Micronano array structure, fabrication method thereof and preparation of mask array for micronano array structure

An array structure, micro-nano technology, applied in the field of preparing the mask array and its preparation, can solve the problems of time-consuming and labor-intensive processing cost, inability to meet the fast processing, inability to meet the requirements, and achieve convenient processing and large-area fast processing. Finished, smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

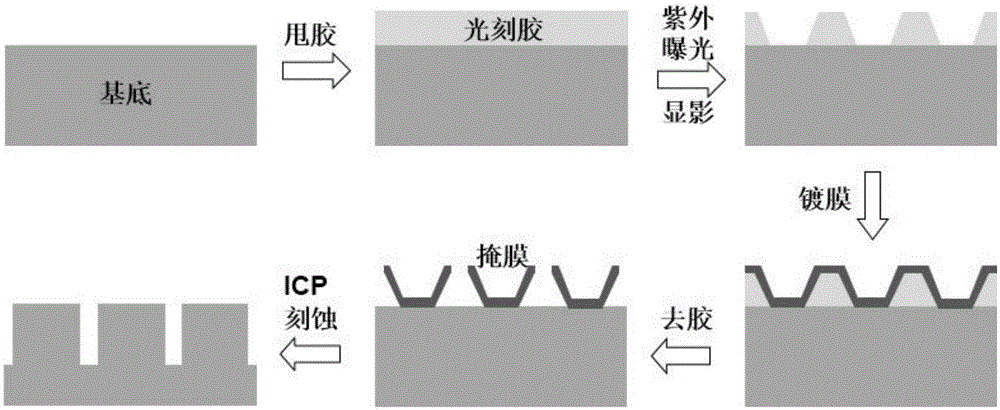

[0061] A method for preparing a micro-nano array structure, comprising the steps of:

[0062] (1) Provide a silicon carbide substrate with a thickness of 330 μm;

[0063] (2) Spin-coat a 2 μm thick UV photoresist on the silicon carbide substrate, and then bake for 5 minutes;

[0064] (3) Use a UV lithography machine to expose the UV photoresist according to a predetermined circular pattern for 40 seconds, and develop it in a developer for 40 seconds;

[0065] (4) Plating 400nm copper with electron beam evaporation coating instrument;

[0066] (5) Putting into an acetone solution to remove the ultraviolet photoresist to obtain a mask array;

[0067] (6) Using reactive ion etching for 10 minutes, transfer the columnar array structure to the silicon carbide substrate, precisely control the structural height of the micron column, and obtain the micronano array structure;

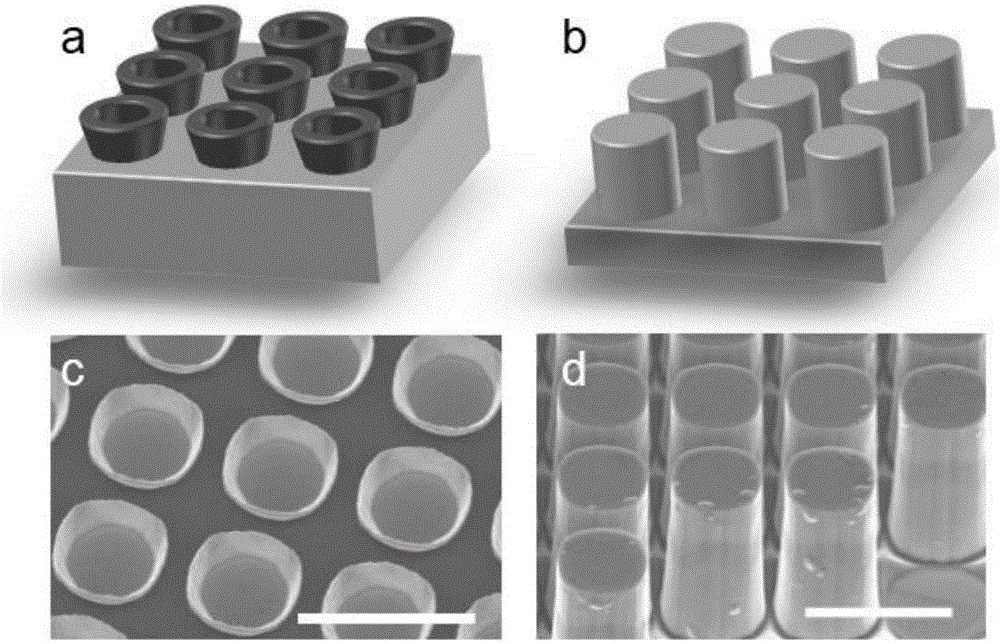

[0068] The schematic diagram of the prepared circular mask array is shown in figure 2 a, SEM image as sh...

Embodiment 2

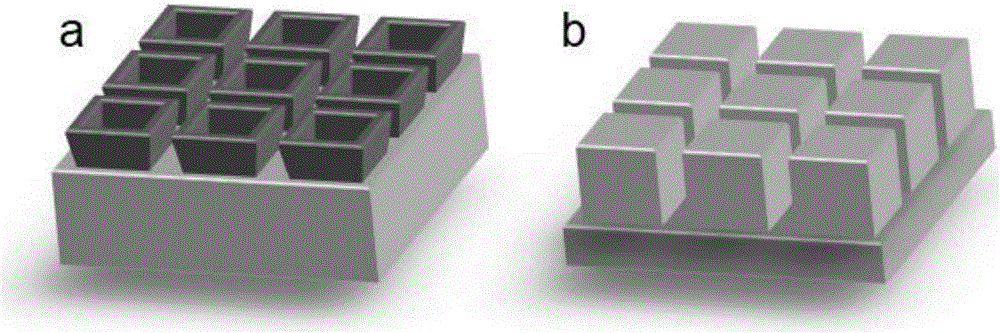

[0070] A method for preparing a micro-nano array structure, the only difference from Example 1 is that the predetermined pattern is different, which is a square shape. According to the preparation method of Example 1, the period of the prepared mask array is 8 μm, and the upper surface edge of the warped edge The length is 6 μm, the height is 2 μm; the micro-nano array structure is a steep and smooth square cylinder with a period of 8 μm, a side length of 6 μm, and a height of 14.5 μm.

[0071] The schematic diagram of the prepared square mask array is shown in image 3 a, Schematic diagram of the square column structure of the micro-nano array. image 3 b.

Embodiment 3

[0073] A method for preparing a micro-nano array structure, the only difference from Example 1 is that the predetermined pattern is different, which is a regular cross (the regular cross is a cross-shaped structure with 12 sides, and the lengths of each side are equal), according to According to the preparation method of Example 1, the period of the prepared mask array is 8 μm, the side length of the upper surface of the raised edge is 6 μm, and the height is 2 μm; the micro-nano array structure is a straight and smooth cylinder, the period is 8 μm, and the side length is 2 μm. 6 μm and a height of 14.5 μm.

[0074] The schematic diagram of the prepared cross-shaped mask array is shown in Figure 4 a, Schematic diagram of the cross-shaped column structure of the micro-nano array. Figure 4 b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com