Love wave gas sensor

A gas sensor and acoustic wave technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of poor stability and limit the application range of surface acoustic wave sensors, and achieve the effect of both sensitivity and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The Love wave gas sensor using semiconductor gas sensitive material of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

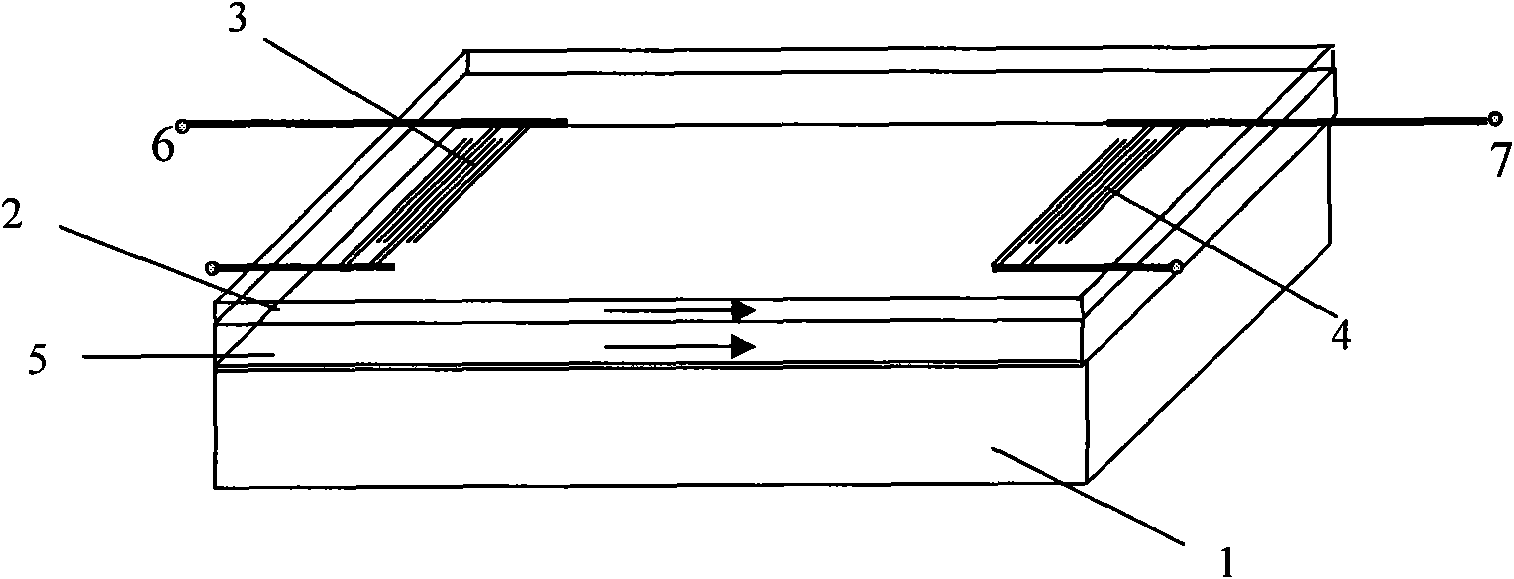

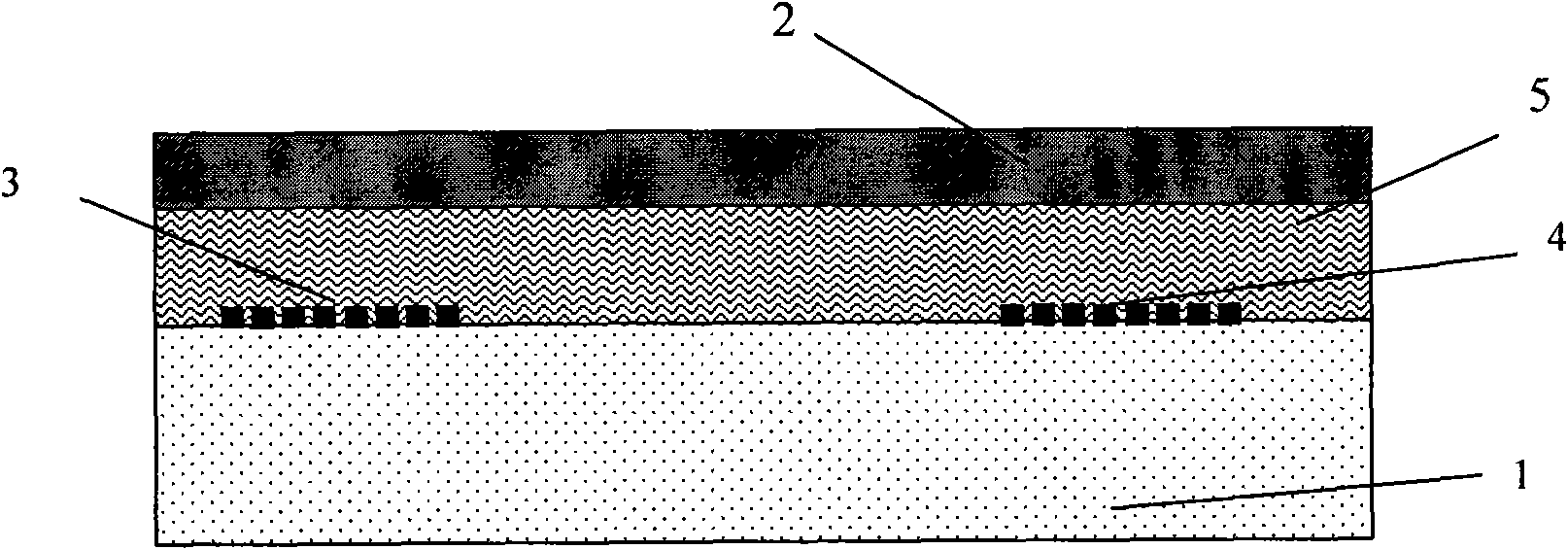

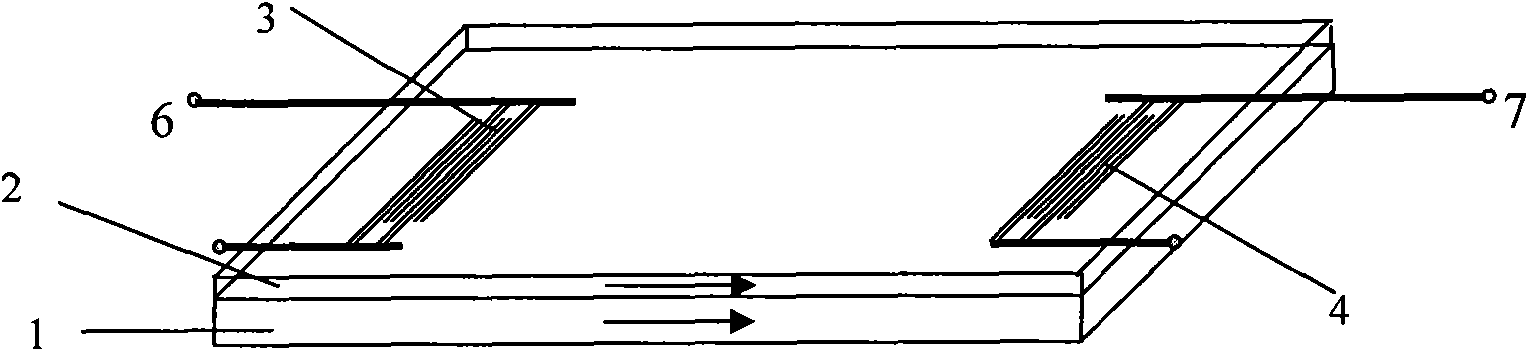

[0020] figure 1 It is the plan view of the first embodiment of the Love wave sensor adopting semiconductor type gas sensitive material of the present invention, figure 2 It is the Love wave sensor adopting the semiconductor gas sensitive material of the present invention figure 1 A cross-sectional view of the embodiment shown. Such as figure 1 as well as figure 2 As shown, the Love wave sensor adopting semiconductor type gas sensitive material of the present invention comprises: piezoelectric substrate 1, the input interdigital transducer 3 and the output interdigital transducer 4 deposited on the piezoelectric substrate 1 surface , the waveguide layer 5 covering the input IDT 3 and the output IDT 4, and the sensitive film 2 covering the waveguide layer 5, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com