Method for preparing patterned phospholipid membrane array on ITO (indium tin oxide) conductive glass

A technology of conductive glass and indium tin oxide, which is applied in the manufacture of semiconductor/solid-state devices, circuits, electrical components, etc., can solve the problem that phospholipid membranes cannot be characterized by fluorescence microscopy, and the array of phospholipid membranes cannot simultaneously realize fluorescence microscopy technology and electrochemical technology Representation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

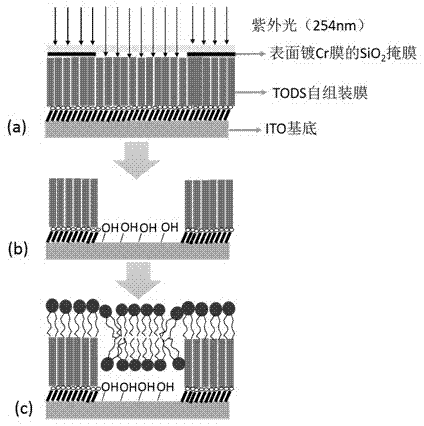

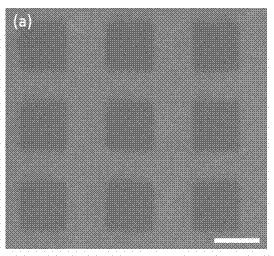

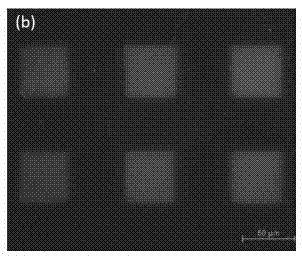

[0019] Embodiment 1: This embodiment provides a method for preparing a patterned phospholipid film array on an indium tin oxide conductive glass, such as figure 1 As shown, the specific implementation steps are as follows:

[0020] (1) Surface treatment of ITO substrate: ITO conductive glass (about 1×1cm 2 ) were ultrasonically cleaned in detergent, distilled water and absolute ethanol for 15 minutes respectively, dried with nitrogen and placed in a plasma cleaner for 30 seconds.

[0021] (2) Self-assembly of octadecyltrimethoxysilane (trimethoxyoctadecylsilane, TODS) on the surface of ITO: Immerse the cleaned ITO glass in (1) into fresh TODS-toluene (volume ratio 1:50) solution, seal the static After standing for 12 hours, take it out and put it into toluene for ultrasonic cleaning for 5 minutes to remove the TODS monomer physically adsorbed on the surface of the self-assembled membrane, then wash the toluene on the surface of ITO with ethanol, and finally dry it with nitrog...

specific Embodiment approach 2

[0027] Specific embodiment two: This embodiment provides a method for preparing a patterned phospholipid film array on an indium tin oxide conductive glass, such as figure 1 As shown, the specific implementation steps are as follows:

[0028] (1) Surface treatment of ITO substrate: ITO conductive glass (about 1×1cm 2 ) were ultrasonically cleaned in detergent, distilled water and absolute ethanol for 15 minutes respectively, dried with nitrogen and placed in a plasma cleaner for 30 seconds.

[0029] (2) Self-assembly of octadecyltrimethoxysilane (trimethoxyoctadecylsilane, TODS) on the surface of ITO: Immerse the cleaned ITO glass in (1) into fresh TODS-toluene (volume ratio 1:50) solution, seal the static After standing for 12 hours, take it out and put it into toluene for ultrasonic cleaning for 5 minutes to remove the TODS monomer physically adsorbed on the surface of the self-assembled membrane, then wash the toluene on the surface of ITO with ethanol, and finally dry it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com