Oxide-containing high-molecular carbon paste and preparation method for heating material with PTC effect

A technology for heating materials and oxides, applied in the field of preparation of heating materials, can solve the problems of limited production and use, type and state can not meet market demand, insufficient distribution of fillers, etc., to achieve soft structure, inhibition of NTC effect, thermal conductivity, etc. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

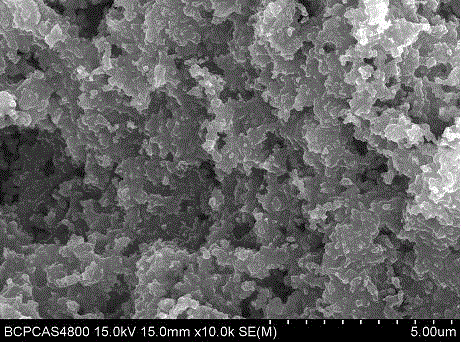

[0032] Example 1 Weigh 25g of methyl vinyl silicone rubber raw rubber (M= 600 000, vinyl content 0.15 mol %), put it into a three-necked flask, add 100g of xylene to it, start stirring at 60°C, and replenish it from time to time Add xylene, after the raw methyl vinyl silicone rubber is dissolved, add 7.5g of carbon black (20-40nm in particle size) and 1.5g of nano-silica (25-40nm in particle size) into the three-necked flask in proportion Continue to stir, and add 80g xylene, after the solution is uniform, stop the reaction and leave it to cool, make the polymer carbon slurry containing oxide, figure 1 It is the SEM image of the carbon paste. It can be seen from the figure that the carbon black is evenly distributed in the methyl vinyl silicone rubber, and the average particle size is 80nm. Glass fiber mesh cloth with a mesh size of 10×10mm is used to make mesh structures of 8×6cm, 10×10cm, and 14×10cm respectively, and copper wires are tied on both sides of the outer ends o...

Embodiment 2

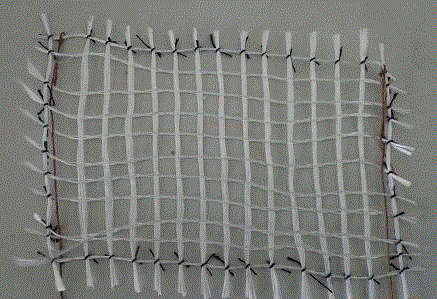

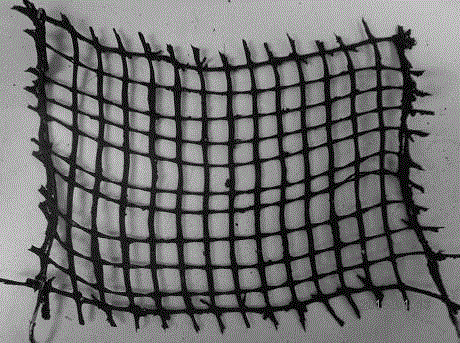

[0033] Example 2 Weigh 25g of methyl vinyl silicone rubber raw rubber (M= 600 000, vinyl content 0.15 mol %), put it into a three-necked flask, add 100g of xylene to it, start stirring at 60°C, and replenish it from time to time Add xylene, after the raw methyl vinyl silicone rubber is dissolved, add 7.5g of carbon black (20-40nm in particle size) and 3.5g of nano-silica (25-40nm in particle size) in proportion to the three-necked flask Continue to stir, and add 80g xylene, after the solution is uniform, stop the reaction and leave it to cool to make a polymer carbon slurry containing oxide. Glass fiber mesh cloth with a mesh size of 10×10mm is used to make mesh structures of 8×6cm, 10×10cm, and 14×10cm respectively, and copper wires are tied on both sides of the outer ends of the mesh warps as The electrodes are made into three specifications of heating mesh skeletons, figure 2 It is the photo of the heating grid skeleton produced. Use benzoyl peroxide (BPO) as the cro...

Embodiment 3

[0034] Example 3Weigh 25g of methyl vinyl silicone rubber raw rubber (M= 600 000, vinyl content 0.15 mol %), put it into a three-necked flask, add 100g of xylene to it, start stirring at 80°C, and replenish it from time to time Add xylene, after the raw methyl vinyl silicone rubber is dissolved, add 7.5g of carbon black (20-40nm in particle size) and 4.5g of nano-silica (25-40nm in particle size) in proportion to the three-necked flask , continue to stir, and add 80g xylene, after the solution is uniform, stop the reaction and leave it to cool to make a polymer carbon slurry containing oxide. Glass fiber mesh cloth with a mesh size of 10×10mm is used to make mesh structures of 8×6cm, 10×10cm, and 14×10cm respectively, and copper wires are tied on both sides of the outer ends of the mesh warps as The electrodes are made into three kinds of heating mesh skeletons. Use benzoyl peroxide (BPO) as the crosslinking agent, weigh 50g of PTC carbon paste, and convert the methyl vinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com