Patents

Literature

45 results about "Membrane array" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

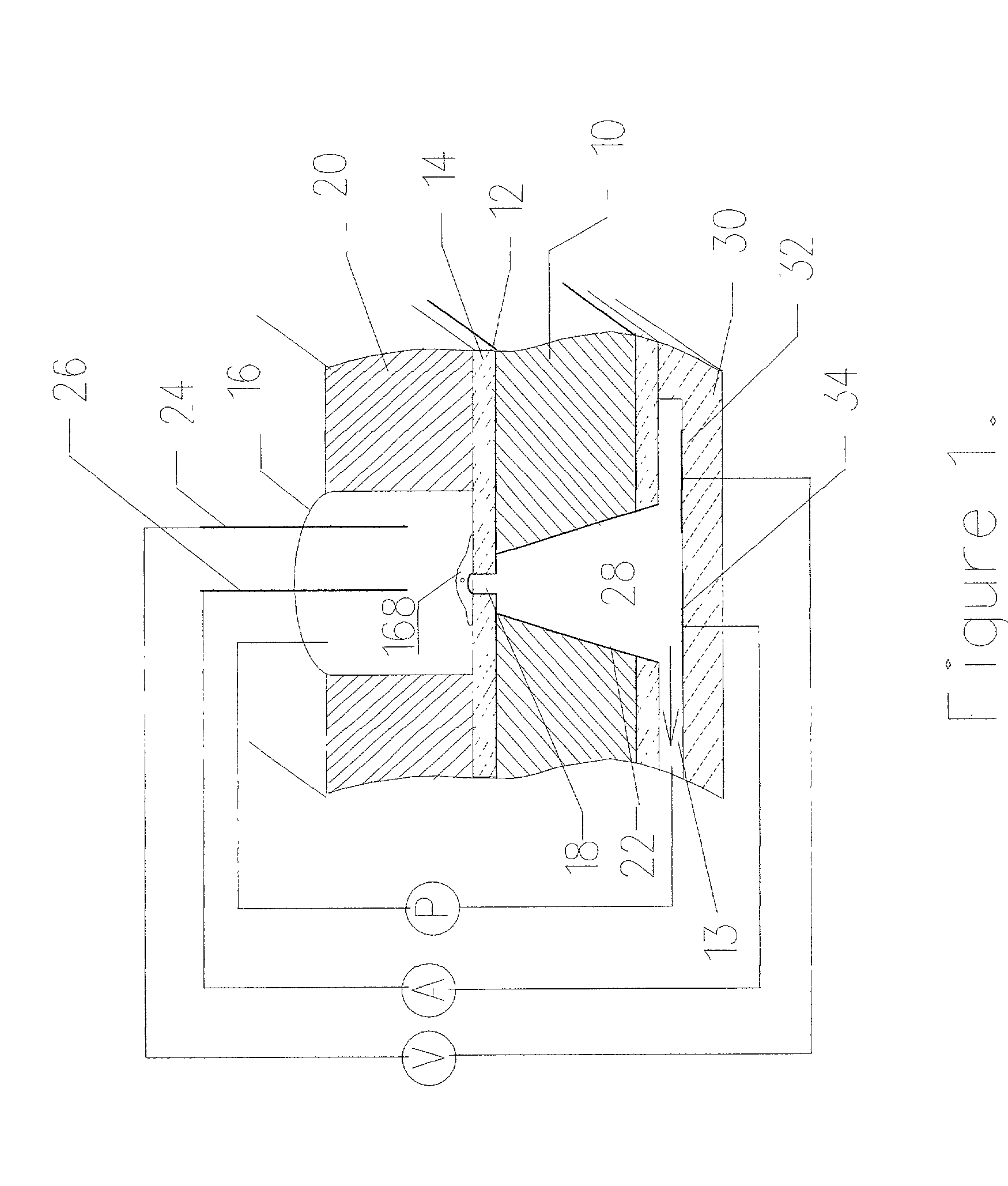

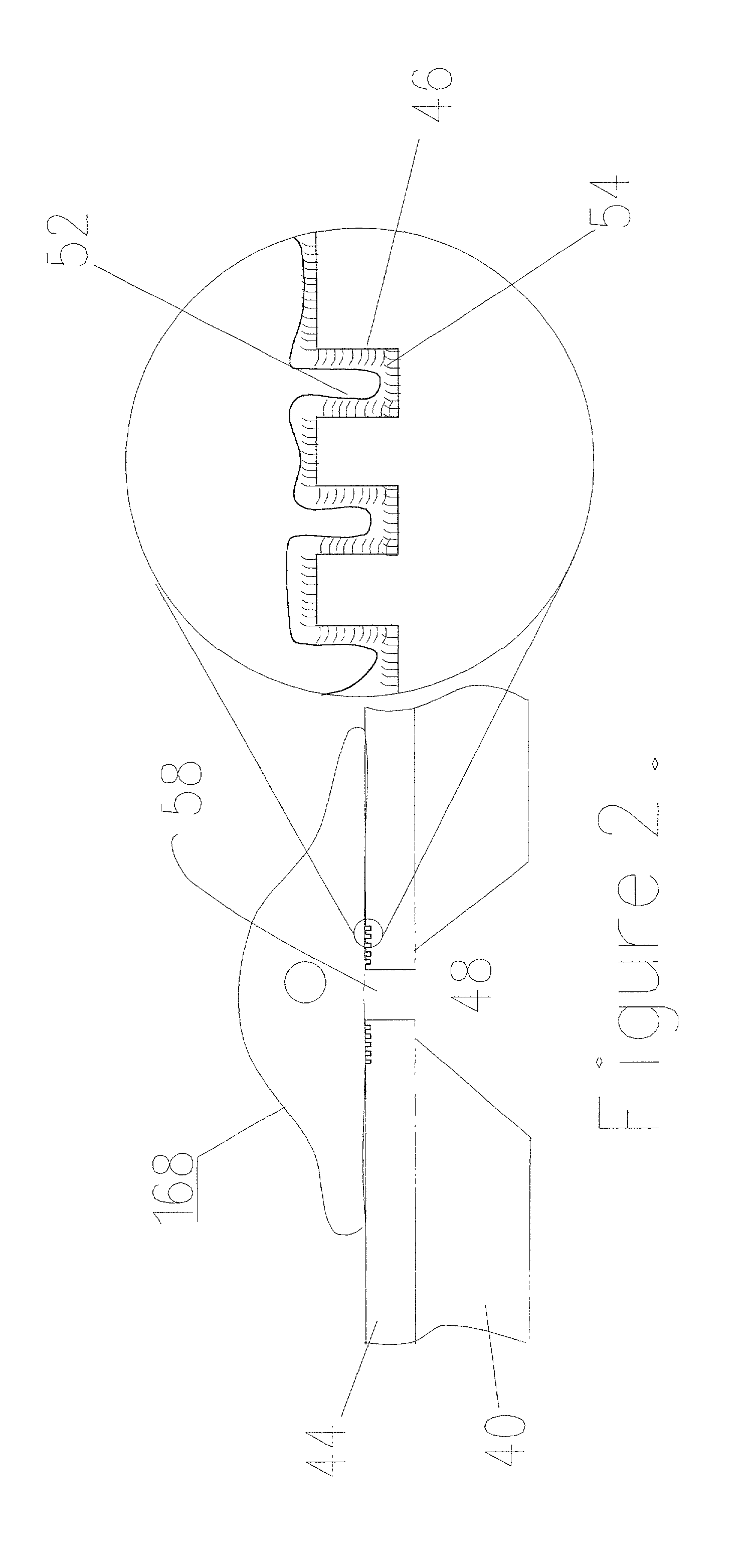

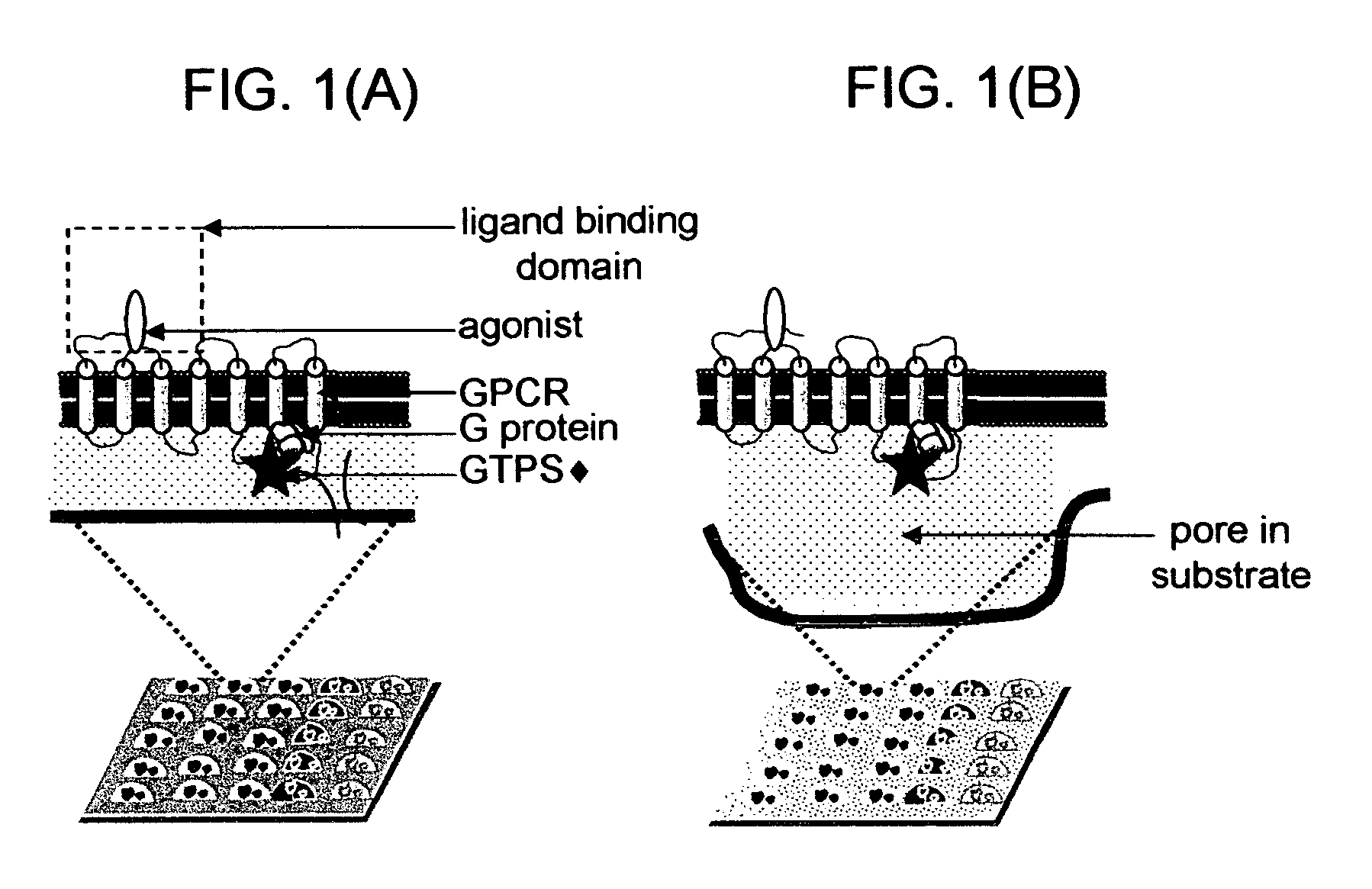

Biosensors for single cell and multi cell analysis

InactiveUS20030104512A1Microbiological testing/measurementBiological testingElectricityBiological cell

The present invention relates to a structure comprising a biological membrane and substrate with fluidic network, an array of membranes and an array of fluidic networks in substrate, a high throughput screen, methods for production of the membrane, substrate structure, and a method for interconnected array of substrate structures and a method for attaching membranes to structure, a method to electrically record events from the membranes and a method to screen large compound library using the array. More particularly, it relates to biological cells and artificial cell membranes adhered to the substrate with a high electrical resistivity seal, a method to manufacture array configuration of such substrates, and a method to screen compounds using the membrane receptors such as ion-channels, ion pumps, & receptors.

Owner:CYTOPLEX BIOSCI

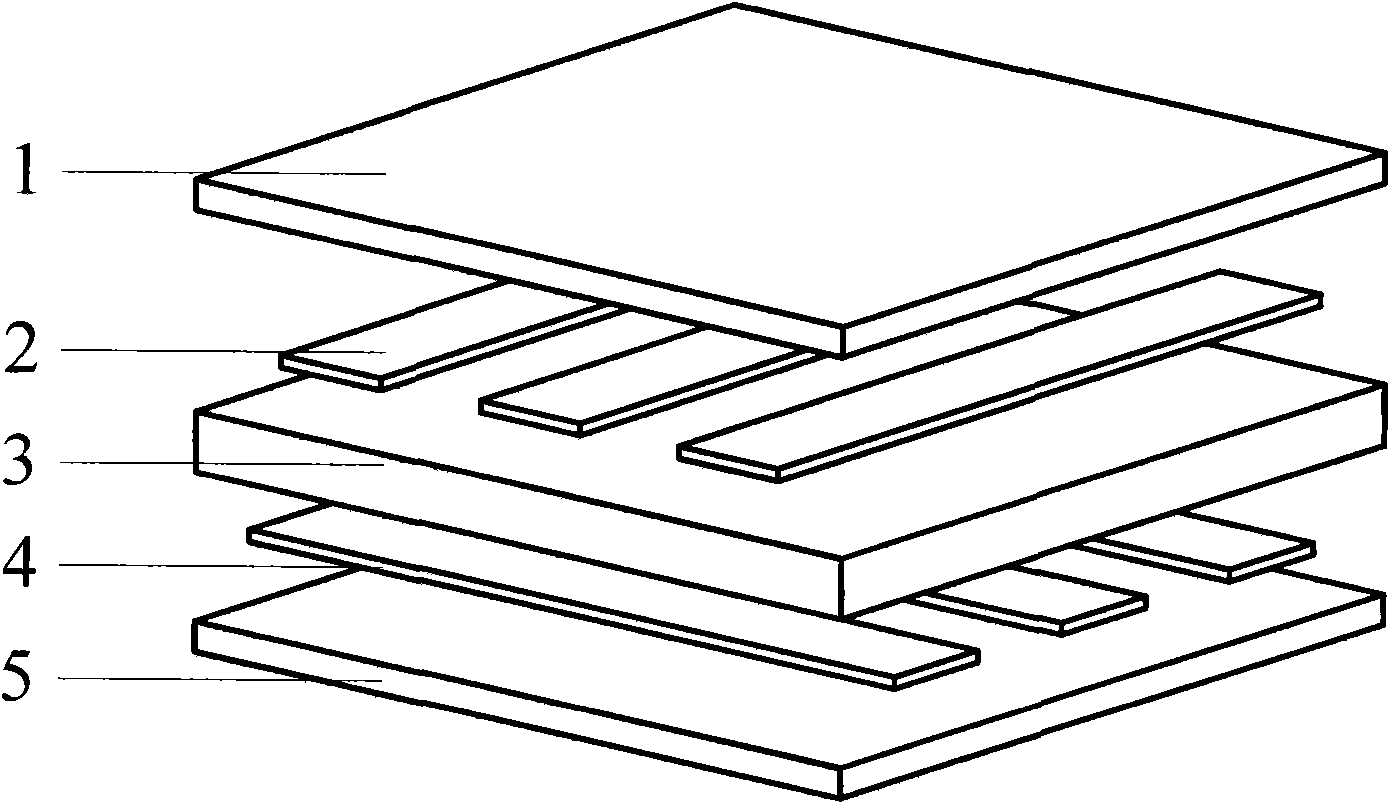

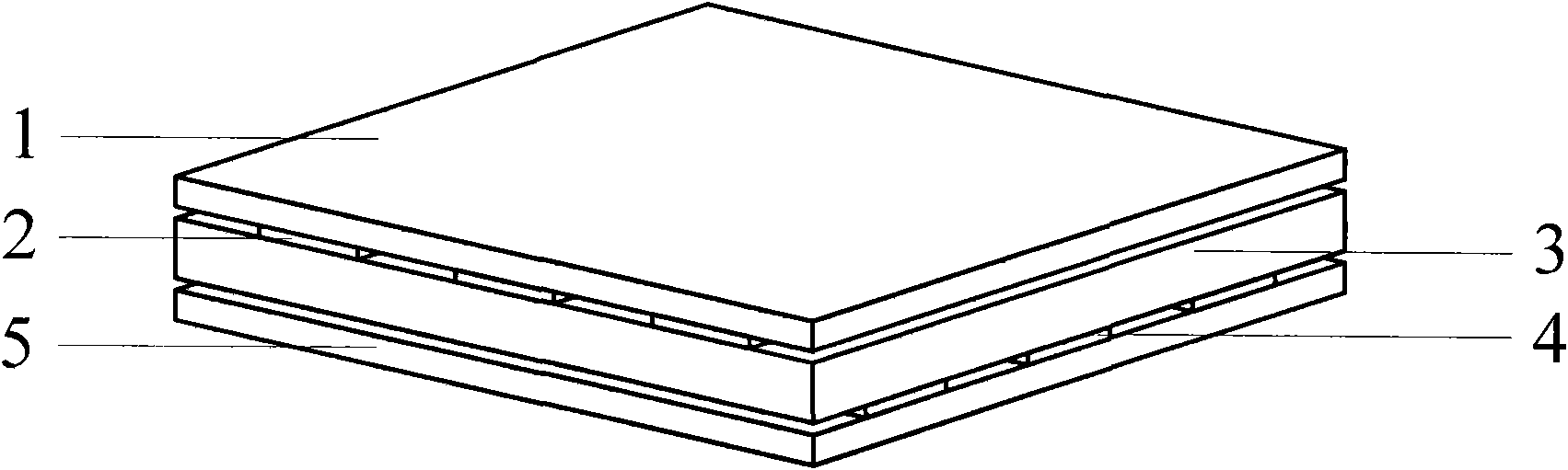

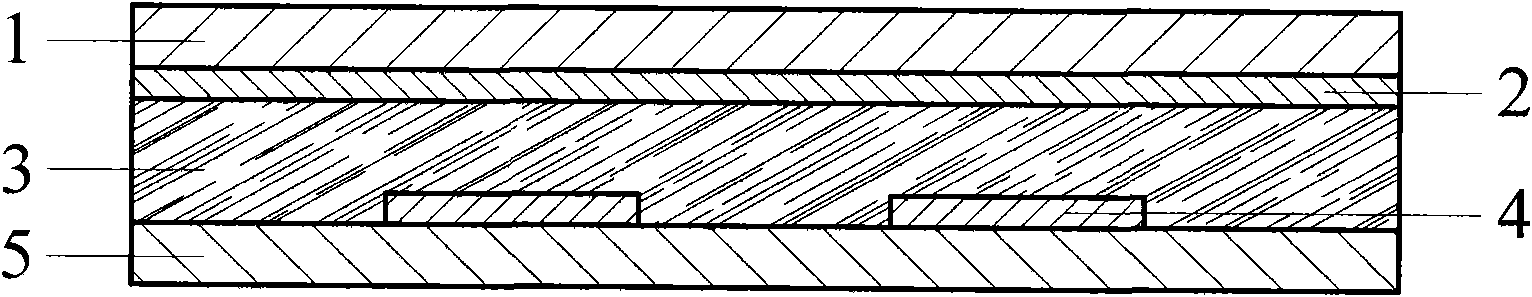

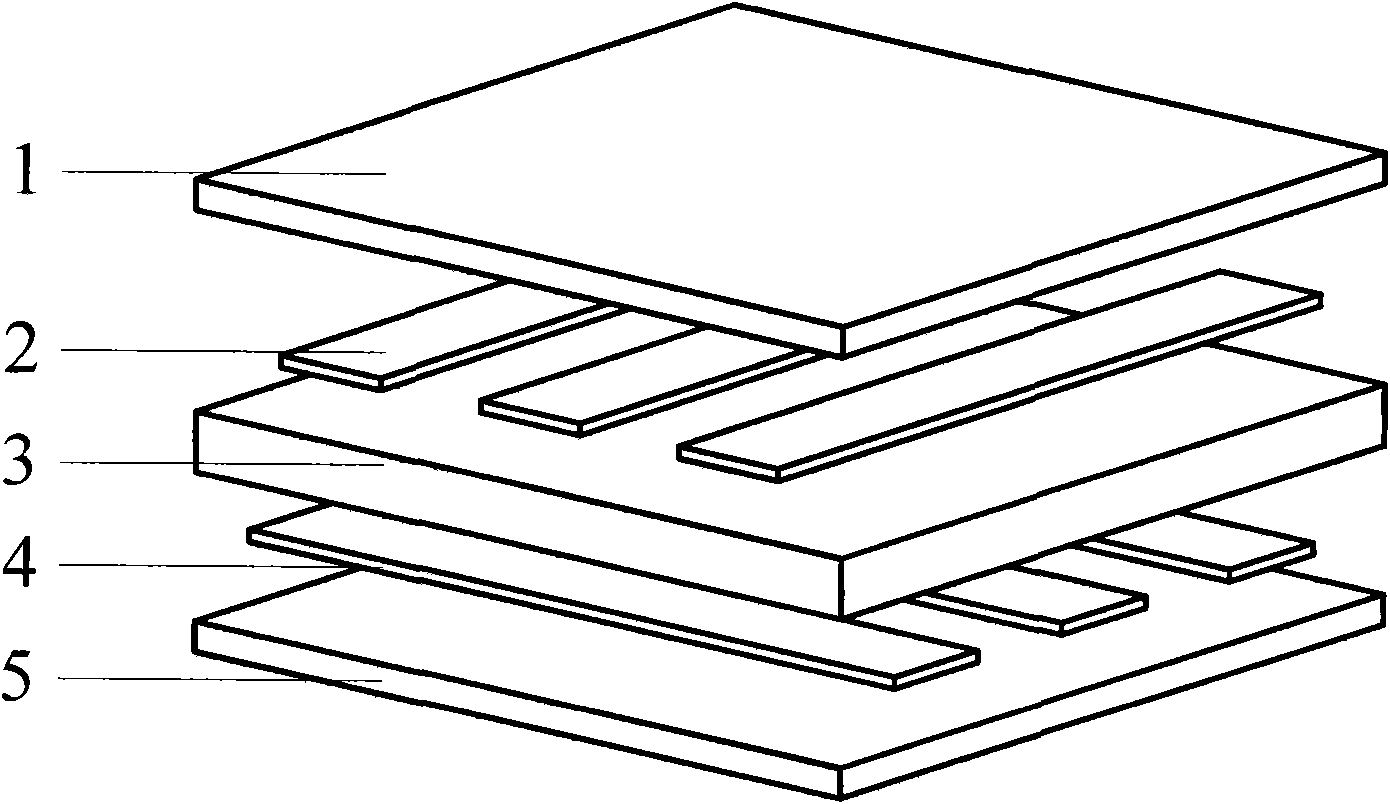

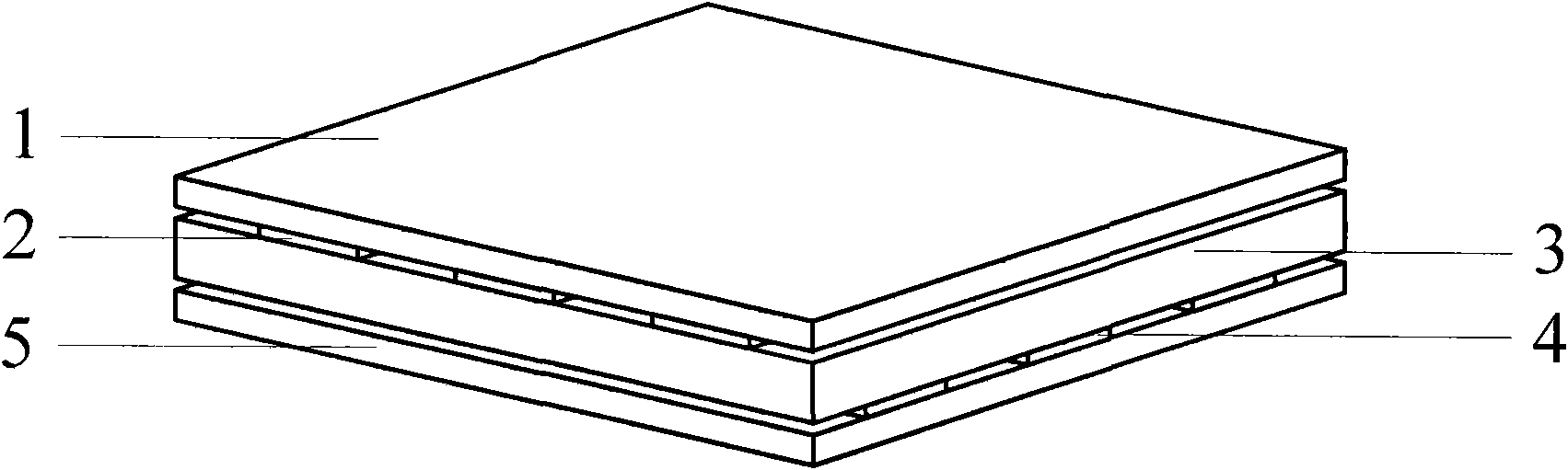

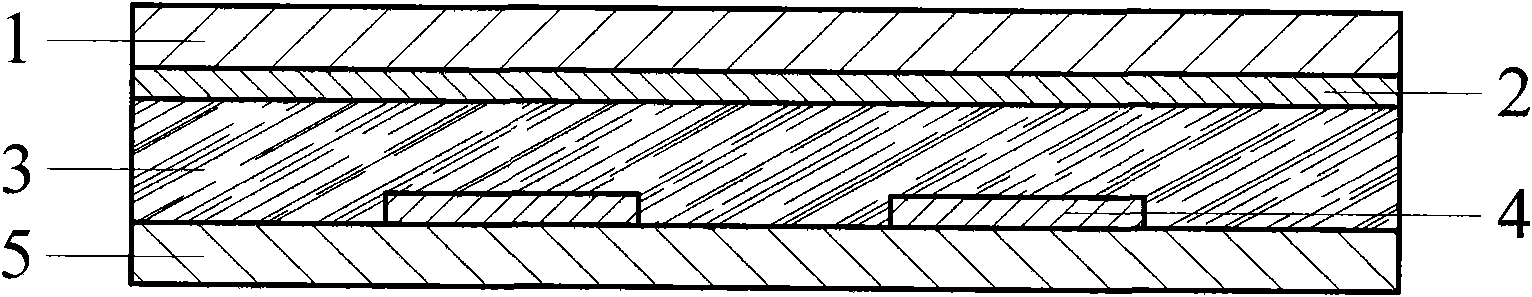

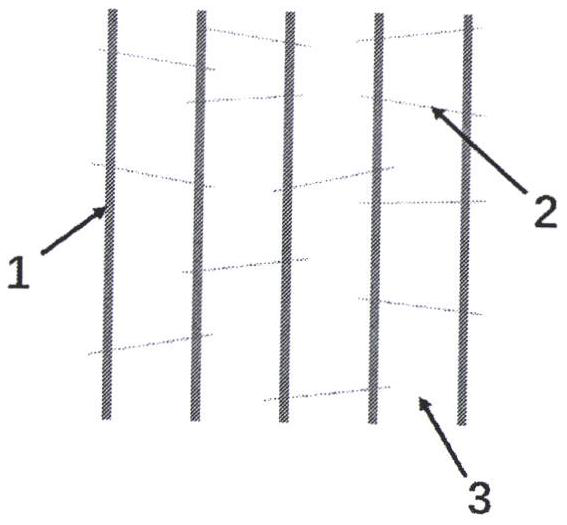

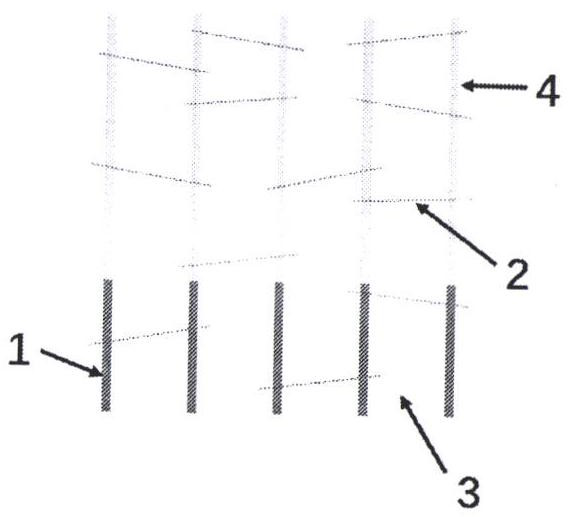

Carbon nanotube / polymer composite membrane array type flexible force sensor and manufacturing method thereof

InactiveCN102374910AReduce contentGood flexibilityDecorative surface effectsForce measurement using piezo-resistive materialsMembrane arrayCarbon nanotube

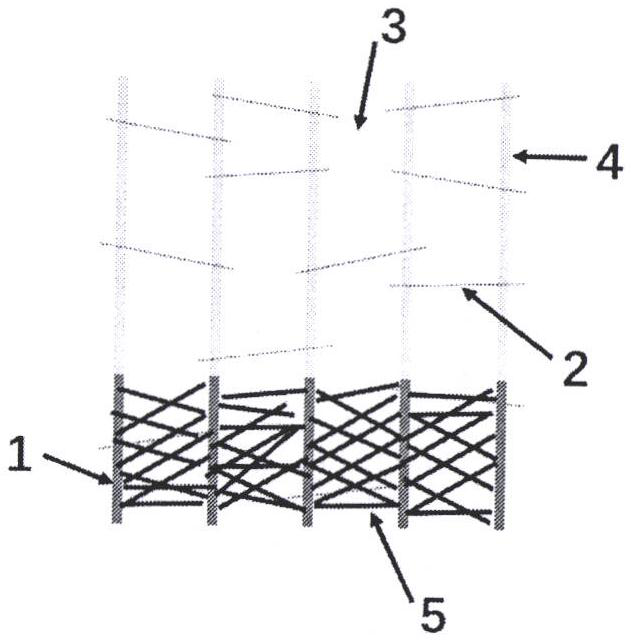

The invention relates to a carbon nanotube / polymer composite membrane array type flexible force sensor and a manufacturing method thereof. The carbon nanotube / polymer composite membrane array type flexible force sensor comprises a parallel metal row electrode and a parallel metal column electrode which are respectively and graphically arranged on the upper and lower surfaces of a carbon nanotube / polymer composite membrane, an upper insulation protecting layer adhered onto the row electrode, and a lower insulation protecting layer adhered onto the column electrode, wherein the row electrode and the column electrode are distributed in a spatial intersection way, and a spatial intersection part and the carbon nanotube / polymer composite membrane contained in the spatial intersection part form a force sensing unit of the array type flexible force sensor; and the carbon nanotube / polymer composite membrane is made by a composite material that carbon nanotubes are uniformly dispersed in a polymer matrix material, and the mass ratio of the carbon nanotubes to the polymer matrix material is (0.1-15): 100. The carbon nanotube / polymer composite membrane in the array type flexible force sensor has the characteristics of excellent flexibility, good repeatability, stable performances, good consistency and the like.

Owner:TSINGHUA UNIV

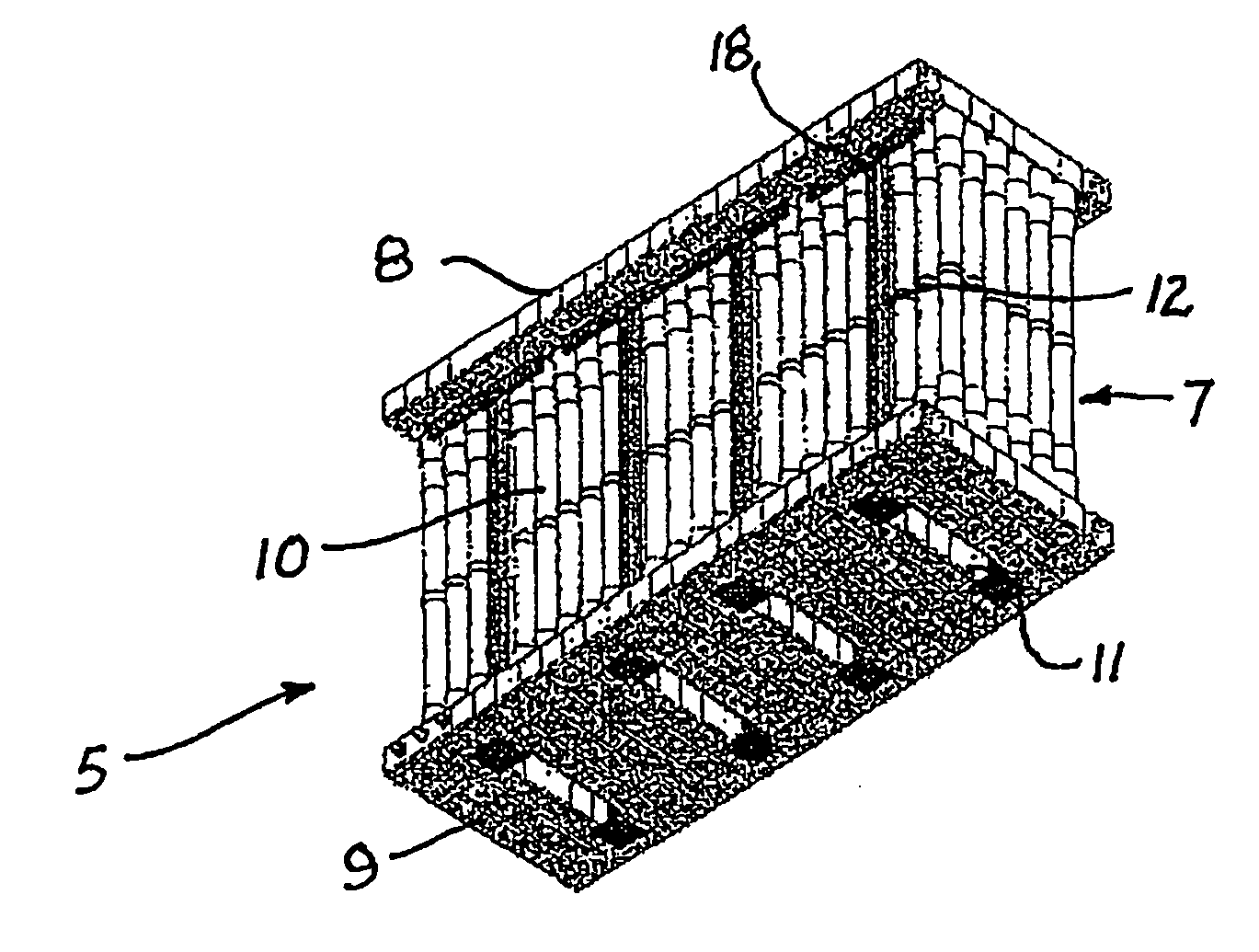

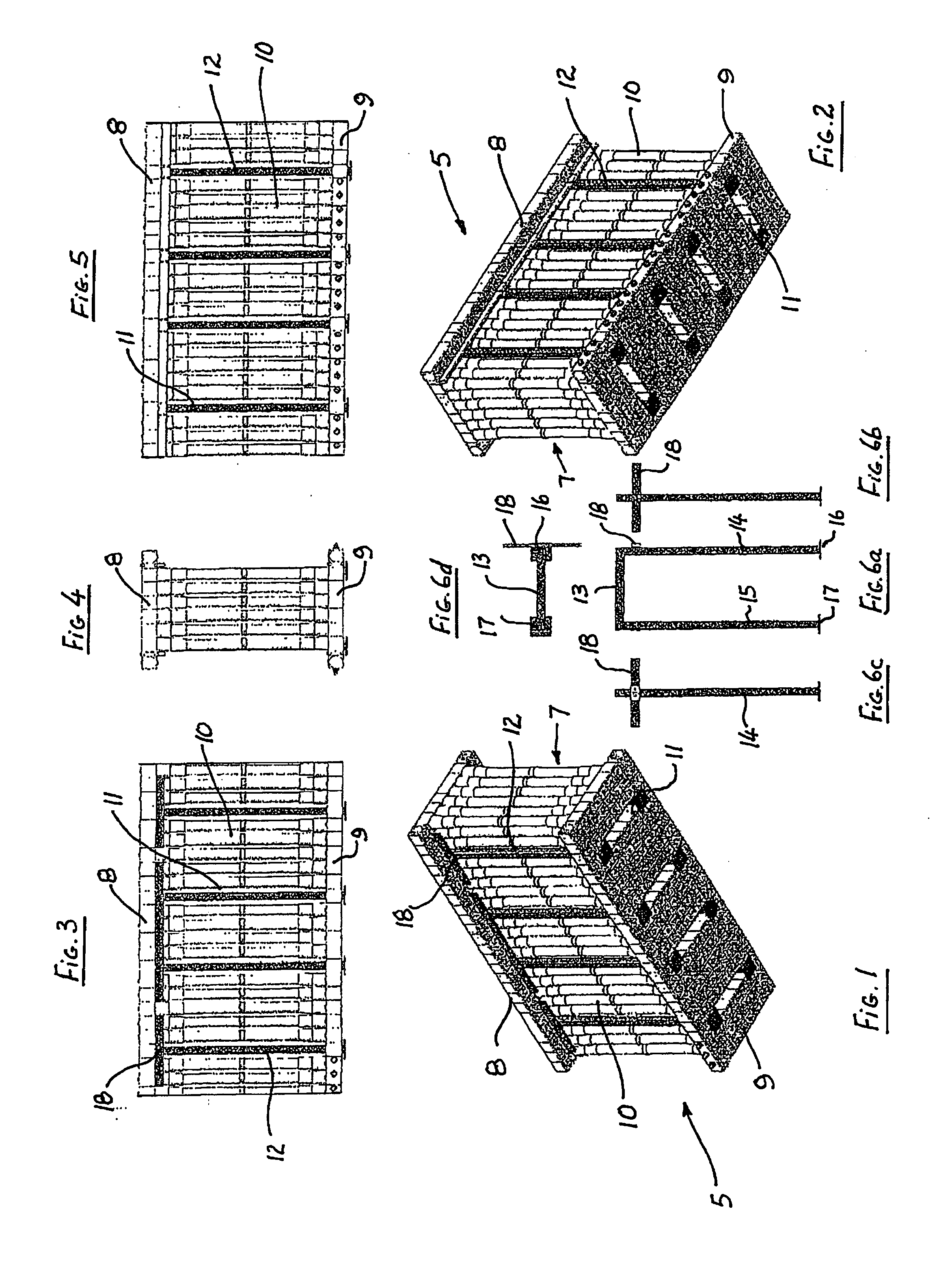

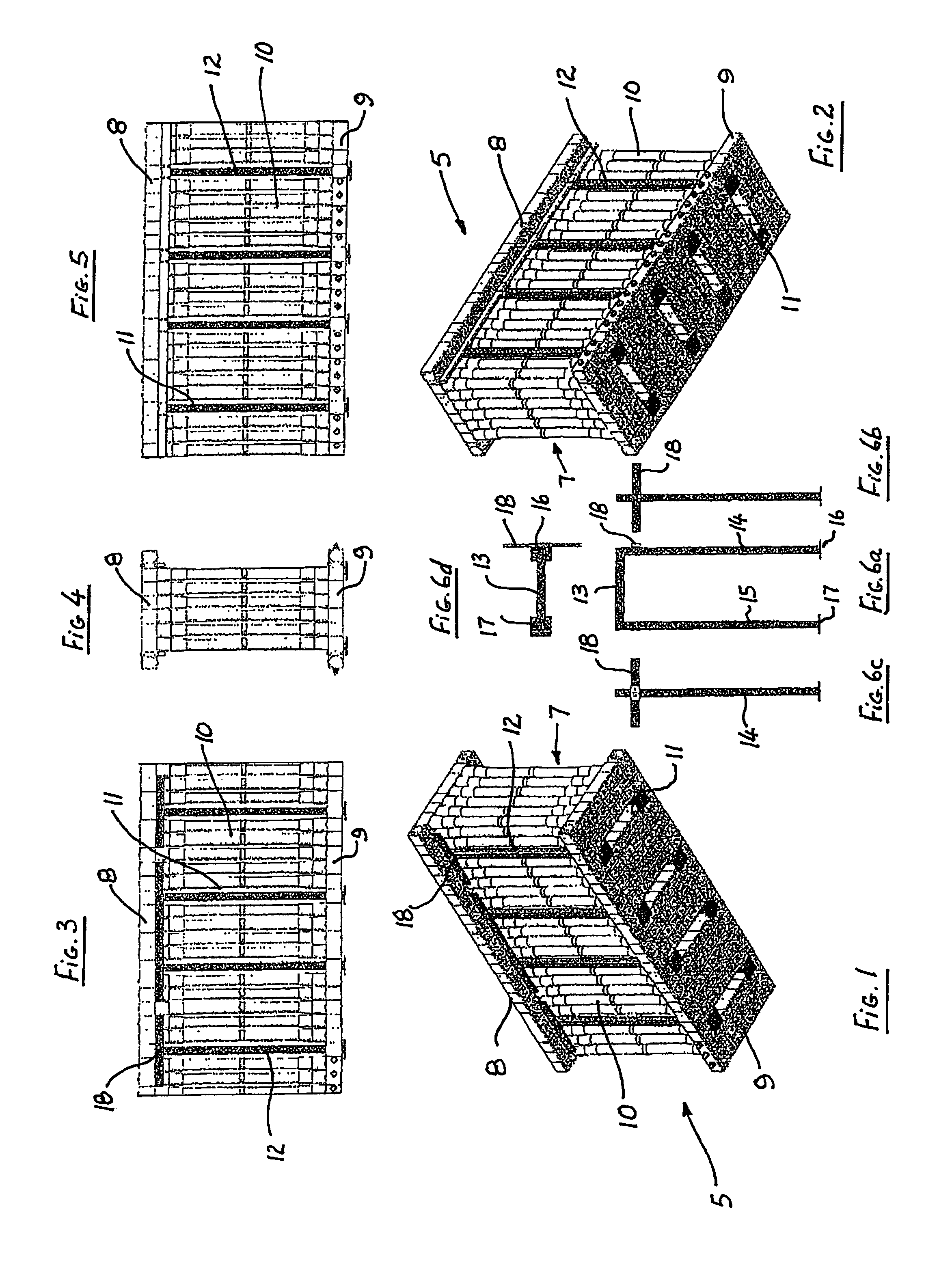

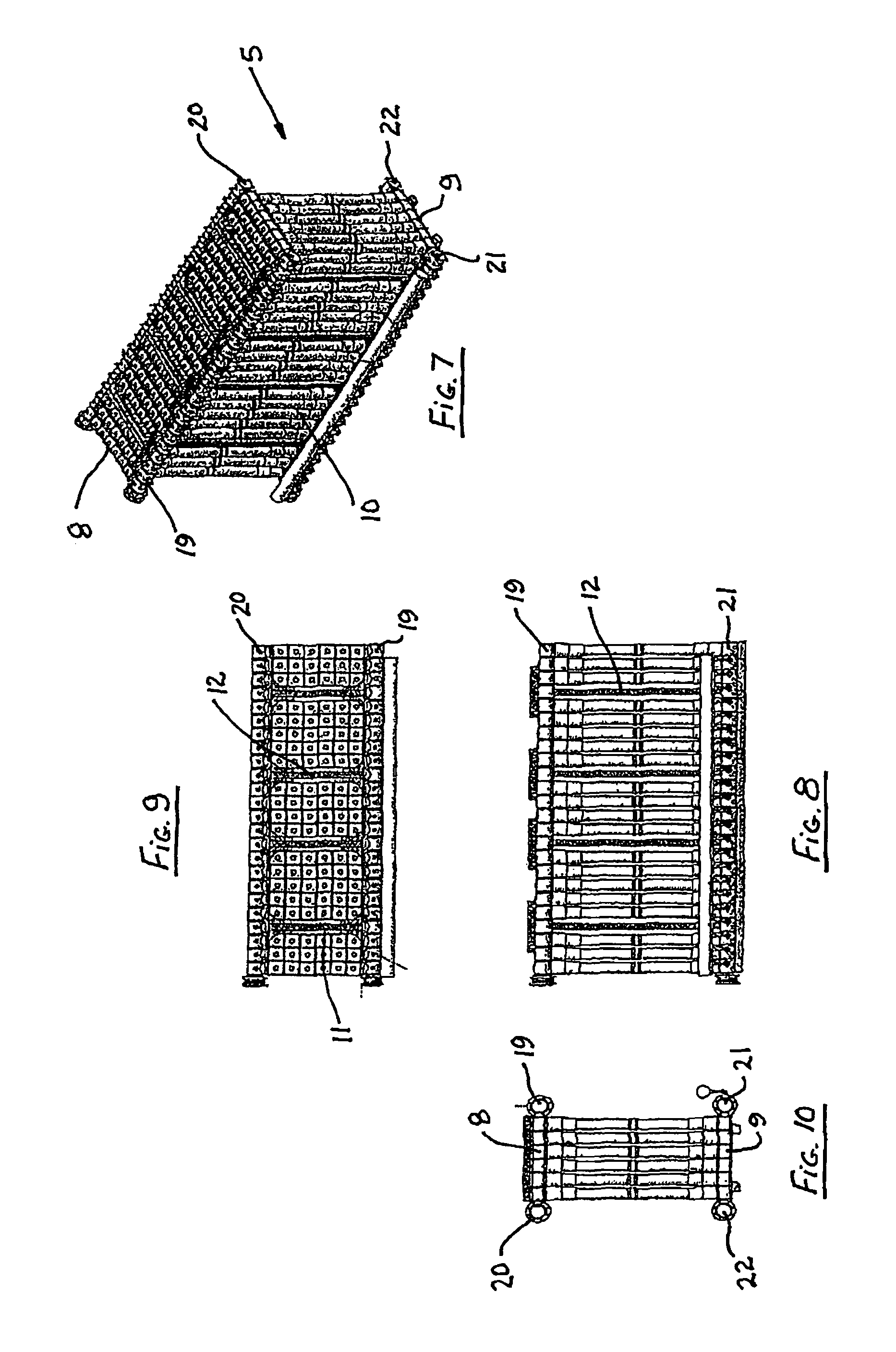

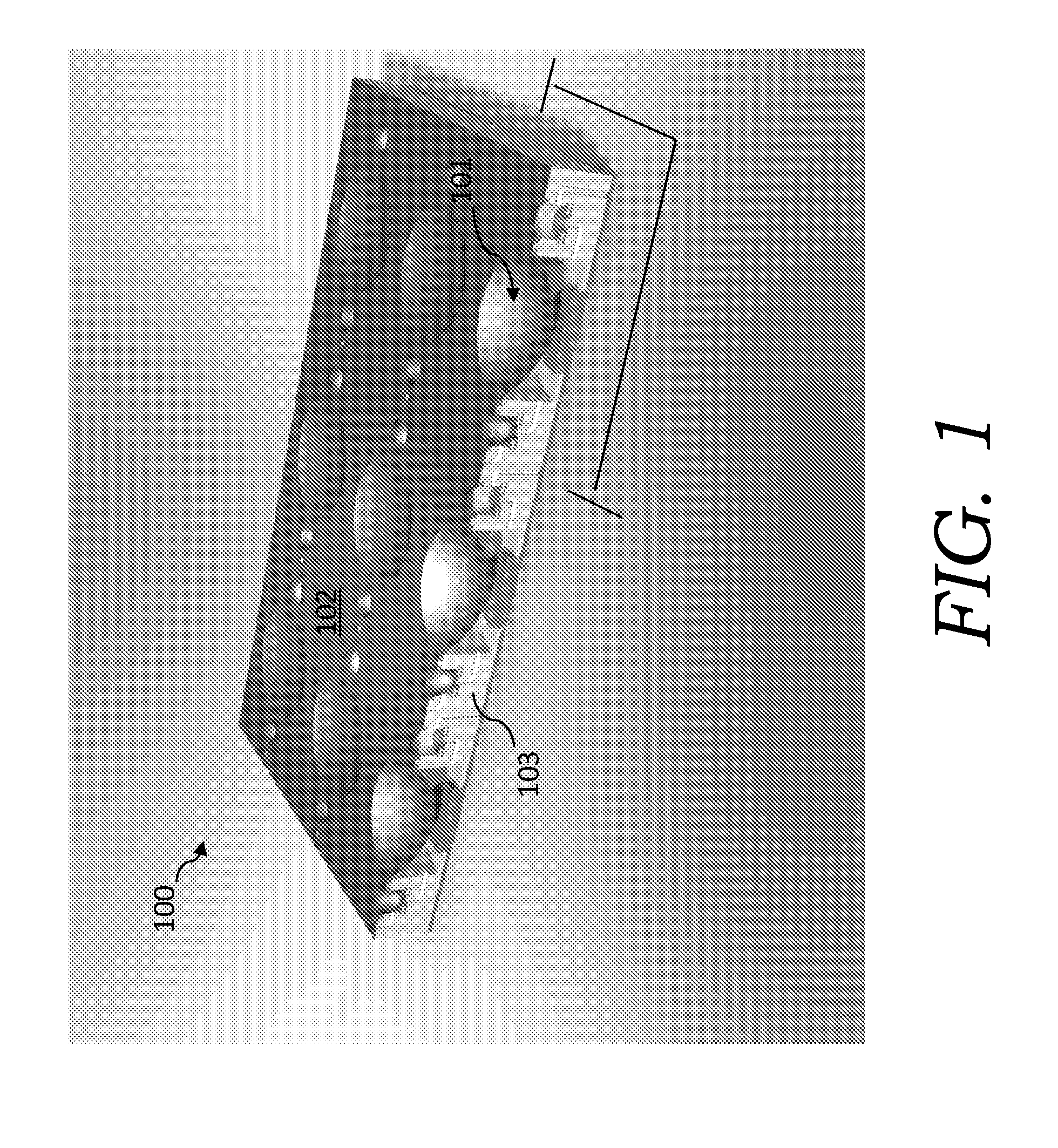

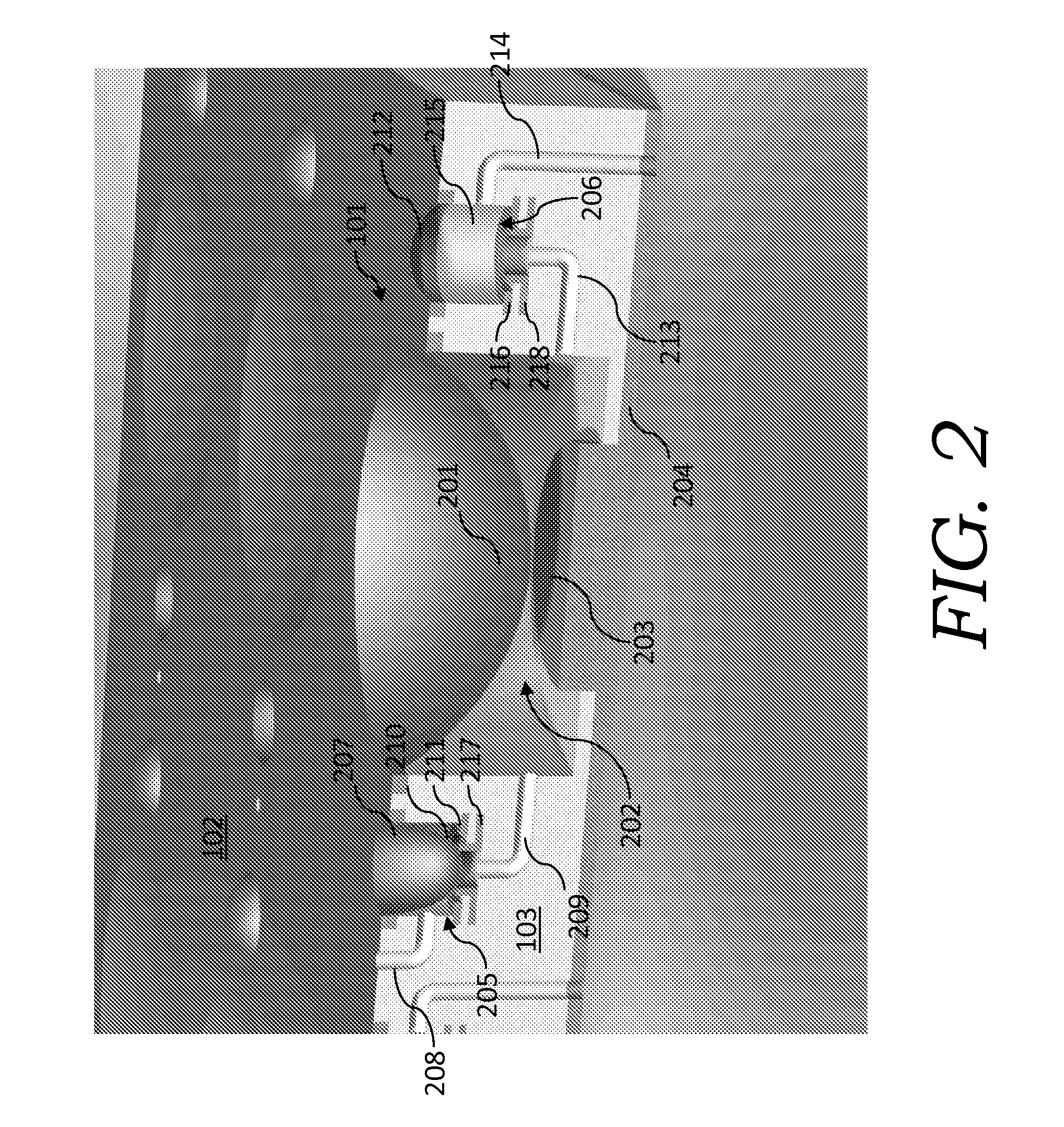

Frame System for Membrane Filtration Modules

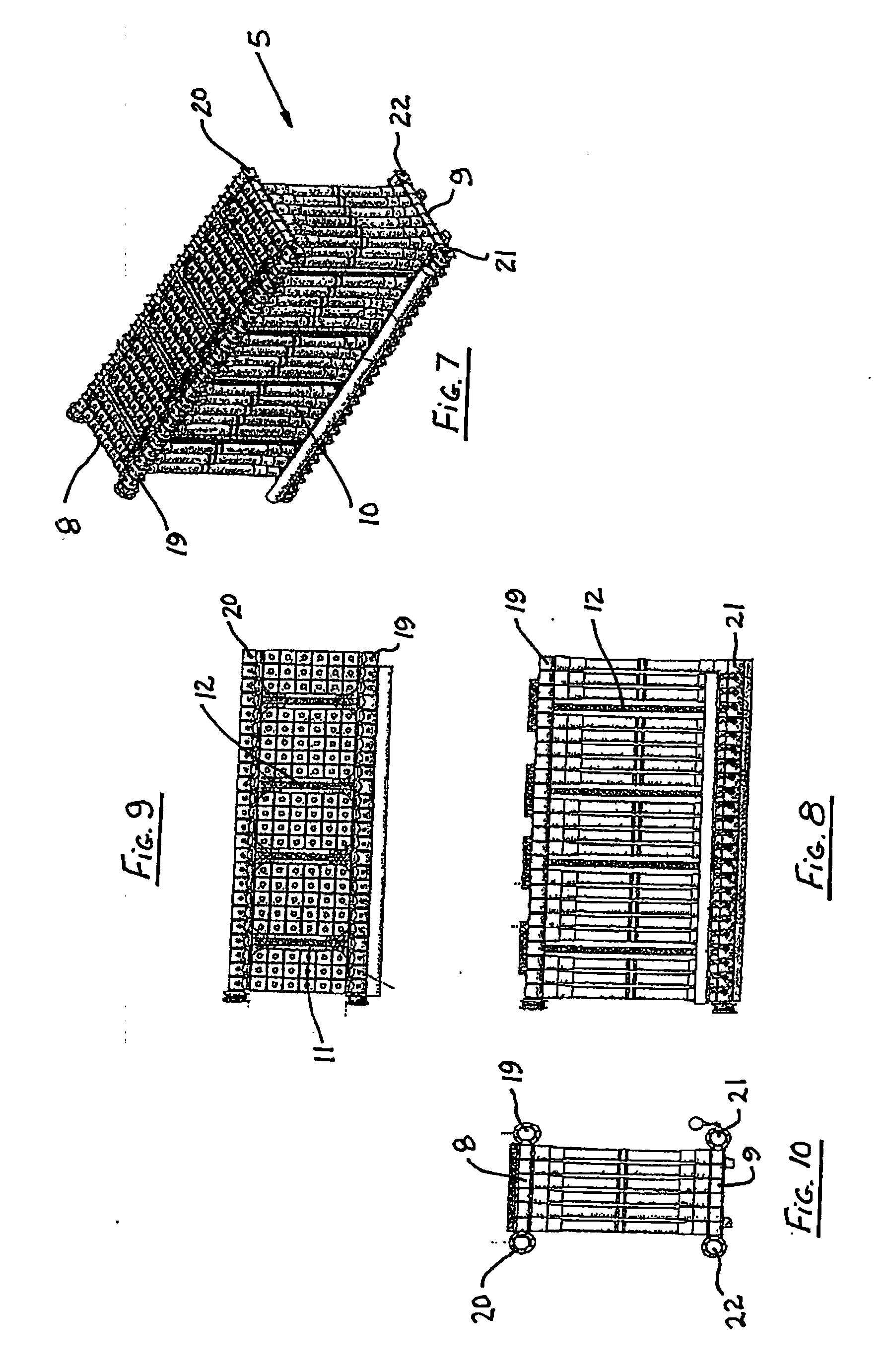

A module arrangement (5) according to an embodiment of the invention consists of a plurality of membrane modules (6) arranged in a two dimensional array (7) and extending between upper and lower block-type manifolds (8) and (9), respectively. The array of modules is further divided into sub-groups of modules (10) separated from each other by space (11) extending transversely across the membrane array (7). An integrated support frame (12) is positioned in the space (11) between the sub-groups (10) and is fixed to the upper and lower manifold blocks (8) and (9) to form an integrated support structure within the module array (7).

Owner:EVOQUA WATER TECH LLC

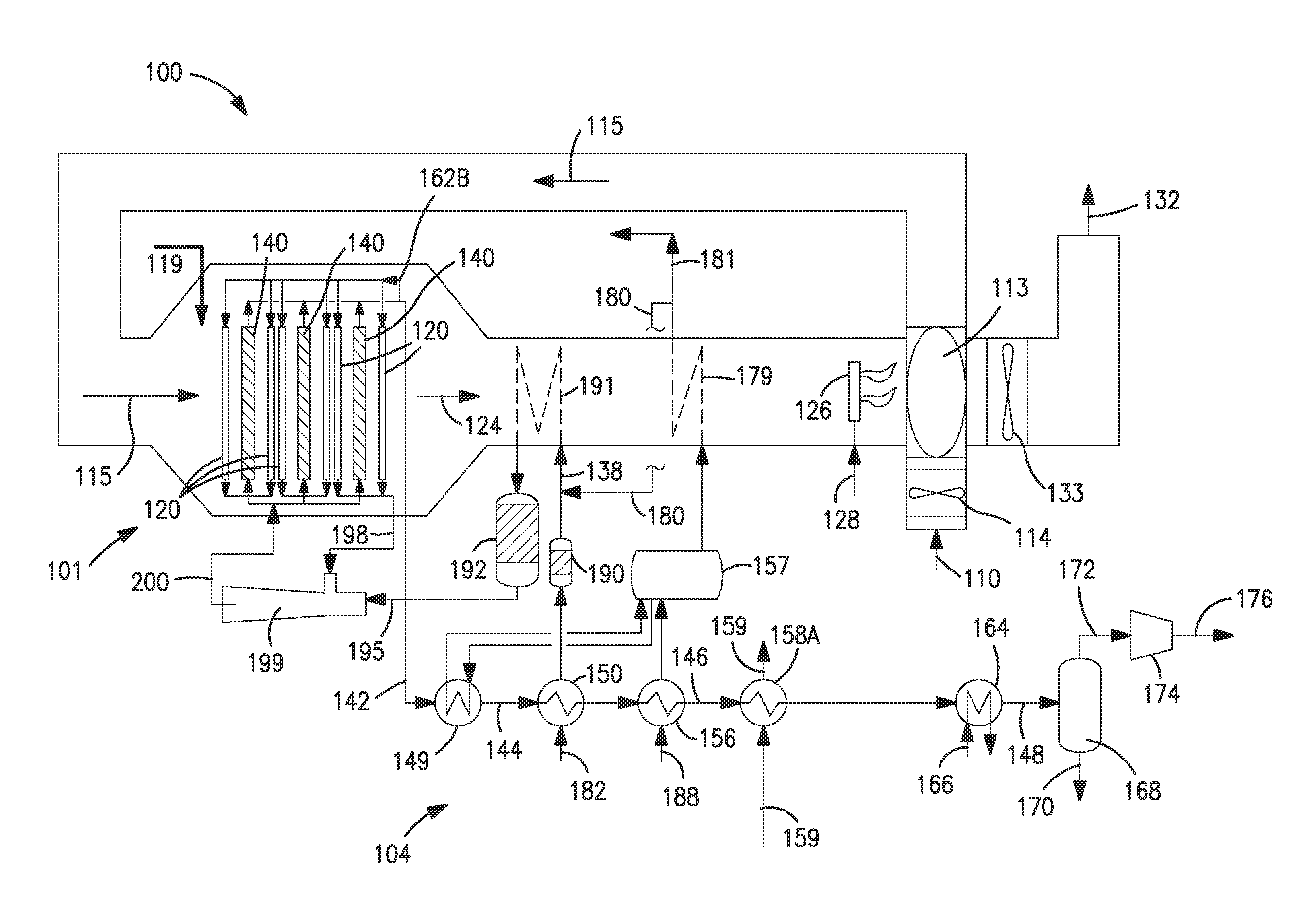

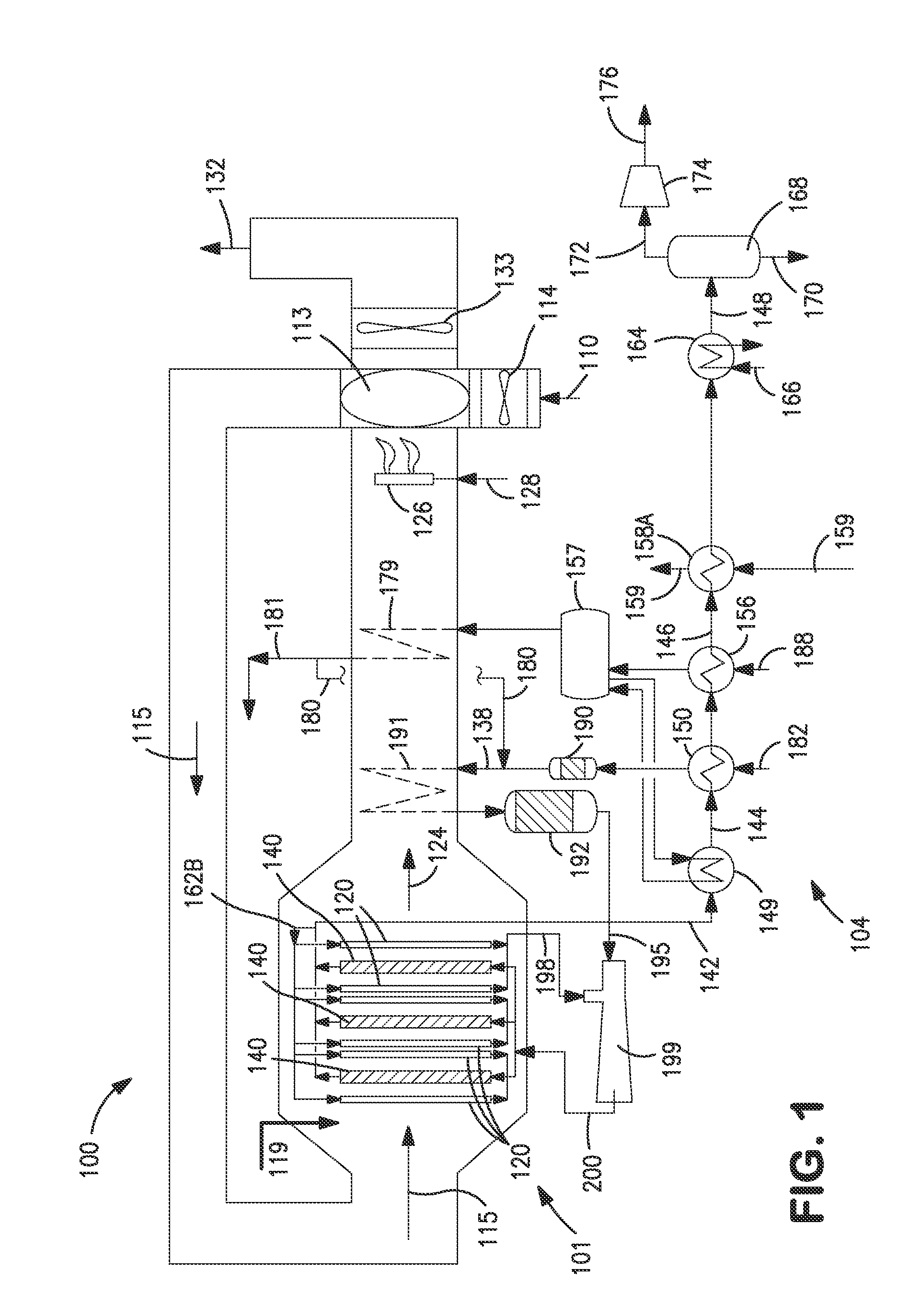

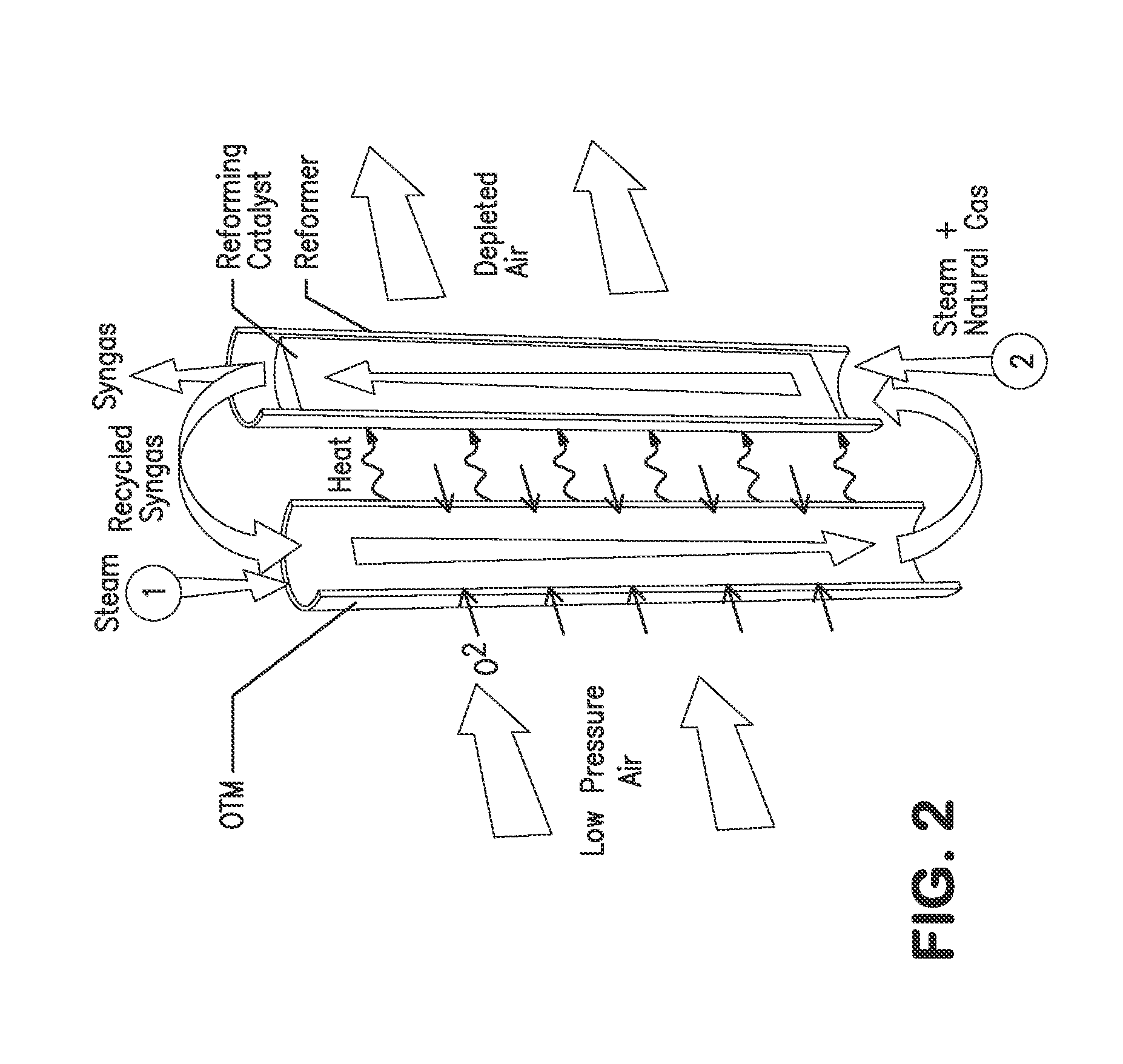

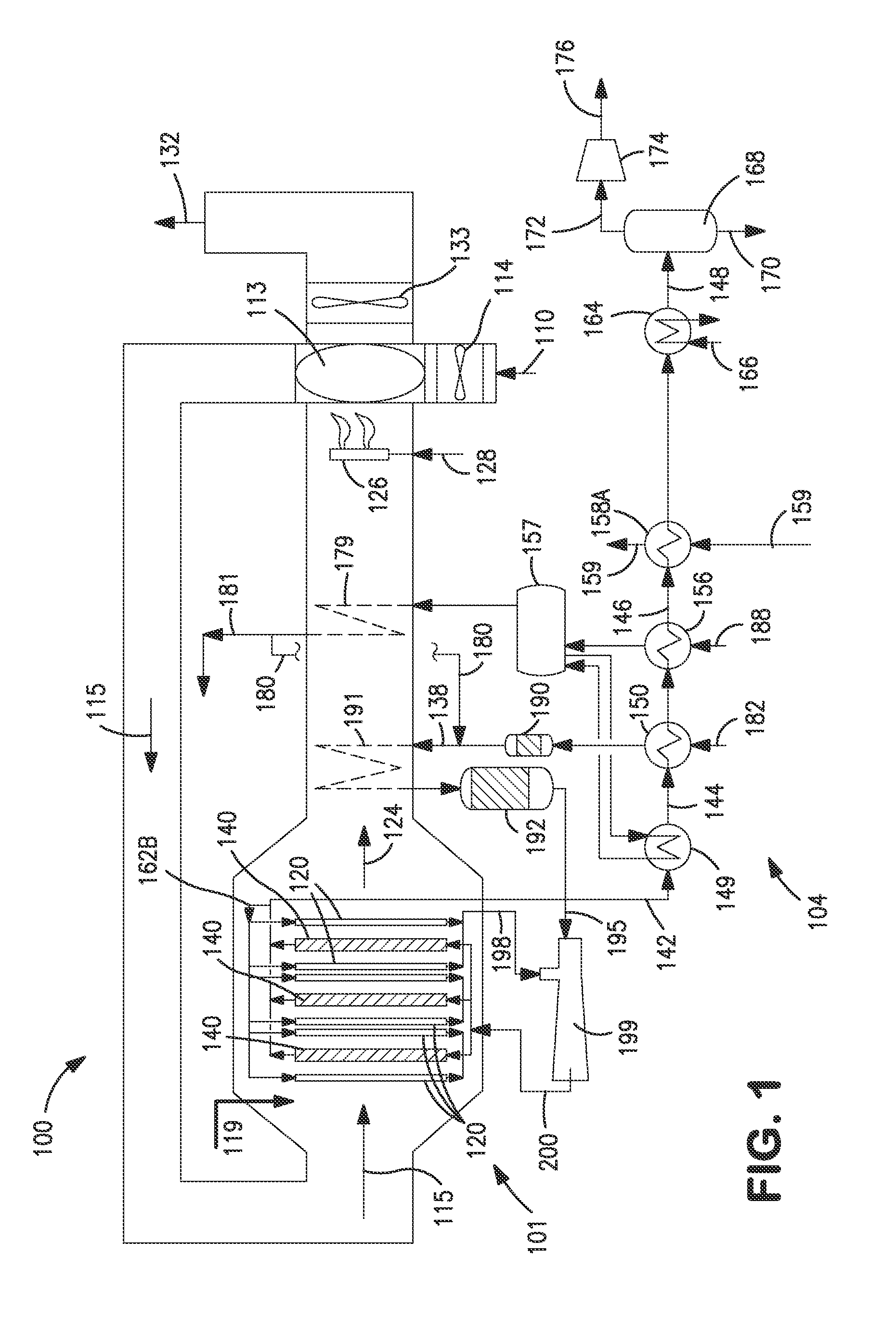

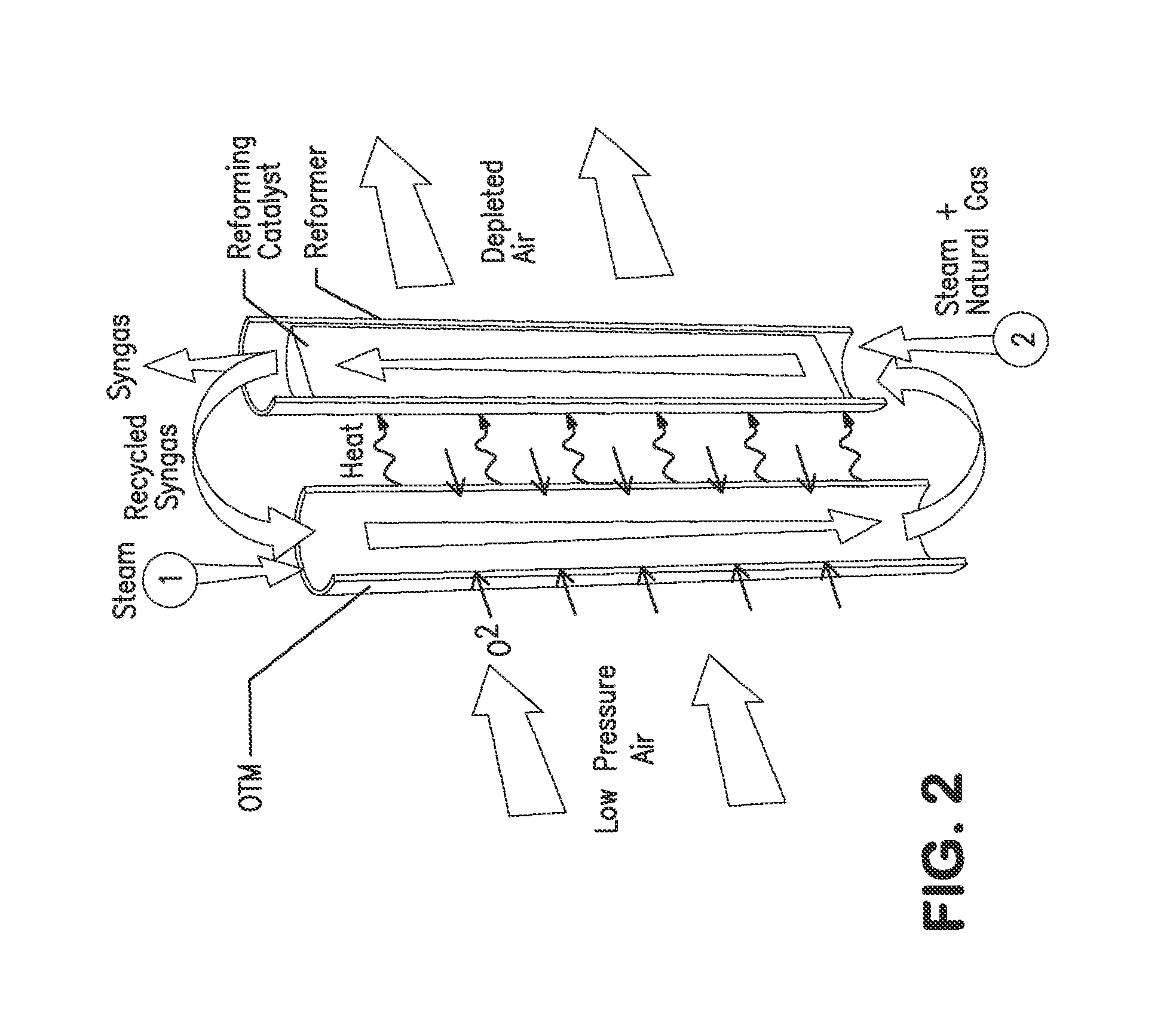

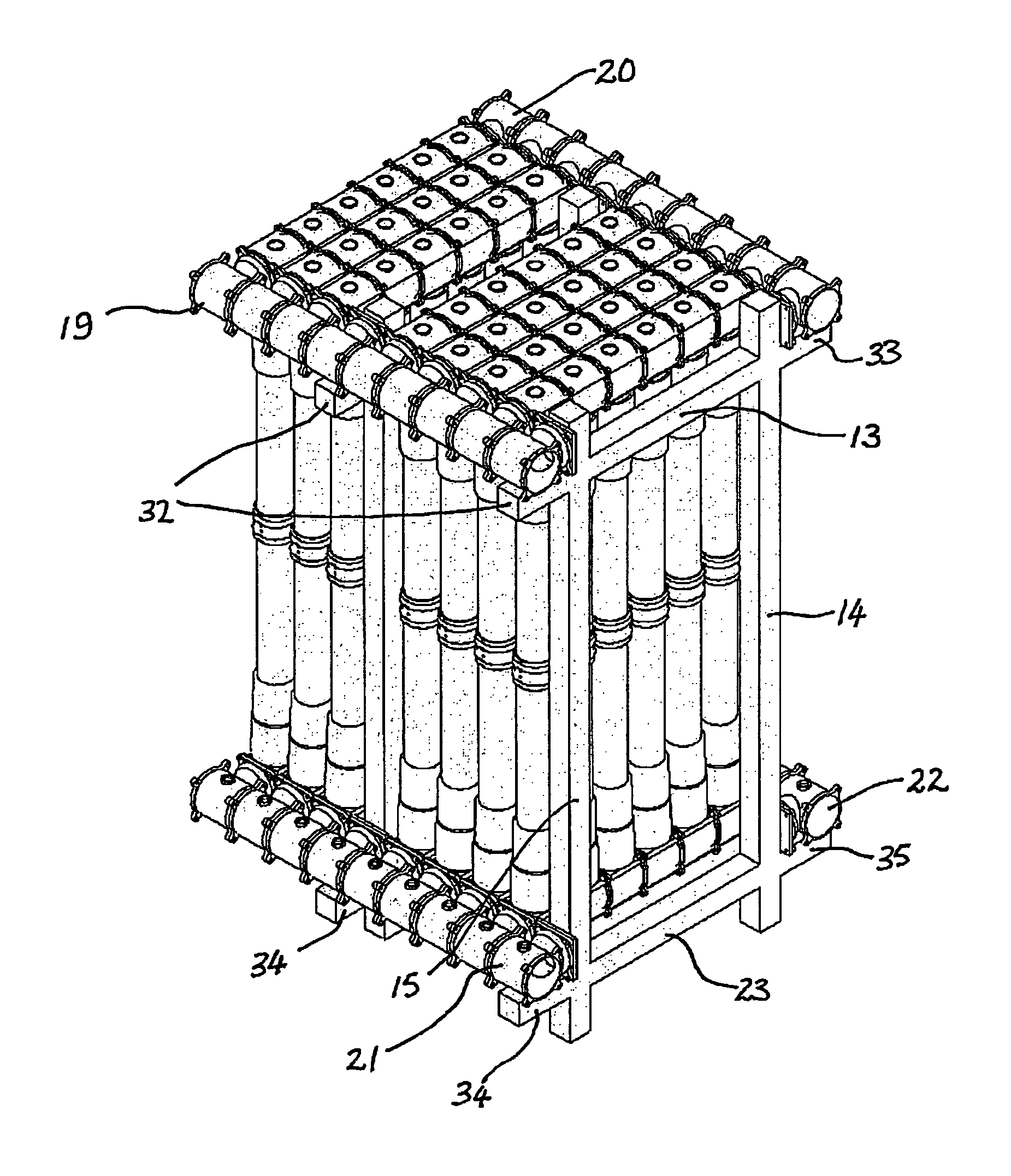

Ceramic oxygen transport membrane array reactor and reforming method

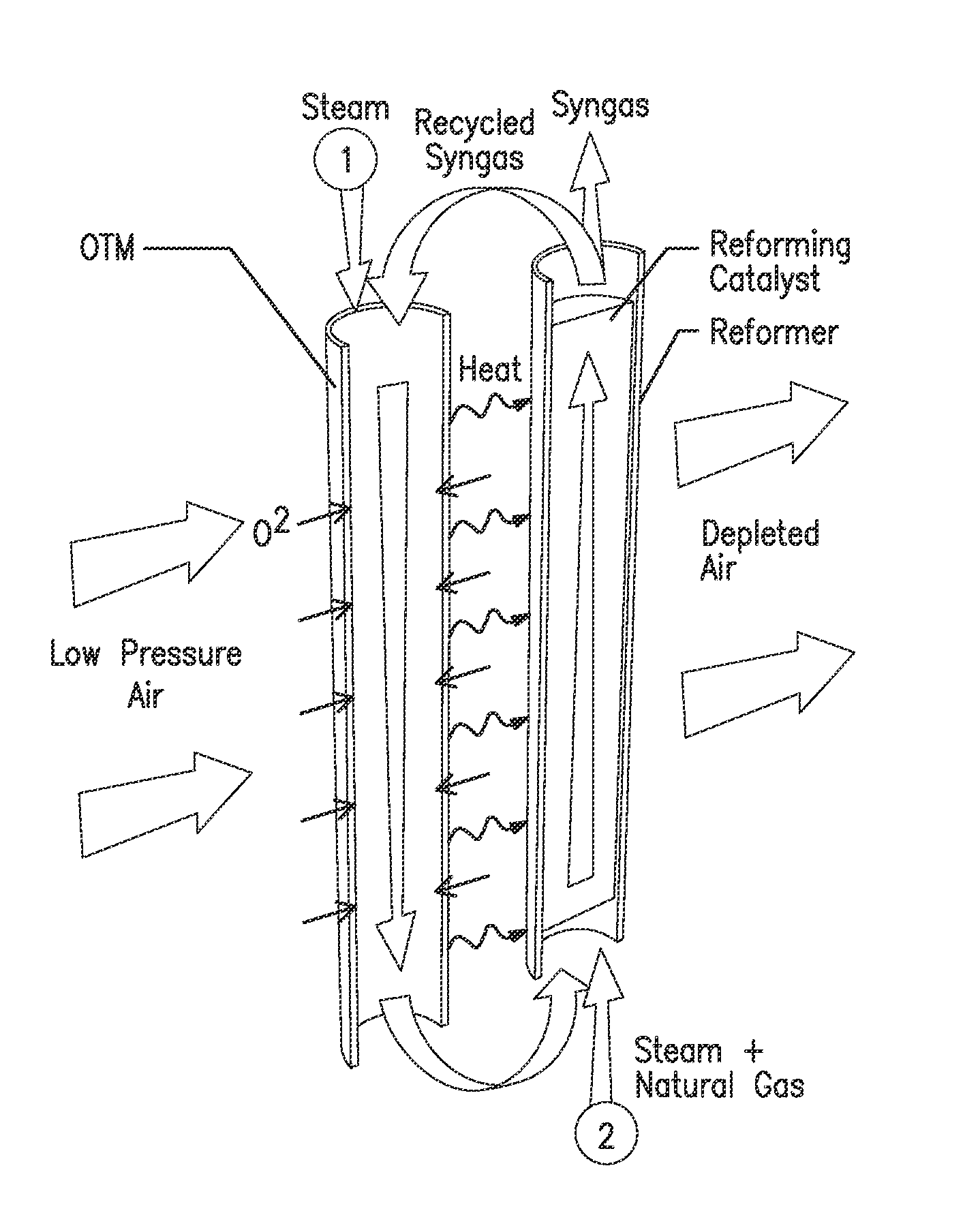

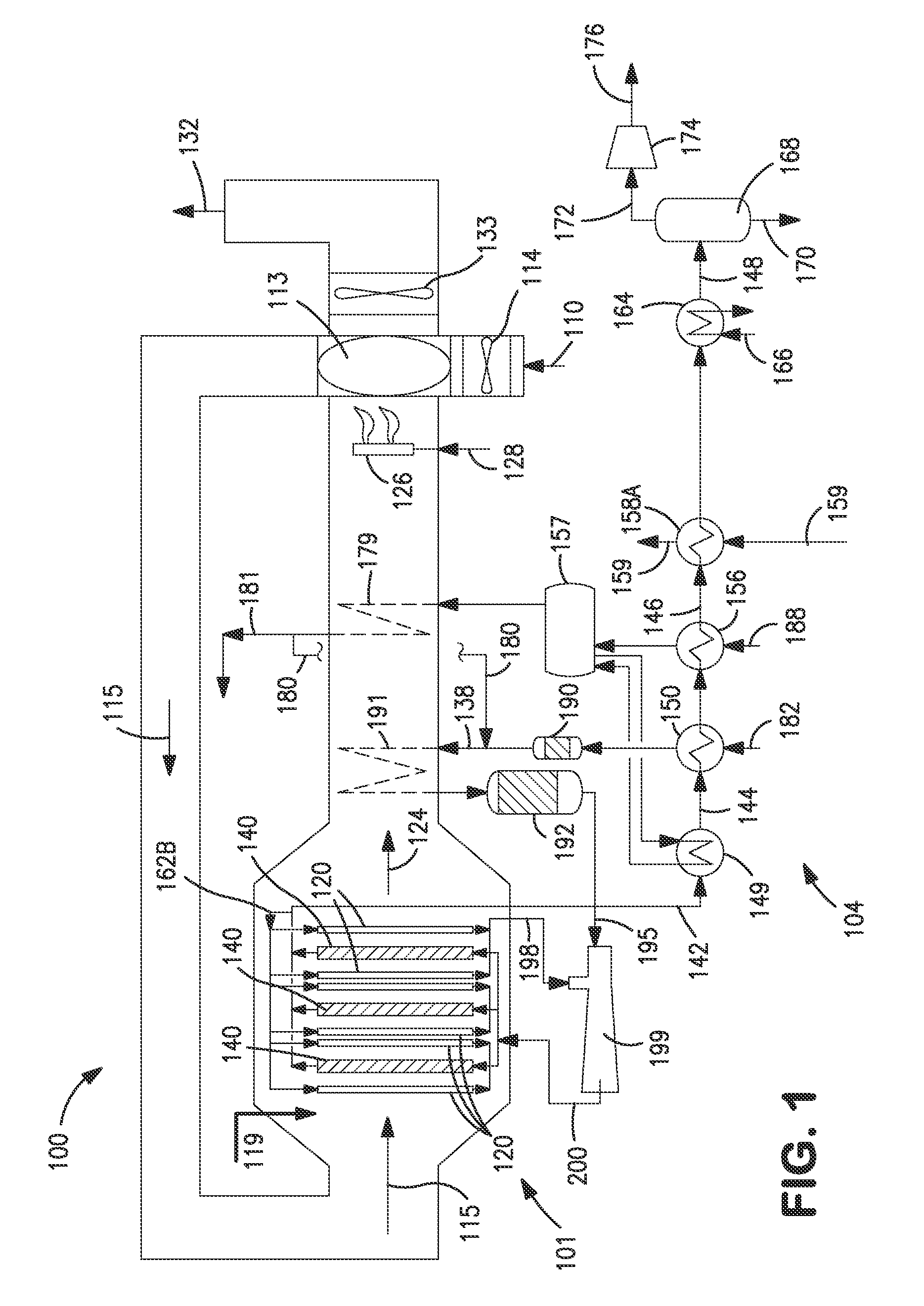

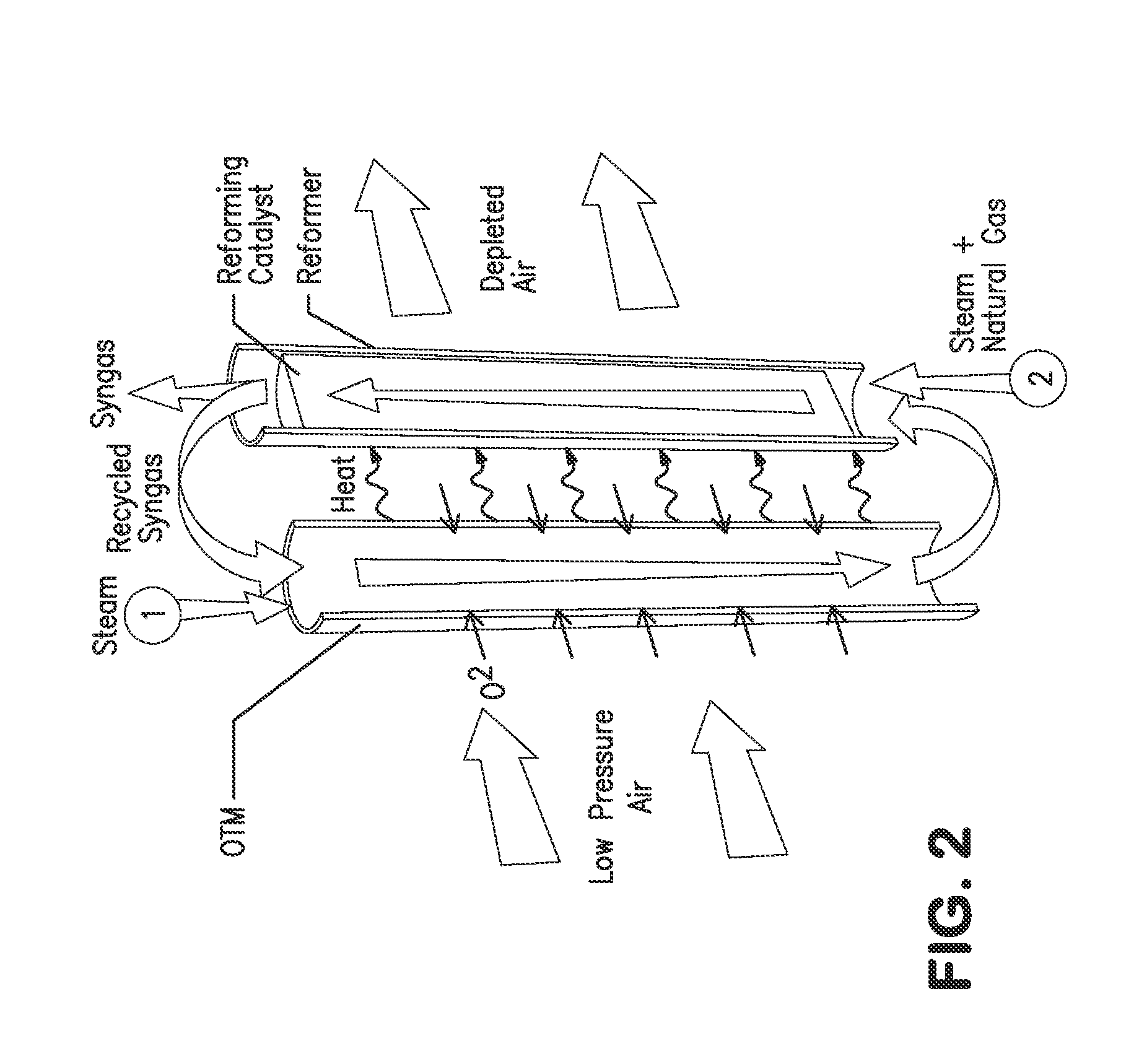

A commercially viable modular ceramic oxygen transport membrane reforming reactor for producing a synthesis gas that improves the thermal coupling of reactively-driven oxygen transport membrane tubes and catalyst reforming tubes required to efficiently and effectively produce synthesis gas.

Owner:PRAXAIR TECH INC

Ceramic oxygen transport membrane array reactor and reforming method

ActiveUS20150096506A1Prevent backflowCatalytic gas-gas reactionHydrogenChemical reactionMembrane array

The invention relates to a commercially viable modular ceramic oxygen transport membrane system for utilizing heat generated in reactively-driven oxygen transport membrane tubes to generate steam, heat process fluid and / or provide energy to carry out endothermic chemical reactions. The system provides for improved thermal coupling of oxygen transport membrane tubes to steam generation tubes or process heater tubes or reactor tubes for efficient and effective radiant heat transfer.

Owner:PRAXAIR TECH INC

Ceramic oxygen transport membrane array reactor and reforming method

Owner:PRAXAIR TECH INC

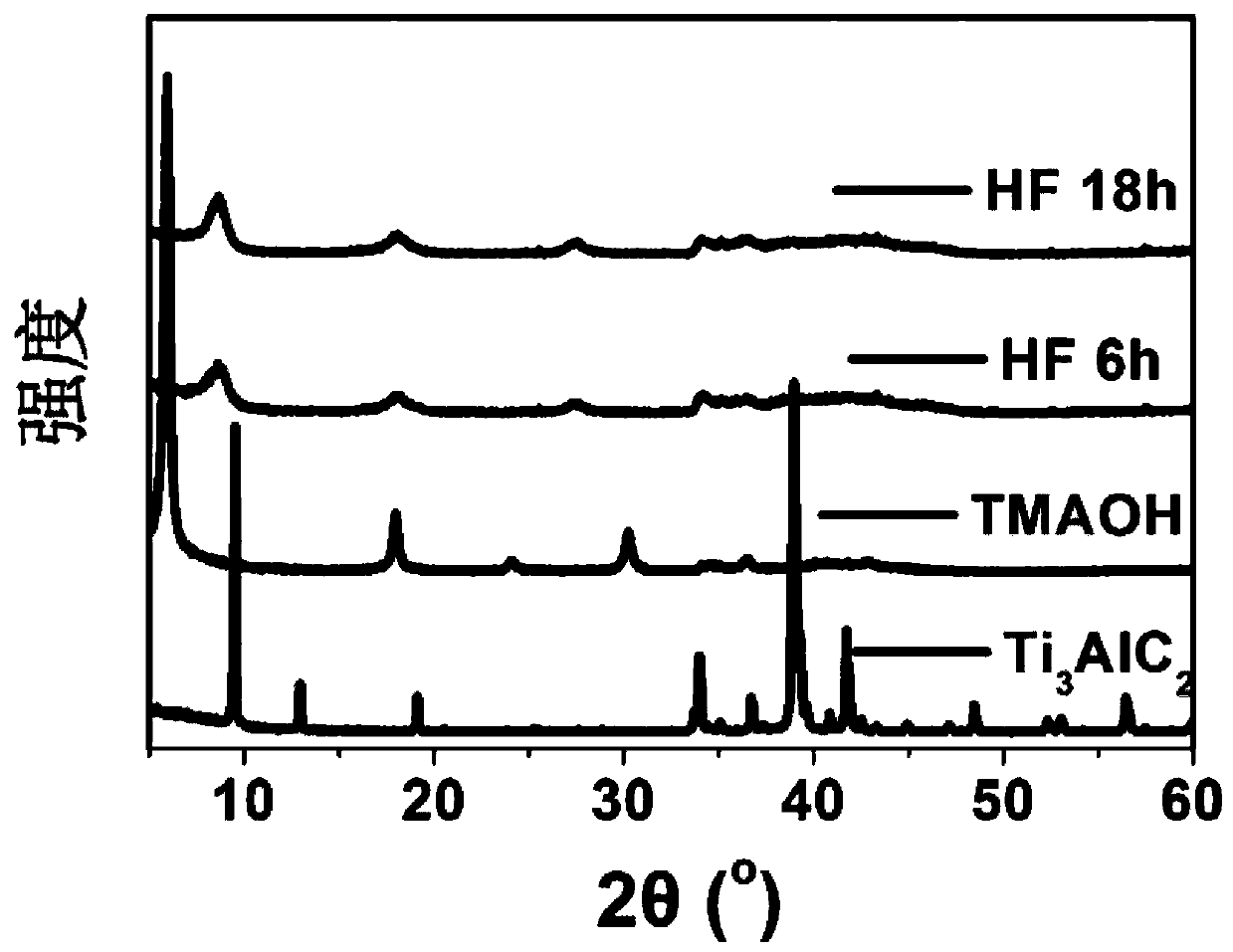

Electronic skin based on MXene material and preparation method thereof

ActiveCN110108375AHigh sensitivityHigh precisionThermometers using material expansion/contactionElectric/magnetic contours/curvatures measurementsTemperature responseRubber material

The invention relates to an electronic skin based on an MXene material and a preparation method thereof. The electronic skin comprises a flexible substrate, a sensitive material and electrodes. The sensitive material is a conductive film array based on the MXene material. The flexible substrate is used for supporting and protecting the sensitive material. The electrodes are distributed at the twoends of the sensitive material. The flexible substrate is made of an elastic rubber material. The temperature response range of the electronic skin is 0 to 200 DEG C and the a sensitivity is from 0.01to 1000 DEG C <-1>.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

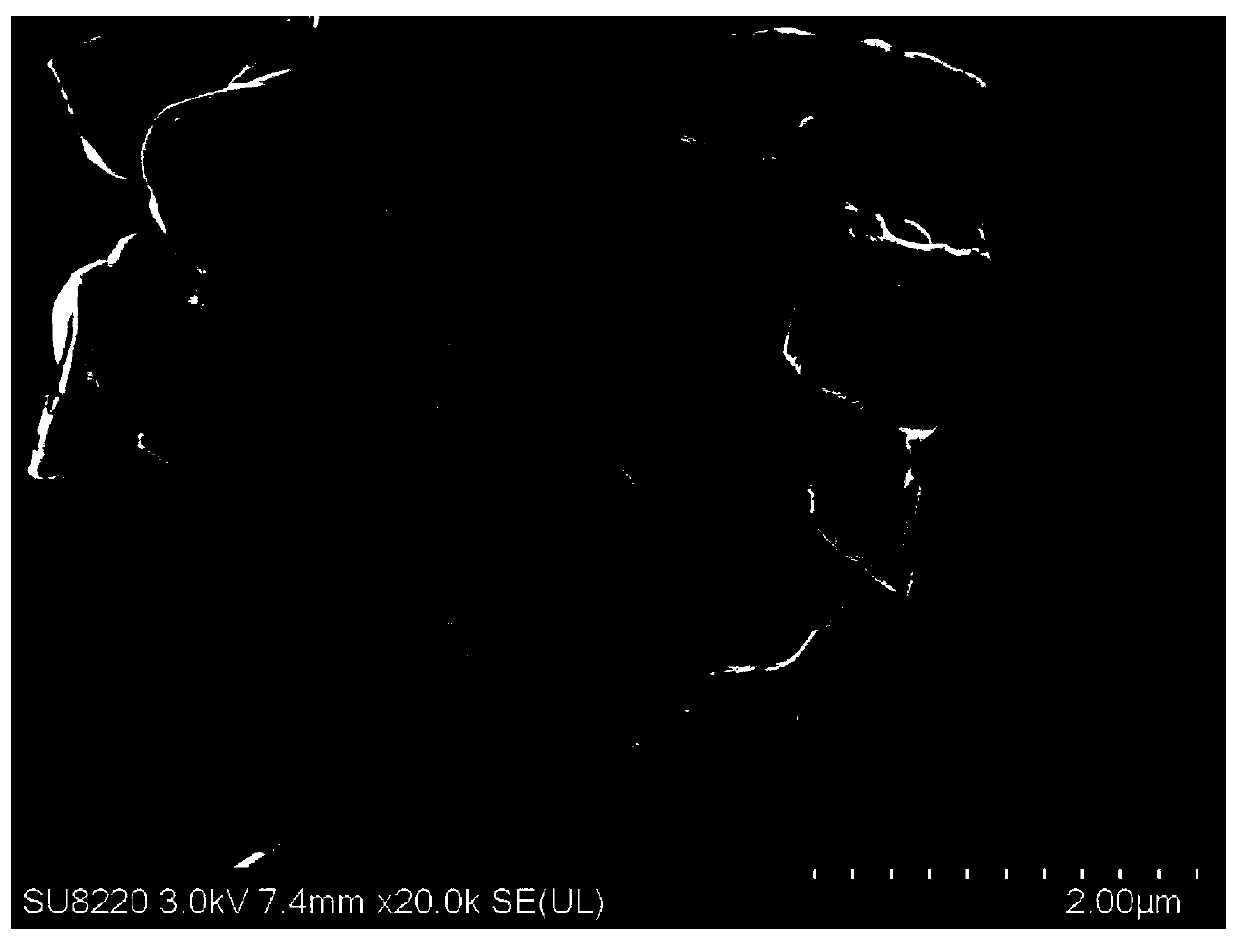

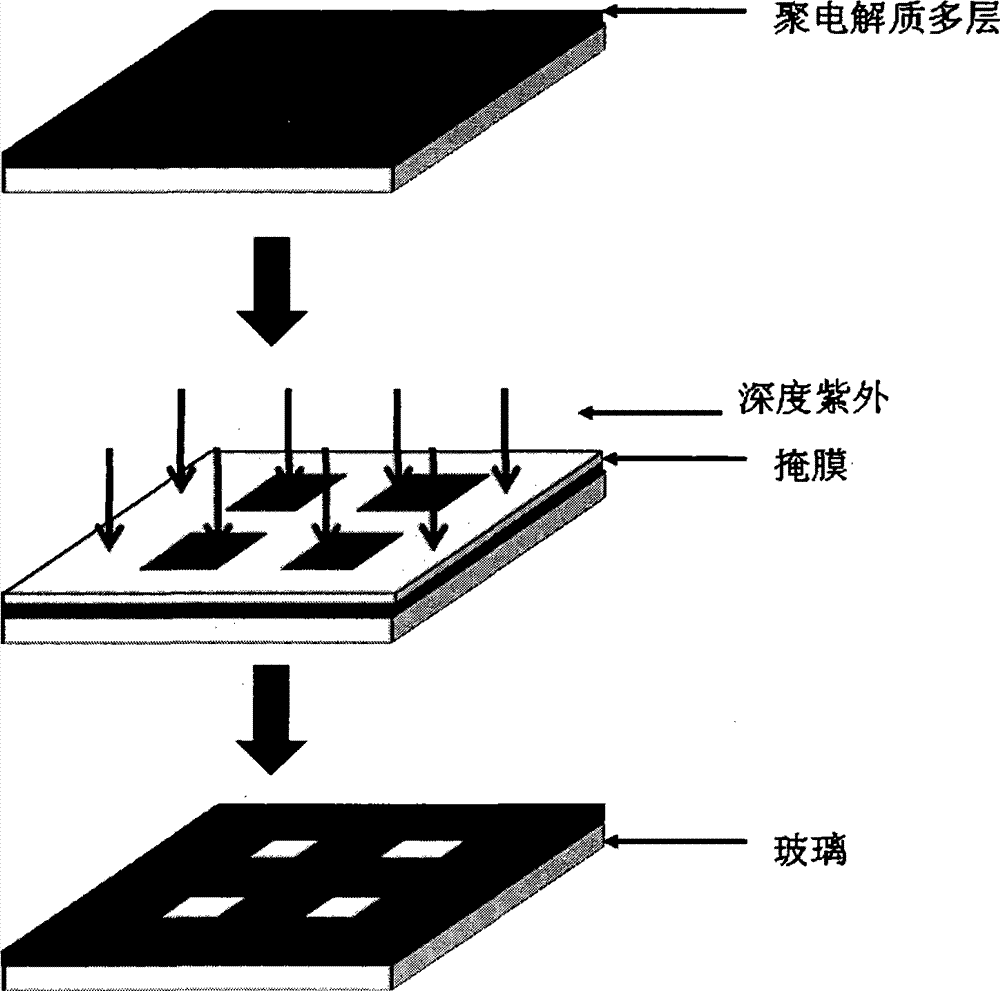

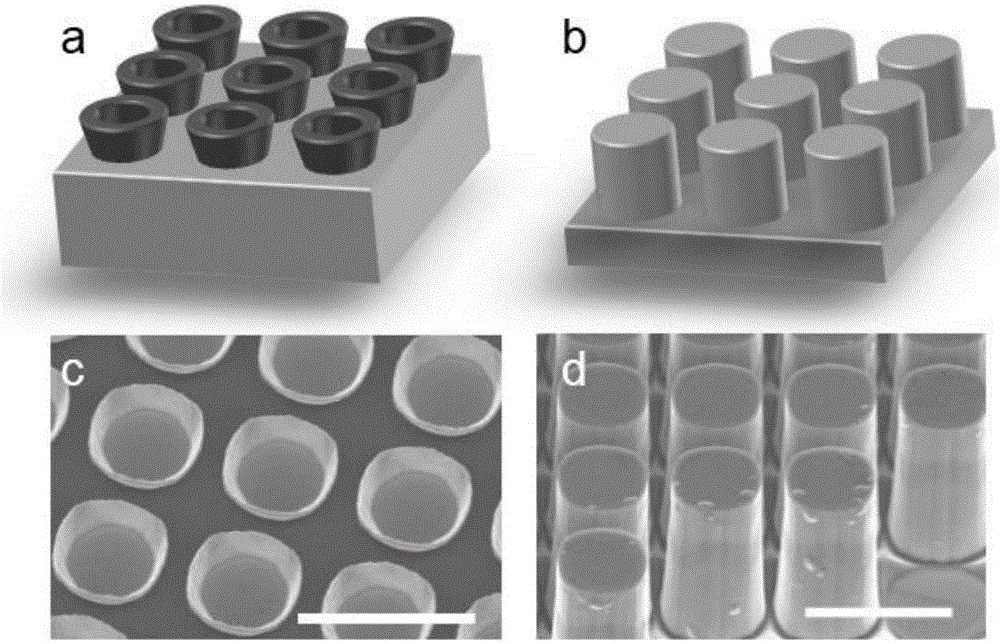

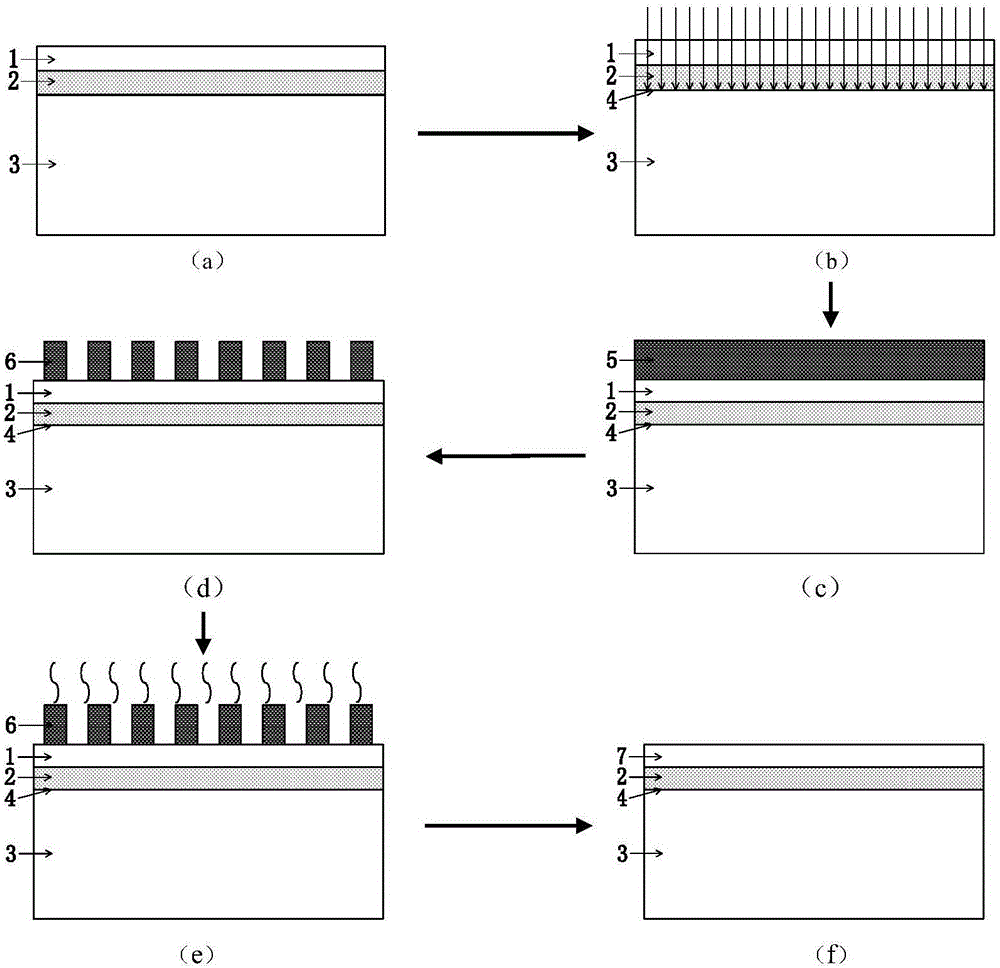

Phospholipid bilayer membrane array fabricated by multilayer polyelectrolyte membrane substrate and fabrication method

InactiveCN103030305AEnrich and expand preparation methodsEasy to operateMultilayer membraneMicro nano

The invention relates to a phospholipid bilayer membrane array fabricated by a multilayer polyelectrolyte membrane substrate and a fabrication method. A static layer-by-layer self-assembly technology is adopted to fabricate polyelectrolyte poly-(4-sodium styrene sulfonate) (PSS) and poly-(diallyl dimethyl ammonia chloride) (PDDA) multilayer membranes on a silicon substrate modified by 3-ammonia propyltriethoxysilane, the modified substrate is subjected to patterning by a photetching technology, arrays of a polyelectrolyte in different types are fabricated, a phospholipid bilayer membrane is fabricated at the bottoms of the arrays, and the phospholipid bilayer membrane array is fabricated. According to the method, the layer-by-layer assembly technology is introduced into the fabrication of the patterned substrate, the fabrication method of the phospholipid bilayer membrane array is enriched and expanded, the method has the advantages of simplicity in operation, mild reaction conditions, good controllability, high stability, low cost and the like, and a reliable technology is provided for the research and application of biological membrane characteristics with respect to the fields of membrane biophysics, interface chemistry, biochemistry, bionics and micro-nano technologies.

Owner:HARBIN INST OF TECH

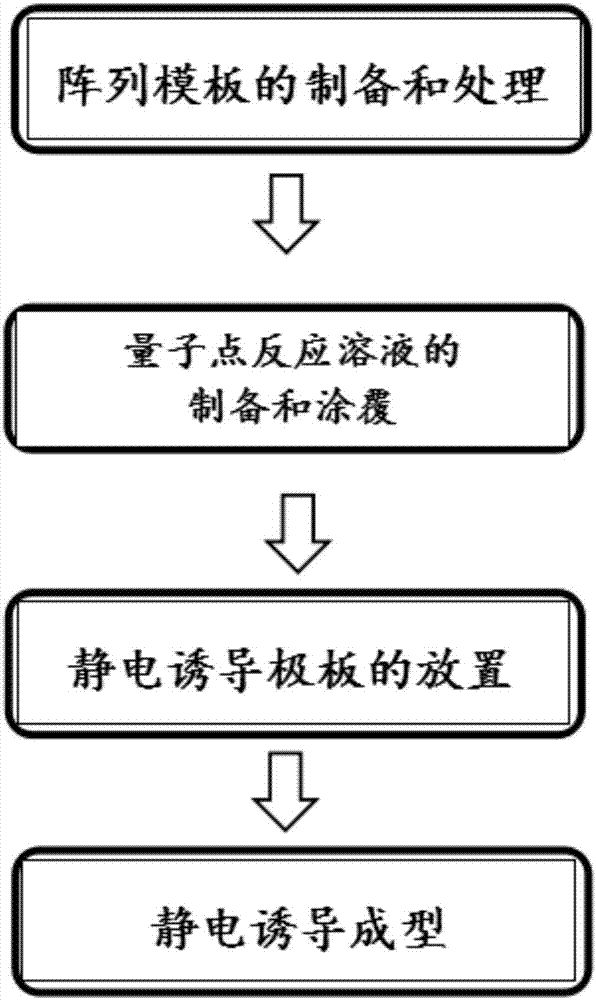

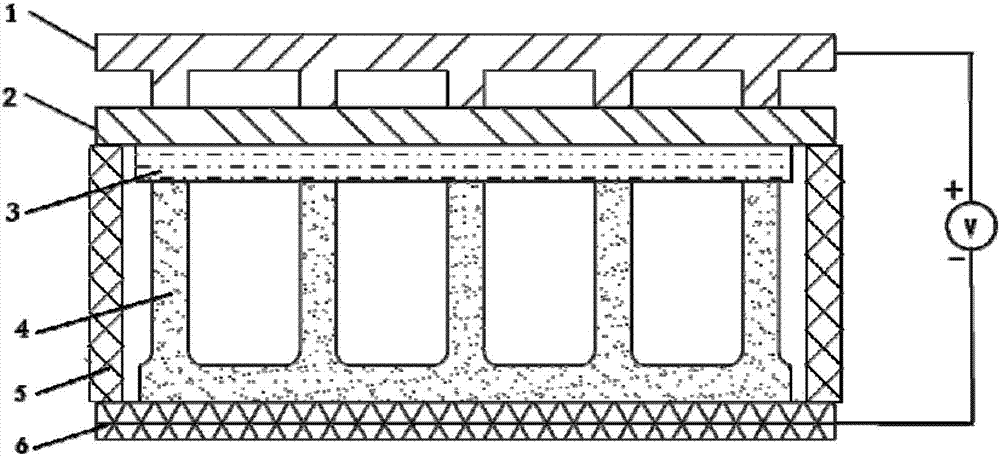

Graphical quantum-dot thin film preparation method based on electrostatic induction

InactiveCN107058984AMolding effect controlIncrease electrostatic forceMaterial nanotechnologySolid-state devicesQuantum dotColor film

The invention discloses a graphical quantum-dot thin film preparation method based on electrostatic induction. The method comprises the steps of (1) preparation and treatment of an array template; (2) preparation and coating of a quantum-dot reaction solution; (3) placement of electrostatic induction pole plates; and (4) electrostatic induction molding. The method combining electrostatic induction and the microstructural template is adopted, a quantum-dot color film substrate is prepared, the preparation process of quantum dots and the molding process of a quantum dot color film array are combined, and accordingly one-step operation is achieved; and the method is easy to operate, high in efficiency and control precision, suitable for molding of red, green and blue quantum dot color film, problems existing in the prior art are effectively solved, the manufacturing cost is lowered, and the method is suitable for a large-scale production process.

Owner:SOUTH CHINA UNIV OF TECH

Frame system for membrane filtration modules

A module arrangement (5) according to an embodiment of the invention consists of a plurality of membrane modules (6) arranged in a two dimensional array (7) and extending between upper and lower block-type manifolds (8) and (9), respectively. The array of modules is further divided into sub-groups of modules (10) separated from each other by space (11) extending transversely across the membrane array (7). An integrated support frame (12) is positioned in the space (11) between the sub-groups (10) and is fixed to the upper and lower manifold blocks (8) and (9) to form an integrated support structure within the module array (7).

Owner:EVOQUA WATER TECH LLC

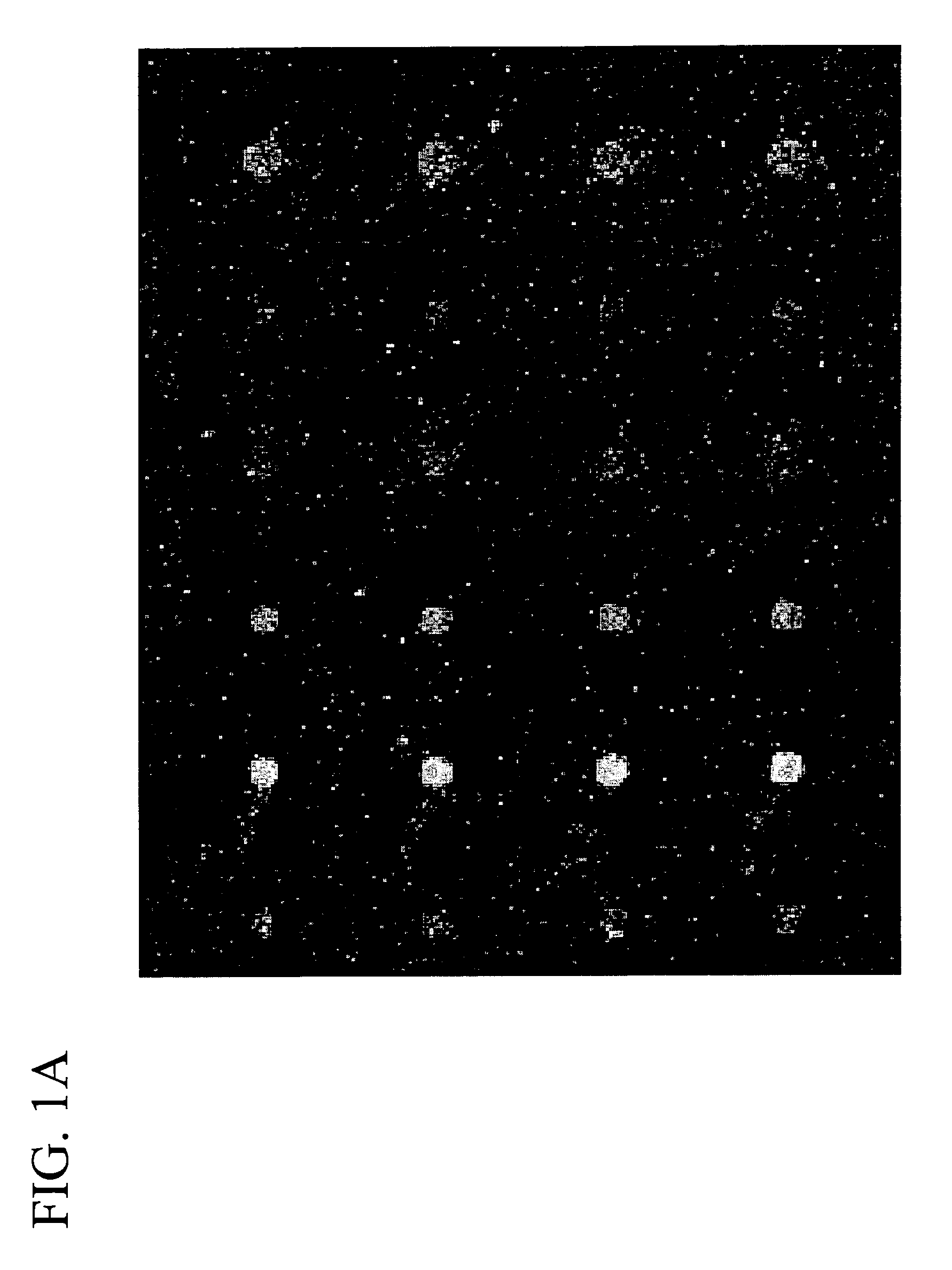

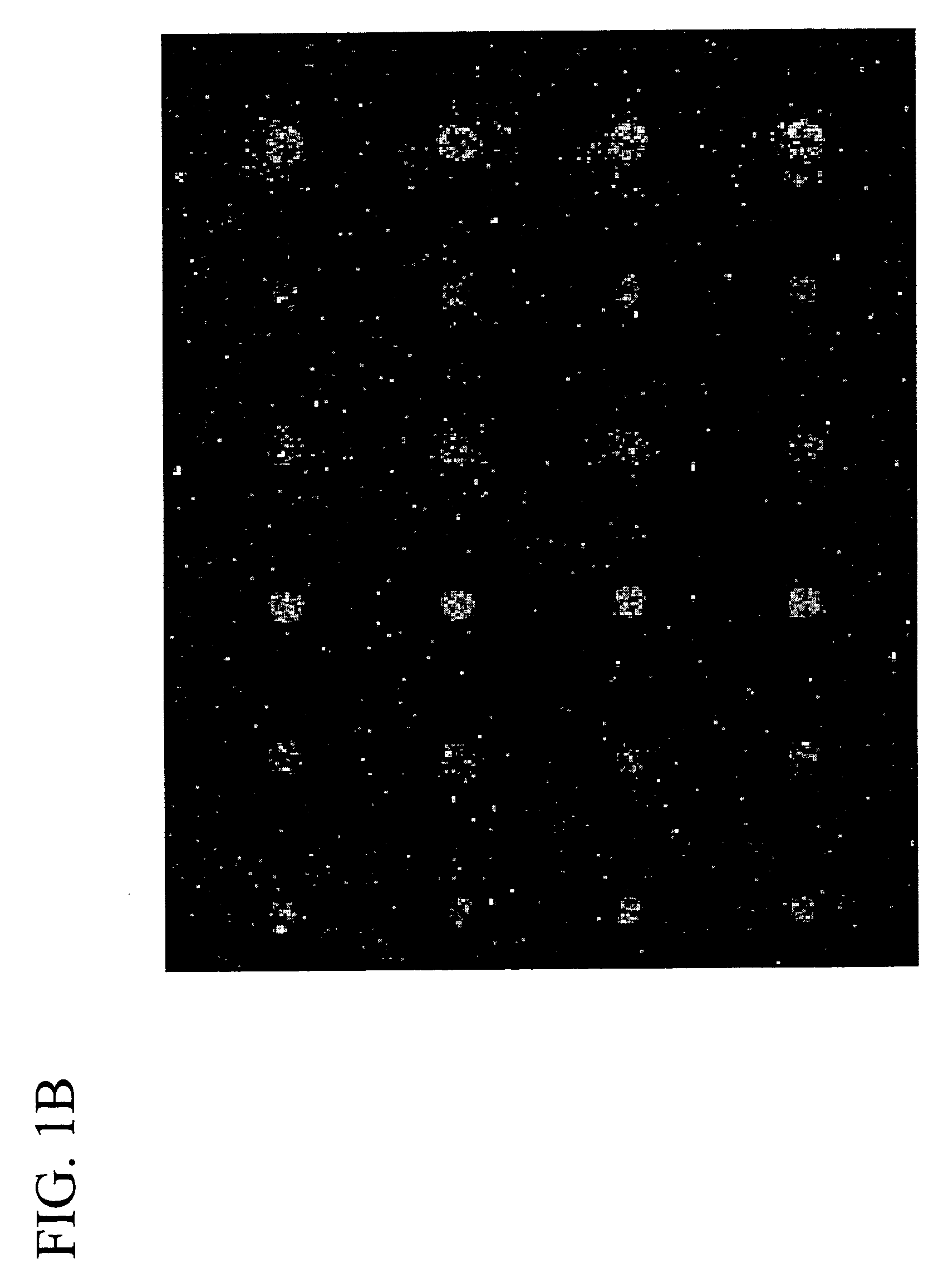

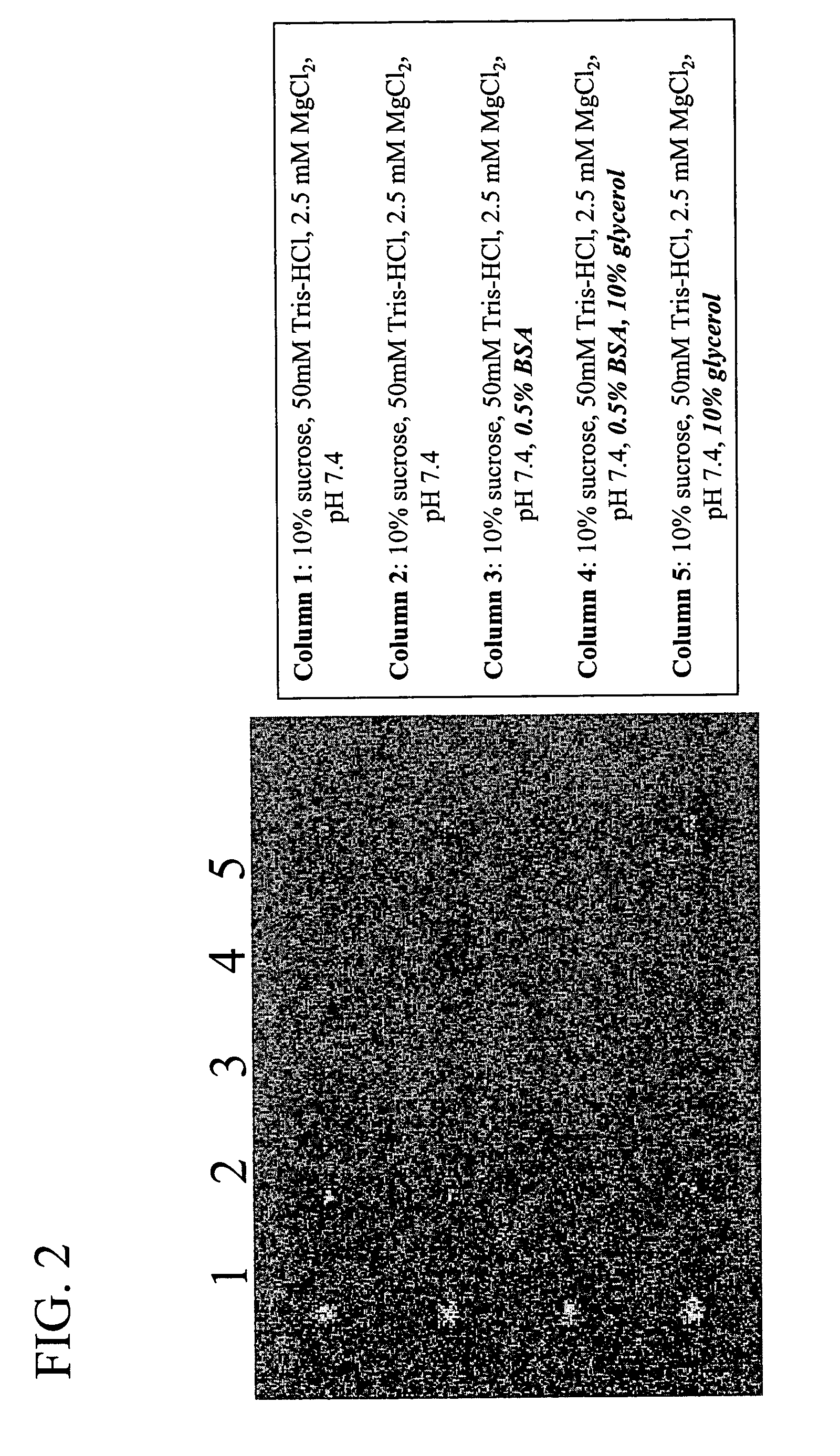

Compositions & methods for reformulating biological membranes for arrays

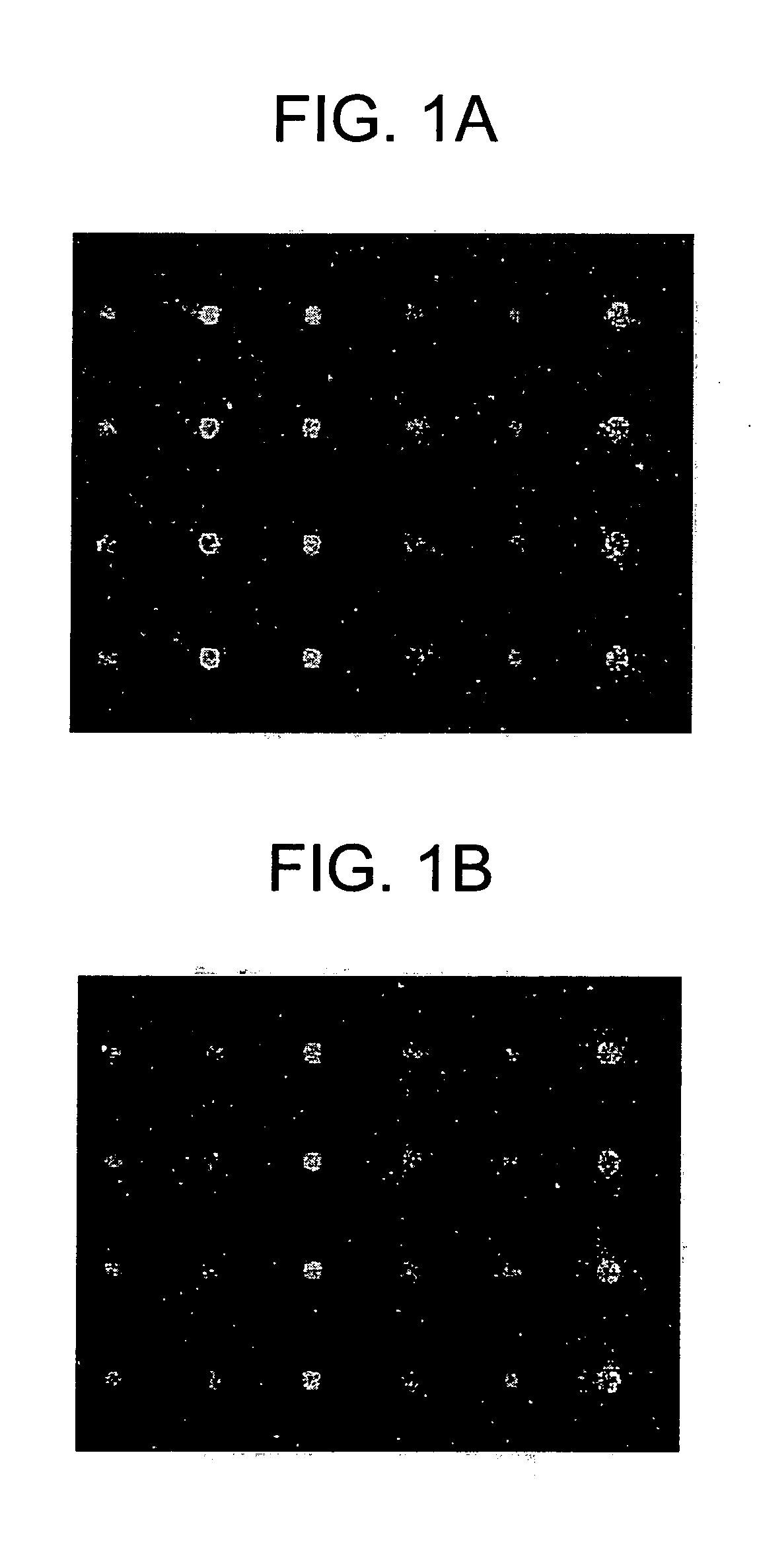

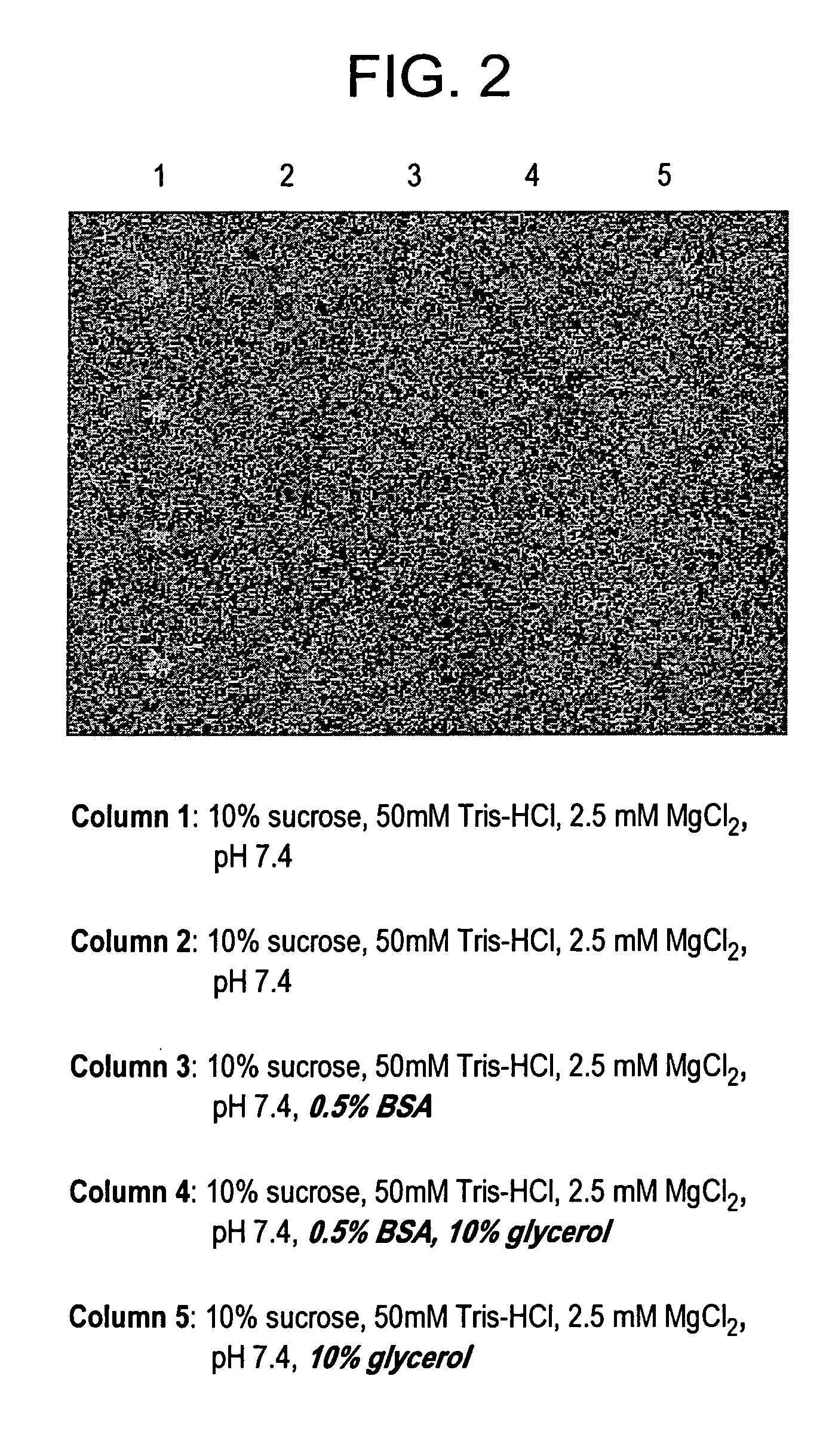

InactiveUS20070141641A1Reduced autofluorescenceControl spreadBiological material analysisTissue cultureMembrane arrayBuffering agent

A standardized, buffered solution or “ink” composition for re-formulating or suspending biological membranes used in the fabrication of membrane arrays. The composition can enhance assay performance and prolong the shelf life of biological membrane arrays. The ink composition comprises a combination of at least two of the following six classes of reagents: 1) a pH buffer reagent; 2) a monovalent or divalent, inorganic salt; 3) a membrane stabilizer; 4) a solution viscosity control reagent; 5) a water-soluble protein; or, 6) a protease inhibitor. A method for fabricating a membrane array using the present ink composition is also described.

Owner:FANG YE +1

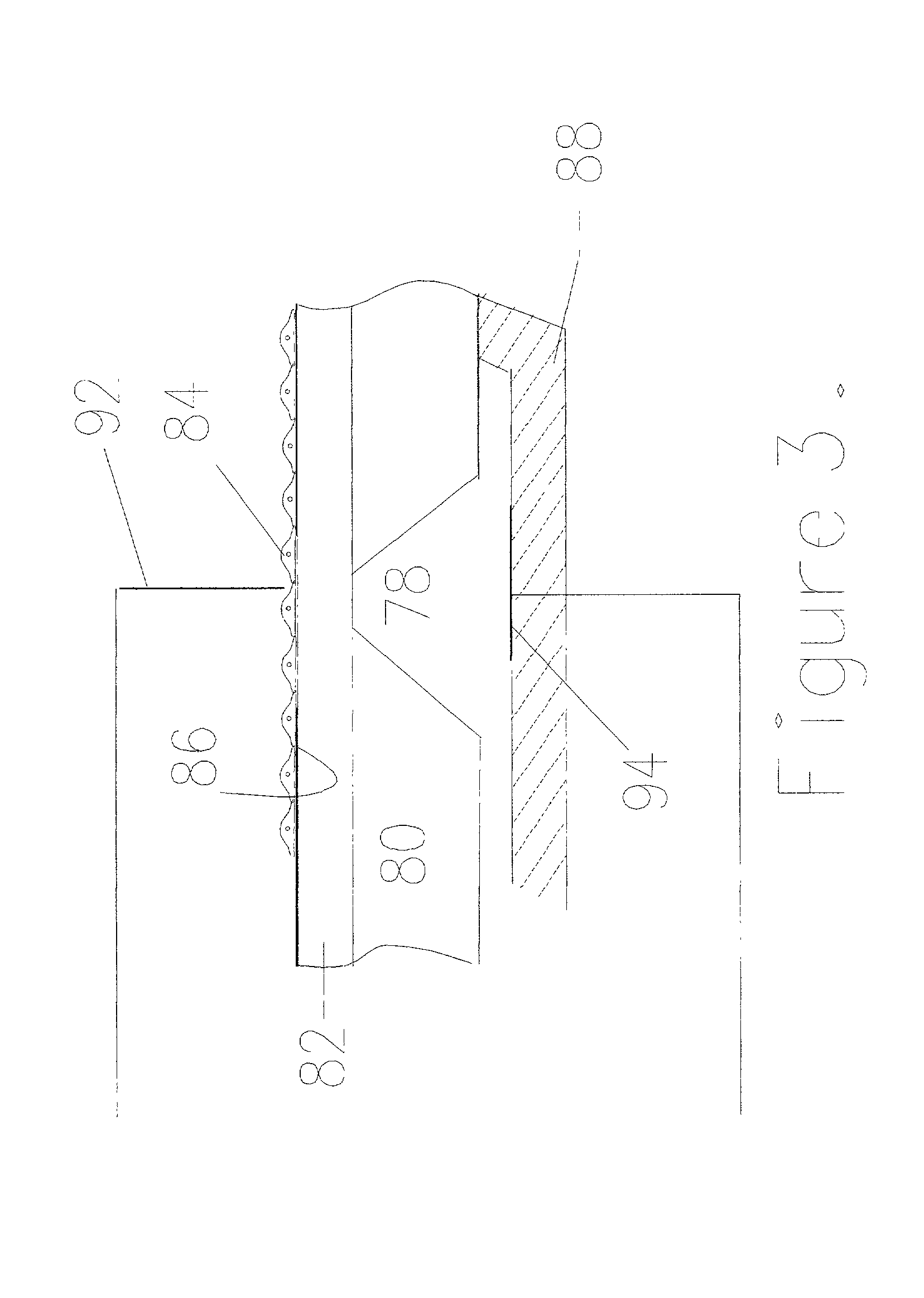

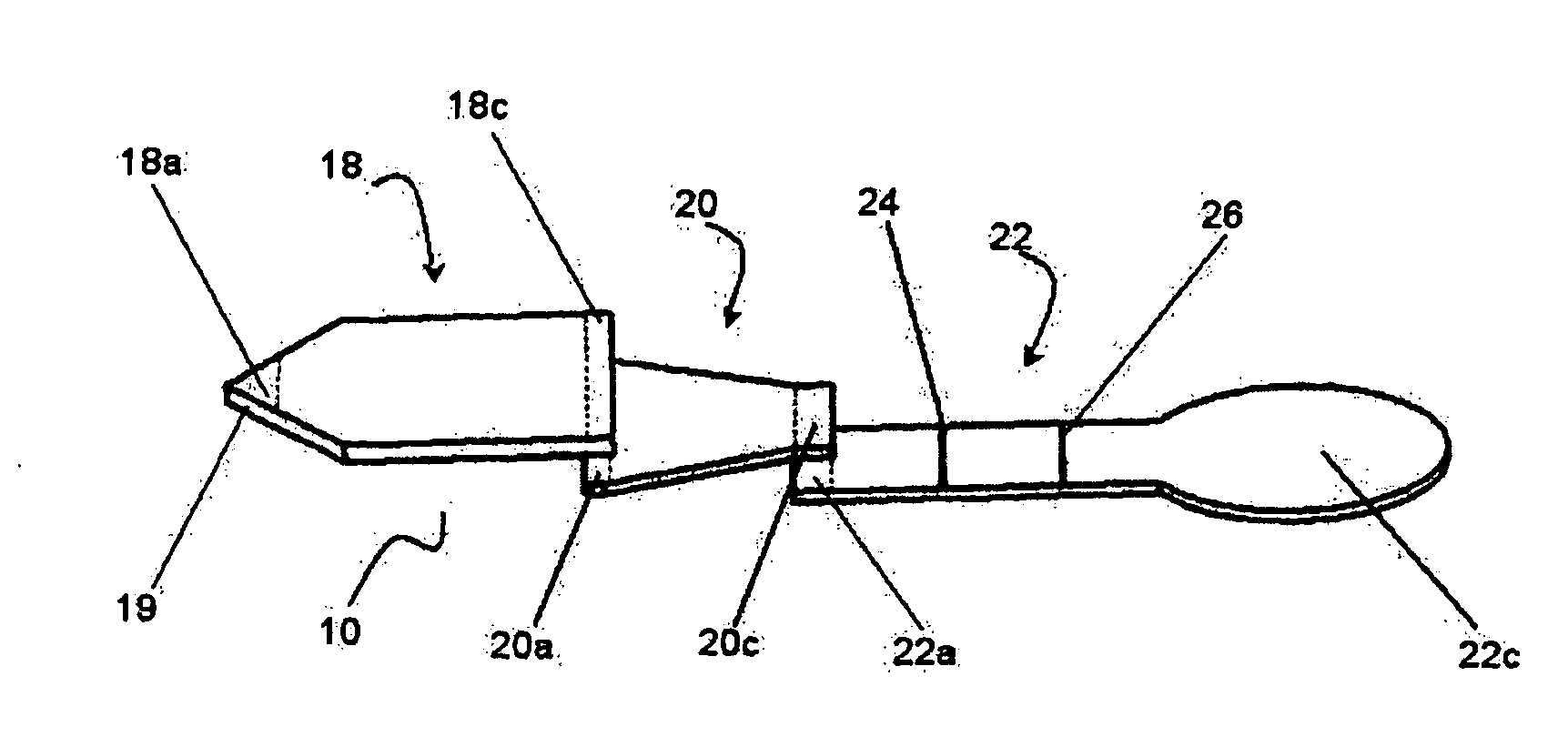

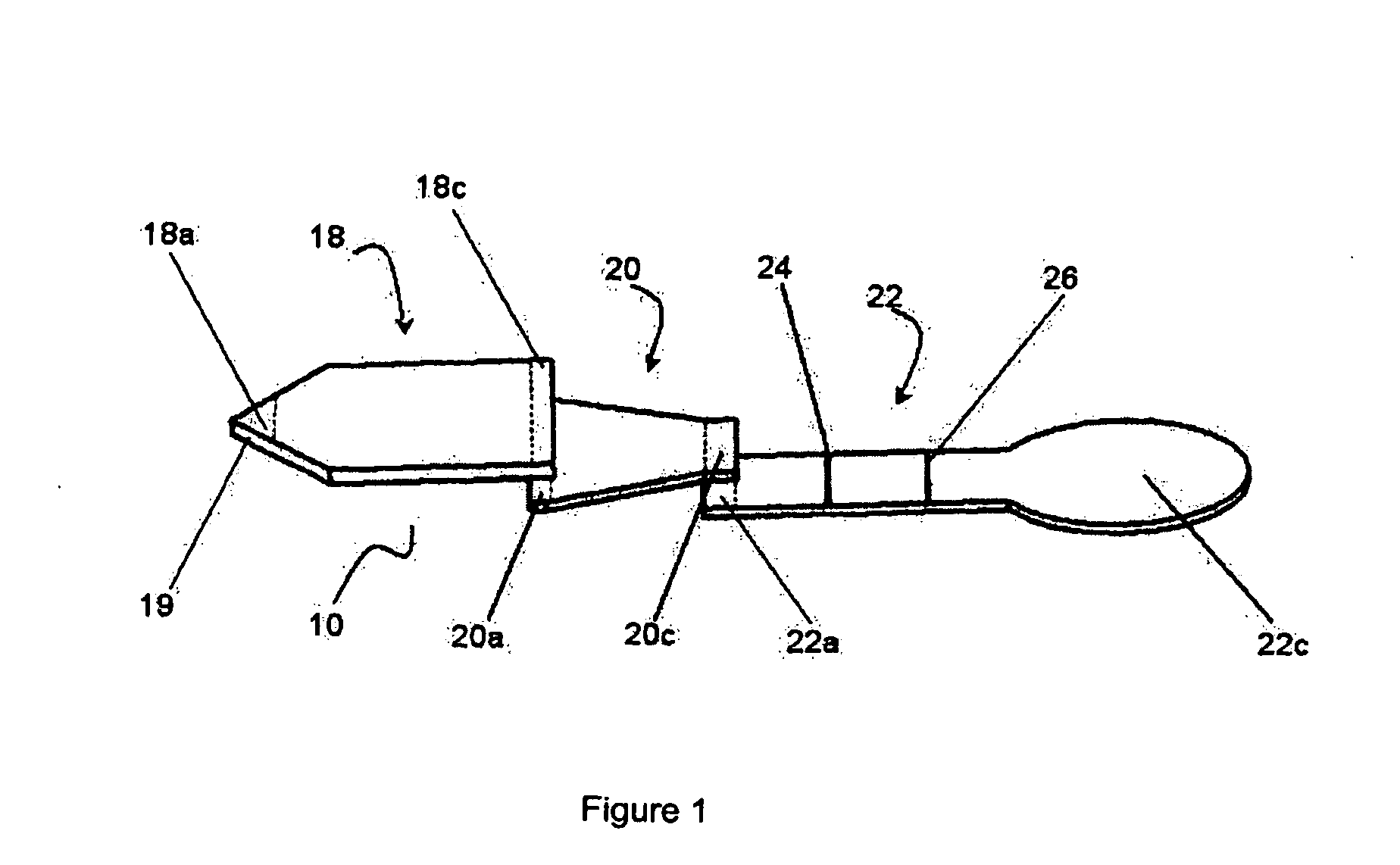

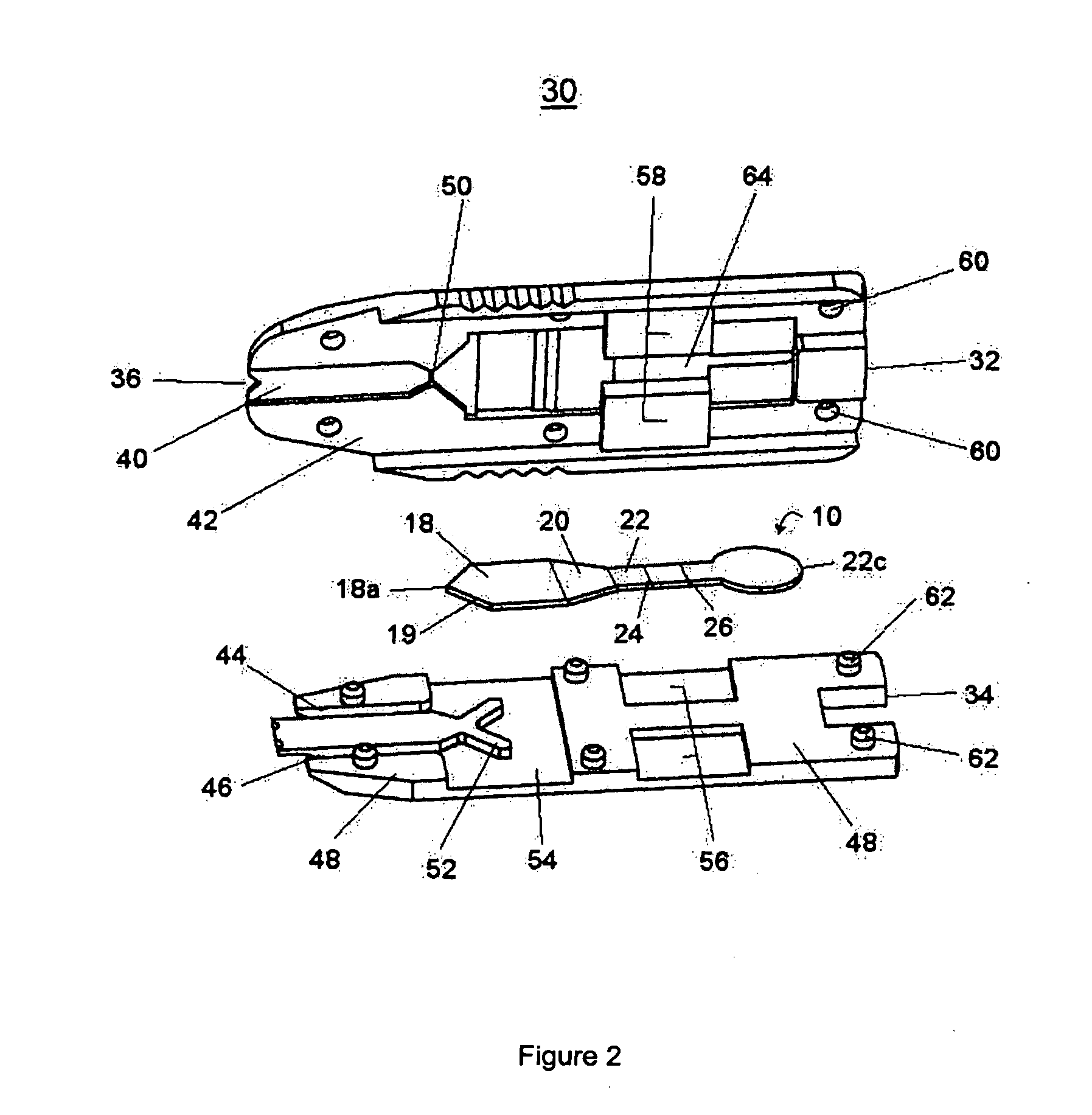

Electrically conductive membrane pump/transducer and methods to make and use same

ActiveUS20150208178A1Reduce complexityLow costElectrothermic-effect transistorPolymeric diaphragmsMembrane arrayEngineering

An improved electrically conductive membrane pump / transducer. The electrically conductive pump / transducer includes an array of electrically conductive membrane pumps that combine to move a larger membrane (such as a membrane of PDMS). The electrically conductive membranes in the array can be, for example, graphene-polymer membranes.

Owner:BRANE AUDIO LLC

Compositions & methods for reformulating biological membranes for arrays

InactiveUS20050048648A1Reduced autofluorescenceControl spreadBiological material analysisTissue cultureInorganic saltsMembrane array

A standardized, buffered solution or “ink” composition for re-formulating or suspending biological membranes used in the fabrication of membrane arrays. The composition can enhance assay performance and prolong the shelf life of biological membrane arrays. The ink composition comprises a combination of at least two of the following six classes of reagents: 1) a pH buffer reagent; 2) a monovalent or divalent, inorganic salt; 3) a membrane stabilizer; 4) a solution viscosity control reagent; 5) a water-soluble protein; or, 6) a protease inhibitor. A method for fabricating a membrane array using the present ink composition is also described.

Owner:CORNING INC

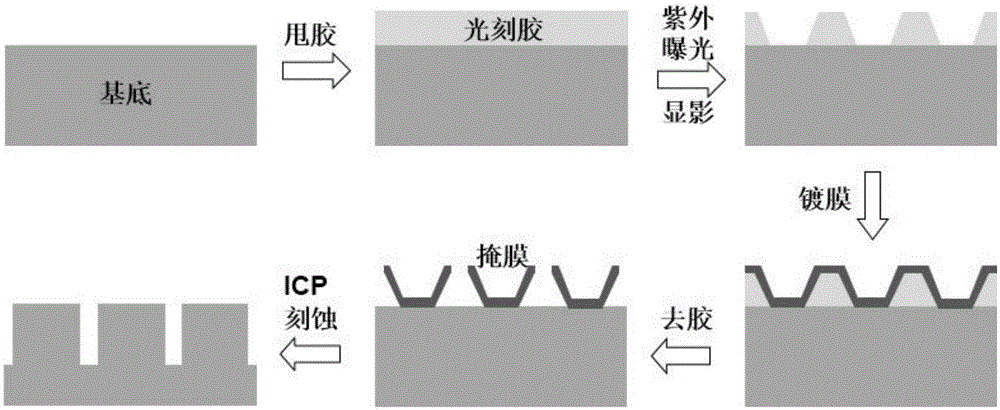

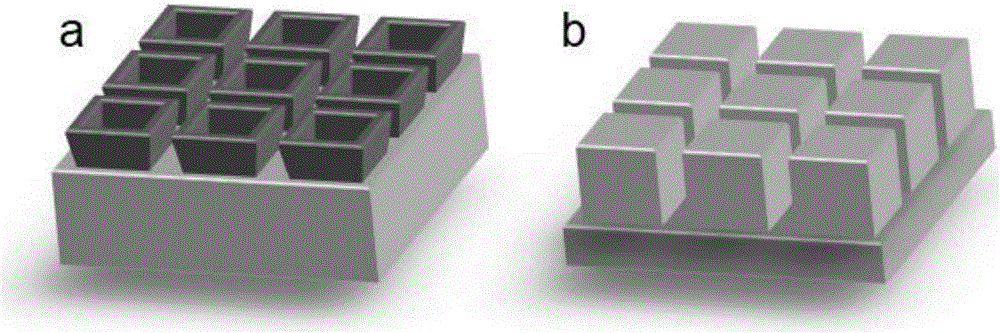

Micronano array structure, fabrication method thereof and preparation of mask array for micronano array structure

ActiveCN106444271AVariable shapeFlat surfaceTelevision system detailsImpedence networksBoundary effectsEngineering

The invention provides a mask array for fabricating a micronano array structure on a substrate and the micronano array structure obtained by fabrication of the mask array. The mask array comprises arrayed mask units, wherein the mask unit comprises a bottom surface and a side surface upwards tiling, and the bottom surface is laid on the substrate. With the mask array provided by the invention, the defects such as distortion, side wall stripes and cylinder steepness reduction due to a boundary effect during transferring a mask shape to the substrate caused by that mask damage such as deformation, defect and shrinkage of a traditional mask in dry etching is easy to generate are overcome, and a suspension mask provided by the invention is free from limitation of materials and shapes; meanwhile, the steep smooth-surface cylinder is also free from the limitation of materials and shapes; and the mask array is simple in process flow, is convenient to process and is relatively low in cost.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Membrane array and analytical device

ActiveUS20100197000A1Rapid and highly efficient and highly sensitive detectionBioreactor/fermenter combinationsBiological substance pretreatmentsSmall sampleAnalyte

A membrane array used to detect one or more analytes from a small sample of fluid with high sensitivity is provided. The membrane array can be employed in various analytical devices and is especially useful for identifying analytes from whole blood with minimal or negligible background interference.

Owner:ZBX CORP

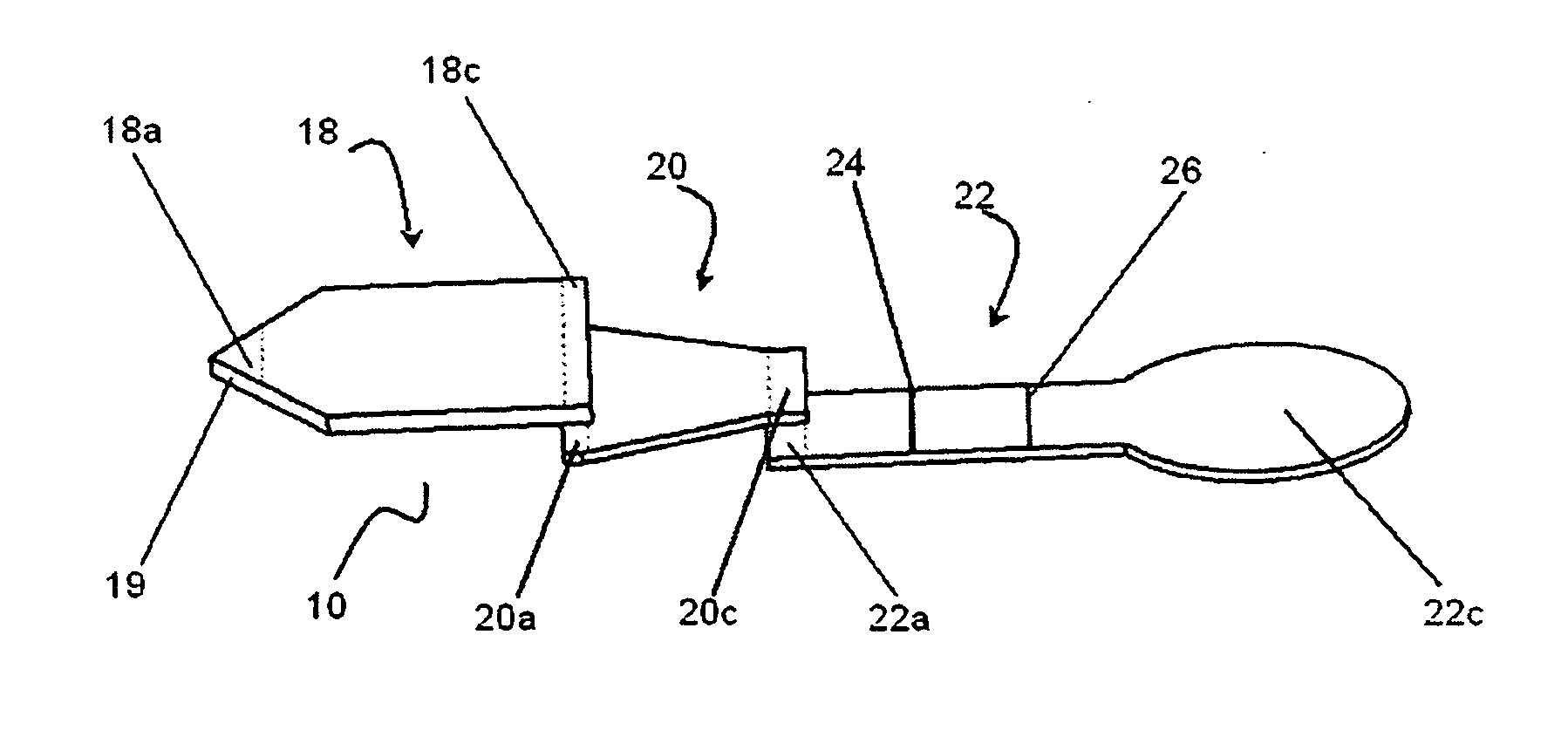

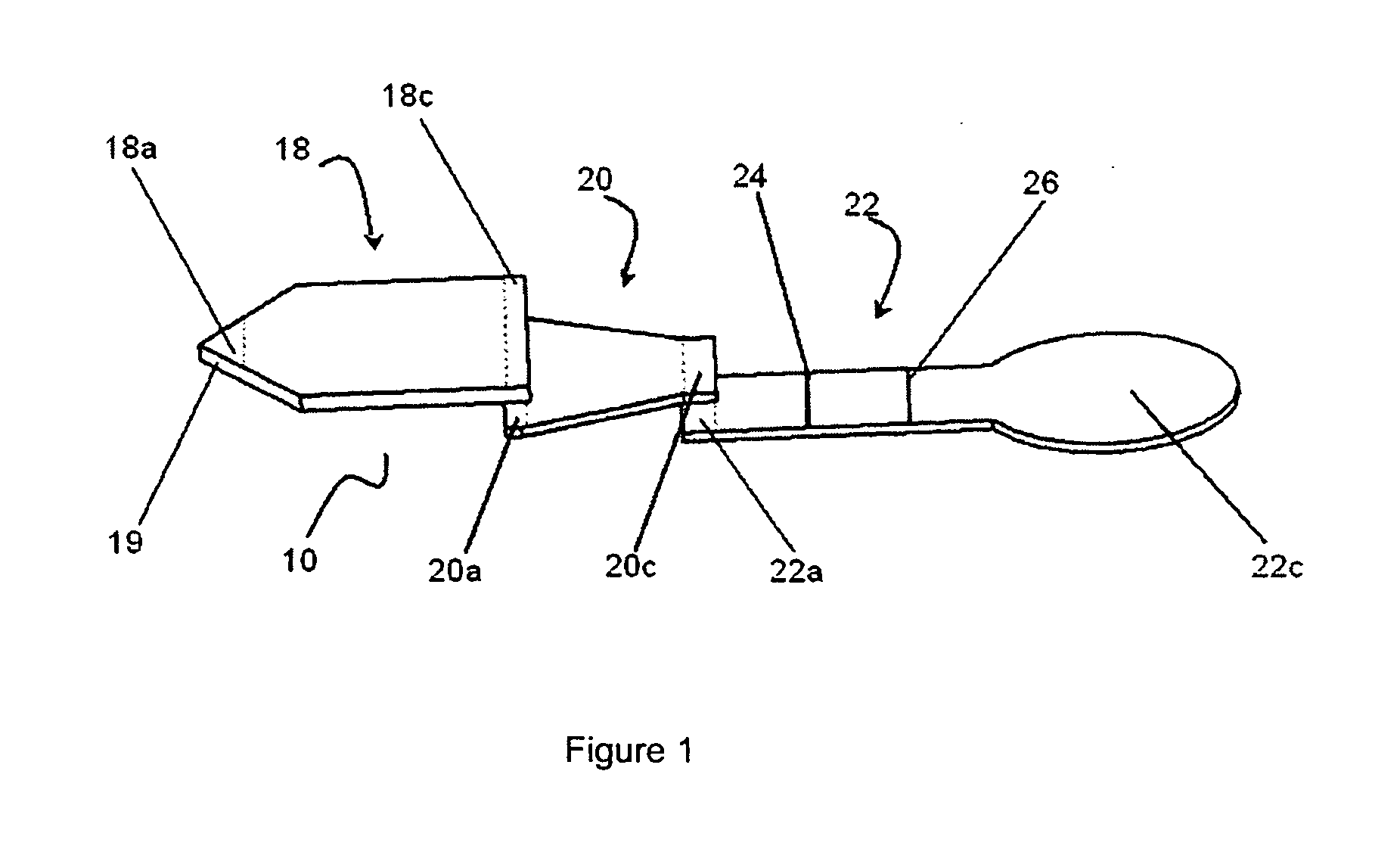

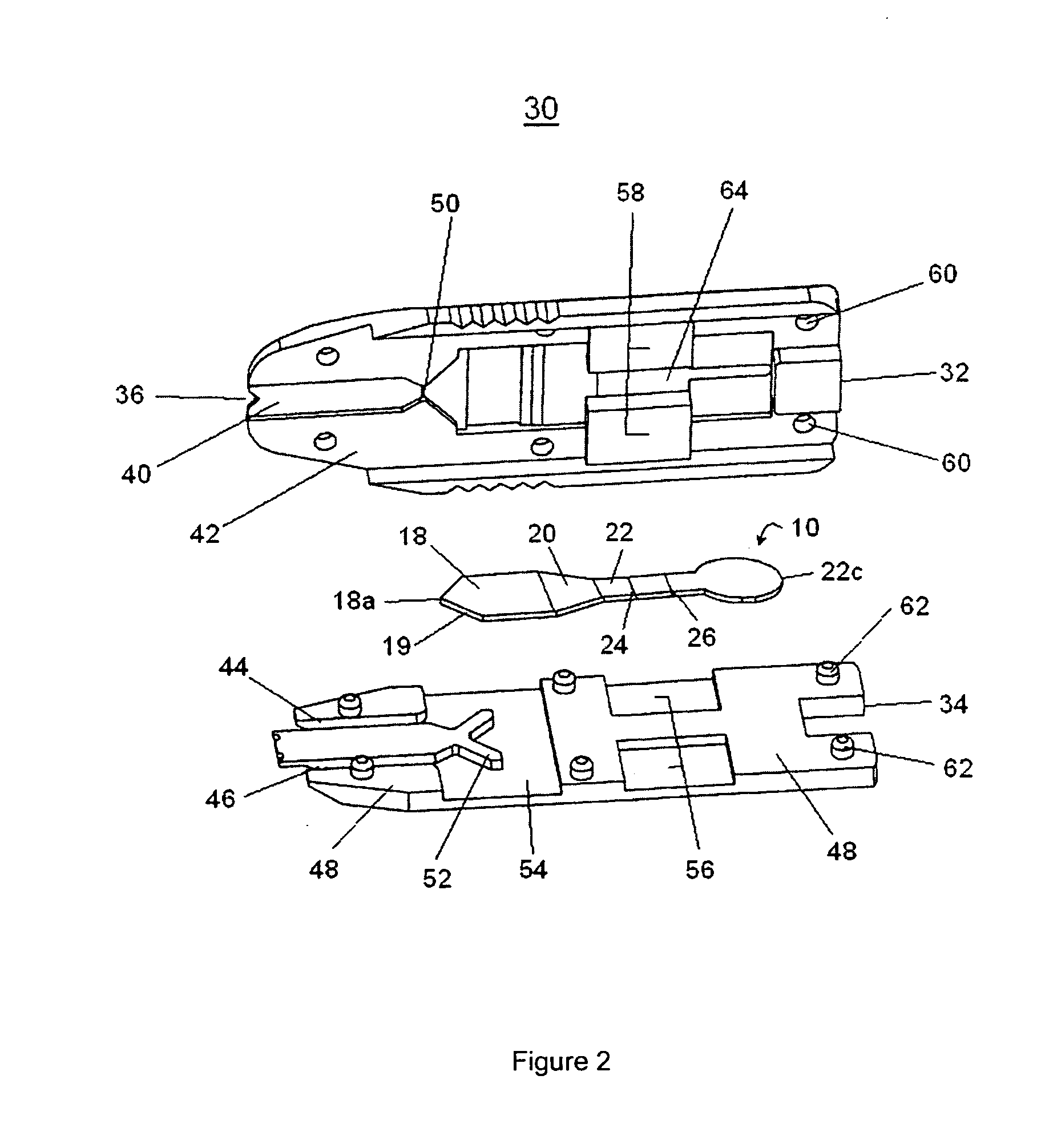

Membrane arrays and methods of manufacture

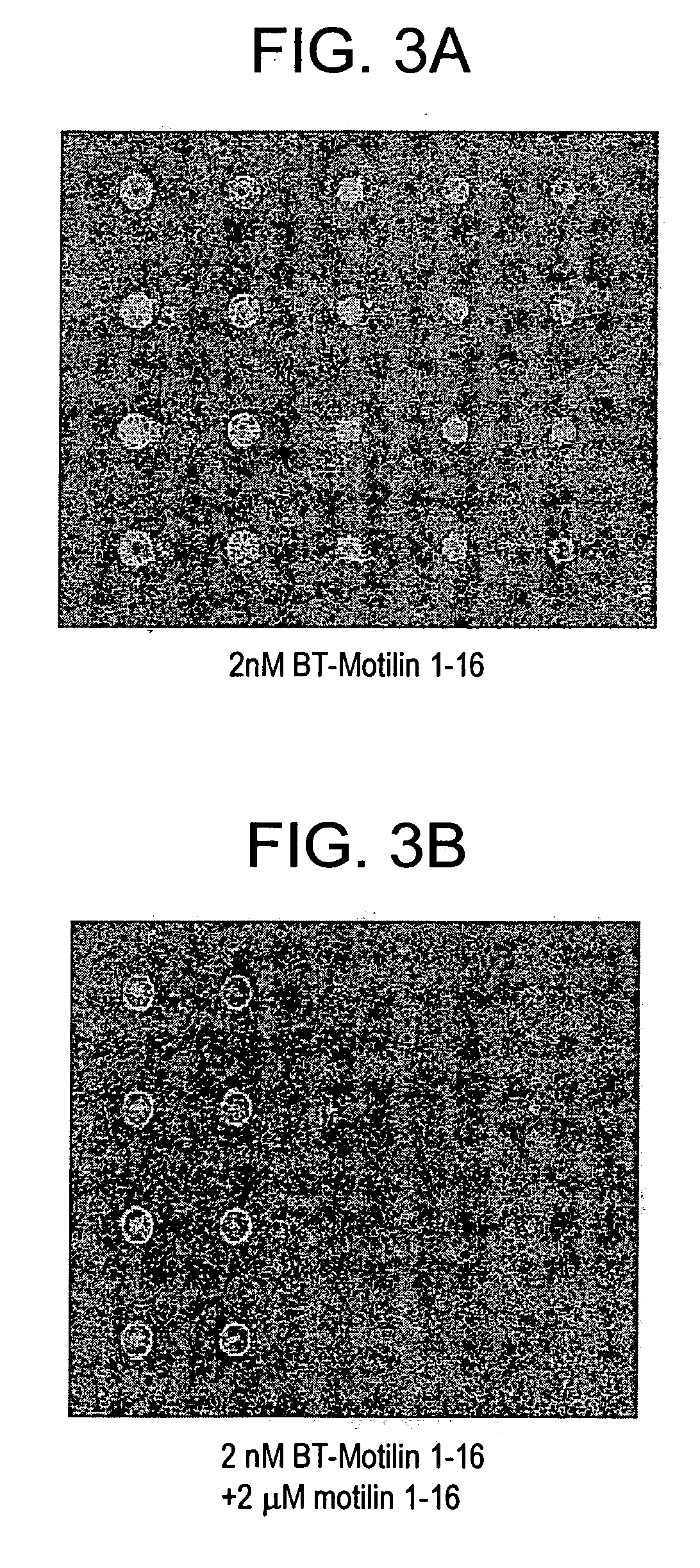

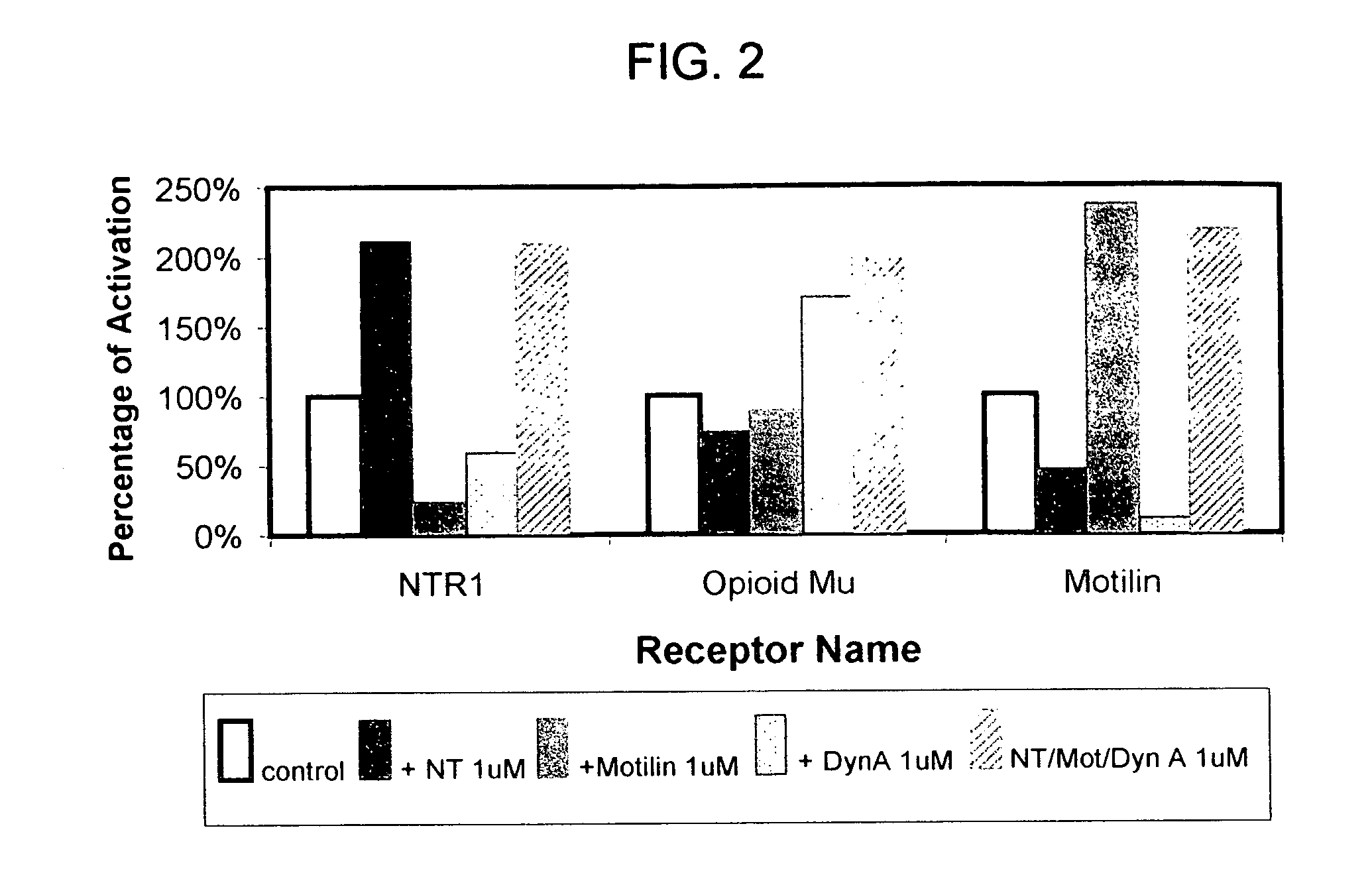

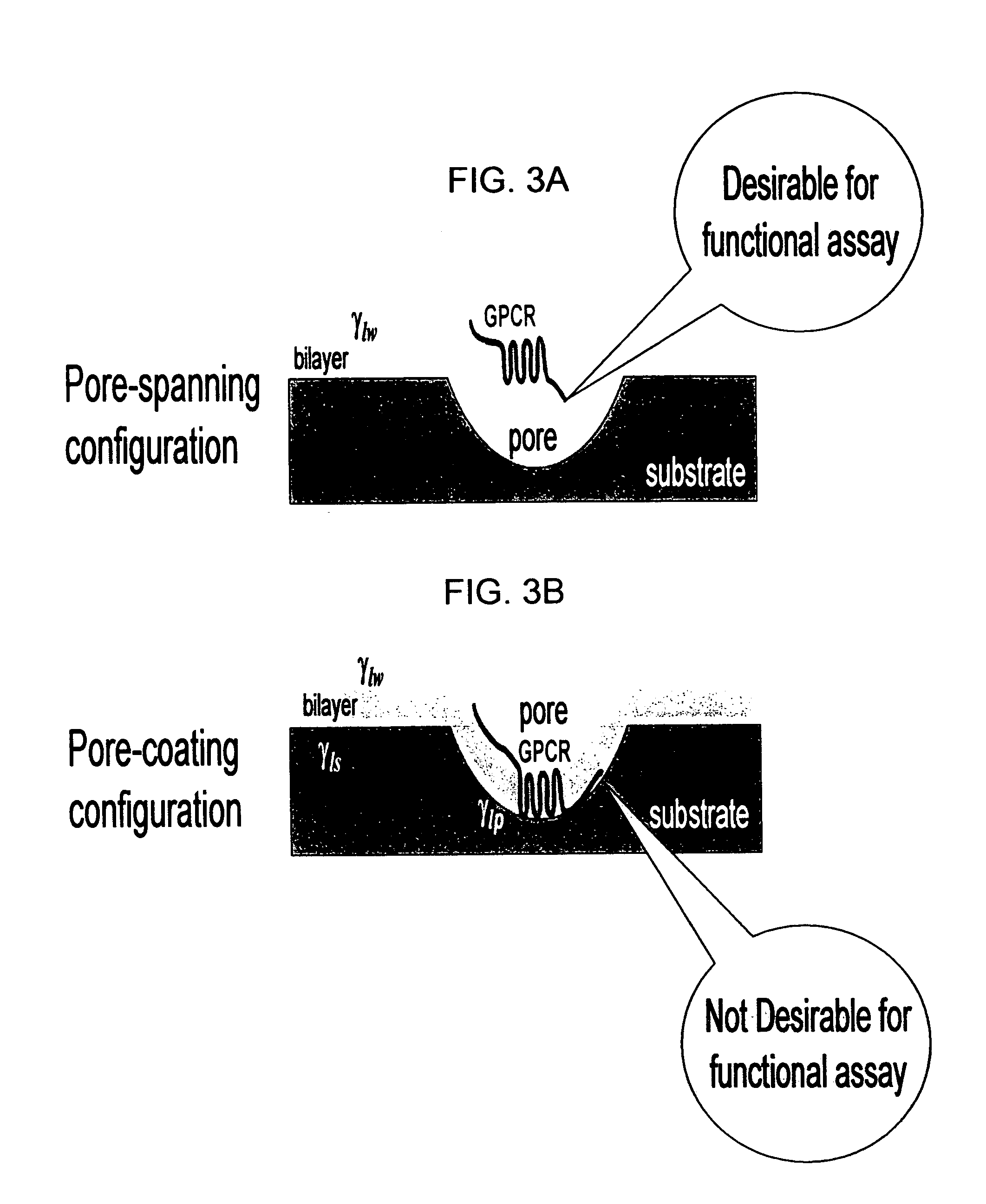

InactiveUS7473533B2Efficient transferBioreactor/fermenter combinationsBiological substance pretreatmentsPorous substrateG protein-coupled receptor

The invention relates to G protein-coupled receptor (GPCR) microarrays on porous substrates for structural or functional analyses of GPCRs, and methods of preparing porous substrate surfaces for receiving membranes that comprise GPCRs. In one embodiment, a GPCR microarray of the invention comprises a membrane adhered to an upper surface of a porous substrate, the membrane spanning across a plurality of pores on the porous substrate to form a plurality of cavities having sufficient geometry to permit entry of assay reagents into each cavity, thereby allowing access of assay reagents to both sides of GPCR in the membrane.

Owner:CORNING INC

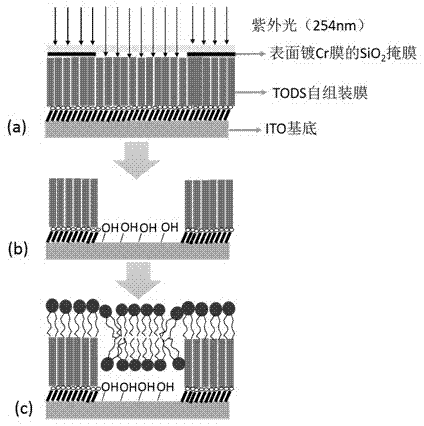

Method for preparing patterned phospholipid membrane array on ITO (indium tin oxide) conductive glass

The invention discloses a method for preparing a patterned phospholipid membrane array on ITO (indium tin oxide) conductive glass, and the method comprises the steps: (1), self-assembling of TODS on the surface of ITO: immersing the washed ITO into fresh TODS-methylbenzene solution, sealing the solution and placing the solution silently for 4-12 hours, taking out the solution, placing the solution into methylbenzene for ultrasonic cleaning for 5-10 min, washing the methylbenzene on the surface of ITO through ethyl alcohol, carrying out drying through nitrogen, and carrying out the sealed storage for later use; (2), the preparation of a patterned ITO substrate: placing a chromium film plate with a patterned lattice on the ITO glass decorated with a TODS self-assembly film, and irradiating the chromium film plate for 17-25 min; (3), dripping 50-200 microlitre of phosphatide vesicle solution on the surface of a patterned ITO electrode, placing the electrode silently for 30-60 min under the temperature 20-60 DEG C, and forming a pattern phosphatide film on the ITO electrode. The phosphatide film prepared through method can be represented through a luminescence microscope and an electrochemical method, can be used for the research of the two-dimensional film electrophoresis of charged species in the film, and achieves the gathering and separating of charged species in the phosphatide film.

Owner:HARBIN INST OF TECH

Membrane array and analytical device

ActiveUS20100137145A1Rapid and highly efficient and highly sensitive detectionLibrary screeningEnzymologyAnalyteSmall sample

A membrane array used to detect one or more analytes from a small sample of fluid with high sensitivity is provided. The membrane array can be employed in various analytical devices and is especially useful for identifying analytes from whole blood with minimal or negligible background interference.

Owner:ZBX CORP

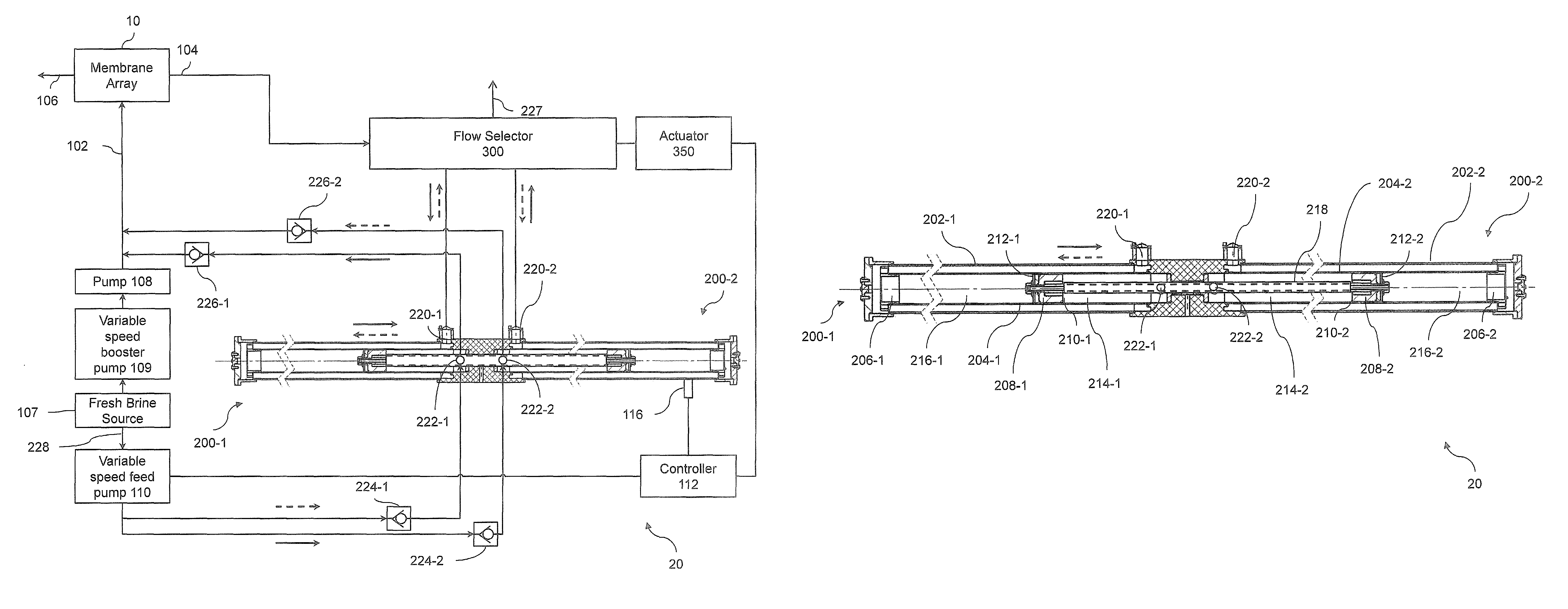

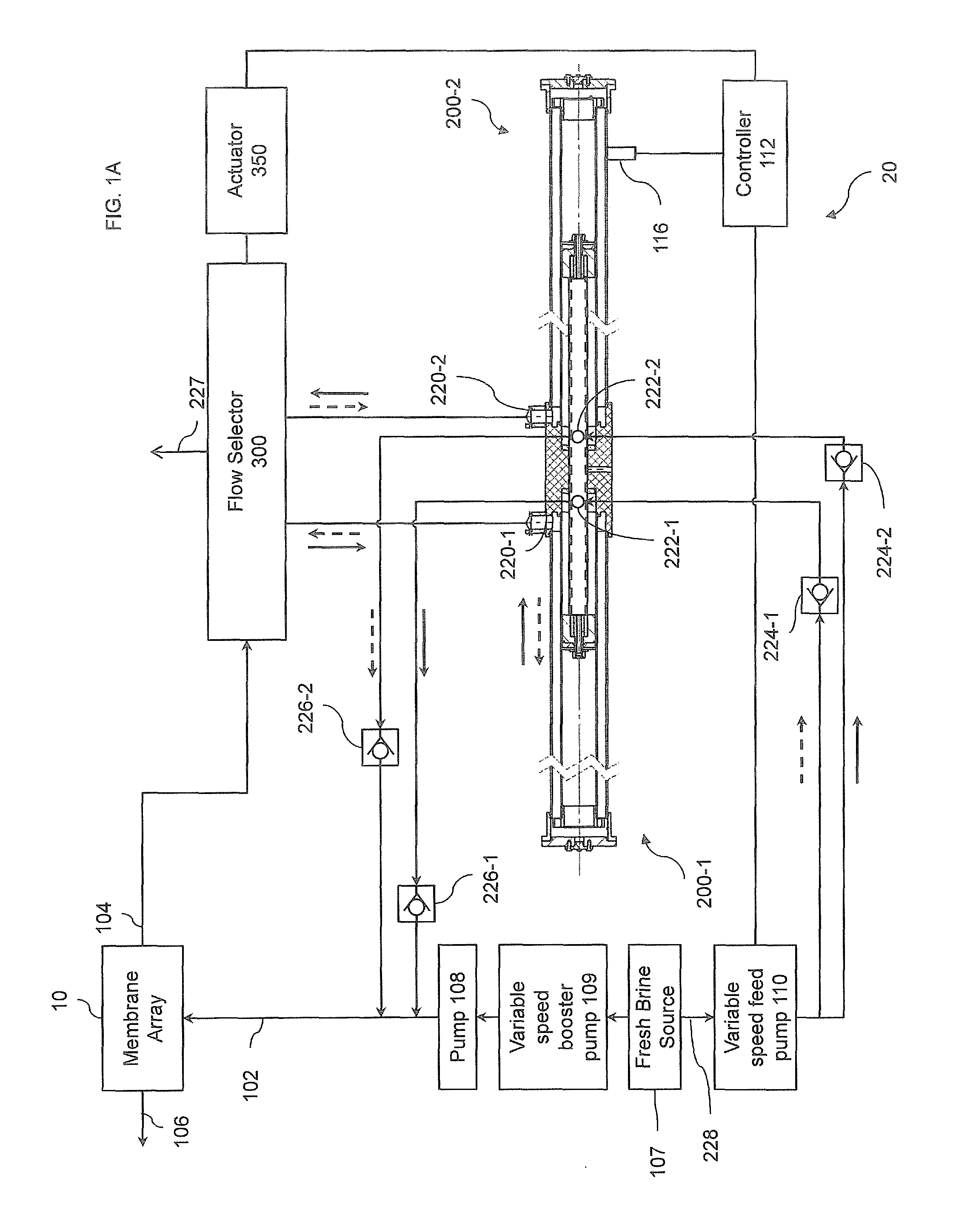

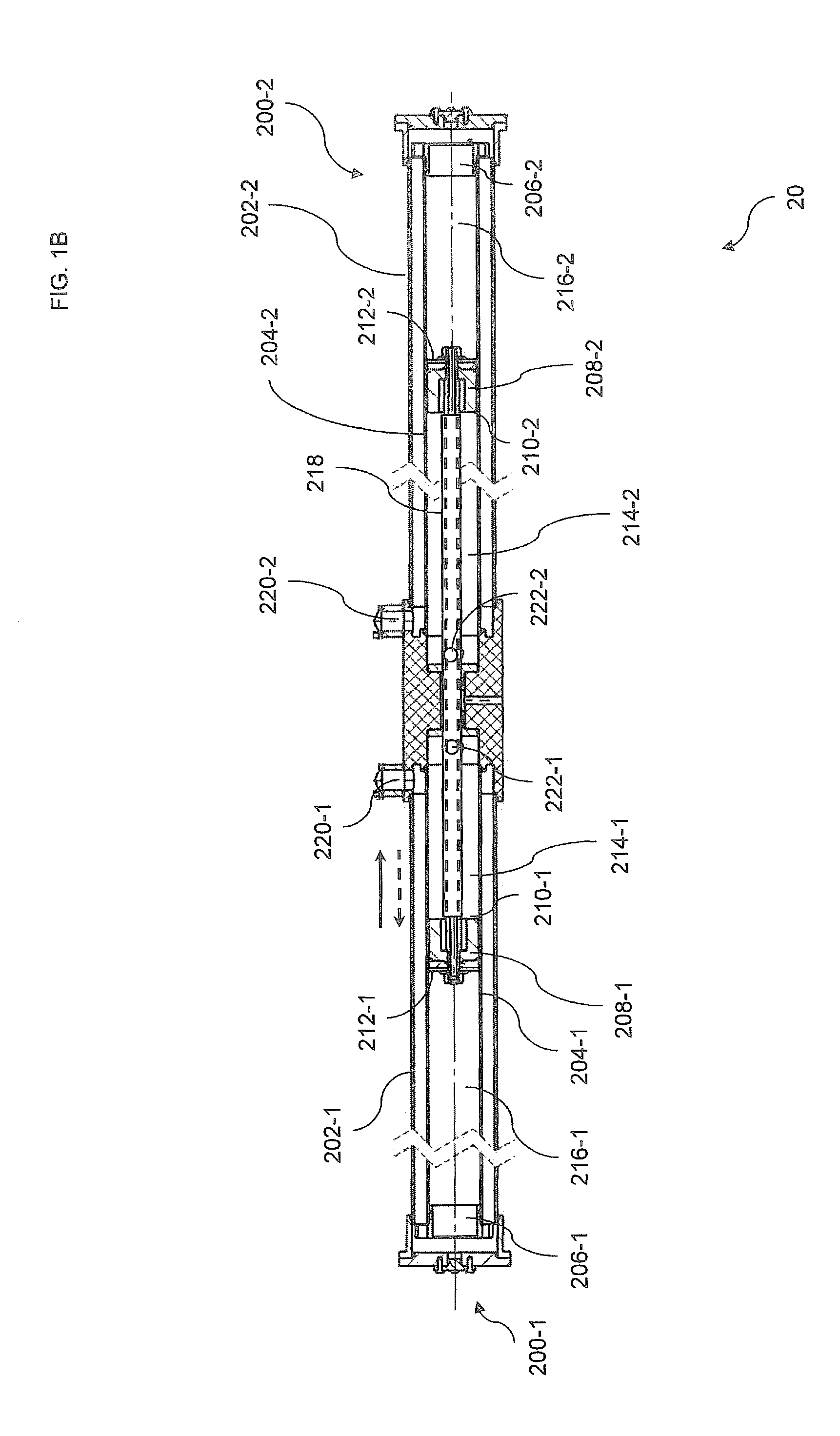

Cylinder arrangement and method of use for energy recovery with seawater desalination

InactiveUS9233340B1Increase the effective surface areaLarge amount of adjustmentWater treatment parameter controlMembranesSaline waterMembrane array

A cylinder arrangement for use with a reverse osmosis membrane array that receives pressurized fresh brine and generates fresh water and pressurized spent brine includes a hollow cylinder with an internal volume subdivided by a piston into two chambers. An arrangement of flow connections directs the pressurized spent brine to one chamber so as to act on the piston, thereby applying pressure to fresh brine within the other chamber for delivery to the reverse osmosis membrane array. The cylinder arrangement includes a pressure vessel enveloping substantially the entirety of the hollow cylinder, so as to define an enveloping volume in fluid flow communication with one of the chambers of the cylinder. Preferred implementations employ a pair of cylinders coaligned, and with their pistons interconnected by a common piston rod.

Owner:RENERGY TECH

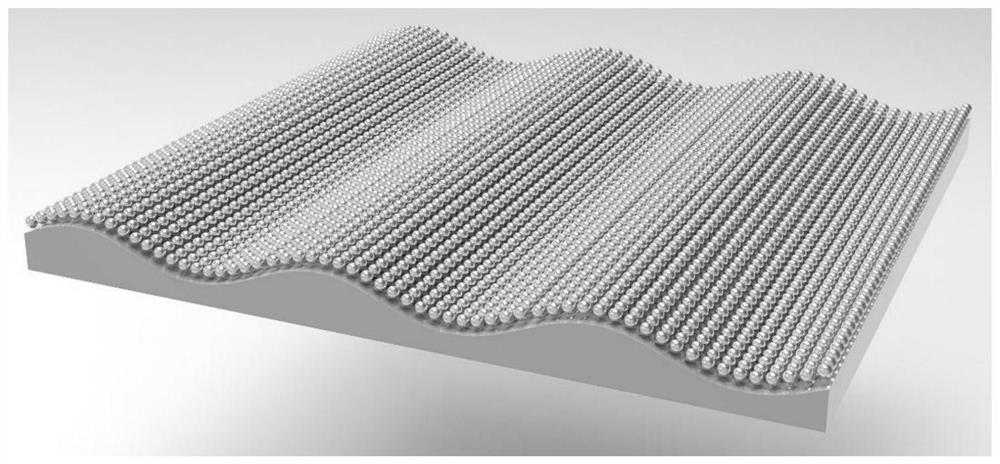

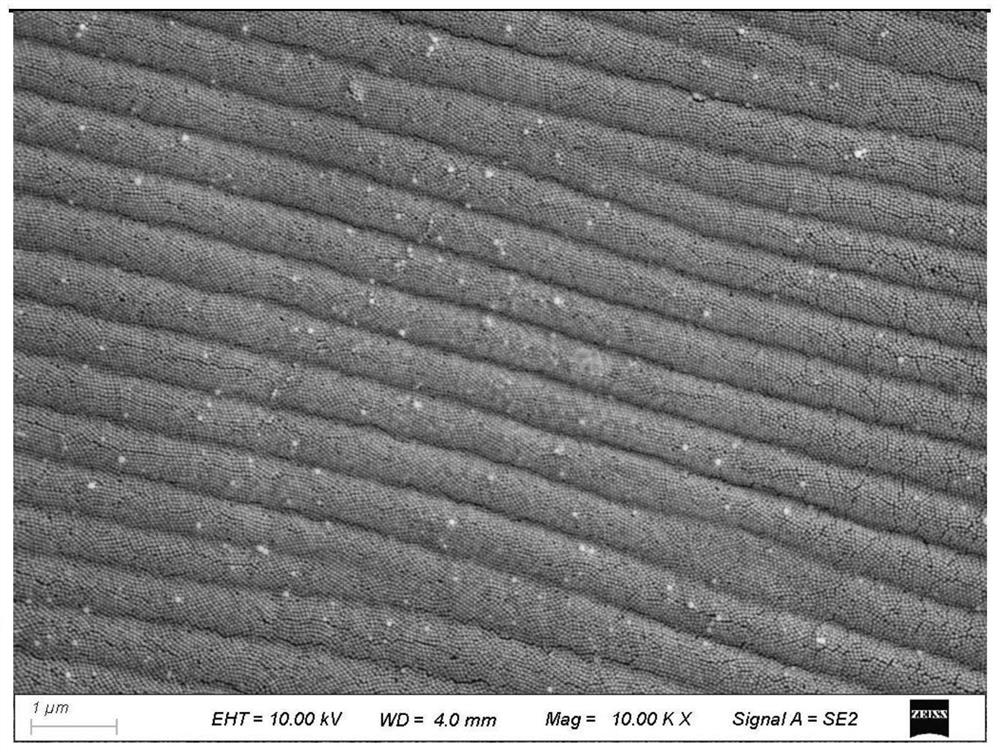

Three-dimensional arrangement nanoparticle film array structure and preparation method and application thereof

ActiveCN113189680AEnhanced interactionSuppression of radiation lossNon-linear opticsOptical elementsRadiation lossOrganic solvent

The invention provides a three-dimensional arrangement nanoparticle film array structure and a preparation method and an application thereof and belongs to the technical field of nano photonics. The preparation method comprises the following steps of coating nano-particles with hydrophobic molecules, and dispersing the coated nano-particles in an organic solvent to obtain a modified nano-particle dispersion liquid; carrying out surface treatment on the three-dimensional template to obtain a hydrophilic three-dimensional template; and adding the water to the surface of the hydrophilic three-dimensional template to form a water film, dropwise adding the modified nanoparticle dispersion liquid to the surface of the water film for self-assembly, and then removing the water film to obtain the three-dimensionally arranged nanoparticle film array structure. The three-dimensional array structure prepared by a self-assembly-template auxiliary method can generate vertical and parallel multi-surface lattice resonance, effectively inhibit radiation loss, enhance interaction between nanoscale light and substances, and have good application prospects in enhancement of nonlinear effect, biosensing, nano laser or enhancement of fluorescence; and the preparation method is good in universality, simple to operate and low in cost.

Owner:TAIYUAN UNIV OF TECH

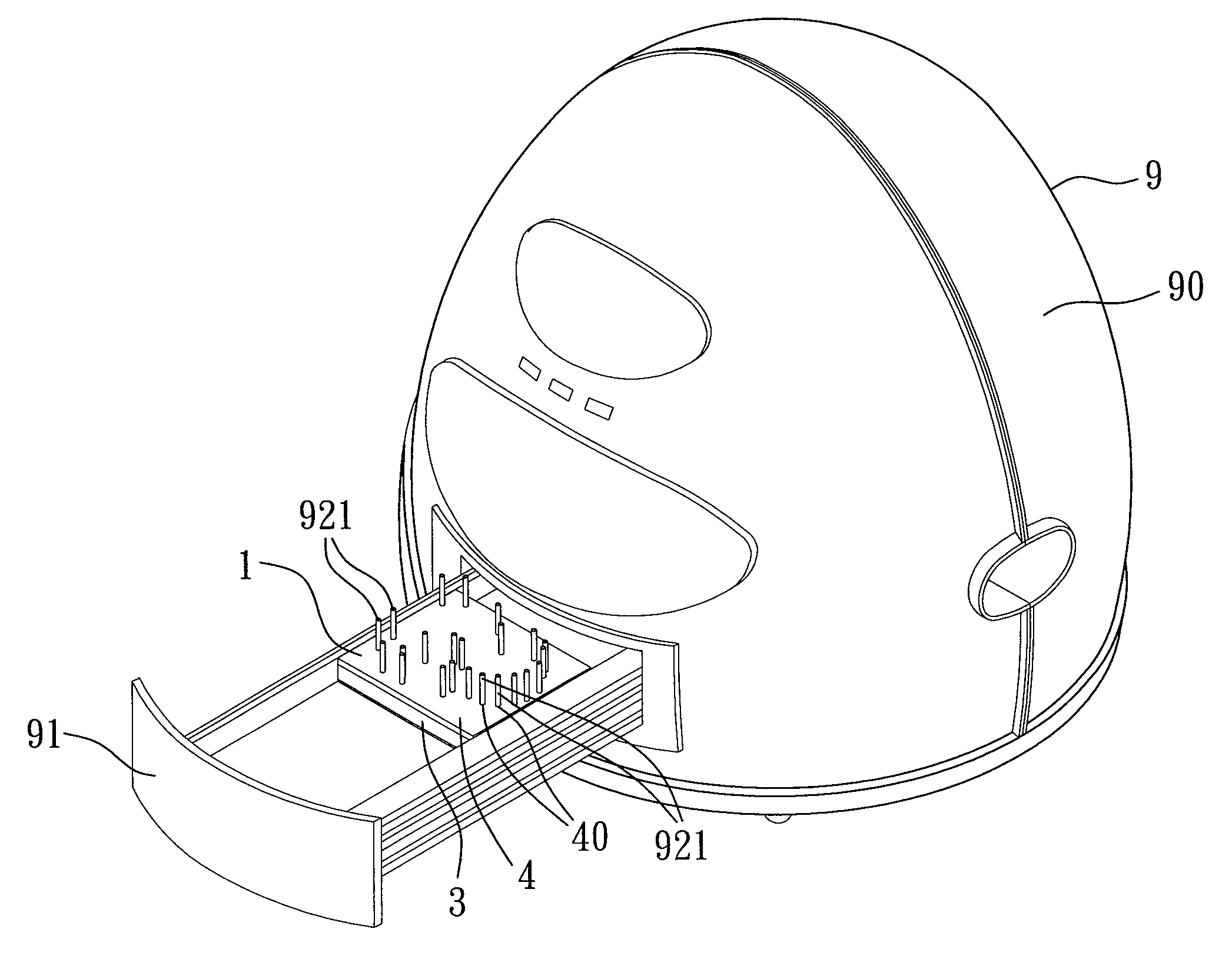

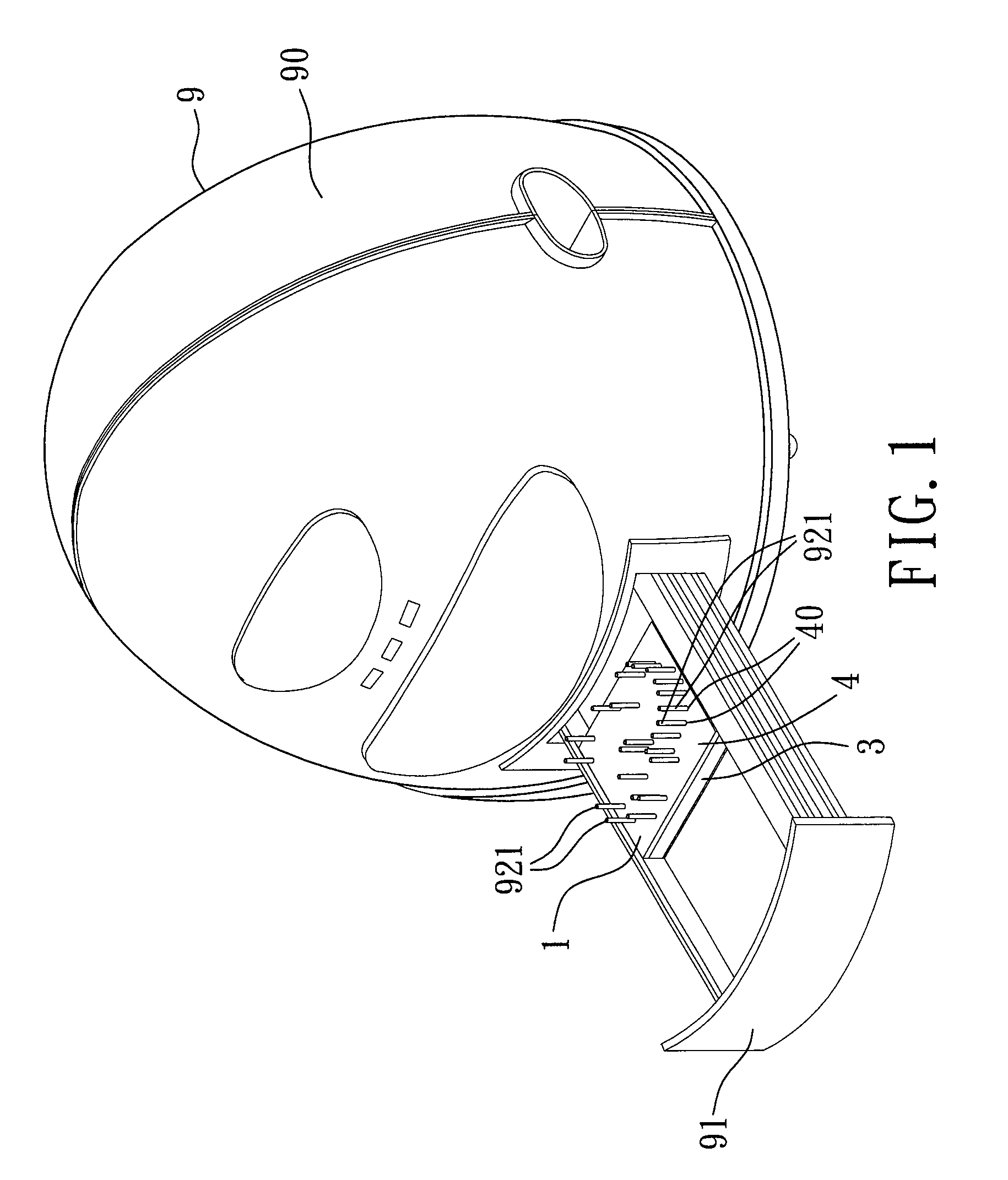

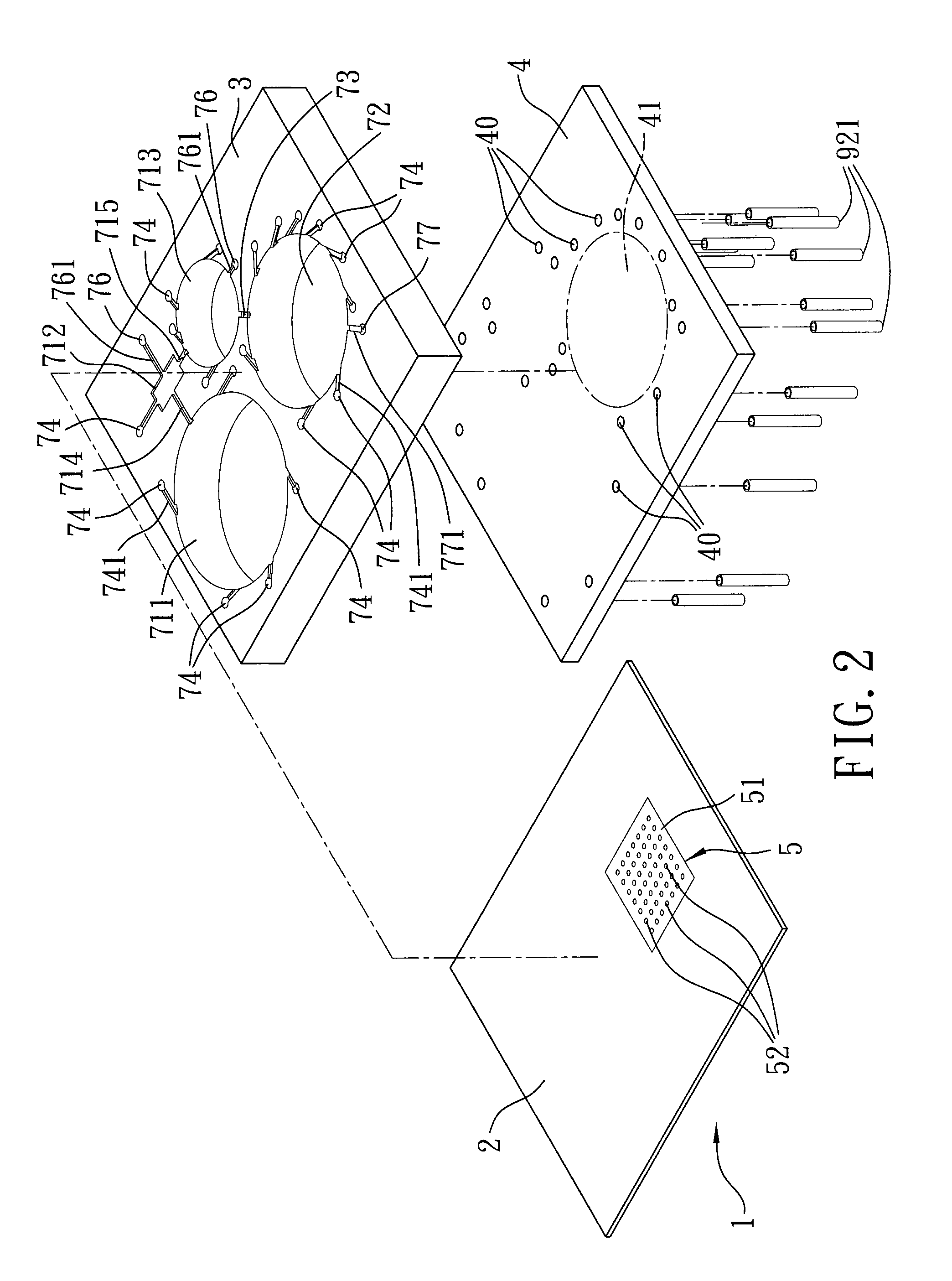

Gene-array operation chip device

A gene-array operation chip device includes a reaction chamber, and a plurality of inlet holes connected respectively to agitation channels for creating agitation currents within the reaction chamber. Each agitation channel has two ends respectively connected to one of the inlet holes and to the reaction chamber. The agitation channels are inclined with respect to radial directions about an axis of the reaction chamber. Preferably, a flow channel interconnecting two reaction chambers has a hydrophobic wall surface to limit a fluid from flowing naturally between the chambers. In an embodiment, the reaction chamber is a hybridization chamber provided with a membrane-array.

Owner:FOOYIN UNIVERSITY

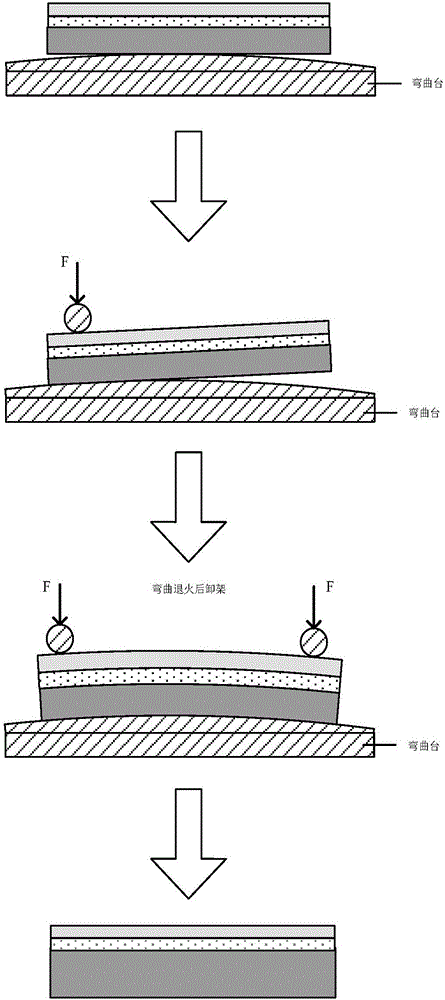

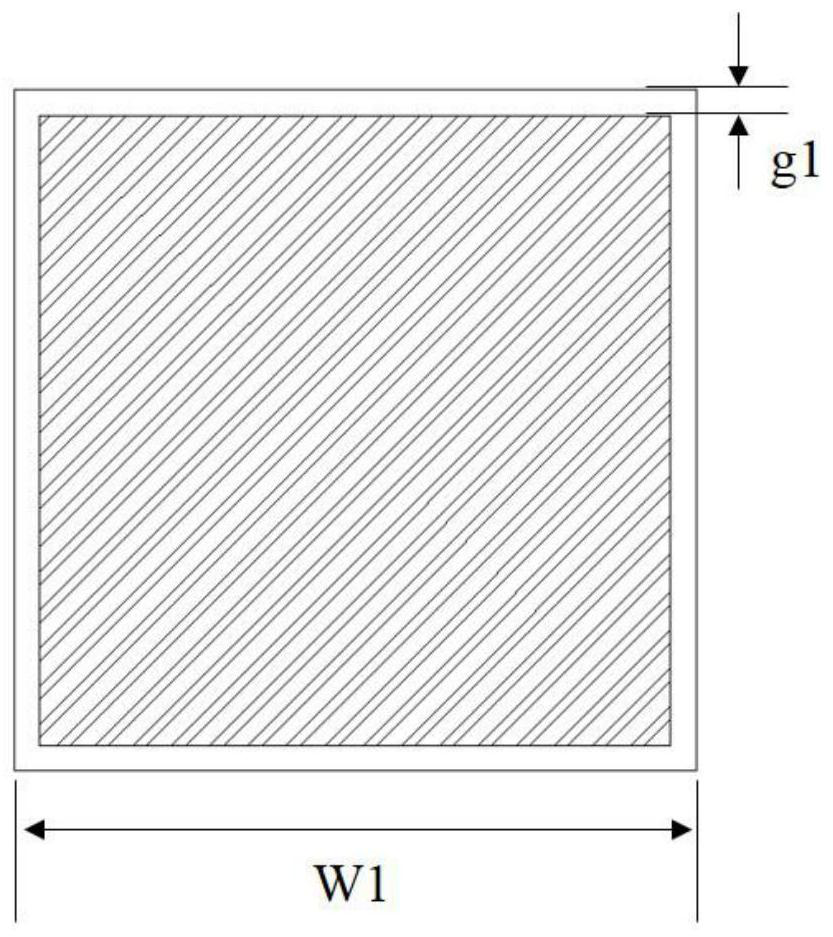

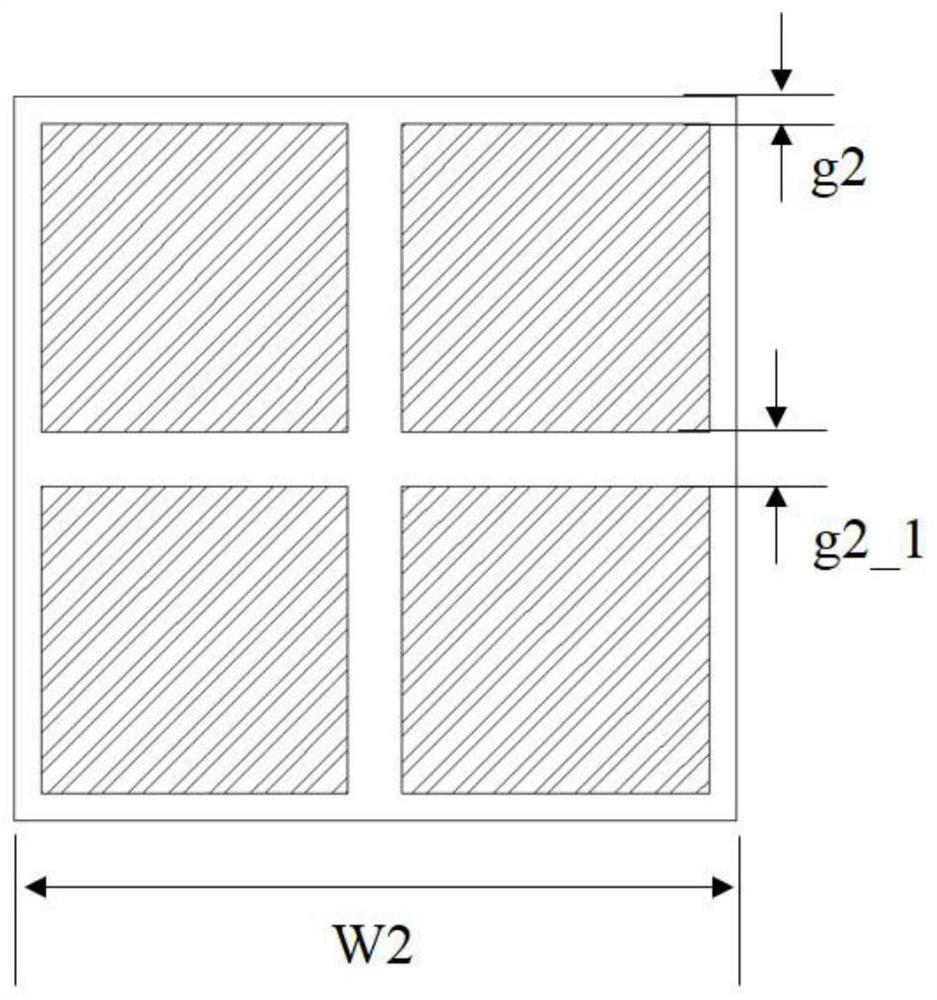

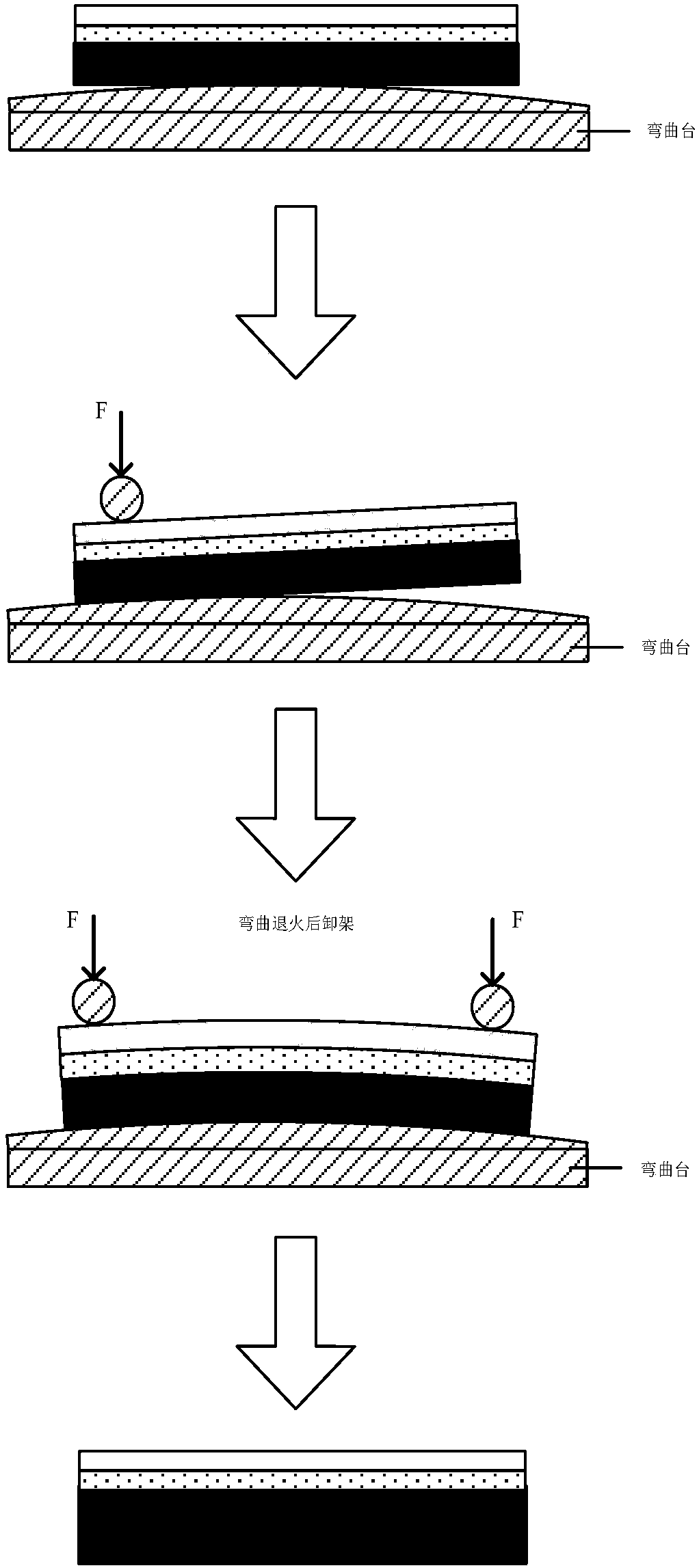

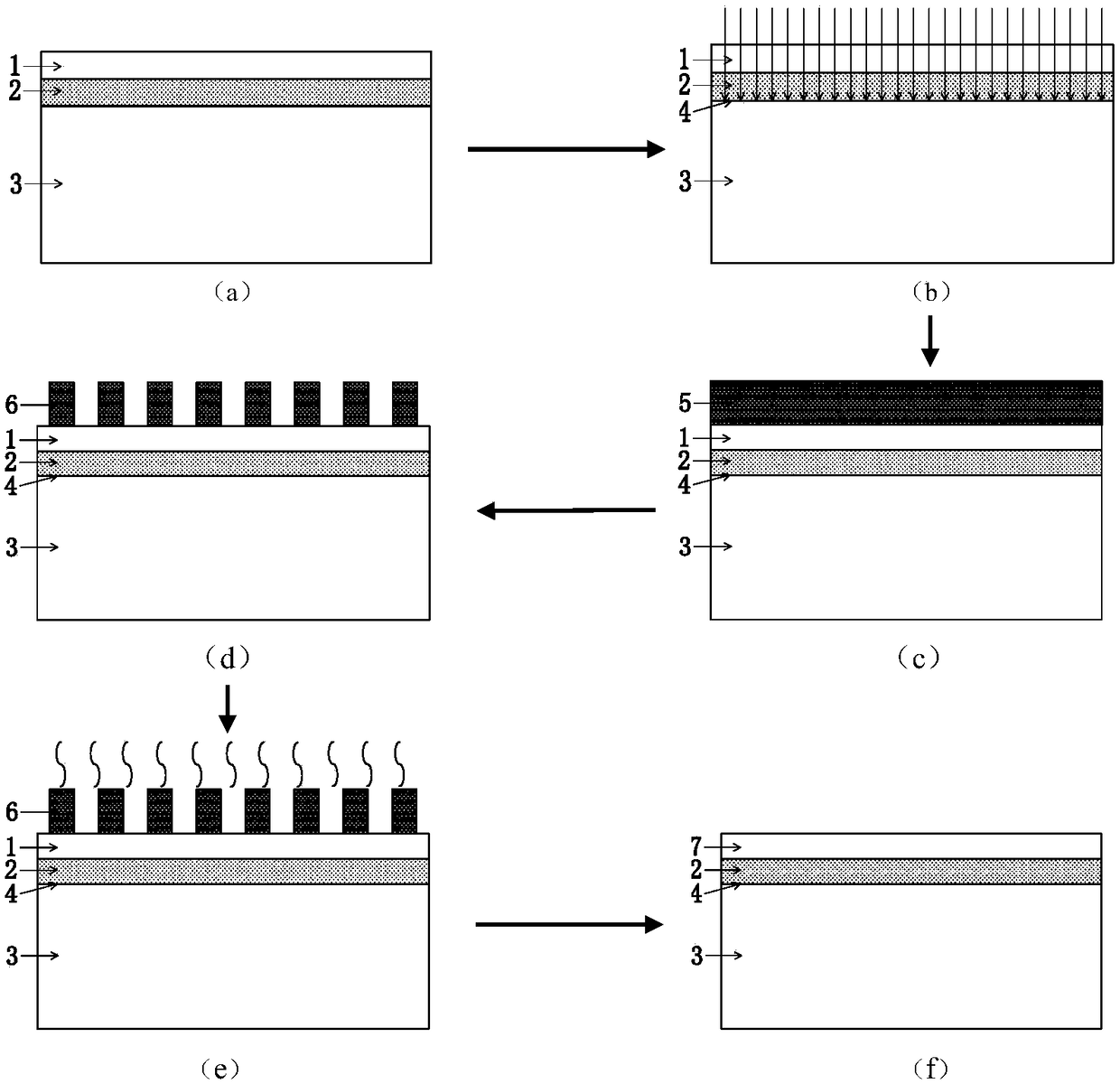

Manufacturing method for wafer level uniaxial strain GeOI based on silicon nitride stress membrane and scale effect

ActiveCN105845616ASimple processAvoid bendingSemiconductor/solid-state device manufacturingMembrane arrayScale effects

The invention discloses a manufacturing method for wafer level uniaxial strain GeOI based on a silicon nitride stress membrane and the scale effect. The realization steps are that 1. a germanium-on-insulator GeOI wafer is cleaned, and He ion injection is performed; 2. a pressure stress SiN membrane of more than -1GPa or a tensile stress SiN membrane of more than 1GPa is deposited on the Ge layer of the top layer of the GeOI wafer after ion injection, and the SiN membrane is etched into strip arrays; 3. annealing is performed on the GeOI wafer having the SiN membrane arrays; and 4. the SiN membrane arrays arranged on the surface of the GeOI wafer are removed through corrosion so that the wafer level uniaxial strain GeOI material is obtained. Strain is introduced into the Ge layer of the top layer by utilizing uniaxial tension or uniaxial compressive plastic deformation of an SiO2 buried insulating layer under the effect of the strip SiN membrane arrays. The manufacturing method is compatible with the existing technology, and the required GeOI wafer used for photoelectric integration and system-on-chip can be manufactured.

Owner:XIDIAN UNIV

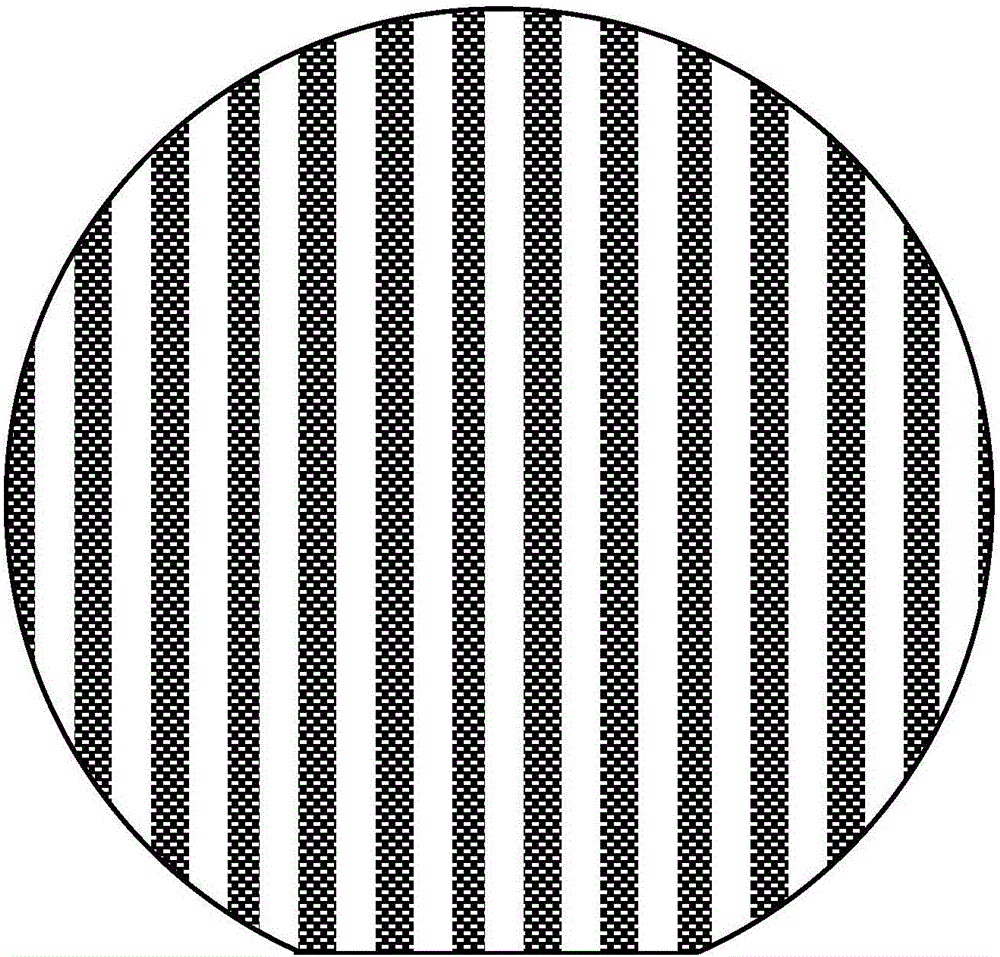

Carbon nanotube / polymer composite membrane array type flexible force sensor and manufacturing method thereof

InactiveCN102374910BReduce contentGood flexibilityDecorative surface effectsForce measurement using piezo-resistive materialsPolymer scienceCarbon nanotube

The invention relates to a carbon nanotube / polymer composite membrane array type flexible force sensor and a manufacturing method thereof. The carbon nanotube / polymer composite membrane array type flexible force sensor comprises a parallel metal row electrode and a parallel metal column electrode which are respectively and graphically arranged on the upper and lower surfaces of a carbon nanotube / polymer composite membrane, an upper insulation protecting layer adhered onto the row electrode, and a lower insulation protecting layer adhered onto the column electrode, wherein the row electrode and the column electrode are distributed in a spatial intersection way, and a spatial intersection part and the carbon nanotube / polymer composite membrane contained in the spatial intersection part form a force sensing unit of the array type flexible force sensor; and the carbon nanotube / polymer composite membrane is made by a composite material that carbon nanotubes are uniformly dispersed in a polymer matrix material, and the mass ratio of the carbon nanotubes to the polymer matrix material is (0.1-15): 100. The carbon nanotube / polymer composite membrane in the array type flexible force sensor has the characteristics of excellent flexibility, good repeatability, stable performances, good consistency and the like.

Owner:TSINGHUA UNIV

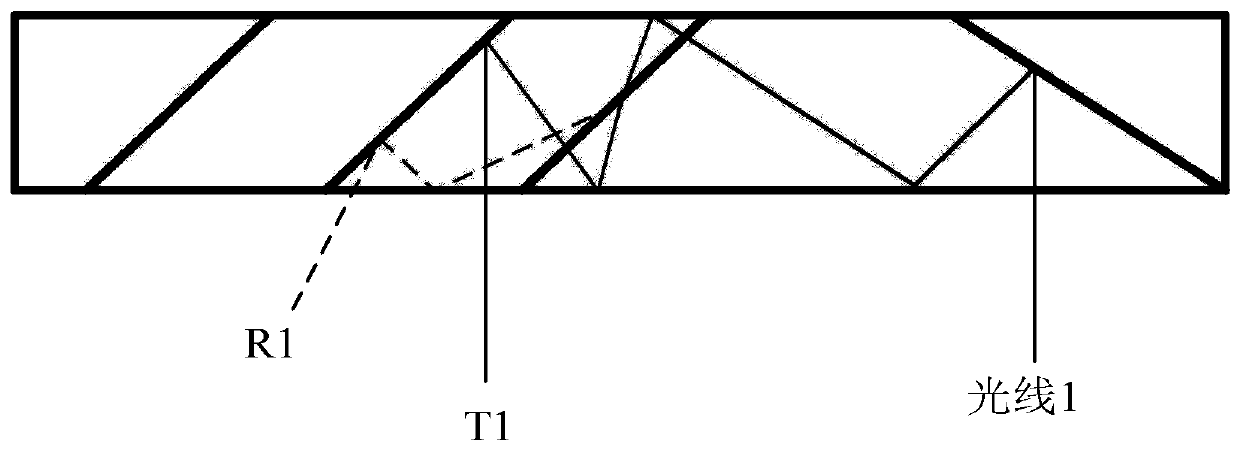

Waveguide device and augmented reality equipment

InactiveCN111474719AAchieve separationImprove image qualityOptical elementsMembrane arrayEngineering

The invention relates to a waveguide device and augmented reality equipment. The waveguide device comprises a waveguide substrate, a geometrical optical input element and a geometrical optical outputelement. The geometrical optical input element is arranged in the optical wave input area of the waveguide substrate and used for coupling input optical waves into the waveguide substrate in a geometrical optical mode; the waveguide substrate is used for transmitting light waves coupled into the waveguide substrate through the geometrical optical input element to the geometrical optical output element in a total reflection mode, the waveguide substrate comprises a first substrate and a second substrate, and the lower surface of the first substrate is connected with the upper surface of the second substrate; the geometrical optical output element is arranged in the optical wave output area of the waveguide substrate and used for outputting the optical waves transmitted to the geometrical optical output element, the geometrical optical output element comprises a semi-permeable membrane array embedded in the first substrate, and the semi-permeable membrane array comprises a plurality of semi-permeable membranes which are arranged in parallel and obliquely.

Owner:谷东科技有限公司

Preparation method of power generation and purified water production integrated functional area

InactiveCN112279331AReduce restrictionsSpontaneous power generationGeneral water supply conservationSeawater treatmentWind waveMembrane array

The invention provides a preparation method of a power generation and water purification production integrated functional area, which comprises the steps of partially reducing a vertically oriented carboxylated graphene / alumina nanofiber composite membrane array, filling aluminum particles in an upper channel, and compounding aminated bacterial cellulose in a lower channel to obtain the power generation and water purification production integrated functional area. The functional area prepared by the method can spontaneously generate electric energy by virtue of directional movement of water flow caused by water evaporation, aluminum particles achieve a quicker evaporation effect by virtue of a plasmon effect, and the graphene / aluminum oxide nanofiber composite membrane array at the upper part of the composite membrane array effectively improves the distillation efficiency and shortens the distillation time, the carboxylated graphene / aluminum oxide nanofiber composite membrane array atthe lower part of the composite membrane array is used for drawing water flow and firmly grasping the water surface, and the capability of preventing stormy waves and turbulence is achieved.

Owner:YANCHENG TEACHERS UNIV

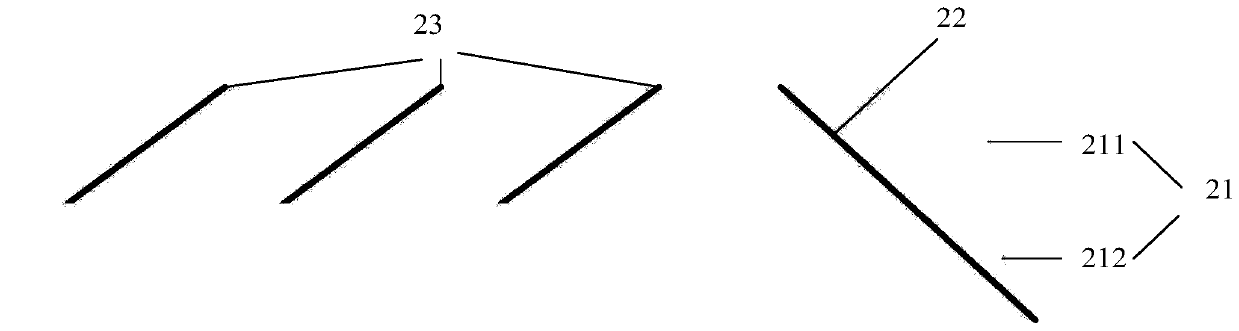

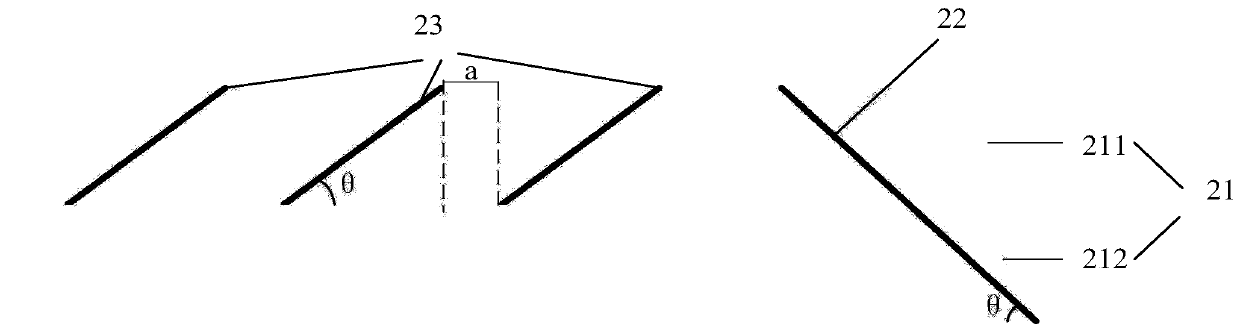

Optimization of an acoustic membrane array

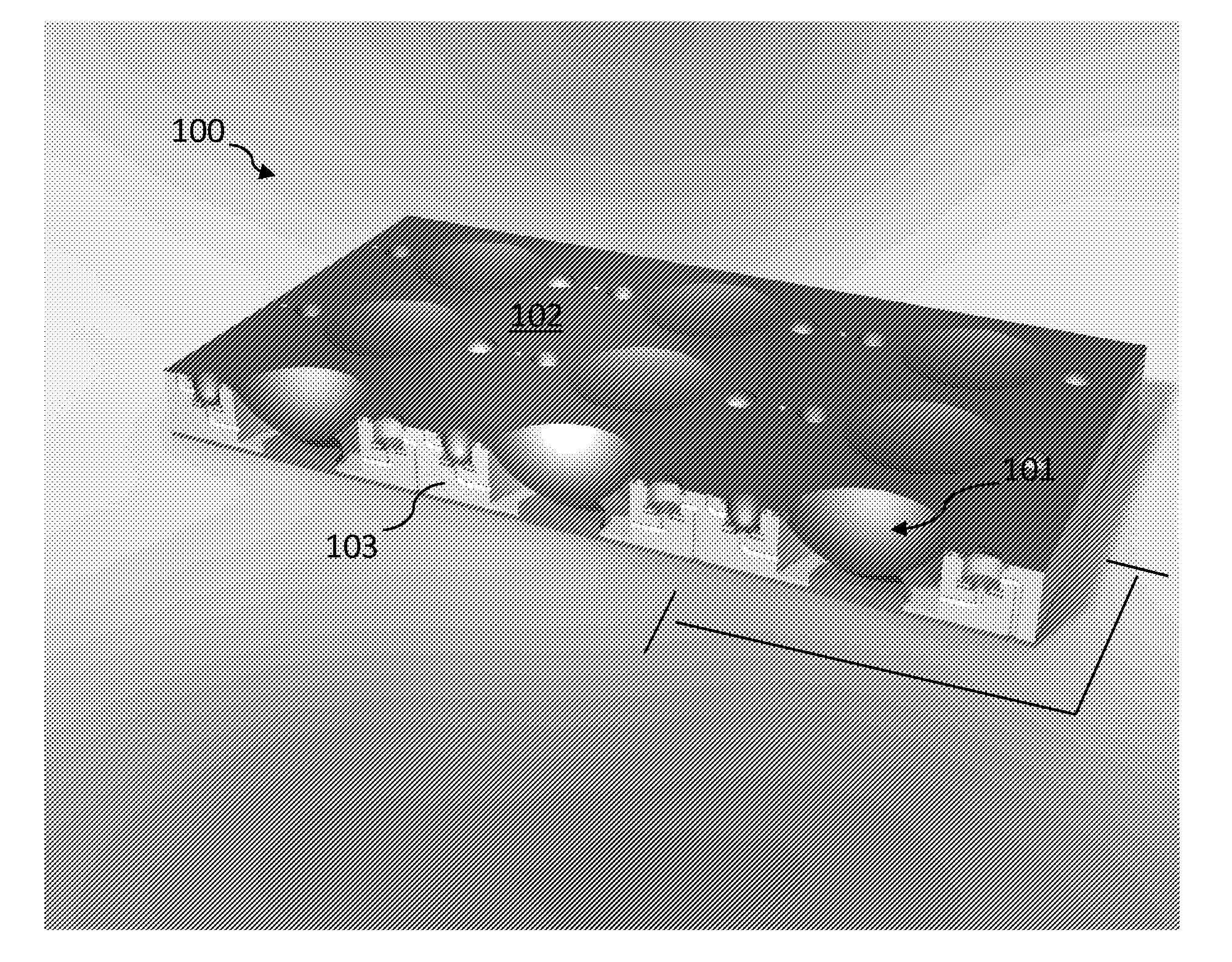

PendingUS20220260531A1Avoid interferenceMaterial analysis using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementResonanceMembrane array

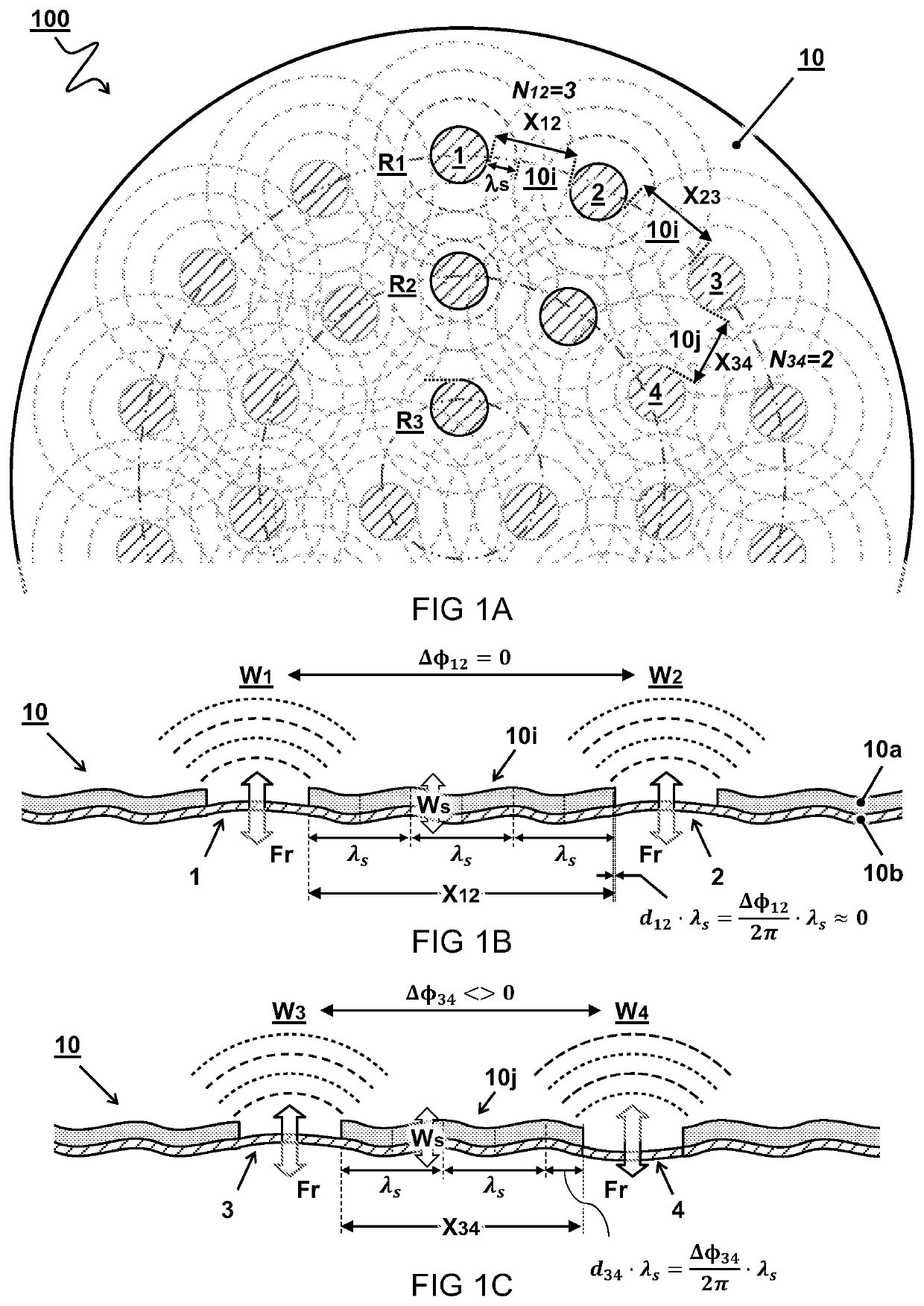

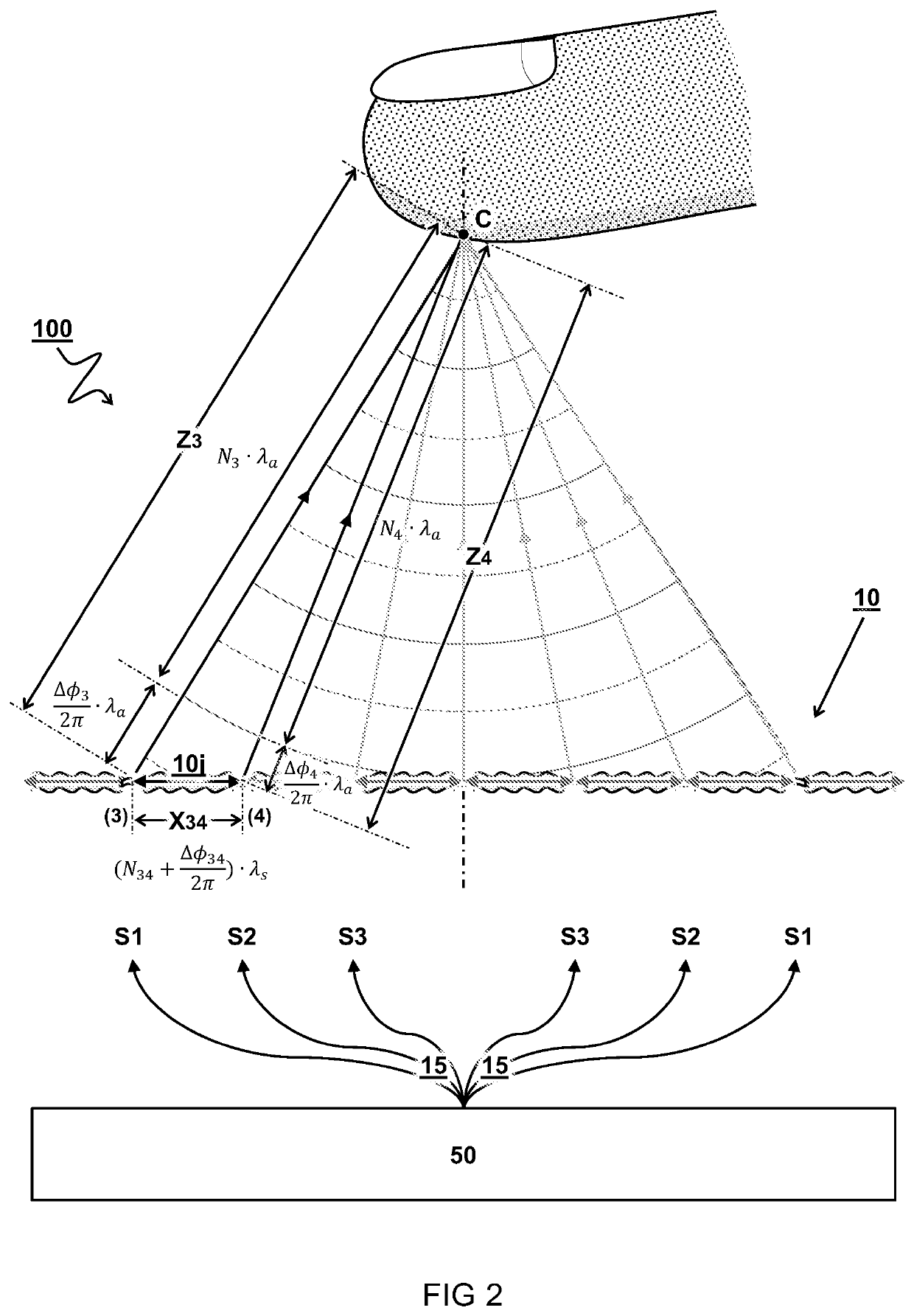

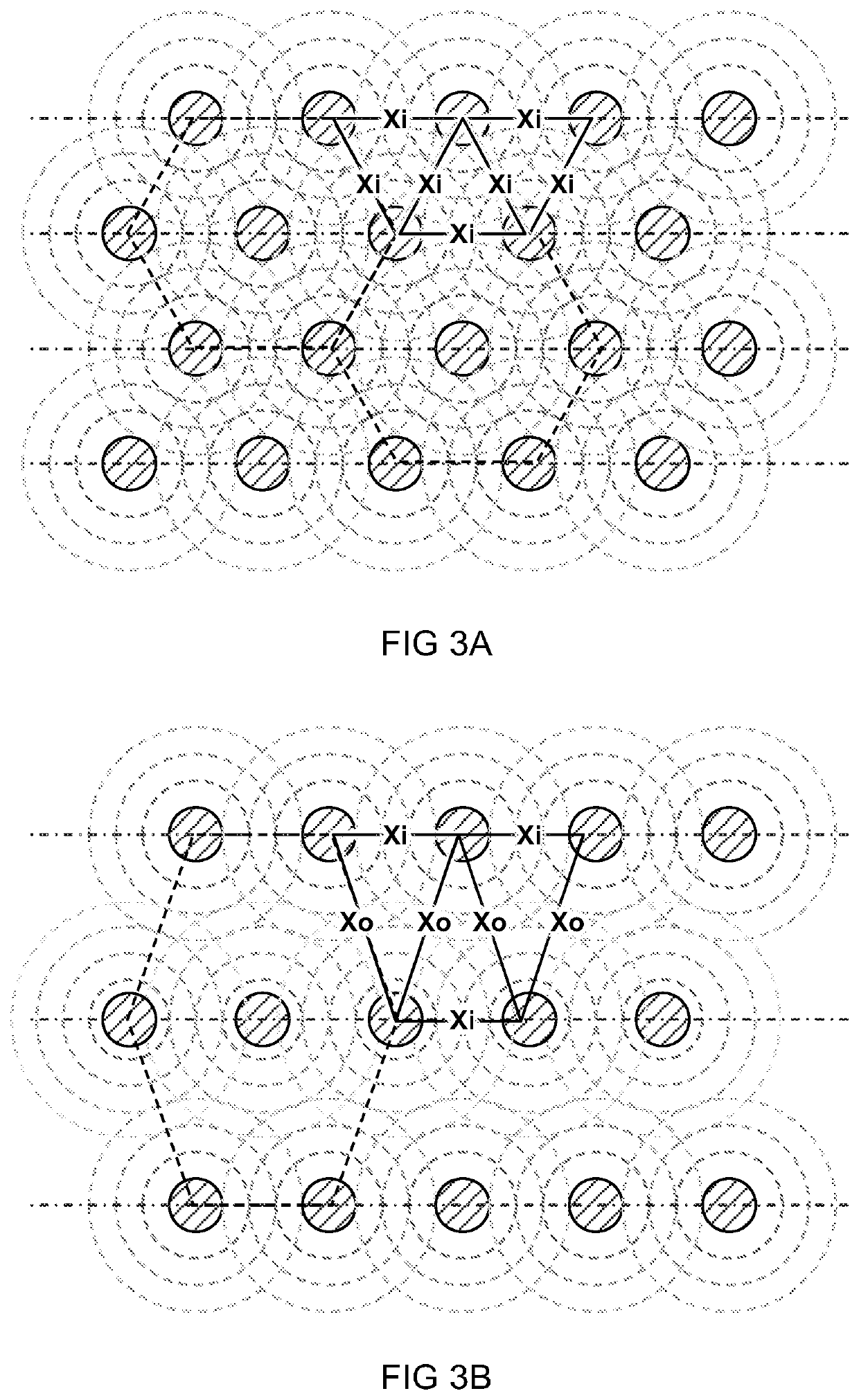

An acoustic device (100) comprises an array of acoustic membranes (1, 2, 3, 4) formed on a foil (10). Each of the acoustic membranes (1, 2, 3, 4) is configured to vibrate ata resonance frequency (Fr) of the acoustic membranes (1, 2, 3, 4) for generating respective acoustic waves (W1,W2,W3,W4). Relative phases (ΔΦ12,ΔΦ34) are determined at which the acoustic membranes (1, 2, 4, 5) are actuated for generating a predetermined interference pattern (C) between the acoustic waves (W1,W2,W3,W4). A lamb wavelength (As) is determined of lamb waves (Ws) at the resonance frequency (Fr) travelling through intermediate sections (lOi, lOj) of the foil between adjacent acoustic membranes (1,2; 3,4). Distances (X12,X34) of the intermediate sections (10i, 10j) between the adjacent acoustic membranes (1,2; 3,4) in the layout are determined in accordance with the relative phases (ΔΦ12,ΔΦ34) and the lamb wavelength for having the lamb waves (Ws), generated by one acoustic membrane (1,3), arrive in phase with an adjacent acoustic membrane (2,4).

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

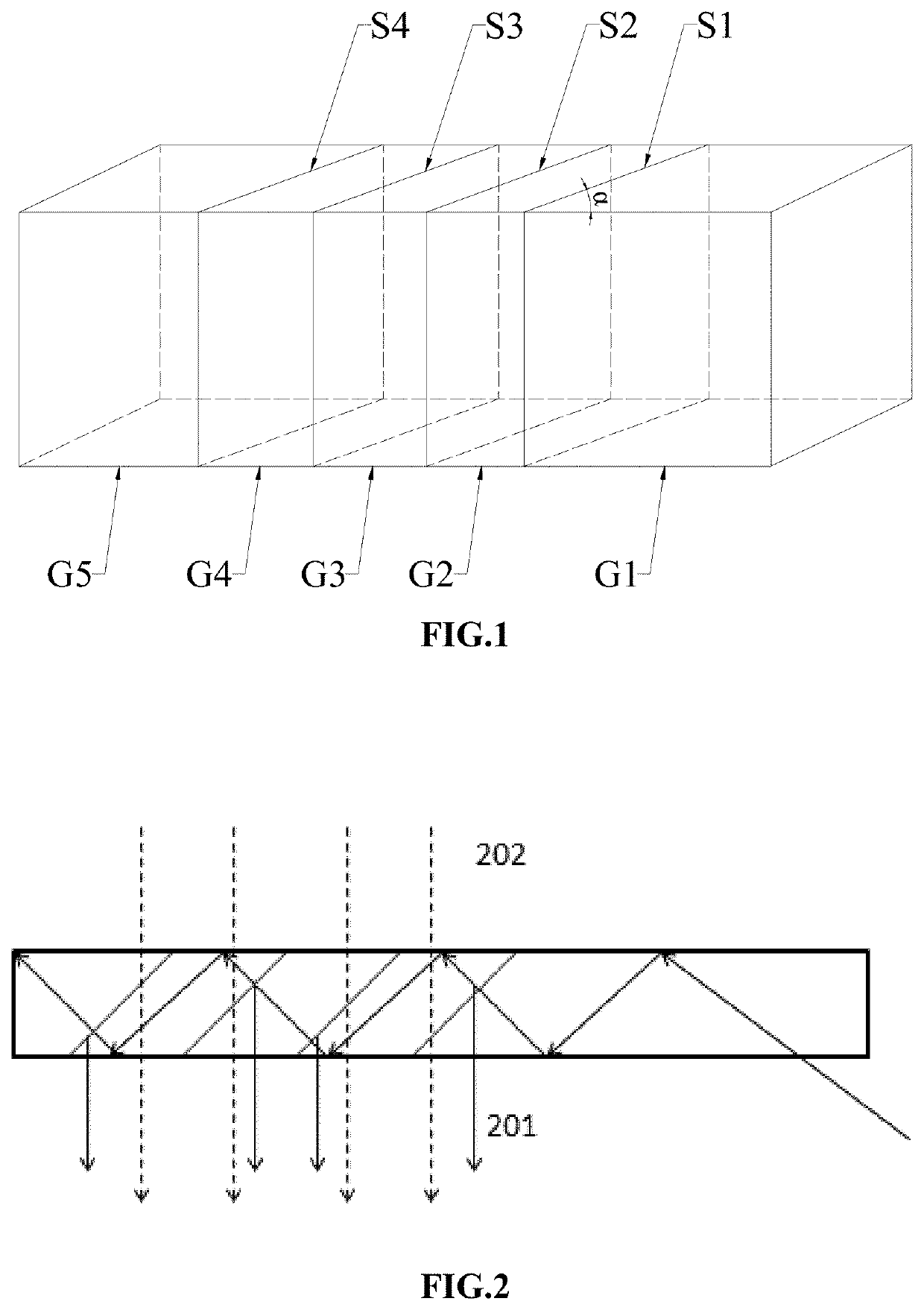

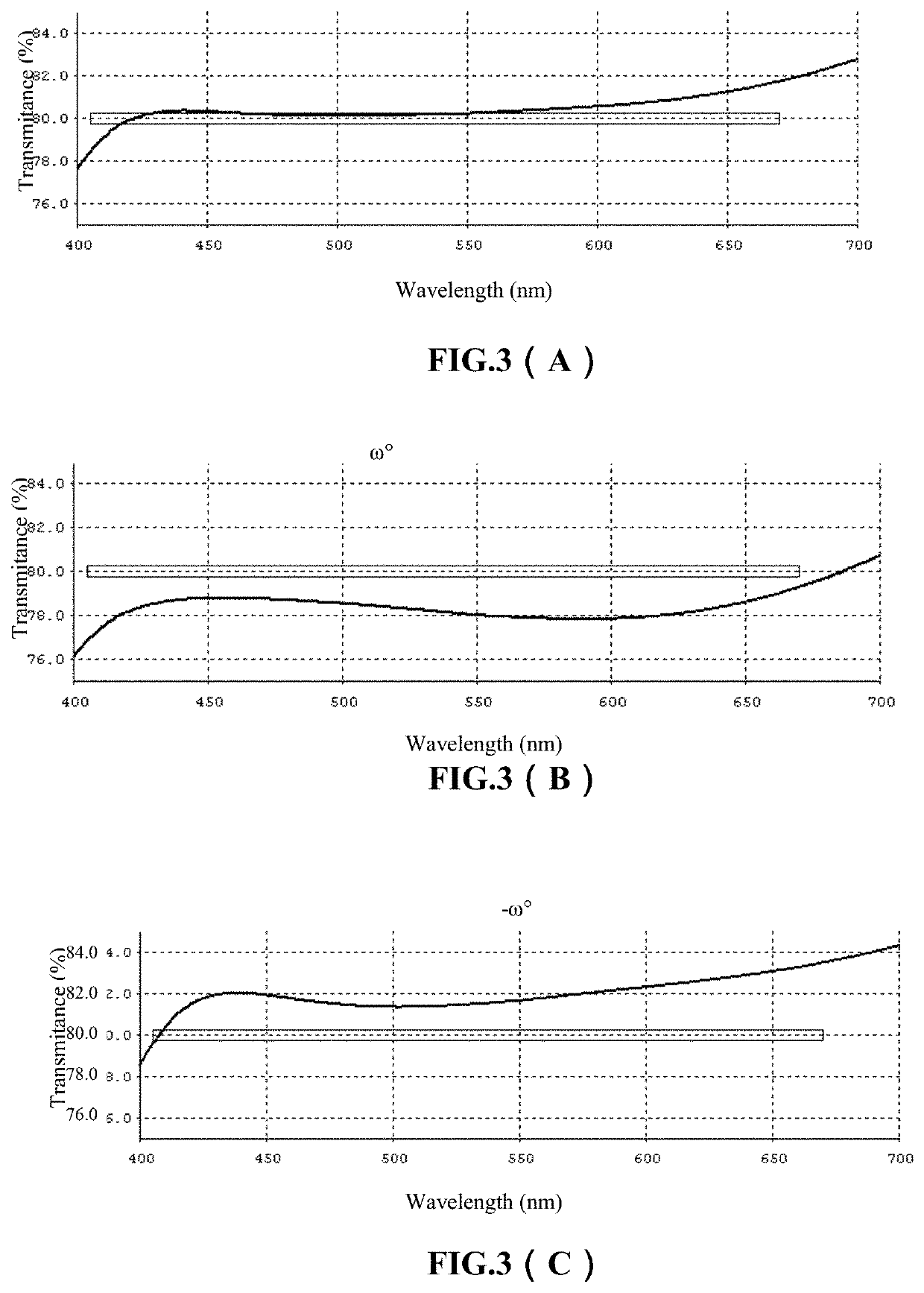

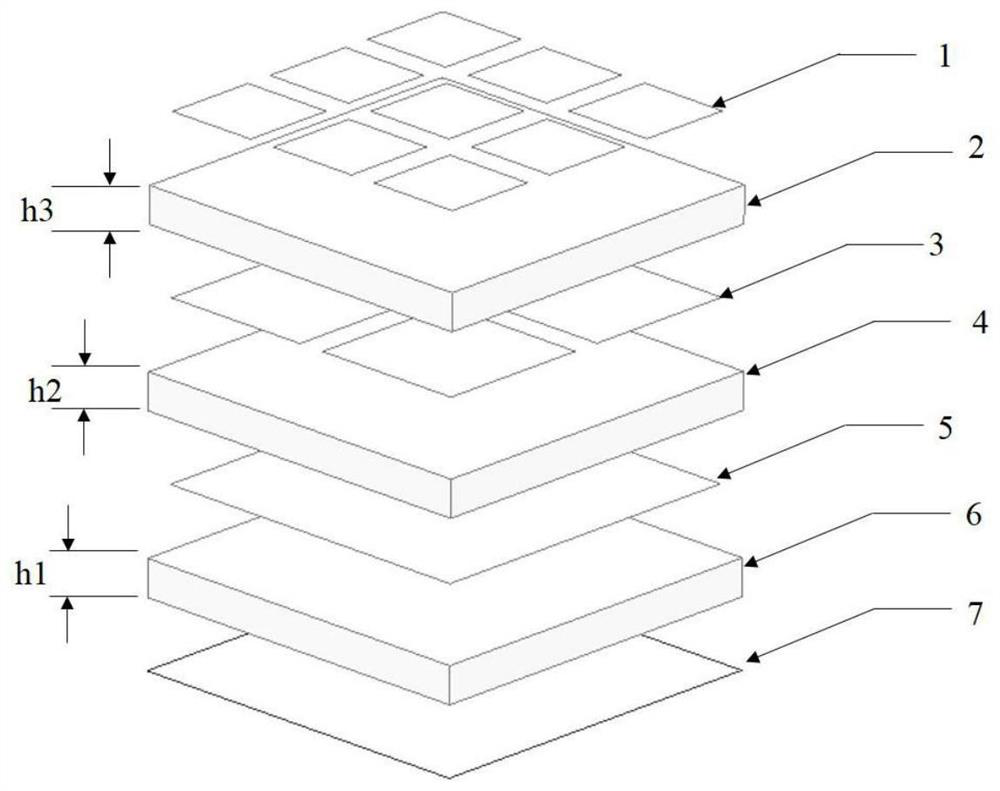

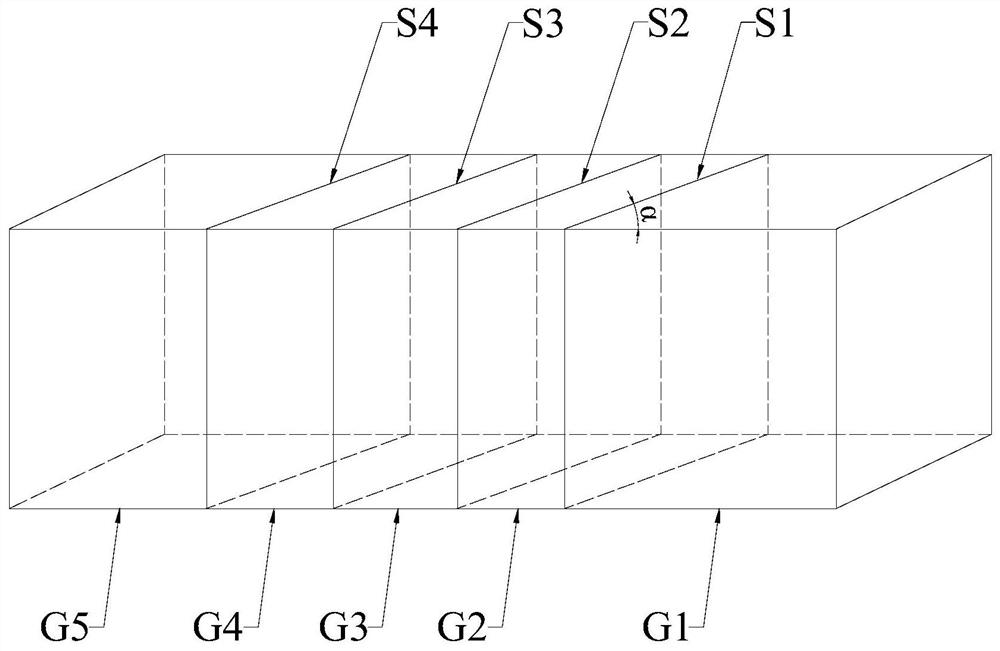

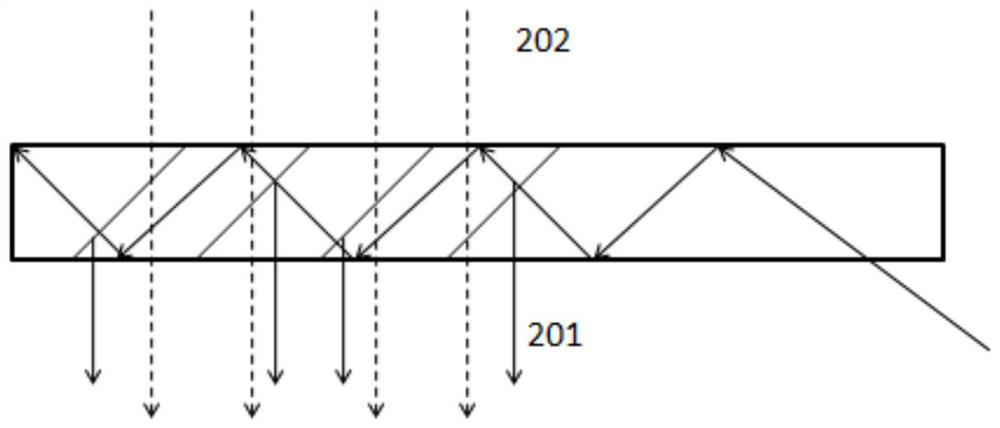

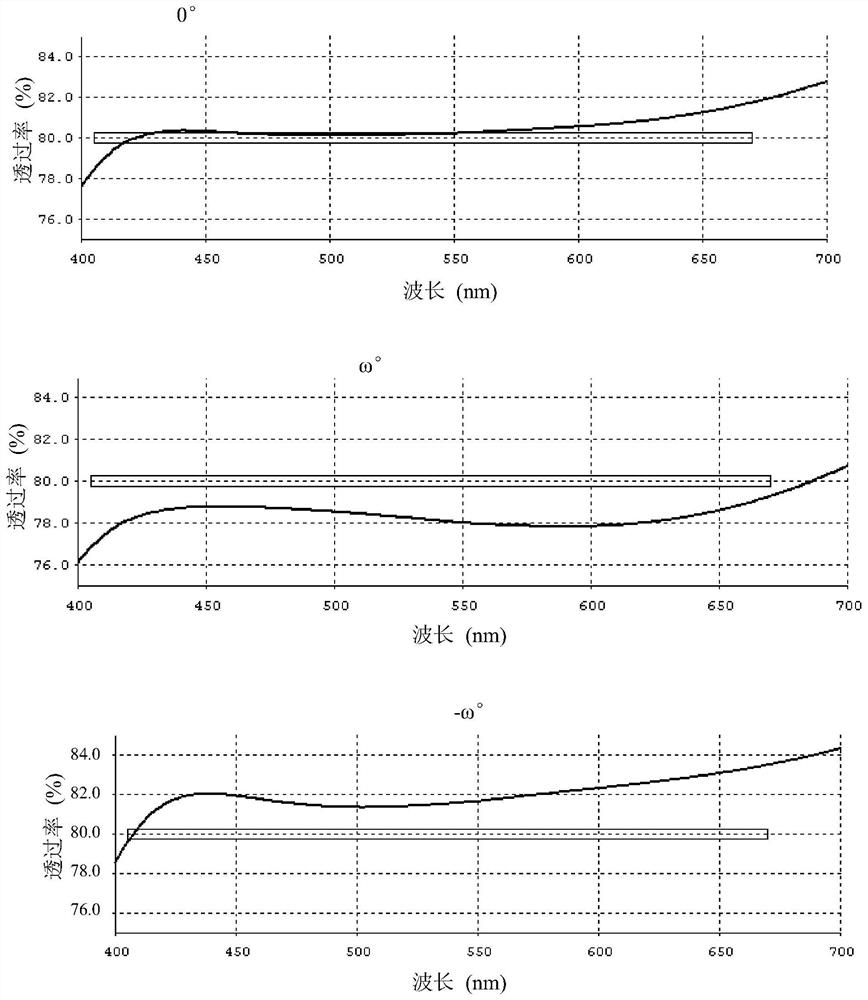

Broadband cascaded splitting film array waveguide and display system comprising same

PendingUS20200363581A1Feasible manufacturing process controlImprove batch productivityMechanical apparatusLight guides for lighting systemsRefractive indexMembrane array

The present disclosure provides a broadband cascaded splitting film array waveguide and a display system comprising the same. The cascaded splitting film array waveguide includes a plurality of glass substrates and a splitting film array, each film of the splitting film array is sandwiched between two adjacent glass substrates and consists of a plurality of H coatings and L coatings alternately arranged in sequence, wherein the H coatings are coatings made of a high refractive index material, the L coatings are coatings made of a low refractive index material, each film of the splitting film array has an even number of coatings, and thicknesses an, pn of the coatings of the film are selected based on the band width and angle of the light beam.

Owner:BEIJING LLVISION TECH CO LTD

Electromagnetic wave absorbing structure

PendingCN112448169ALow costLow profileMagnetic/electric field screeningAntennasUltra-widebandThin membrane

The invention relates to an electromagnetic wave absorbing structure which comprises a metal floor and k layers of wave absorbing modules sequentially arranged on the metal floor. The ith layer of wave absorbing module comprises an ith layer of foam substrate and an ith layer of thin film unit, and the ith layer of thin film unit is arranged on the ith layer of foam substrate; the ith layer of thin film unit comprises p2 * m * n resistive thin films which are arranged on the ith layer of foam substrate in an array manner; the (i + 1) th layer of thin film unit comprises q2 * m * n resistive thin films which are arranged on the (i + 1) th layer of foam substrate in an array mode, q is larger than p, and q and p are both positive integers larger than or equal to 1. The electromagnetic wave-absorbing structure disclosed by the invention can simultaneously meet the requirements of low cost, light weight, low profile and high-efficiency ultra-wideband wave absorption, realizes high-efficiency wave absorption within 10 octave ranges at the profile height of 0.08-0.15[lambda]0 initial working frequency, has the absorptivity of more than 90%, and can effectively cover 30-300MHz, 300MHz 3GHz frequency bands or 3-30GHz and other ultra-wide frequency bands.

Owner:唐明春

Fabrication method of wafer-level uniaxial strain geoi based on silicon nitride stress film and scale effect

ActiveCN105845616BSimple processAvoid bendingSemiconductor/solid-state device manufacturingMembrane arrayIon implantation

The invention discloses a manufacturing method for wafer level uniaxial strain GeOI based on a silicon nitride stress membrane and the scale effect. The realization steps are that 1. a germanium-on-insulator GeOI wafer is cleaned, and He ion injection is performed; 2. a pressure stress SiN membrane of more than -1GPa or a tensile stress SiN membrane of more than 1GPa is deposited on the Ge layer of the top layer of the GeOI wafer after ion injection, and the SiN membrane is etched into strip arrays; 3. annealing is performed on the GeOI wafer having the SiN membrane arrays; and 4. the SiN membrane arrays arranged on the surface of the GeOI wafer are removed through corrosion so that the wafer level uniaxial strain GeOI material is obtained. Strain is introduced into the Ge layer of the top layer by utilizing uniaxial tension or uniaxial compressive plastic deformation of an SiO2 buried insulating layer under the effect of the strip SiN membrane arrays. The manufacturing method is compatible with the existing technology, and the required GeOI wafer used for photoelectric integration and system-on-chip can be manufactured.

Owner:XIDIAN UNIV

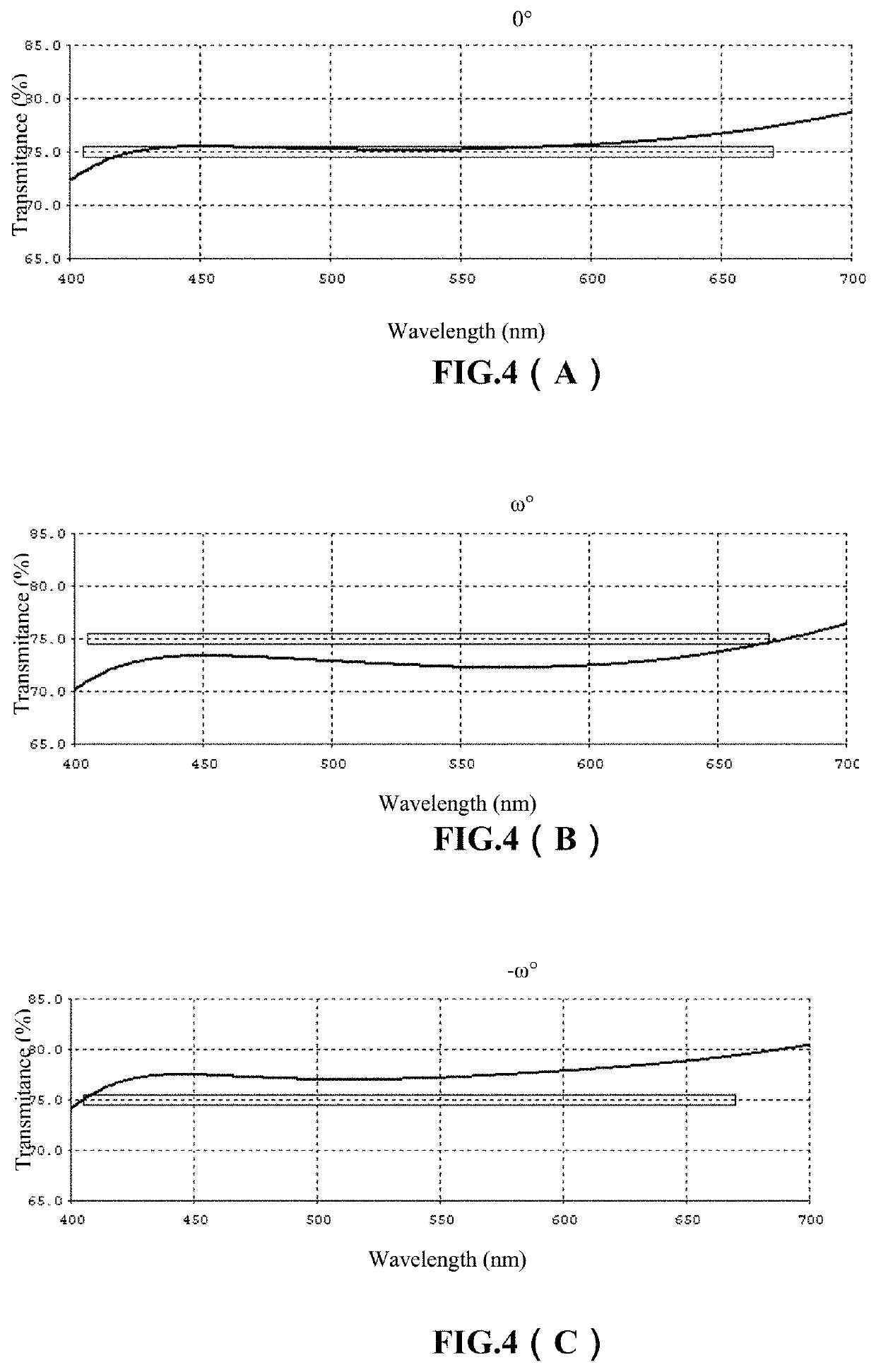

Wide Bandwidth, High Uniformity Cascaded Splitter Film Array Waveguide and Its Application

ActiveCN107728253BBandwidthThere is no obvious attenuation of the edge imageOptical light guidesWaveguideMaterials science

The invention provides a wide bandwidth, high uniformity cascade splitting film array waveguide and its application. The cascaded light-splitting film array waveguide includes a multi-layer glass substrate and a light-splitting film array sandwiched between two adjacent substrates. The structure of each light-splitting film array is independently: α 1 Hβ 1 L / α 2 Hβ 2 L / ...α n‑1 Hβ n‑1 L / α n Hβ n L, where H is a film layer of high refractive index material, L is a film layer of low refractive index material, the number of layers of each light-splitting film array is 2n, and the thickness of each film layer in the light-splitting film array is α n , β n Select based on bandwidth and beam angle requirements. By adopting the solution of the present invention, the single-chip combiner of the traditional video transmission-type augmented reality optical system is split into multiple pieces, breaking through the shackles of the mutual restriction of the utilization rate of light energy of the virtual image and the transmittance of the external real scene. When the external transmittance reaches more than 75%, the light energy utilization rate of the miniature image source reaches 70%.

Owner:BEIJING LLVISION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com