Electronic skin based on MXene material and preparation method thereof

A technology for electronic skin and sensitive materials, applied in thermometers based on material expansion/contraction, electromagnetic measurement devices, and electric/magnetic profile/curvature measurement, etc. problem, to achieve the effect of low cost, wide response range and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

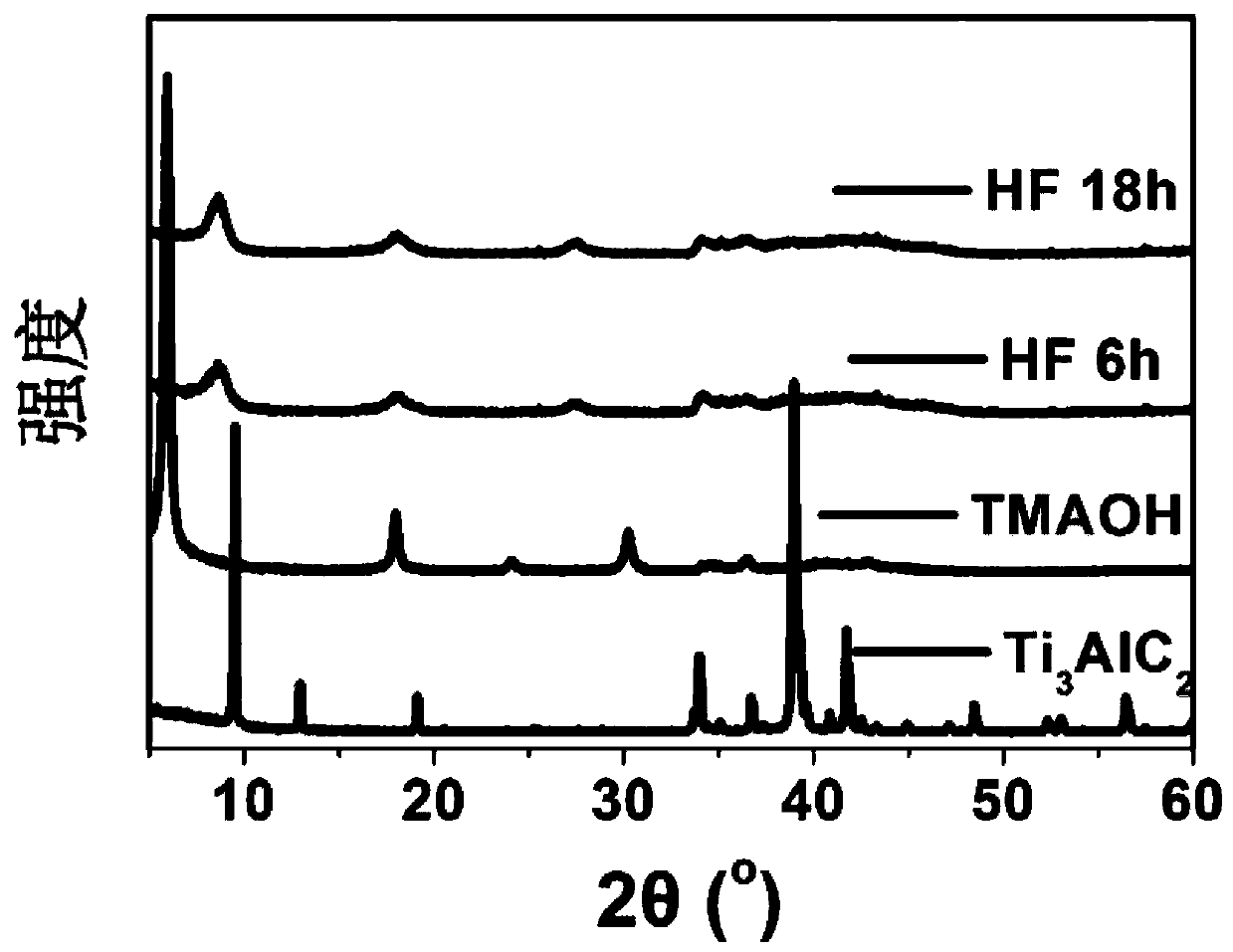

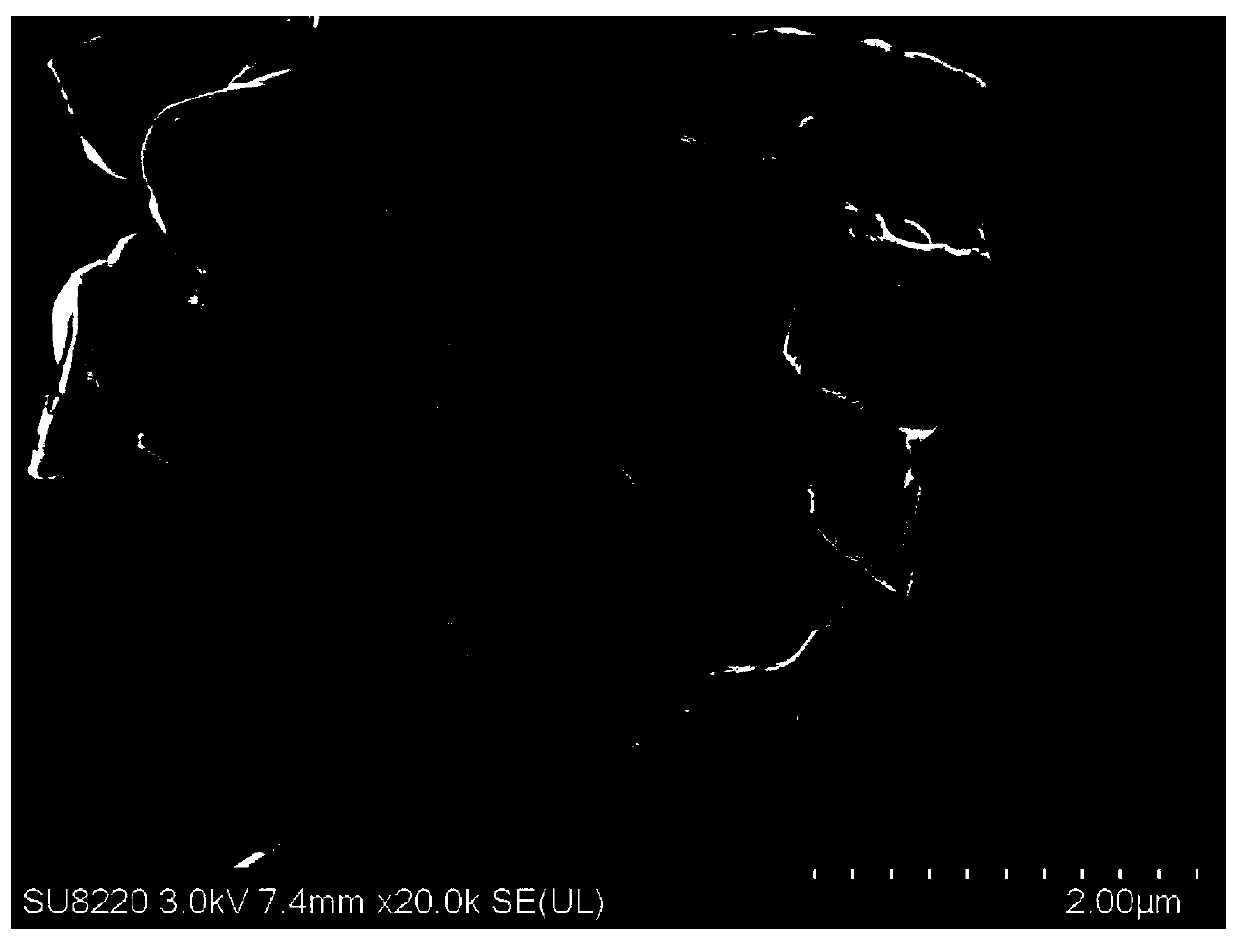

[0056] Preparation of MXene materials. Among them, MXene materials (such as Ti 3 C 2 、Ti 2 C. Hf 3 C 2 、 Ta 3 C 2 、 Ta 2 C, Zr 3 C 5 , V 2 C, etc.), that is, two-dimensional transition metal carbide or carbonitride, is a new type of graphene-like layered two-dimensional crystal material, and its chemical formula is M n+1 x n , which can be obtained from the parent phase material MAX phase (such as Ti 3 AlC 2 、Ti 2 AlC, Hf 3 AlC 2 、 Ta 3 AlC 2 、 Ta 2 AlC, Zr 3 AlC 5 , V 2 AlC, etc.) are etched (n=1, 2, 3, M is a transition metal element, A is a main group element, X is carbon and / or nitrogen). Compared with the complex preparation process of graphene, the chemical liquid phase etching method used in the preparation of MXene is easy to operate and controllable, and the cost is low, and the surface of MXene prepared by this method has functional groups such as hydroxyl and oxygen, which can be modified by covalent modification. and surface modification can ...

Embodiment 1

[0066] 1.0-3.0g 200 mesh Ti 3 AlC 2 Add 10.0-30.0ml of hydrofluoric acid with a mass fraction of 20wt% to the powder, and etch for 0.5h. The etched product was centrifuged and washed with deionized water until the pH was greater than 5, and then freeze-dried for 12 hours to obtain Ti 3 C 2 powder. Take 1.0-5.0g Ti 3 C 2 powder, add 10.0-50.0ml of tetramethylammonium hydroxide with a mass fraction of 25wt% and stir for 24 hours, wash off the tetramethylammonium hydroxide by centrifugation with deionized water, then add 100.0-500.0ml of deionized water, and peel off 0.5 h, and then centrifuge the peeled product at 3500 rpm for 1 h, and the supernatant obtained after separation is a single-layer or few-layer MXene material. Take 100.0 ml of the supernatant, vacuum filter and vacuum dry to obtain a conductive film (size (6-7) mm × (6-7) mm). Pour the PDMS prepolymer into the mold and prepolymerize at 80°C for 5min. Then attach the conductive film array on the PDMS surface ...

Embodiment 2

[0068] 1.0-3.0g 200 mesh Ti 3 AlC 2 Add 10.0-30.0ml of hydrofluoric acid with a mass fraction of 20wt% to the powder, and etch for 0.5h. The etched product was centrifuged and washed with deionized water until the pH was greater than 5, and then freeze-dried for 12 hours to obtain Ti 3 C 2 powder. Take 1.0-5.0g Ti 3 C 2 powder, add 10.0-50.0ml of tetramethylammonium hydroxide with a mass fraction of 25wt% and stir for 24 hours, wash off the tetramethylammonium hydroxide by centrifugation with deionized water, then add 100.0-500.0ml of deionized water, and peel off 0.5 h, and then centrifuge the peeled product at 3500 rpm for 1 h, and the supernatant obtained after separation is a single-layer or few-layer MXene material. Take 100.0 ml of the supernatant, vacuum filter and vacuum dry to obtain a conductive film (size (6-7) mm × (6-7) mm). Pour the PDMS prepolymer into the mold and prepolymerize at 80°C for 10min. Then attach the conductive film array on the PDMS surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com