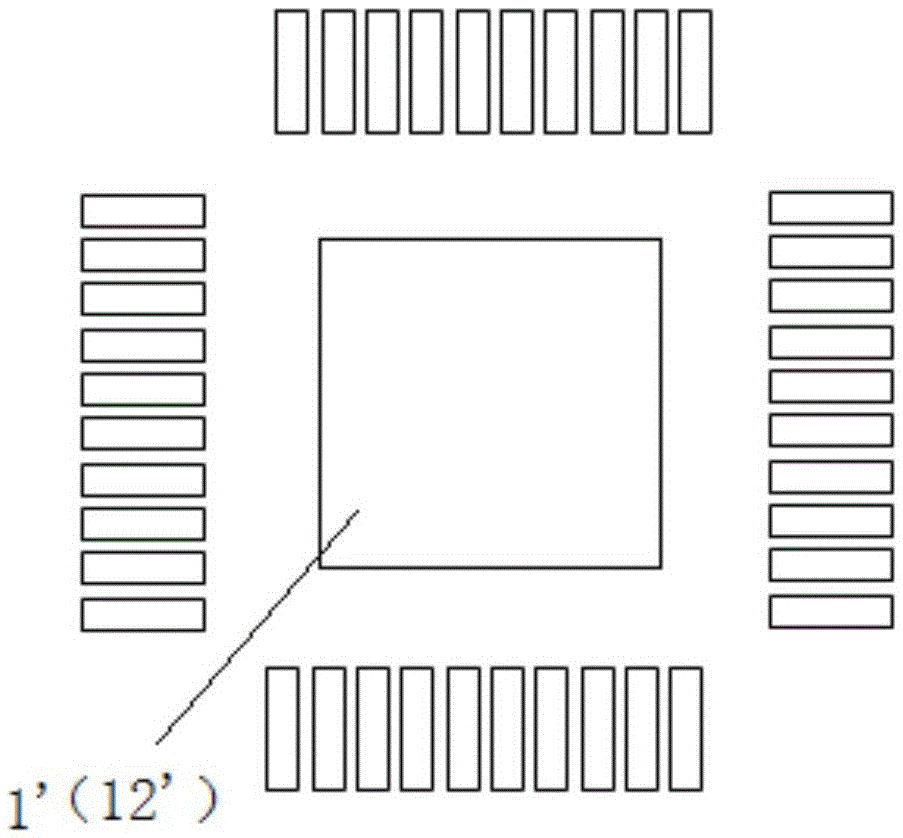

Heat-conducting bonding pad and package structure of QFP chip with heat-conducting bonding pad

A technology for thermal pads and pads, which is used in semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve the problems of poor thermal conductivity of thermal pads, improve the welding effect, reduce air bubbles, and ensure the welding effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

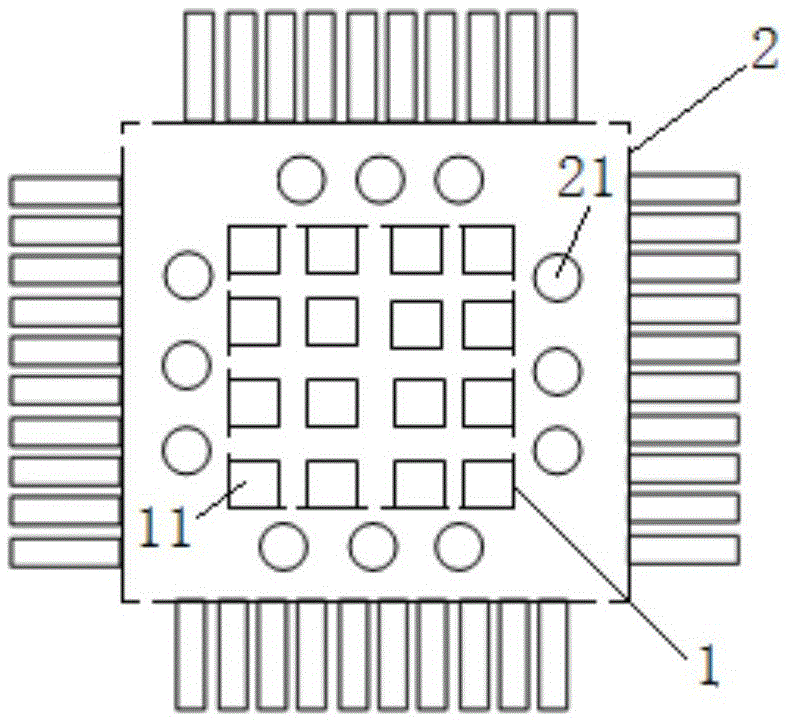

[0046] use has image 3 The heat conduction pad of the structure shown is used as the heat conduction pad of the packaging structure to package the QFP chip. The pad part is a square with a side length of 50 mils, and the distance between adjacent pad parts is 20 mils. The shortest distance of the area is 20mils, and the diameter of the vent hole is 30mils.

Embodiment 2

[0048] use has image 3 The heat conduction pad of the structure shown is used as the heat conduction pad of the packaging structure to package the QFP chip. The pad part is a square with a side length of 40 mils, and the distance between adjacent pad parts is 25 mils. The shortest distance of the area is 15mils, and the diameter of the vent hole is 20mils.

Embodiment 3

[0050] use has image 3 The heat conduction pad of the structure shown is used as the heat conduction pad of the packaging structure to package the QFP chip. The pad part is a square with a side length of 60 mils, and the distance between adjacent pad parts is 15 mils. The shortest distance of the area is 25mils, and the diameter of the vent hole is 40mils.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com