Electromagnetic wave absorbing structure

An electromagnetic wave absorbing and resistive film technology, applied in electrical components, magnetic field/electric field shielding, antennas, etc., can solve the problems of high profile height, heavy weight, high density, etc., and achieve the effect of low profile and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

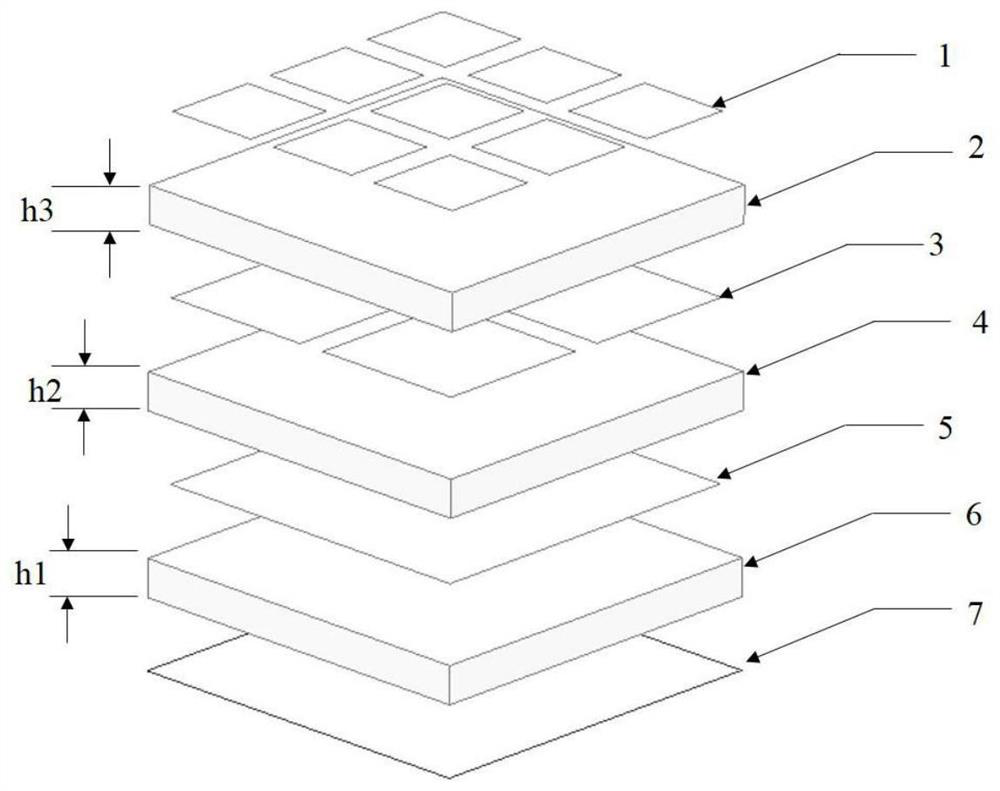

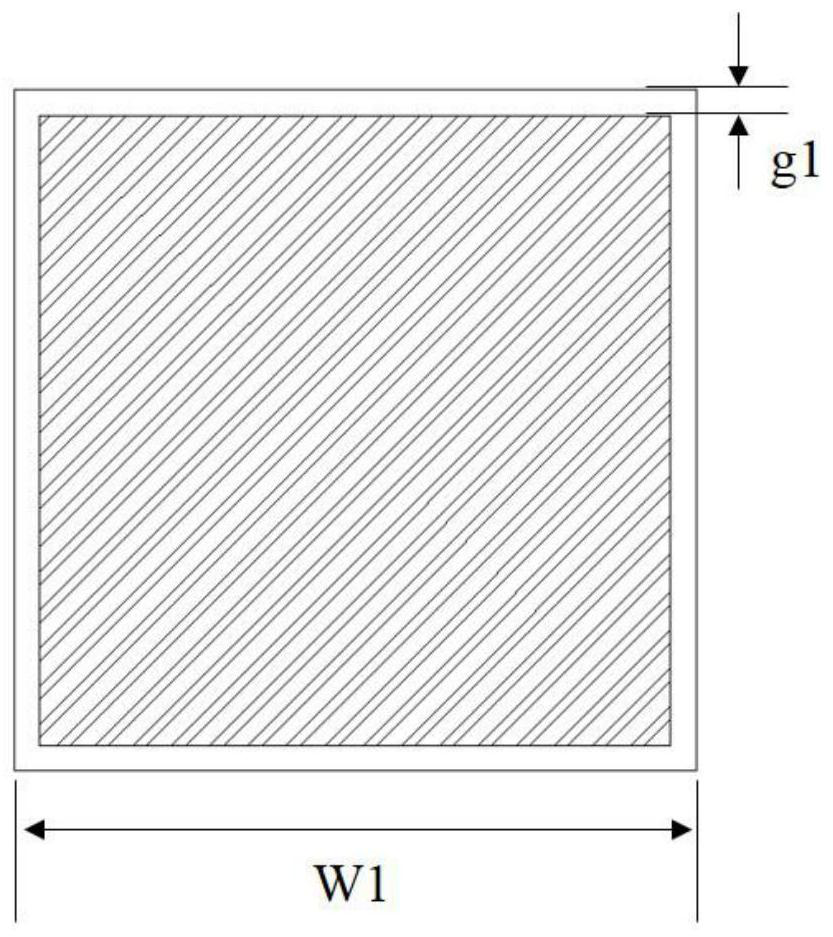

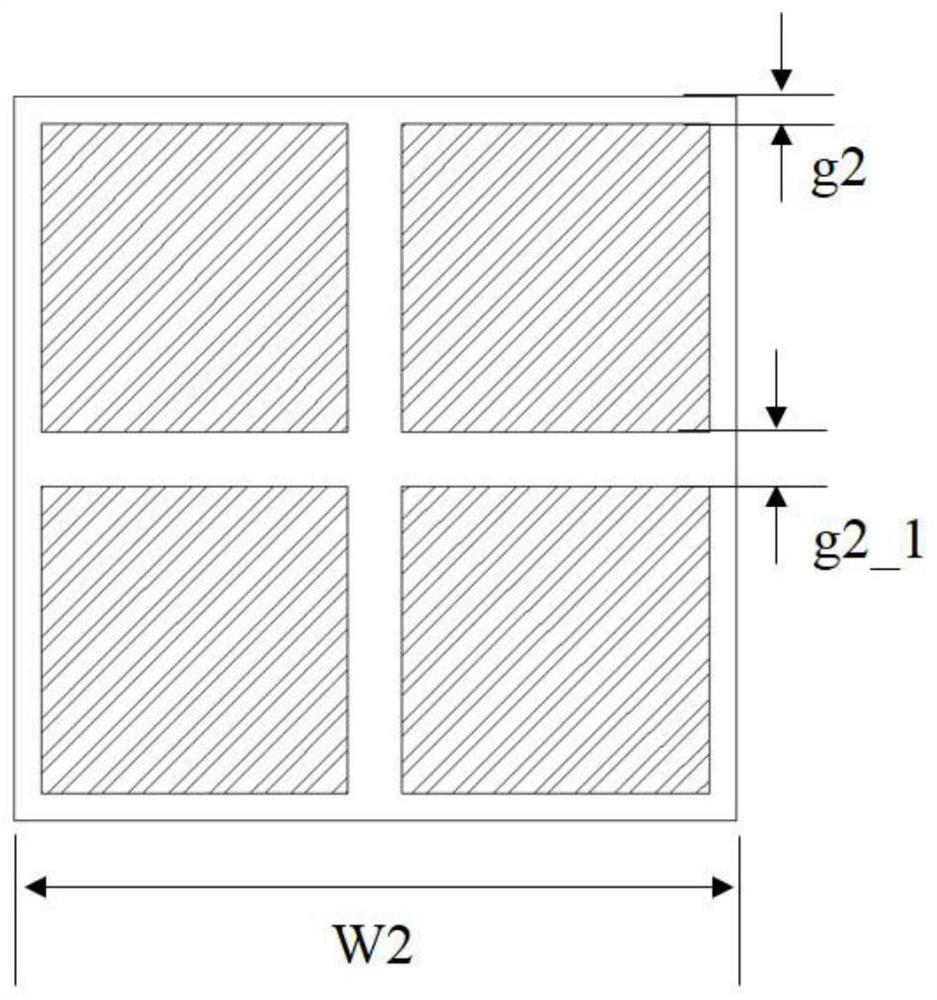

Embodiment 1

[0043] When the three-layer film unit is 1:2 2 :3 2 When setting the resistance film, its specific size parameters are (s unit: mm): W1=W2=W3=250mm, g1=g2=g3=14mm, g1_1=g2_1=g2_2=g3_1=g3_2=g3_3=28mm, h1=h2 =h3=40mm. The square resistance of the first film unit is s1=90ohm / sq, the square resistance of the second film unit is s2=210ohm / sq, and the square resistance of the third film unit is s3=255ohm / sq. In the case of vertically incident TE or TM waves, this embodiment has Figure 7 The absorbing performance shown. It has a reflection coefficient below -10dB in the entire frequency band of 0.3-3GHz, among which, the entire frequency band of 0.4-2GHz has a reflection coefficient of below -15dB, and the profile height is 0.12λ 0 .

Embodiment 2

[0045] When the three-layer film unit is 1:2 2 :3 2 When setting the resistance film, its specific size parameters are (s unit: mm): W1=W2=W3=80mm, g1=g2=g3=3mm, g1_1=g2_1=g2_2=6mm, h1=h2=h3=8mm. The square resistance s1 of the first film unit is 120 ohm / sq, the square resistance s2 of the second film unit is 190 ohm / sq, and the square resistance s3 of the third film unit is 377 ohm / sq. In the case of vertically incident TE or TM waves, this embodiment has Figure 6 The absorbing performance shown. It has a reflection coefficient below -10dB in the entire frequency band of 1.2-14GHz, and the profile height is 0.1λ 0 .

Embodiment 3

[0047] When the four-layer film unit is 1:2 2 :3 2 :4 2 When setting the resistance film, its specific size parameter is (s unit: mm): W1=W2=W3=W4=25mm, g1=g2=g3=g4=0.5mm, g1_1=g2_1=g3_1=g3_2=g4_1=g4_2= g4_3=1mm, h1=h2=h3=h4=4mm. The square resistance of the first layer of thin film unit s1=90ohm / sq, the square resistance of the second layer of thin film unit s2=210ohm / sq, the square resistance of the third layer of thin film unit s4=350ohm / sq, the square resistance of the fourth layer of thin film unit s4 = 377 ohm / sq. In the case of vertically incident TE or TM waves, this embodiment has Figure 8 The absorbing performance shown. It has a reflection coefficient of about -20dB in the entire frequency band of 2.5-38GHz, and the profile height is 0.14λ 0 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com