Method and system for calculating transient junction temperature of IGBT (Insulated Gate Bipolar Translator) module

A junction temperature, transient technology, applied in the field of power electronics, can solve problems such as damage, inability to realize IGBT, and lack of methods for transient junction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

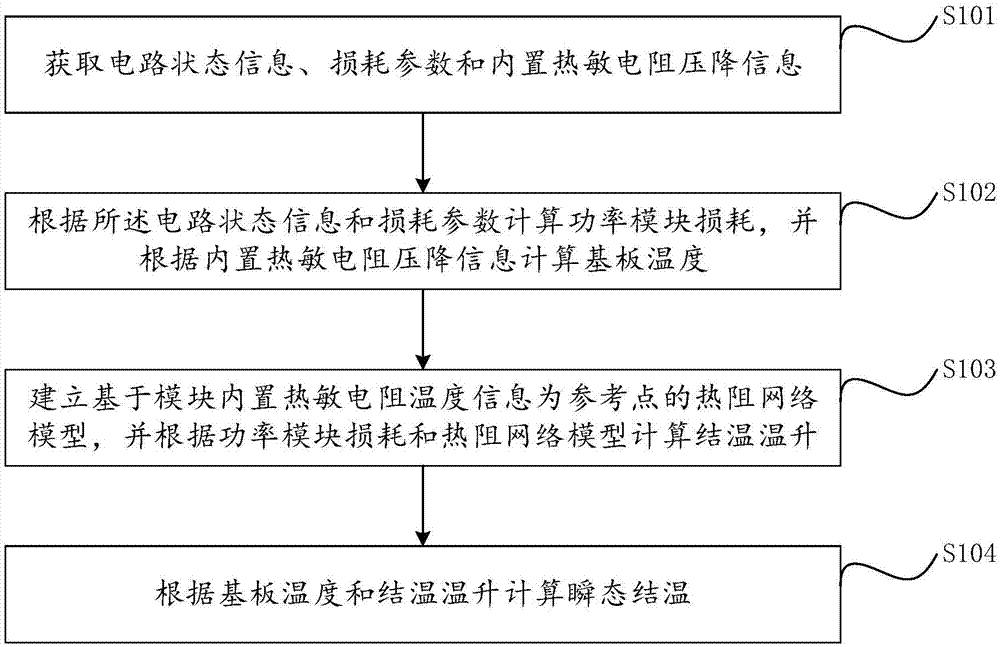

[0066] figure 1 It is a flowchart of a method for calculating the transient junction temperature of an IGBT module provided by Embodiment 1 of the present invention.

[0067] refer to figure 1 , the method of calculating the transient junction temperature of the IGBT module includes:

[0068] Step S101, obtaining circuit status information, loss parameters and built-in thermistor voltage drop information;

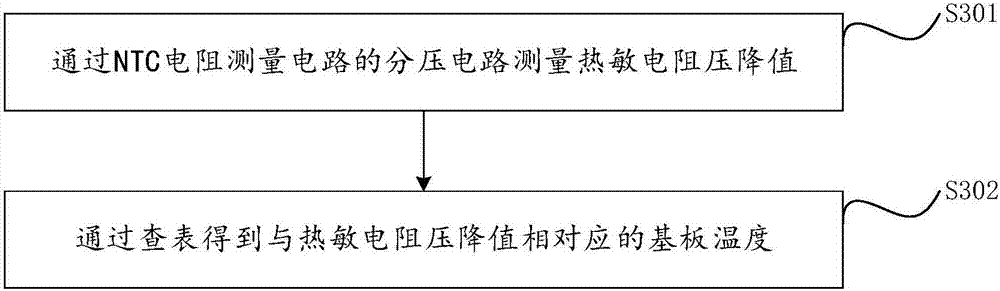

[0069] Step S102, calculating the loss of the power module according to the circuit state information and loss parameters, and calculating the substrate temperature according to the voltage drop information of the built-in thermistor;

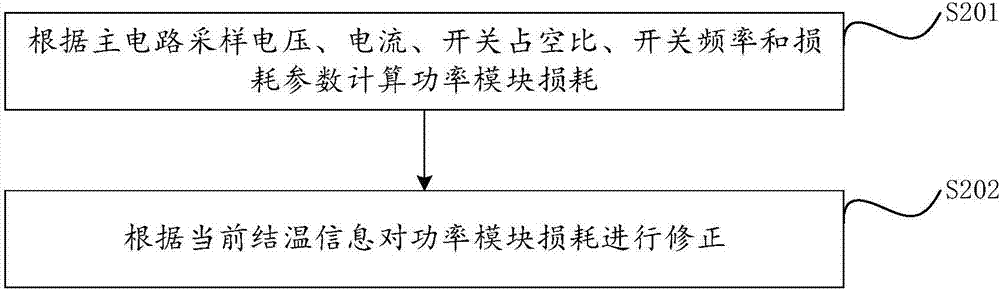

[0070] Specifically, a switching device power loss model is established. The power loss model calculates the power module loss P by sampling electrical signals such as voltage, current, switch duty cycle, switching frequency, etc. (t).

[0071] Step S103, establishing a thermal resistance network model based on the temperature informatio...

Embodiment 2

[0111] Figure 5 A system structure diagram for calculating the transient junction temperature of an IGBT module provided by Embodiment 2 of the present invention.

[0112] refer to Figure 5 , the system for calculating the transient junction temperature of the IGBT module includes:

[0113] An acquisition unit 10, configured to acquire circuit state information, loss parameters and built-in thermistor voltage drop information;

[0114] The first calculation unit 20 is configured to calculate the power module loss according to the circuit state information and loss parameters, and calculate the substrate temperature according to the voltage drop information of the built-in thermistor;

[0115] The second calculation unit 30 is used to establish a thermal resistance network model based on the temperature information of the built-in thermistor in the module as a reference point, and calculate the junction temperature rise according to the power module loss and the thermal res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com