Technique of solid phase heat carrier for recycle cracking heavy oil and gasification technique

A carrier and heavy oil technology, applied in the direction of non-catalytic thermal cracking, cracking, petroleum industry, etc., can solve the problems of low yield of light oil, high requirements for heavy oil raw materials, short cracking time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

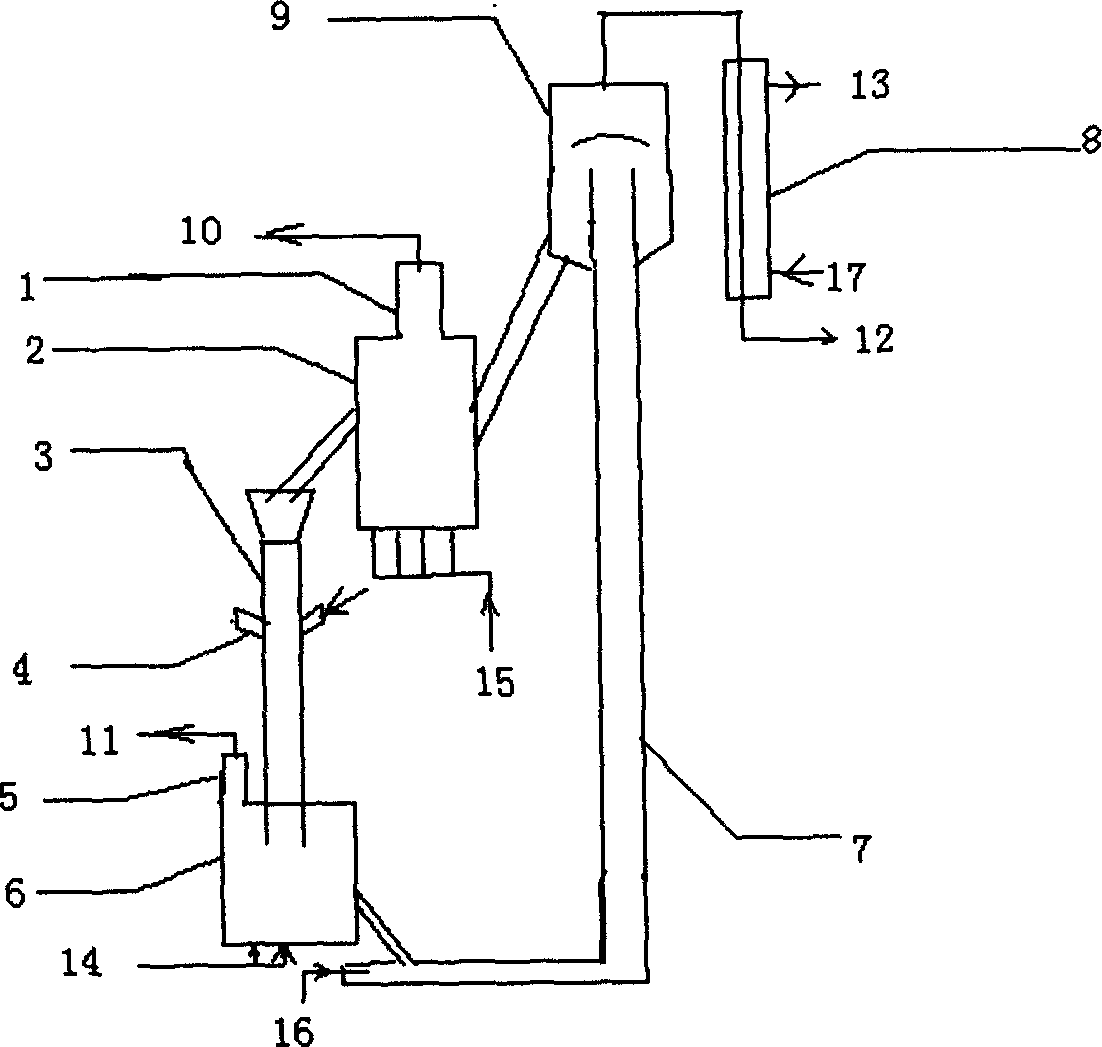

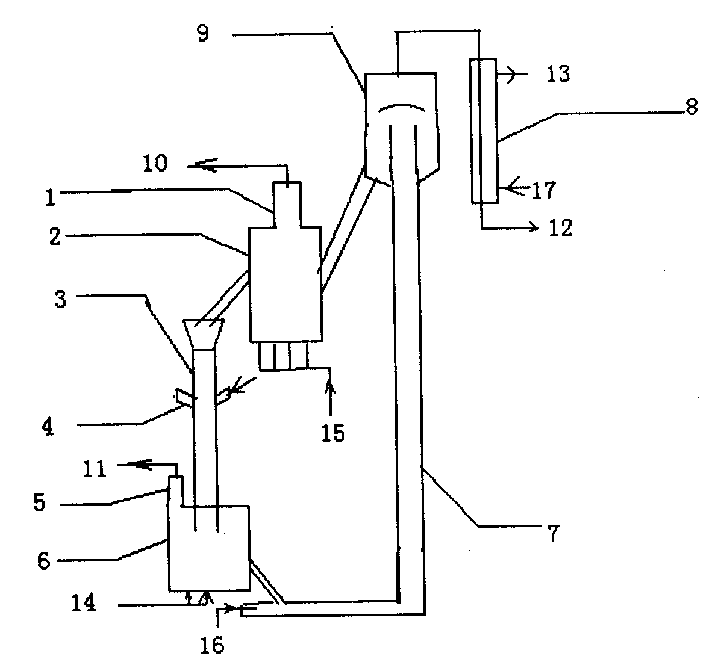

[0007] Example 1, the heavy oil preheated to 150°C-340°C is sprayed into the middle part of the descending riser (3) from the feed port of the descending riser (3) with a high-efficiency atomizing nozzle (4), and the oil mist is drawn from the flow The 750°C-950°C high-temperature semi-coke falling from the gasification bed (2) is heated, vaporized and cracked; the oil gas and semi-coke run downward to the bottom of the descending riser (3) and pass through the oil-gas separator (5) for gas-solid separation Oil gas enters fractionating tower separation from pyrolysis gas outlet (11); Semi-coke enters ascending riser ( 7) Carry out air scorching, and when the temperature rises to 800°C-1200°C, gas-solid separation is carried out through the solid-phase carrier separator (9); high-temperature flue gas enters the flue gas heat exchanger (8) from the flue gas outlet (12) ) heat exchange to generate 200°C-1000°C high-temperature water vapor for gasification; 800°C-1200°C semi-coke ...

Embodiment 2

[0008] Example 2, using a high-efficiency atomizing nozzle (4) to spray heavy oil preheated to 150°C-340°C from the feed port of the descending riser (3) into the middle of the descending riser (3), and the oil mist is drawn from the flow The 750°C-950°C high-temperature limestone falling from the gasification bed (2) is heated, vaporized and cracked; the oil gas and coke-containing limestone run downward to the bottom of the descending riser (3) and pass through the oil-gas separator (5) for gas solidification Separation; oil and gas enter the fractionation tower for separation; the coke-containing limestone is stripped by the solid-phase carrier stripper (6) and then enters the ascending riser (7) for air scorching. When the temperature rises to 950°C-1200°C, the The phase carrier separator (9) performs gas-solid separation; the high-temperature flue gas enters the flue gas heat exchanger (8) for heat exchange to generate superheated steam at 200°C-1000°C for gasification; th...

Embodiment 3

[0009] Example 3, the heavy oil preheated to 150°C-340°C is sprayed from the feed port of the descending riser (3) into the middle of the descending riser (3) with a high-efficiency atomizing nozzle (4), and the oil mist is drawn from the flow The 750°C-950°C high-temperature dolomite falling from the gasification bed (2) is heated, vaporized and cracked; the oil gas and coke-containing dolomite run downward to the bottom of the descending riser (3) and pass through the oil-gas separator (5) Gas-solid separation; oil and gas enter the fractionation tower for separation; coke-containing dolomite is stripped by the solid-phase carrier stripper (6) and enters the ascending riser (7) for air scorching. When the temperature rises to 950°C-1200°C , gas-solid separation is carried out through the solid-phase carrier separator (9); the high-temperature flue gas enters the flue gas heat exchanger (8) to exchange heat to generate superheated steam at 200°C-1000°C for gasification; Coke-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com