Process for preparing electrically conductive high-molecular composite material by in-situ graft to modify electrically conductive filler

A technology of conductive composite materials and conductive fillers, which is applied in the field of conductive polymer composite materials, can solve the problems of strict chemical cross-linking processing technology, damage to the mechanical properties of composite materials, high cross-linking requirements, etc., and achieve continuous work and intermittent Effects of long working life, improved repetitive stability, and good thermal conductivity

Inactive Publication Date: 2002-08-14

SUN YAT SEN UNIV

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The usual cross-linking methods include chemical cross-linking, radiation cross-linking or silane cross-linking, etc. Although they are of great help to improve the electrical properties of materials, there are also some problems in practical applications: firstly, cross-linking has great influence on the process or Equipment has high requirements, for example, chemical cross-linking has strict requirements on processing technology, which is difficult to control during processing, and radiation cross-linking requires high-energy radiation sources, which are not available in general factories.

In addition, cross-linking also damages the mechanical properties of composite materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0061] Example 1 880 1.10×10 2 72 89 17

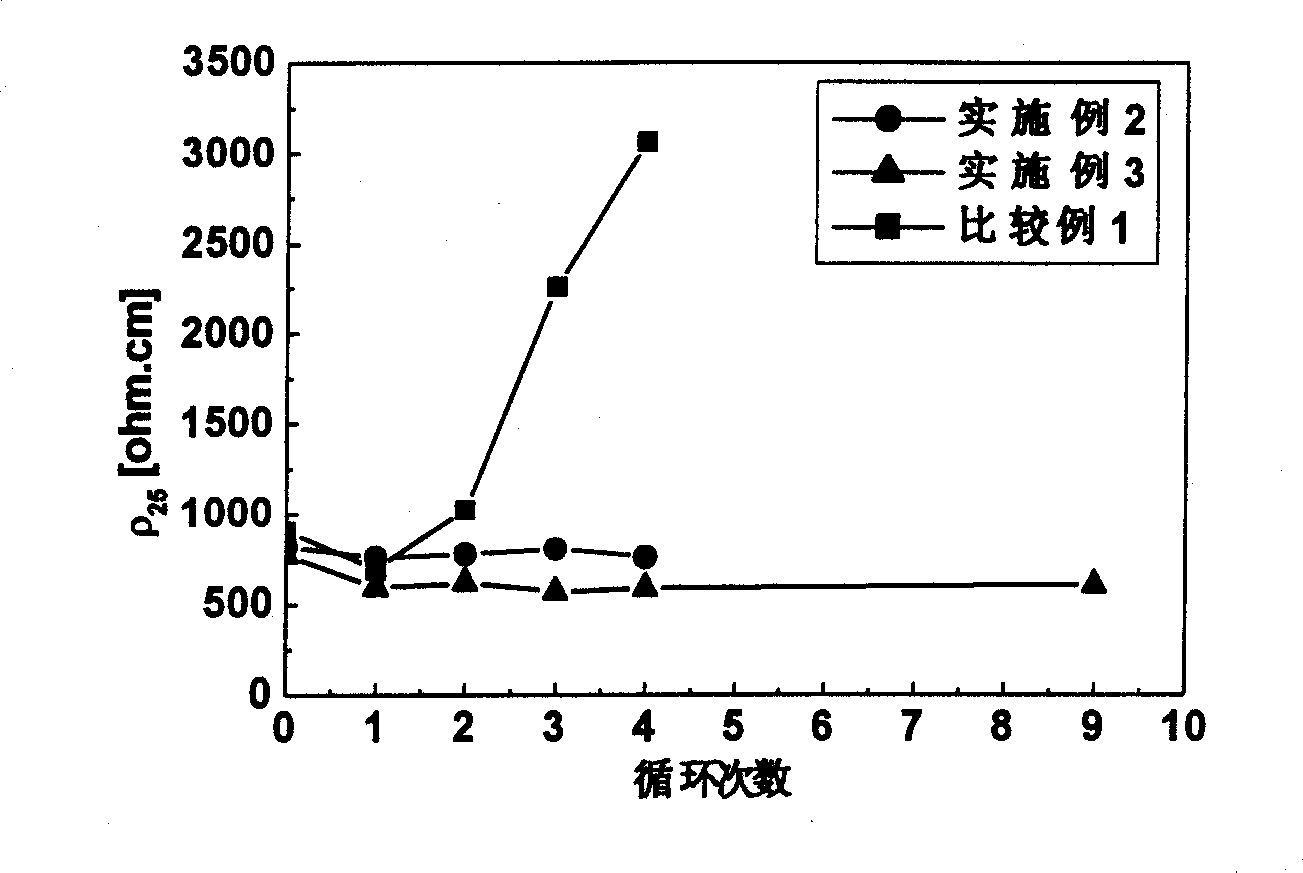

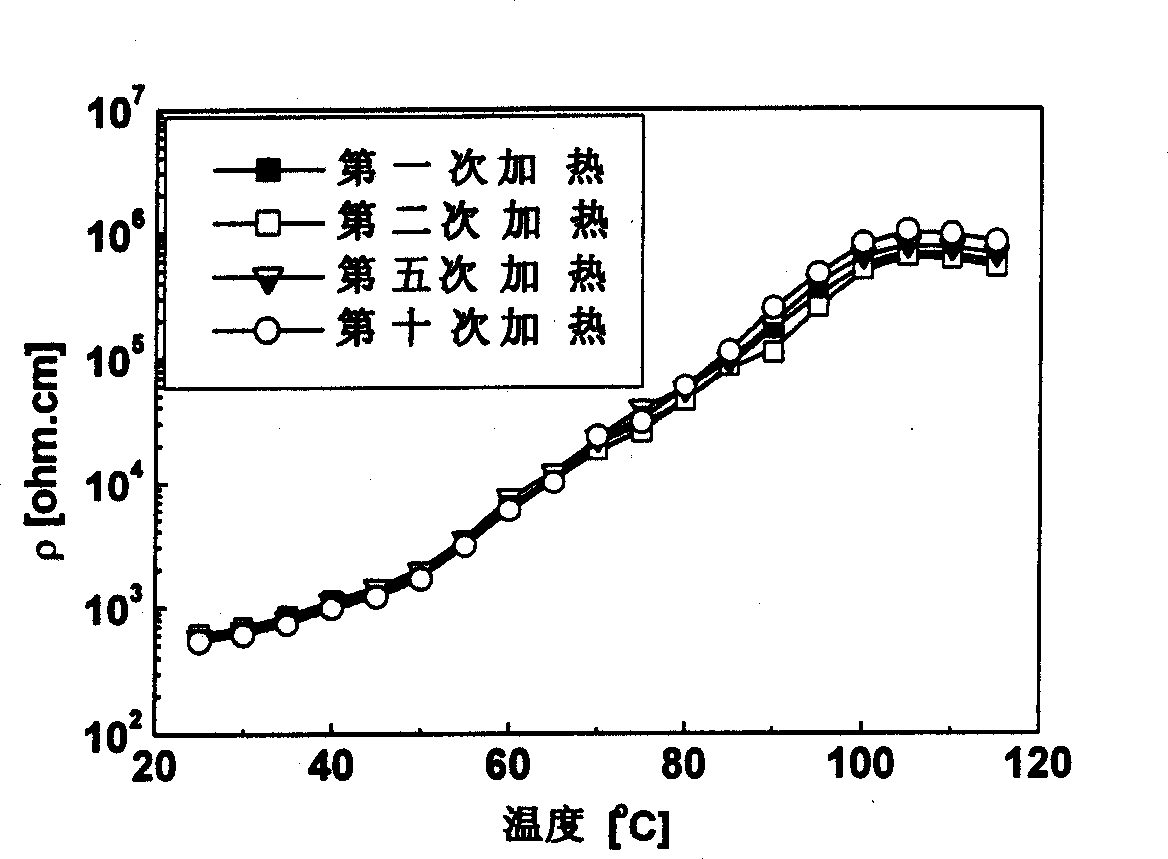

Embodiment 2

[0062] Example 2 865 1.60×10 2 71 87 16

Embodiment 3

[0063] Example 3 810 1.23×10 3 69 81 12

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

An electrically conductive composite high-molecular material with positive temp coefficient (PTC) for heater with self limitation of temp and over-current protection element is prepared through pre-treating the electrically conductive filler by reactive treating agent and chemically graft reaction between said filler, treating agent and high-molecular base body. Its advantages include high adhesive to metallic electrode, high PTC and high stability.

Description

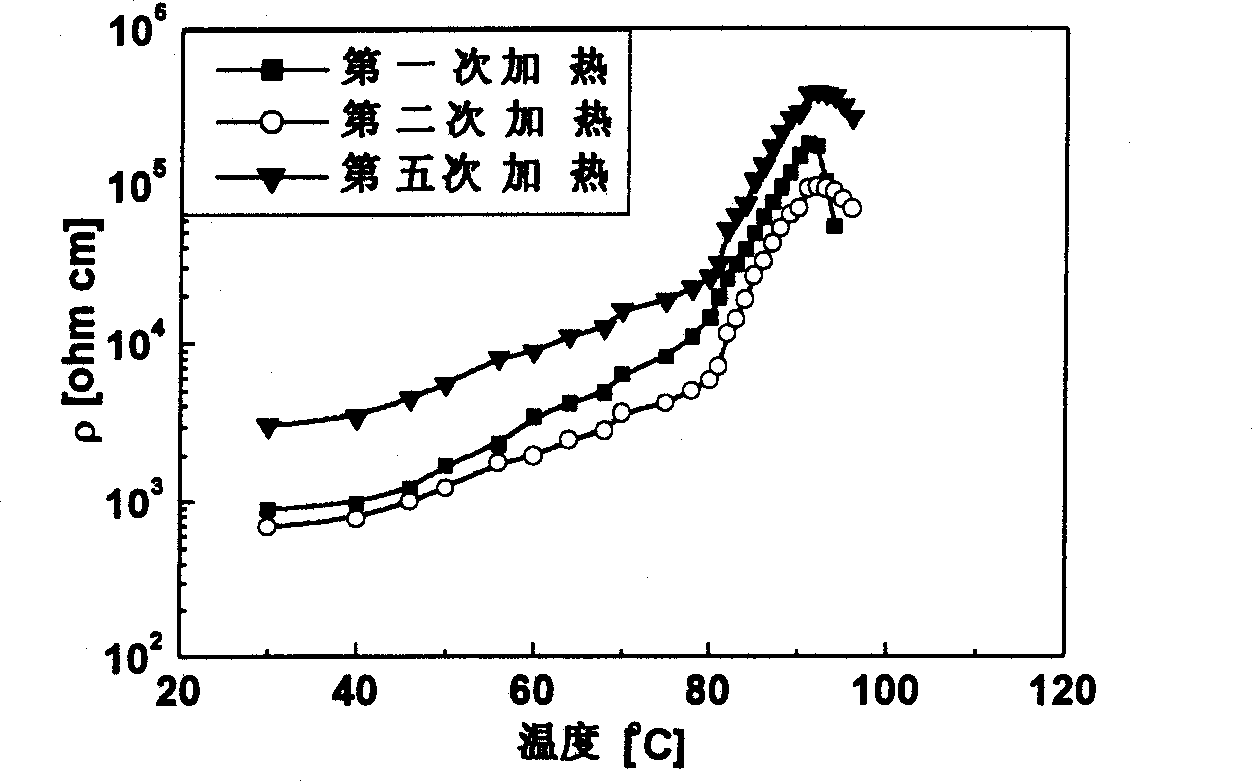

technical field [0001] The invention relates to a conductive polymer composite material with a positive temperature coefficient (PTC) which is formed by modifying a conductive filler to fill a polymer or a resin matrix of a blend thereof by using an in-situ grafting method. Background technique [0002] A conductive polymer composite material with positive temperature coefficient characteristics composed of a single polymer matrix filled with unmodified conductive fillers such as carbon black, has adjustable conductivity in a wide range, easy to shape, and flexible , low cost and high PTC strength (≥10 5 ) and other characteristics (see: US4,514,620; US4,732,701; US5,164,133; CN87102932; CN87102924). On this basis, the PTC composite material (Chinese patent application: CN97108956) composed of a blended polymer matrix is filled with an unmodified conductive filler, so that the stability of the PTC effect of the composite material is improved...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08K3/04C08L33/00

Inventor 张明秋侯艳辉容敏智

Owner SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com