Method and device for reducing and baking for high-valent manganese minerals

A roasting device and high-priced manganese technology, which is applied in the field of electrolytic manganese metal roasting equipment, can solve the problems of increased reduction cost, complicated process, easy ring formation, etc., and achieve good reduction effect, sufficient reduction reaction, and long residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

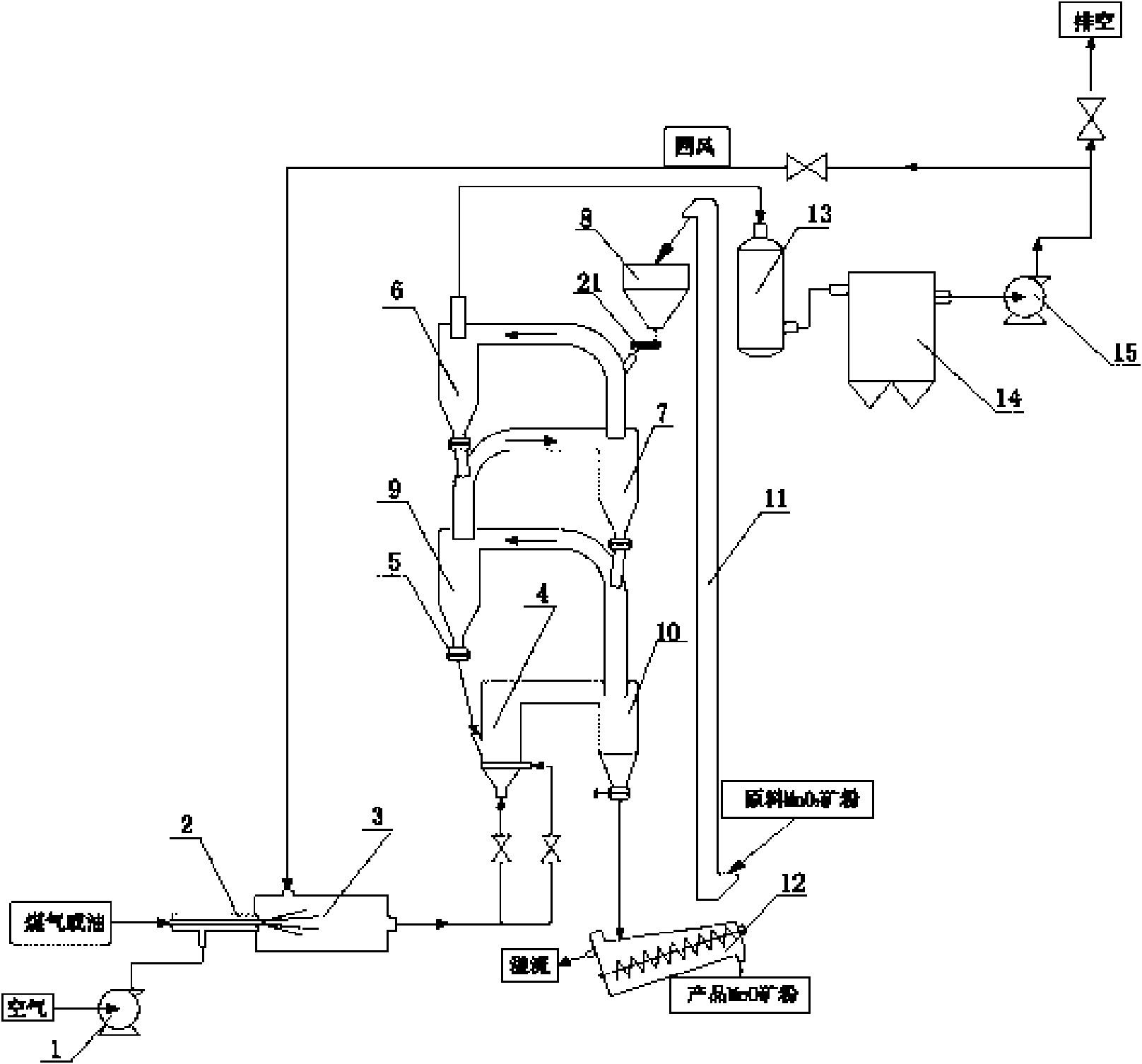

[0026] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0027] The present invention is used for the reduction roasting method of high-valent manganese ore, and its steps are:

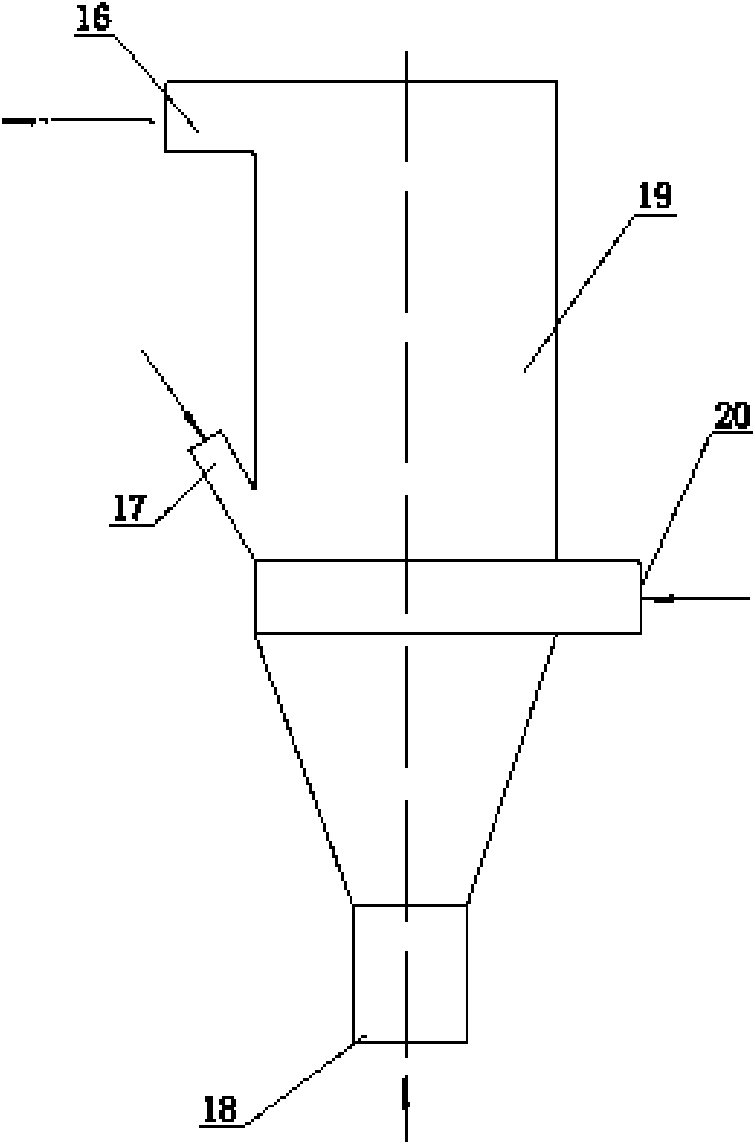

[0028] (1), combustible gas and air are passed into the burner 2 installed on the hot blast stove 3 and burned in the hot blast stove 3, and the air excess coefficient of the control combustion is 0.7~0.9, so that the temperature of the gas coming out of the hot blast stove 3 reaches 700-1000°C, the reducing atmosphere meets the process requirements of 3-10% CO, and then this gas is introduced from the bottom and side of the fluidized roaster 4;

[0029] (2) Finely grind the manganese ore until 80% passes through a 100-mesh sieve and lift it to the feeding bin 8 on the upper part of the reduction roasting device through the lifting conveying device 11, and then feed it into the suspension preheating assembly through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com