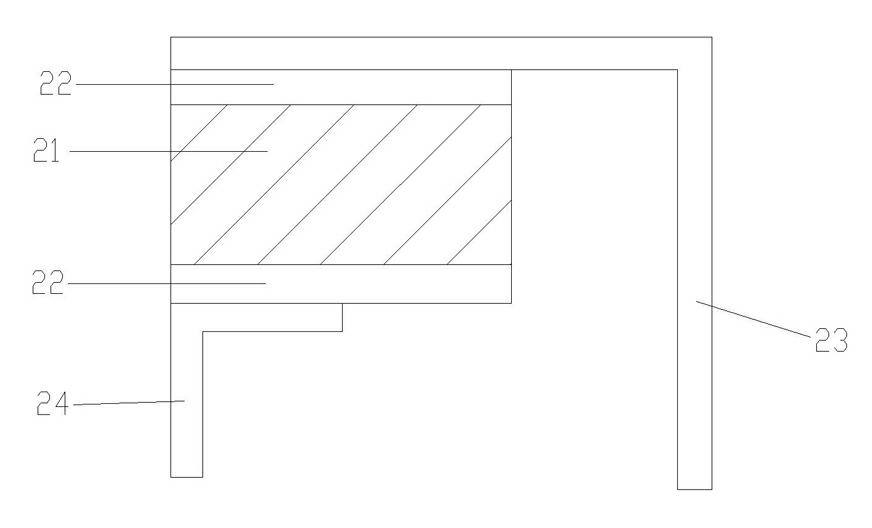

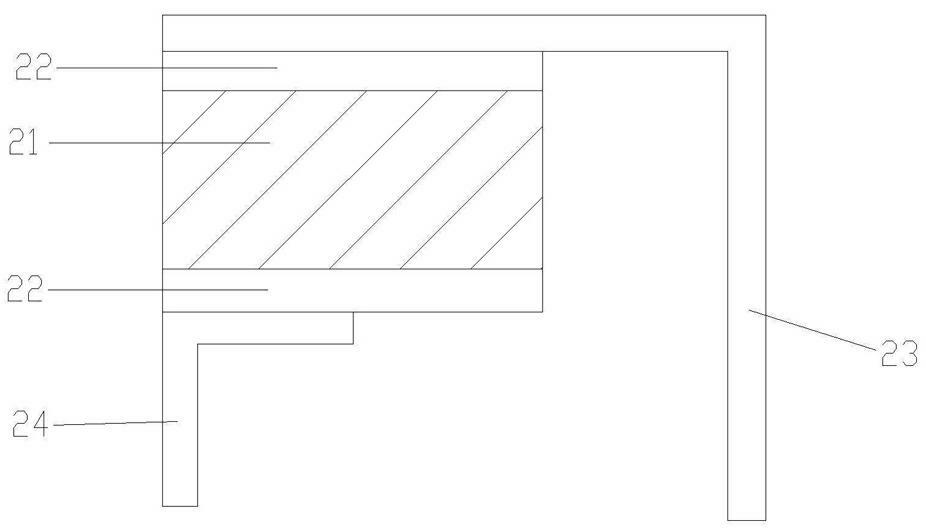

[0044] Step 3: Composite the metal electrodes on the upper and lower surfaces of the sheet by hot pressing, and perform heat treatment, punch into chips on a punching machine and pass through gamma rays, electron accelerators or cobalt sources (Co 60 ) for radiation cross-linking, the radiation dose is 70~200KGY;

[0045] Step 4: Af...

Embodiment 1

[0049] First preheat the conductive filler and auxiliary filler in an oven at 110 degrees for 4 hours, and then put

[0050] Conductive filler: carbon black (VXC200 model produced by Cabot Corporation of the United States) 660g,

[0051] Auxiliary filler: magnesium hydroxide 600g,

[0052] Coupling agent: vinyltriethoxysilane 24g

[0053] Mix well in a high speed blender, mix the above mixture with

[0054] Polymer material: high-density polyethylene 1000g,

[0055] Cross-linking agent: DCP (dicumyl peroxide) 3.6g,

[0056] Sensitizing crosslinking agent: Trimethylolpropane triacrylate 30g,

[0057] Antioxidants: Tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester (Antioxidant 1010) 4g, and tris(2,4-diphosphite tert-butylphenyl) ester (antioxidant 168) 12g, put into the internal mixer and knead at 180°C, after 10 minutes of kneading time, the material will be crushed, and the above crushed product will be uniformly mixed at room temperatu...

Embodiment 2

[0064] First preheat the conductive filler and auxiliary filler in an oven at 110 degrees for 4 hours, and then put

[0065] Conductive filler: carbon black (model VXC605 produced by Cabot Corporation of the United States) 460g,

[0066] Auxiliary filler: alumina 800g,

[0067] Mix well at room temperature, then mix the above mixture with

[0068] Polymer material: 800g high-density polyethylene,

[0069] Sensitizing crosslinking agent: Trimethylolpropane trimethacrylate 20g,

[0070] Add it into the internal mixer and mix it at 180°C. After 10 minutes of mixing time, the material will be crushed. Mix the above crushed material evenly at room temperature and then mix it in the twin-screw extruder. The temperature of each section of the extruder Set at 170°C, 180°C, 190°C, and 200°C respectively, and extrude the pull sheet into a sheet with a thickness of 1.6mm;

[0071] Combine the nickel foil that has been roughened on one side on the upper and lower surfaces of the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com