Low-resistance type automatic-temperature-limited polymer heat tracing cable

A polymer, temperature tracing technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of low PTC strength and high low temperature resistivity, and achieve the effect of improving PTC strength, improving gelation, and improving PTC strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

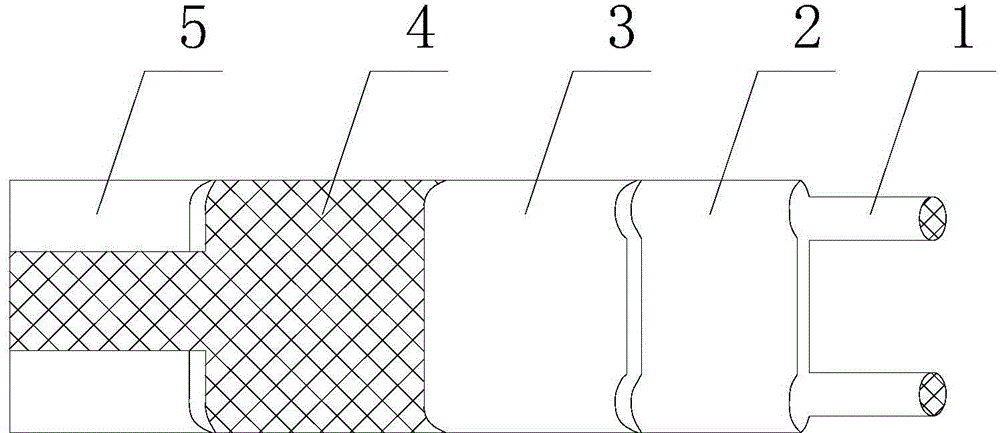

[0019] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a low-resistance polymer self-limiting temperature tracing heating cable proposed by the present invention.

[0020] refer to figure 1 , a low-resistance polymer self-limiting temperature heating cable proposed by the present invention includes a flat strip-shaped PTC core strip, and the PTC core strip is composed of two heating wires 1 arranged in parallel and a PTC material layer coated on the outside 2, the PTC core tape is coated with an insulating layer 3, a metal shielding layer 4 and a wear-resistant sheath layer 5 in sequence; the PTC material is a polymer-based PTC composite material.

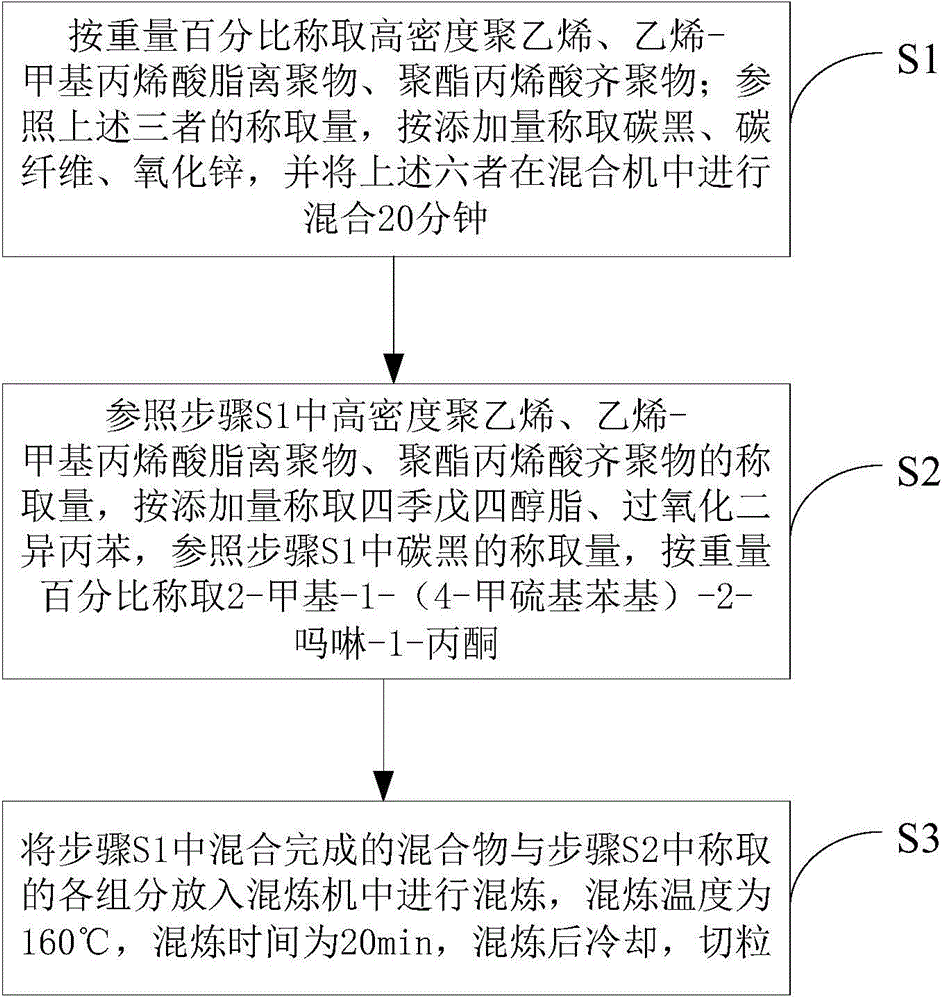

[0021] In one embodiment, the polymer-based PTC composite material is made of high-density polyethylene, carbon black, ethylene-methacrylate ionomer, polyester acrylic oligomer, carbon fiber, tetraerythritol fat, zinc oxide, peroxide Made of dicumyl, 2-methyl-1-(4-methylthiophenyl)-2-morpholine-1-prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com