Cable filler composition

A technology of cable filling and composition, which is applied in the field of automatic temperature-controlling cable filler composition, which can solve the problems of general flame retardancy and achieve the effects of high PTC strength, good temperature control performance and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

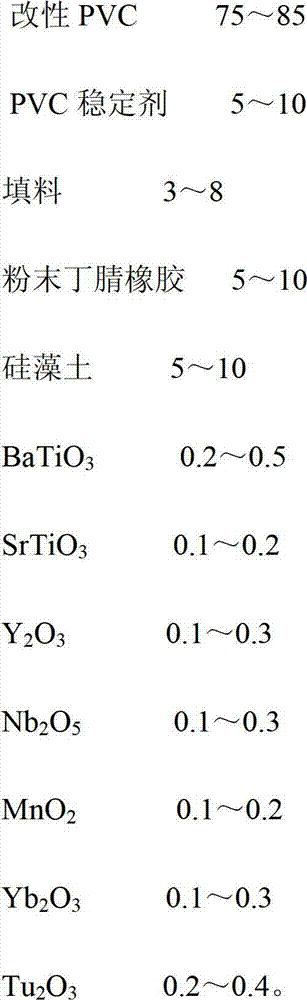

Method used

Image

Examples

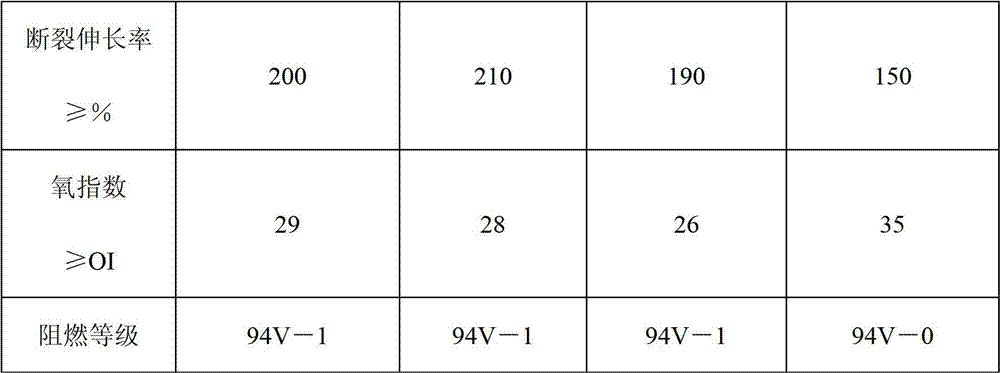

Embodiment 1

[0016] 75Kg modified PVC, 7Kg PVC stabilizer, 3Kg calcium carbonate filler, 8Kg powdered nitrile rubber, 6Kg diatomaceous earth, 0.4Kg BaTiO 3 , 0.15Kg SrTiO 3 , 0.2Kg Y 2 o 3 , 0.3Kg Nb 2 o 5 , 0.15Kg MnO 2 , 0.2Kg Yb 2 o 3 , 0.3Kg Tu 2 o 3 Put it into a high-speed mixer and heat and mix for 20 minutes at a heating temperature of 115°C; BaTiO 3 , SrTiO 3 , Y 2 o 3 , Nb 2 o 5 , MnO 2 , Yb 2 o 3 , and Tu 2 o 3 The fineness is 1500 mesh; the mixed material is extruded and granulated by a granulator to obtain a cable filler composition. The automatic temperature control cable material filler composition is used in the production of heating cables to make automatic temperature control type heating cables, and the self-limiting temperature of the heating cables is 78±4°C.

Embodiment 2

[0018] 80Kg modified PVC, 8Kg PVC stabilizer, 4Kg calcium carbonate filler, 5Kg powdered nitrile rubber, 5Kg diatomaceous earth, 0.2Kg BaTiO 3 , 0.2Kg SrTiO 3 , 0.15Kg Y 2 o 3 , 0.2Kg Nb 2 o 5 , 0.2Kg MnO 2 , 0.2Kg Yb 2 o 3 , 0.4KgTu 2 o 3 Put it into a high-speed mixer and heat and mix for 30 minutes at a heating temperature of 110°C; BaTiO 3 , SrTiO 3 , Y 2 o 3 , Nb 2 o 5 , MnO 2 , Yb 2 o 3 , and Tu 2 o 3 The fineness is 1500 mesh; the mixed material is extruded and granulated by a granulator to obtain a cable filler composition. The automatic temperature control cable material filler composition is used in the production of heating cables to make automatic temperature control type heating cables, and the self-limiting temperature of the heating cables is 73±4°C.

Embodiment 3

[0020] 85Kg modified PVC, 5Kg PVC stabilizer, 3Kg calcium carbonate filler, 7Kg powdered nitrile rubber, 6Kg diatomaceous earth, 0.5Kg BaTiO 3 , 0.1Kg SrTiO 3 , 0.3Kg Y 2 o 3 , 0.1Kg Nb 2 o 5 , 0.15Kg MnO 2 , 0.2Kg Yb 2 o 3 , 0.3KgTu 2 o 3 Put it into a high-speed mixer and heat and mix for 25 minutes at a heating temperature of 117°C; BaTiO 3 , SrTiO 3 , Y 2 o 3 , Nb 2 o 5 , MnO 2 , Yb 2 o 3 , and Tu 2 o 3 The fineness is 2000 mesh; the mixed material is extruded and granulated by a granulator to obtain a cable filler composition. The automatic temperature control cable material filler composition is used in the production of heating cables to produce automatic temperature control type heating cables, and the self-limiting temperature of the heating cables is 71±4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com