Electrically conductive composite material possessing positive temperature coefficient

A conductive composite material and positive temperature coefficient technology, applied in the field of conductive polymer composite materials, can solve the problems of strict chemical cross-linking processing technology, damage to the mechanical properties of composite materials, high cross-linking requirements, etc., to achieve continuous work and The effects of long intermittent operation life, improved repetitive stability, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through embodiments and accompanying drawings.

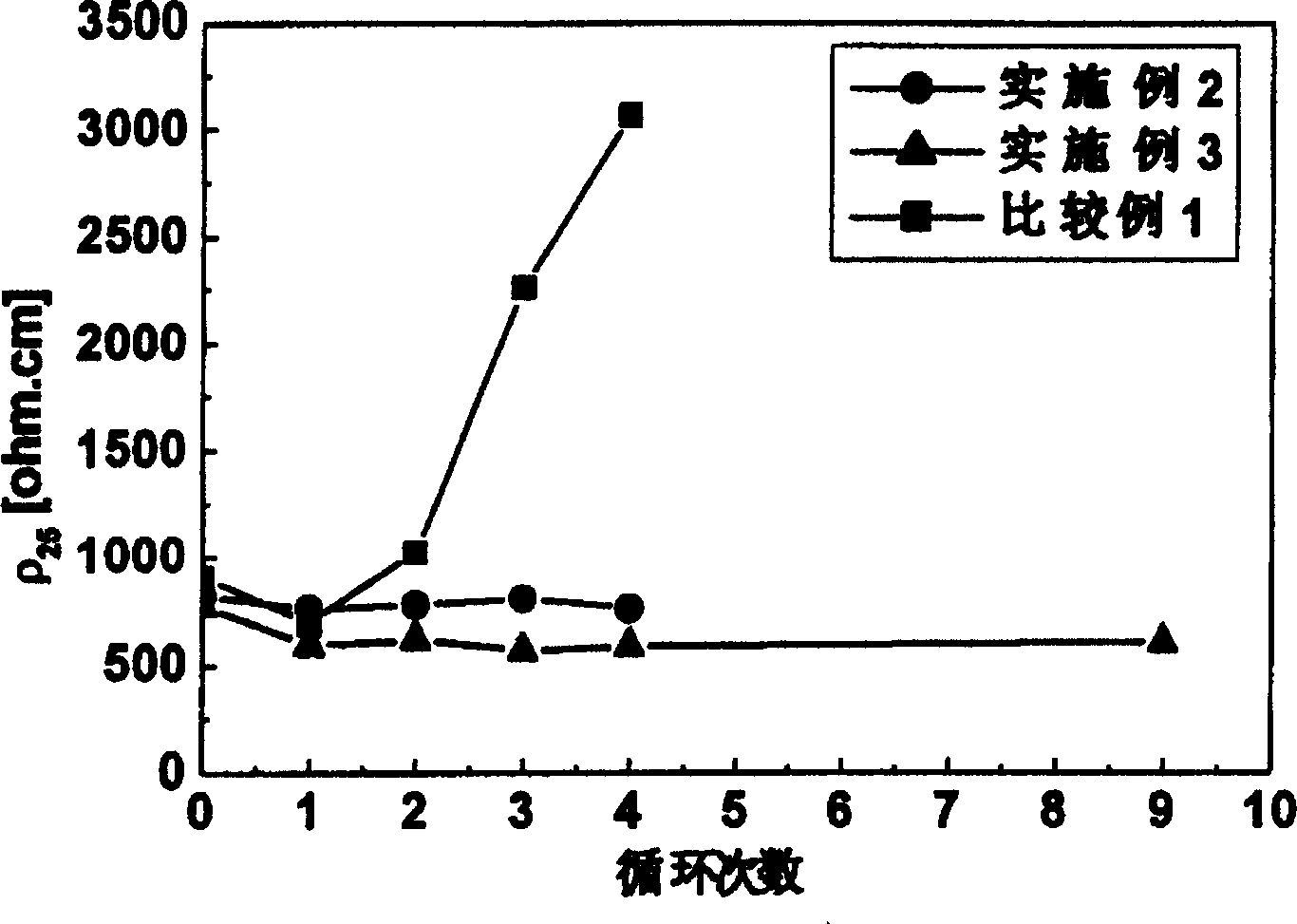

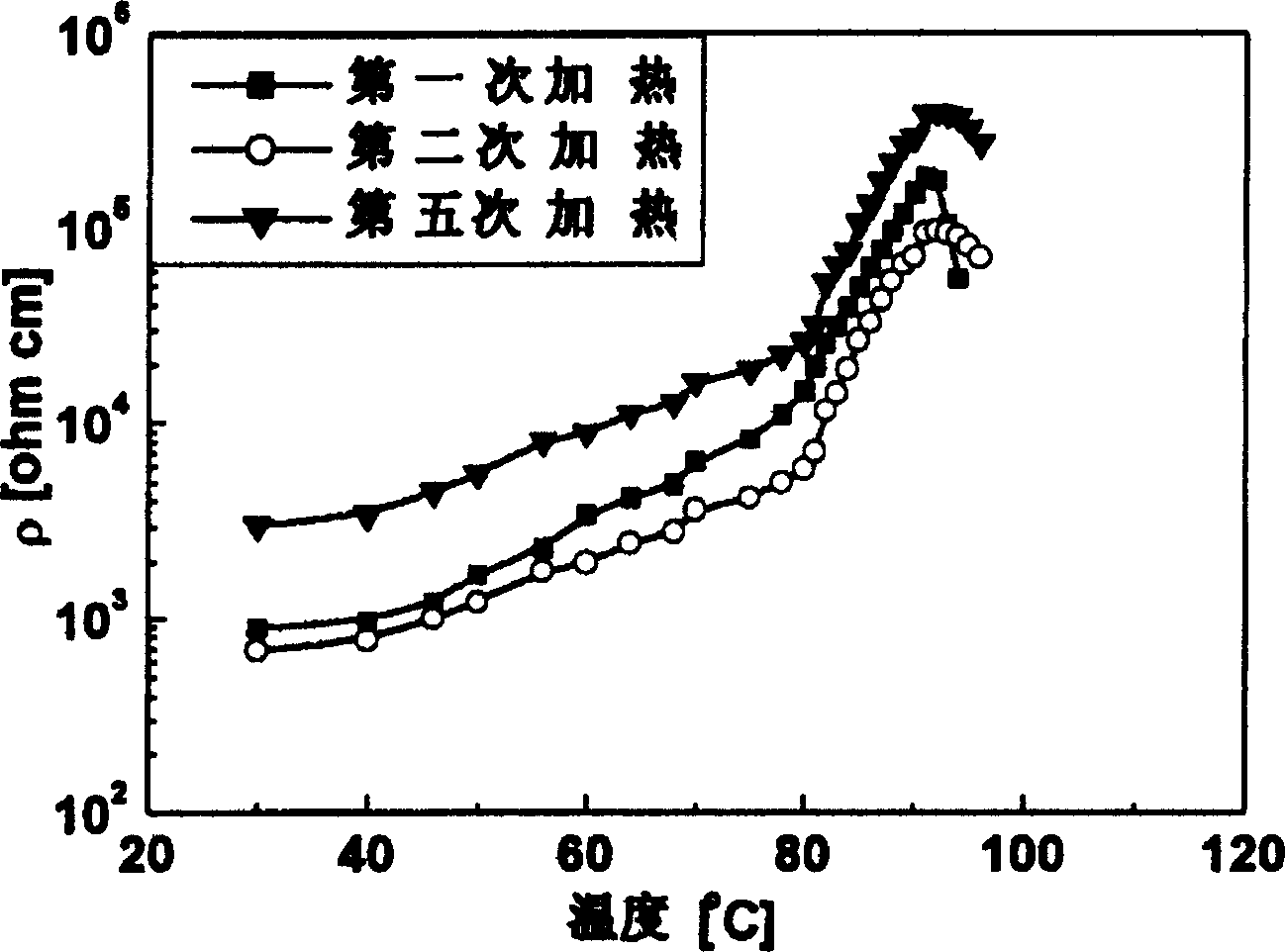

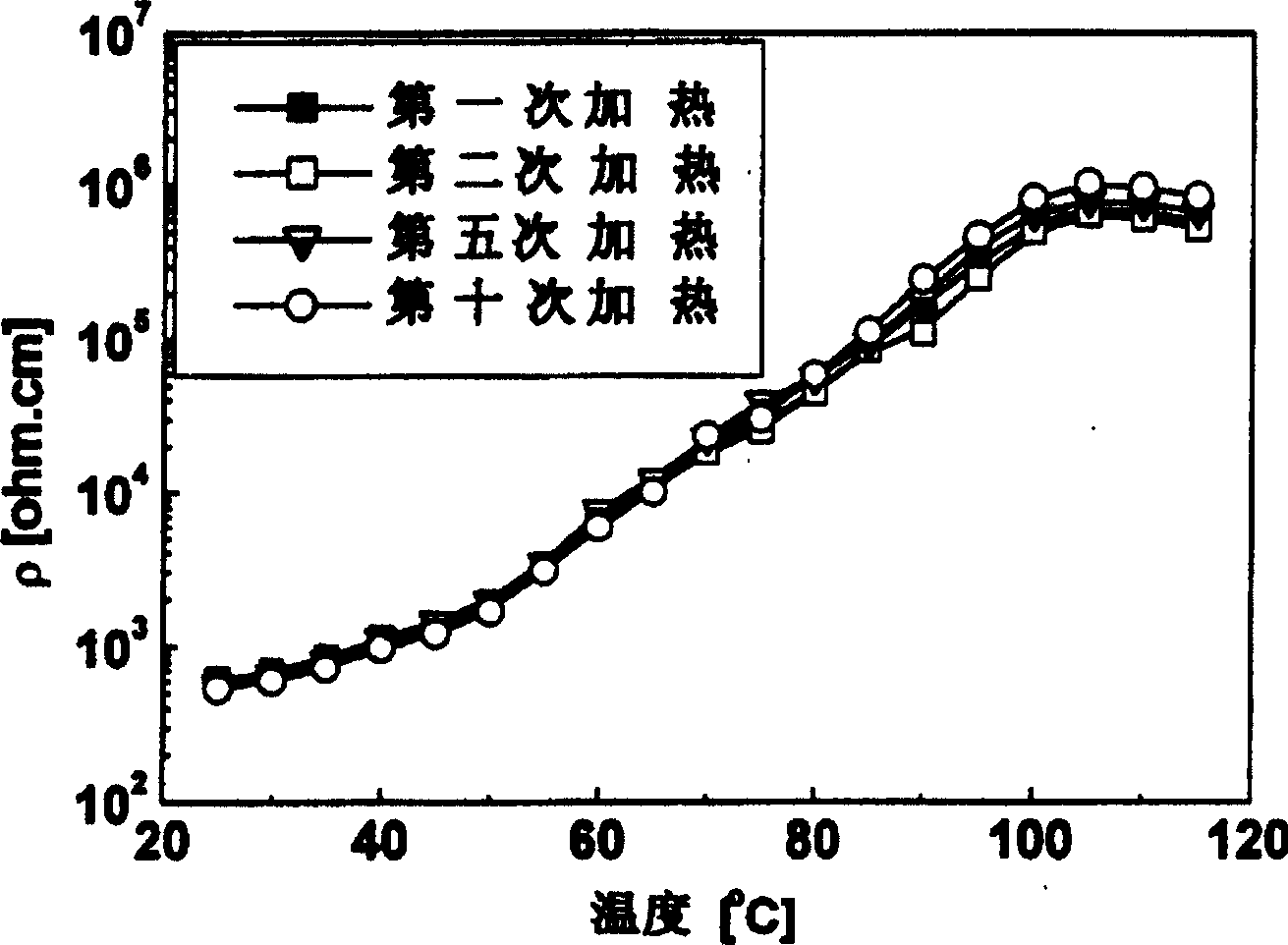

[0032] Examples 1-11 manufactured PTC conductive composite materials according to the above-mentioned specific steps and process conditions, and Comparative Examples 1-4 except that the conductive filler was not treated, other steps and process conditions were the same as in the examples. Following table 1, table 2 are the character of each component raw material used in embodiment and comparative example, and table 3 is the charging amount (by weight) of component raw material in each embodiment and comparative example, and table 4 is each embodiment And the performance of the product composite material of comparative example.

[0033] type

[0034] The average particle size

[0035] A1 / A2

[0036] Room temperature resistivity

[0037] *In order to characterize the PTC effect of the material or the characteristics of the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com