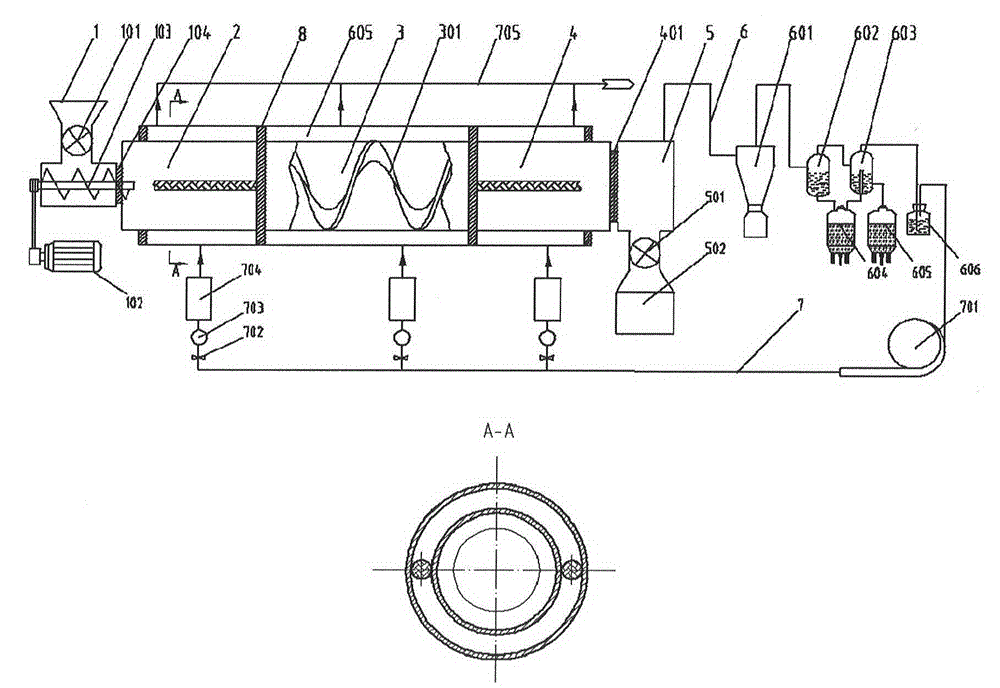

Rotary sectional heating biomass continuous pyrolysis equipment

A segmented heating and biomass technology, applied in the direction of biofuel, special carbonization, climate sustainability, etc., can solve the problems of energy loss and low pyrolysis efficiency, and achieve the effect of overcoming uncontrollable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

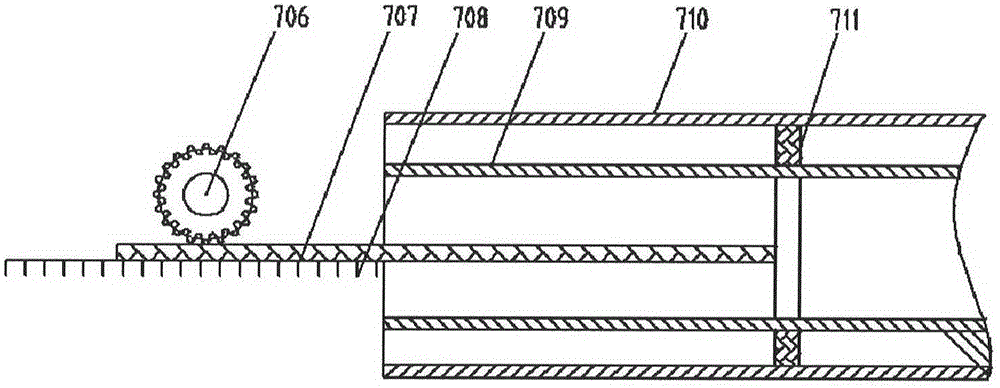

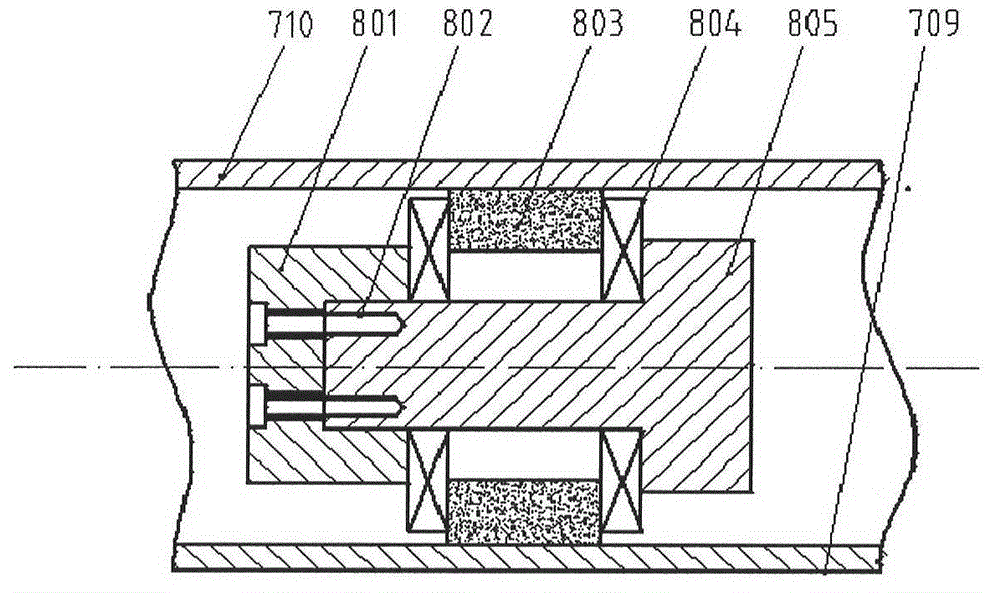

Method used

Image

Examples

Embodiment

[0026] Example: Production of biochar using corn stalks

[0027] The biochar is produced by adopting the rotary type segmental heating biomass continuous pyrolysis equipment of the present invention, the raw material is corn stalks, the length is about 3-4mm, the moisture content is 10-20%, and the density is about 100kg / m 3, turn on the starting electric furnace outside the rotary furnace, raise the temperature to the set temperature, then add the straw into the hopper, turn on the air switch and the feeding screw to transport the straw to the rotary furnace, adjust the heat shield to the appropriate position, When the corn stalks move to the solid-gas separation part, the carbonization is completed. At this time, the biochar is discharged into the carbon collection bin through the discharge air lock, and the pyrolysis mixed gas is discharged into the oil-gas separation part. The heavy tar is separated and collected, and then the mixed gas enters the oil-water-gas three-phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com